Double-headed screws are used to connect the fixed link function of machinery. Double-headed bolts have threads on both ends and a screw in the middle, both coarse and fine. They are generally used in mining machinery, bridges, cars, motorbikes, boiler steel structures, crane towers, large span steel structures and large buildings.

Double-headed bolts generally require surface treatment. There are many types of bolt surface treatment, generally commonly used are electroplating, blackening, oxidation, phosphating, non-electrolytic zinc flake coating treatment, etc. However, electroplated fasteners account for a large proportion of the actual use of fasteners. In particular, they are more widely used in industries and fields such as automobiles, tractors, home appliances, instrumentation, aerospace,solar energy and communications. However, for threaded fasteners, not only is a certain degree of corrosion resistance required in use, but also the interchangeability of the threads must be ensured, which can also be referred to here as spinability. In order to meet both the ‘corrosion protection’ and ‘interchangeability’ requirements of threaded fasteners in use, it is essential to have a specific plating standard.

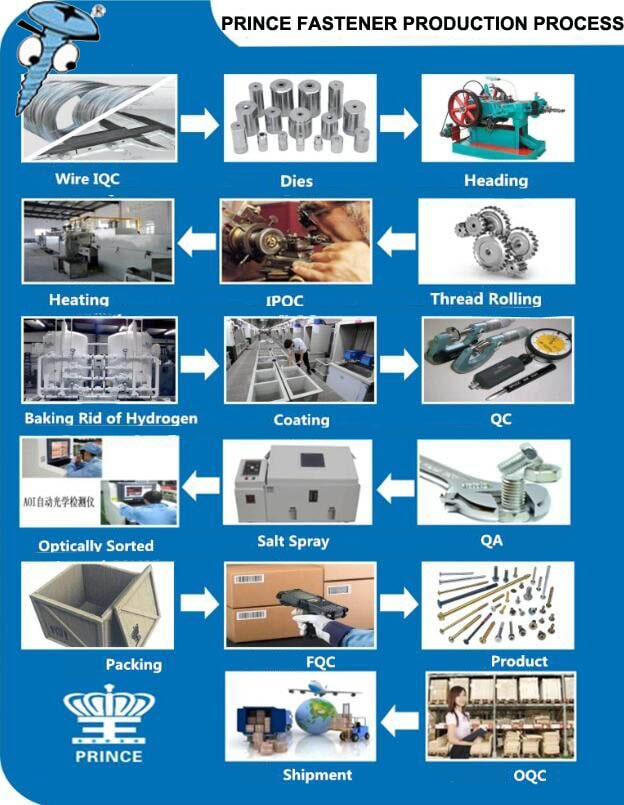

The production of double-headed bolts requires fixed equipment and machine tool processing, but the processing procedure is relatively simple, there are mainly the following processes: first of all, it is necessary to pull the material, pulling the material is to use the pulling machine to pull the distorted material straight, after this process to carry out the next process, the next process is to use the cutting machine to pull the long straight material according to the customer’s requirements cut into the length required by the customer, which is completed The second process, and the third process, is to put the cut short material on the wire rolling machine to roll out the wire buckle; here the ordinary double-headed bolt is finished, but of course if other requirements are needed, then other processes are also needed.

The bolt is generally known as a larger diameter screw, according to which the screw is much smaller in diameter compared to the bolt. Double-headed bolts do not have a head and are also referred to as double-headed studs. Double-headed bolts are threaded at both ends and do not contain a thread in the middle, which is a bare rod. Double-headed bolts are used in large equipment such as reducer frames. In practice, the external load will have a vibration plus the influence of the temperature will cause the friction to become smaller, and over time the threaded connection will loosen and fail. Therefore, it is necessary to do a good job of maintaining the double-headed bolts in normal times. Double-headed bolts or foot bolts in the role of mechanical friction for a long time will be a problem, in the event of a problem will have to remove the engine oil pan, carefully check the use of the engine shaft tile, check the clearance between the shaft tile is too large, if the gap is too large should be replaced in a timely manner. In the replacement of double-headed bolts should also replace the connecting rod bolts. Some large equipment such as nail making machine in the usual operation, if you find that the engine is not very stable when running or appear strange noise, but also to stop in time to check, so as to avoid bigger problems