私たちのサービス

1.1001TP3現地メーカー。

2.最適な素材選択

3.best リードタイムおよび安定した生産。

4.豊富な輸出経験

5.プロフェッショナル・サービス

6.QSコントロール

[table id=4 /]

Prince Fastener Plasterboard Screws are self-tapping screws most ordinarily designed with one thread that runs all the method from the bottom of the top to the tip.

The thread of a prince fastener chipboard screw is usually deemed as ‘coarse’. this implies there’s a bigger distance between the peaks of the thread. Therefore, the screw can undergo the soft material plenty faster.

Plasterboard Screws are available 2 common types: sleek shank and full thread.

Although there are many types of Plasterboard Screws, they all have the following main characteristics:

(1)一般的に浸炭炭素鋼で作られている(製品全体の99%を占める)。ステンレス製もある。

鉄または非鉄金属

A chipboard screw is a product that has undergone heat treatment and is suitable for the installation of electric tools. It is mainly used for connection and fastening between wooden plates and thin steel plates. Chipboard screws are currently used to replace wood screws in many fields and are widely applied now. It can replace the use of ordinary wood screws (wood screws are not heat). At the same time, the wood screws are currently first proposed by the navigation standard to produce the production of rods, which not only saves materials, but also has a sharp thread.

Some of the most typical ones are チップボードネジ and self-tapping deck screws. These are helpful as screws for particle board. Chipboard screws are pretty comparable to standard screws. However, one notable difference is that their grooves are typically asymmetrical to allow for better resistance against pull-out.

Chipboard screws, also named particleboard screws, are self-tapping screws with thin shafts and coarse threads. They are made of stainless steel or carbon steel and then galvanized. Chipboard screws of different lengths can be used in a variety of applications.

The main difference between woodscrews and chipboard screws lies in the threads which, on a chipboard screw, run all the way along the screw’s length to the underside of the head. This makes chipboard screws particularly useful where an extra-strong hold is required, such as when installing garden decking.

Chipboard screwsare a product that has been heated, suitable for installation of electric tools. It is mainly used in the connection and fastening between wooden plates, wooden plates and thin steel plates. To a large extent, it can replace the use of ordinary wood screws.

In the entire fastener industry, this product is a variety as important as drywall screws and huge sales. It is widely used in furniture manufacturing industries, but the use of the DIY market is still limited. At present, domestic consumers purchase this variety in building materials supermarkets, mainly used to install guide rails, hinges (such as*16, etc.), combined with fish -like expansion installation (such as 4*40, etc.), and replacement of wood screw installation and making furniture and cabinets. The Chipboard screws screw that is added to the tooth pattern is an improved product for ordinary Chipboard screws screws. It is mainly optimized from the design of the thread, pursuing higher drilling speed, and solving the use of hard wood to use easily caused The problem of cracking is high in technical content.

MDF has a smooth finish as it consists of wood grains that are of the same size. Particle-boards do not have a smooth surface as they consist of wood shavings and chips.

Particle Board Screws are the same as a coarse thread drywall screw but available in shorter lengths than standard drywall screws. They feature a bugle head, spaced threads, extra sharp point, and black phosphate finish.

And you need to use the right materials. For consumables, Allfasteners have the range and expertise to help you get any building job done. For different types of timber, there are different types of fasteners. For very soft timbers, MDF or chipboard, you need to use chipboard screws.

Both drywall screws and chipboard screws have countersunk, half countersunk, and round head designs. The grooves of drywall screws are deeper and look better. Under normal circumstances, it is half-toothed, while fiberboard screws are generally full-toothed.

Chipboard screws are a product that is armal processing and suitable for installation of electric tools. It is mainly used for connection and fastening between wooden plates, wooden plates and thin steel plates.

Chipboard screwsare currently used to largely use the use of wood screws. Its application is very wide and sells very large in China.

Self tapping screws nail is also called Self tapping screws screws. It is one of the types of threaded fastening in the pre-drilling hole of metal or non -metal materials. There are depression, head, etc.

Self-tapping screw

The difference between Chipboard screwsand Self tapping screws nails

Chipboard screws are currently used to replace wood screws to a large extent. It is widely used in China. The Chipboard screwswith a deep -headed head, a semi -immersed head, round head, etc. The thread rises in a single line spiral, generally the whole teeth, with 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 6mm and other specifications. 5mm, 6mm. The technical content of the Chipboard screwsis high, and the nails are not easy to crack. The cracking problem in some hard wood can also be solved by using the threading of ordinary Chipboard screwsto be resolved. Chipboard screwsare suitable for wooden materials and are suitable for electric tool installation. It is currently mainly used in furniture manufacturing, cabinets and other fields.

Self tapping screws nails are generally used for wooden materials and thin metal boards. Self tapping screws screw thread rises on the screw, but the thread is smaller than the chipboard screws, and the surface of the thread has high hardness. Therefore, in the thin metal plate connection, the inner thread is attacked in the thread bottom of the connector to form a connection.

First of all, from their diameter, the diameter of the Chipboard screws includes six specifications of 3 mm, 3.5 mm, 4 mm, 4.5 mm, 5 mm, and 6 mm. Among them, 4 mm, 5mm, and 6 mm are the most common. The diameter of the drywall screws screw does not have so many specifications, only 3.5 mm. The drywall screws screws and fiber plates have the design of the head, semi -immersive head, and round head. In general, it is semi -teeth, and the fibrous board screw is generally full tooth. The biggest feature of the drywall screws screw in appearance is the shape of the horn head. If it is divided according to the thread, it can also be divided into two types of single -line coarse wall screws and double -line fine dental wall screws.

In the entire fastener industry, this product is a variety as important as drywall screws screws and huge sales. It is widely used in furniture manufacturing industries, but the use of the DIY market is still limited. At present, domestic consumers purchase this variety in building materials supermarkets, mainly used to install guide rails, hinges (such as 3.5*16, etc.), combined with fish -like expansion installation (such as 4*40, etc.) Essence The quality is better. It is better to choose the element card produced by the Shanghai Hangou Standard Metric Performing Article Factory. The quality packaging prices are more economical and affordable. Adding claws and cutting Chipboard screws screws are improved products for ordinary Chipboard screws screws. It is mainly from the thread The design is optimized, the pursuit of higher drilling speed, and solving the problem of using cracking on hard wood, which is easy to cause cracking. The technical content is high.

The application range of chipboard screws in the furniture manufacturing industry is relatively wide. It is a product similar to dry wall plates, and its sales are relatively large. In the building materials market, domestic consumers are more popular with it. It has many applications in installing rails, hinges, fish -like expansion installations, and wood screw installation and making furniture. Among them, the best manufacturer of chipboard screws is Prince Fastener The chipboard screws produced by this company are worth choosing in terms of quality and price. After the reconstruction of ordinary fiber board screws, it will become claws and cut tail chipboard screws. It is mainly transformed in the design of the thread. In this way, the problem of cracking caused by hard wood will be solved.

プリンスファスナーは、あなたのための競争力のあるコストで高品質のネジを作成するためにここにあり、あなたのビジネスのための技術的なサポートと排他的なサービスを提供します。

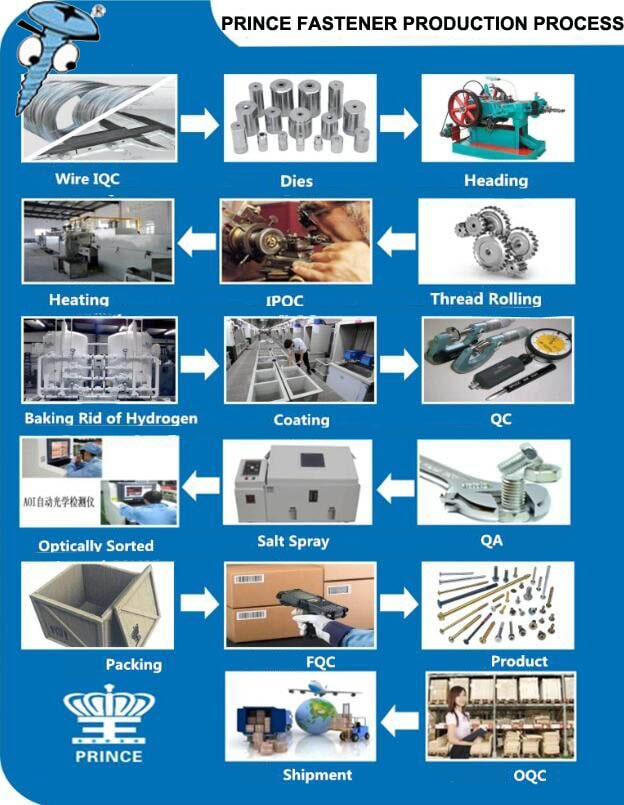

プリンスファスナーねじ製造の基本コンセプト

1、プリンスファスナー製造ねじに分けることができます:冷間圧造、ホット機械加工(旋盤、フライス盤など)。

2、冷間圧造はプラスチック金属を使用することで、冷間機械的な圧力や描画を使用して、金属の固体変形に達する。

3、ホットアップセッティングは、加熱と圧力処理後の材料の形状を満たすようにすることです。

設計要件。

4、プリンスファスナーの機械加工は、頭の6つのコーナーの特殊または特殊なボルトの小バッチは、フライス加工後にオンになります。

5、スクリューボルトのスレッド:機械的および手動ねじ切り、ダイスに似ています。

6、ミリングテール:一般的にプリンスファスナーカッティングマシンの終わりまでに完了します。

7、冷間圧造と熱間動揺の違い:冷間圧造ボルトの表面はより美しく、ダース赤いボルト表面の酸化皮は良く見えません;

現象の原因と成形過程の原因の分析

1、偏心:2つの赤と不適切なインストールと調整マシン。

2、ミノ:インストール不良と不適切なプリンスファスナー調整機で。

3、頭部が丸くない:ダイまたはパンチの成形の選択が十分でない。

4、亀裂のモードを再生する:亀裂やダイスのR角、モデルが2つの衝突によって打たれるように。

5、ヘッドダブル:パンチが悪い。

6、フラッシュ:不良、パンチング成形は、主にパンチとダイの間の穴のクリアランスが大きすぎるか、または短すぎる赤い棒である。

7、クラック角度:パンチ針バーストまたは2パンチとパンチは重くない。

8、ヘッドクラッキング:材料、または金型(金型のパンヘッド六角ワッシャーヘッドなど)、および潤滑油を使用してエラー。

一般的な圧延の不利な現象と原因の分析

1、加工亀裂:歯板とプリンスファスナーの古いマシンを調整します。

2、鈍い尾:機械が適切に調整されていない、歯板が古すぎる。

3、曲がったテール:シートボードのシートのコントロールスクリューがきつすぎる。

4、尾:歯の摩耗プレートと不適切な調整機。

プリンスファスナー製造は、世界の主要な販売代理店、卸売業者、小売業者、企業、および端末の顧客にサービスを提供するためにコミットされ、顧客の様々な要件に応じてファスナー、非標準部品のすべての種類をカスタマイズすることができます異なる業界のお客様に全体的なサポートソリューションを提供し、顧客が便利で高速を達成するために作る "ワンストップファスナー購買 "経験

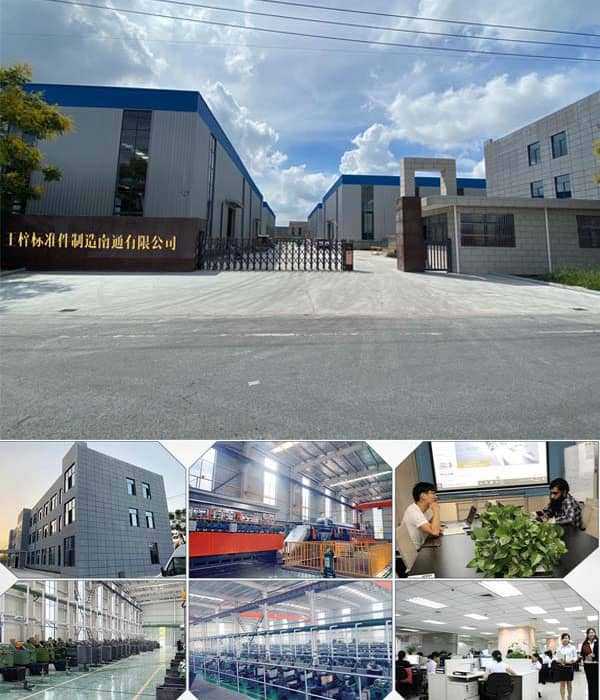

プリンスファスナーは、ヘッド加工機、ねじ転造盤、ネット炉、微小硬度計や微細構造検査機のような台湾から導入された高度な製造設備を所有しています。私達は良質および競争価格であなたがほしいプロダクトを提供してもいいです!

Q:あなたの品質についてお聞かせください。

A: 王子締める物に高度の生産があり、試験装置 .Every プロダクトは 100% です

私達の qc 部によって郵送物の前に点検される

Q: あなたは商社ですか?

A:プリンスファスナーは、上海、中国で30年の製造経験を持つ工場です。

Q: 納期はどのくらいですか?

A: 一般的に、在庫がある場合は5-10日、在庫がない場合は15-20日です。

数量。

Q: サンプルはありますか?

無料ですか、それとも別料金ですか?

A: はい、サンプルを無料で提供することができます。

Q:支払い条件はどうなっていますか?

A: 前もって30% T/T、出荷前のバランス。

Q: 当社を選ぶ理由は何ですか?

A: 1) 24営業時間以内にご返信ください。

2)経験豊富なスタッフがお客様のご質問にお答えします。

3)カスタマイズされた設計は利用できます。ODM&OEM は歓迎されます。

4)特別割引と販売保護は、私たちの消費者に提供されます。

5)プリンスファスナーは、無料サンプルを提供することができ、消費者が最初に貨物を支払う必要があり、高価なサンプル費用は、次の順序で追加されます。

6) 正直な輸出された販売人として、王子の締める物は専門の工場、質の引用語句、よいサービス、巧みなを常に使用します

私達のプロダクトが良質および安定した特徴で終了することを保障する技術者。

Q:価格はどうですか?

A:リーズナブルな価格で高品質の製品。私に尋ねて下さい、私達はあなたのための価格を引用しますすぐに参照して下さい。

Q:どのような製品を製造していますか?

A: 私達の主要なプロダクトは次のとおりです: 乾式壁ねじ、chipboard ねじ、機械ねじ、セルフ・タッピングねじ、自己の鋭いねじ、非/標準

ねじ、工学締める物(高力ボルト;ナット;洗濯機;アンカー)、ステンレス鋼ねじ、セルフドリルねじ、セルフタッピングねじ、ねじ転造ねじ、ねじ切断ねじ、マシンねじ、コンクリートねじ、屋根ふきねじ、

乾式壁ねじ、パーティクルボードねじ、チップボードねじ、建設ねじ、コーチねじ、ラグスクリュー、木ねじ、ユーロ

ねじ、統一されたねじ、家具ねじ、Sems ねじ、親指ねじ、翼ねじ、プラスねじ、止めねじ、メートル止めねじ、板金ねじ、目ねじ、保証ヘッドねじ

24時間以内にご連絡いたします。

お急ぎのお問い合わせは、whatsapp番号:+86-18930191254までご連絡ください。