Welcome to Prince Fastener, your ultimate destination for all things fastening solutions! Today, we’re diving deep into the world of セルフタッピングねじ—a versatile and indispensable component in both industrial and everyday applications. Whether you’re a seasoned engineer, a DIY enthusiast, or someone seeking to grasp the intricacies of fastening systems, this blog post aims to provide a comprehensive understanding of self-tapping screws.

Self-tapping screws are a marvel of engineering, offering a seamless and efficient way to join various materials without the need for pre-threading. These screws have revolutionized the way we approach fastening tasks, from automotive and appliance assembly to woodworking and plastic fabrication. At Prince Fastener, we take pride in offering a wide range of high-quality self-tapping screws, each designed to meet specific requirements and ensure the highest level of performance and reliability.

In this blog post, we’ll explore the definition, features, and diverse applications of self-tapping screws. We’ll also explore the differences between self-tapping screws and other fastening options, such as self-drilling screws, and provide detailed guidance on how to use self-tapping screws effectively for optimal results. Whether you’re looking to enhance your knowledge or find the perfect fastening solution for your next project, you’ve come to the right place. Let’s get started on this journey into the world of self-tapping screws!

What Are Self-Tapping Screws?

A セルフタッピングネジ is a special type of fastener designed with a sharp point and hardened threads. It creates its mating thread in a pre-drilled hole, eliminating the need for tapping. これは makes them essential components for joining thin metal sheets, plastics, wood, and other materials.

Key Features:

- Sharp Tip Design: The pointed tip of a self-tapping screw enables easy penetration and self-tapping into the Material.

- High Thread Hardness: Hardened thread surfaces withstand significant torque without stripping.

- Simple Installation: You can directly drive these screws into a pre-drilled hole, significantly boosting installation efficiency.

- Strong Adaptability: They connect various materials, including metal, plastic, and wood.

Classification of Self-Tapping Screws:

By Material:

- Steel Self-Tapping Screws: Offer high strength, perfect for metal connections.

- Stainless Steel Self-Tapping Screws: Offer excellent corrosion resistance, making them ideal for humid environments or applications requiring high corrosion resistance.

- Aluminum Self-Tapping Screws: Lightweight, suitable for applications where weight is a concern.

- Plastic Self-Tapping Screws: Specifically designed for plastic materials, offering sound insulation.

By Head Shape:

- Round-Head Self-Tapping Screws: These screws feature a rounded head, making them ideal for use on smooth surfaces.

- Flat-Head Self-Tapping Screws: Their heads sit flush with the material surface, providing a clean aesthetic finish.

- Countersunk Head Self-Tapping Screws: These screws have heads that sink below the material surface, making them ideal for applications that require a flat surface.

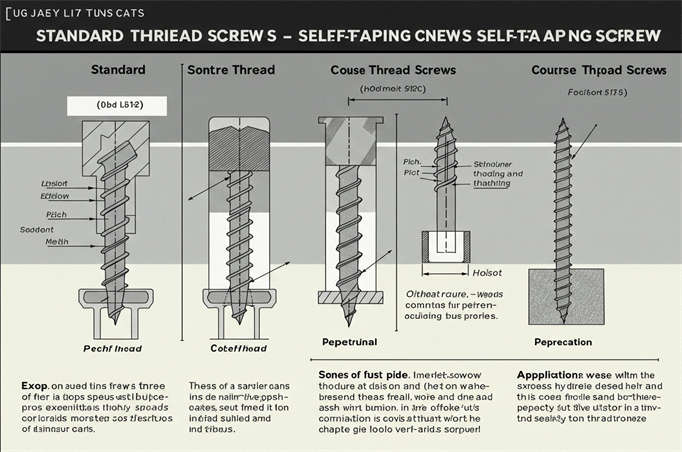

スレッドタイプ別:

- Standard Thread Self-Tapping Screws: Suitable for general material connections.

- Fine Thread Self-Tapping Screws: Feature a small pitch, ideal for connecting thin materials with high connection strength.

- Coarse Thread Self-Tapping Screws: Feature a large pitch, making them suitable for thicker materials and offering faster assembly.

アプリケーション

- Metal Connections: We use them extensively in car bodies, appliance casings, and other metal assemblies.

- Plastic Product Connections: Ideal for plastic casings and pipes.

- Wood Connections: Commonly found in furniture manufacturing and woodworking.

- Electronic Equipment Assembly: Widely used for connecting electronic device casings and brackets.

セルフタッピングネジ は広く使われている in industrial and daily life due to their simple installation and strong adaptability.

Self-Tapping Screws vs. Self-Drilling Screws: What’s the Difference?

While セルフタッピングねじ and self-drilling screws share similarities, they exhibit distinct differences in design, performance, and Application. Here are their primary distinctions:

1. Definition

- Self-Tapping Screw: This pointed screw, hardened through a treatment process, taps its threads into a pre-drilled hole. You typically need to drill a pilot hole in the MaterialMaterial, close to the screw’s diameter.

- Self-Drilling Screw: This screw features a drill bit-shaped tip, allowing it to drill its hole and tap threads without a pre-drilled pilot hole. We commonly use them for thinner metal materials, such as steel and aluminium sheets.

2. Design Characteristics

- Self-Tapping Screw:

- Pointed Tip Design: The tip is relatively blunt, primarily guiding the screw into the pre-drilled pilot hole.

- High Thread Hardness: Its hardened thread surface withstands significant torque.

- Pilot Hole Requirement: You must pre-drill a pilot hole close to the screw’s diameter; otherwise, the screw may not enter smoothly.

- Self-Drilling Screw:

- Drill Bit-Shaped Tip: The head resembles a drill bit, enabling it to drill and tap threads directly into the Material.

- Higher Thread Strength: It must both drill the material and form threads during the drilling process.

- No Pilot Hole: You can drill and tap threads directly into the Material without pre-drilling.

3. Applications

- Self-Tapping Screw:

- Metal Connections: For example, automotive bodies and appliance casings often require pre-drilled holes.

- Plastic Product Connections: These include plastic casings and pipes, which usually require pre-drilled holes.

- Wood Connections: In furniture manufacturing and woodworking, pre-drilled holes 使用.

- Self-Drilling Screw:

- Thin Metal Connections: Like light steel keels, metal roofs, and metal curtain walls, these require no pre-drilling; they are directly drilled and tapped.

- Metal-to-Metal Connections: Ideal for steel structures, particularly in areas requiring rapid installation.

- Metal-to-Plastic Connections: For instance, metal brackets connected to plastic casings, allowing for quick installation.

4. Installation Steps

- Self-Tapping Screw:

- You must pre-drill a pilot hole in the connecting MaterialMaterial; the pilot hole diameter is usually slightly smaller than the screw’s outer diameter.

- You drive the screw into the pilot hole with a screwdriver or power drill, and the screw then engages the MaterialMaterial independently.

- Self-Drilling Screw:

- No pre-drilling is necessary; you drive the screw directly into the MaterialMaterial.

- Using a power drill or electric drill, the screw’s drill bit portion is drilled first, and then the threaded portion is tapped.

5. Functional Characteristics

- Self-Tapping Screw:

- Connection Strength: Offers high connection strength, making it suitable for applications that require a strong and fast connection.

- Applicable Materials: Works with metal, plastic, and wood.

- Self-Drilling Screw:

- Installation Speed: Provides speedy installation, especially for thin metal connections.

- Applicable Materials: Primarily used for thin metal materials, such as steel and aluminium sheets.

6. Advantages and Disadvantages

- Self-Tapping Screw:

- Advantages: High connection strength; strong adaptability to various materials; hardened threads ensure durability.

- Disadvantages: Requires pre-drilling, adding an extra installation step; cannot be used directly in materials without a pilot hole.

- Self-Drilling Screw:

- Advantages: Fast assembly, no pre-drilling required; suitable for thin metal materials, especially for quick installation.

- Disadvantages: This method is generally not suitable for thicker materials, as thread strength may be lower than that of self-tapping screws, making it less ideal for high-wear connections.

セルフタッピングネジ are more suitable for high-strength connections where the connecting MaterialMaterial can be metal, plastic, or wood, but they require pre-drilled holes. セルフドリリングスクリュー are better for connecting thin metal materials, offering high assembly efficiency without the need for pre-drilling, but they provide lower connection strength.

In practical applications, you must choose the screw based on specific MaterialMaterial, required connection strength, and installation efficiency.

Types of Self-Tapping Screws

We classify セルフタッピングねじ by head shape, screw type, Application, and MaterialMaterial. Here is a detailed classification:

1. By Head Shape

- Round-Head Self-Tapping Screws: These screws feature a rounded head, making them ideal for use on smooth surfaces.

- Countersunk Head Self-Tapping Screws: Their heads sink below the material surface, making them ideal for applications that require a flush finish.

- Flat-Head Self-Tapping Screws: The head sits flush with the surface of the connecting Material, providing a pleasing aesthetic.

- Pan Head Self-Tapping Screws: The head shape resembles a cylinder with a convex top, suitable for larger contact areas.

- Hex Head Self-Tapping Screws: Feature a hexagonal head, making them easy to tighten with a wrench.

- Truss Head Self-Tapping Screws: The head shape resembles an umbrella, making them suitable for applications that require a specific aesthetic.

- Washer Head Self-Tapping Screws: The head includes a built-in washer, reducing wear on the connecting MaterialMaterial.

2. By スレッドタイプ

- Type AB Self-Tapping Screws: Versatile and suitable for various materials.

- Type B Self-Tapping Screws Feature a blunt end, making them suitable for use with soft materials.

- Type C Self-Tapping Screws Feature a coarse thread design, making them suitable for soft materials like plastic.

- Type F Self-Tapping Screws: High-frequency hardened, suitable for sheet metal.

- Twin-Lead Self-Tapping Screws Feature a double-lead thread design with more precise and sharper thread angles, making them suitable for plastic or other high-density materials.

3. By Application

- General Self-Tapping Screws: Suitable for general material connections.

- Self-Tapping Locking Screws: The thread features an arc-triangular cross-section, is surface-hardened, and is suitable for pre-drilled holes in metal, offering high strength and low tightening torque.

- Drywall Self-Tapping Screws: Often phosphated, these screws are suitable for connecting drywall panels in construction.

- Plastic Self-Tapping Screws: Specifically designed for use with plastic materials, providing strong insulation.

4. By Material

- Steel Self-Tapping Screws: Offer high strength, suitable for metal connections.

- Stainless Steel Self-Tapping Screws: Offer excellent corrosion resistance, making them ideal for humid environments or applications requiring high corrosion resistance.

- Plastic Self-Tapping Screws: Suitable for plastic materials, lightweight.

5. By Point Type

- Drill Point Self-Tapping Screws: The tail is drill-shaped, making it easy to drill into materials.

- Blunt Point Self-Tapping Screws: The tail is flat, suitable for areas without pre-drilled holes.

- Cutting Point Self-Tapping Screws: The tail is specially processed, suitable for applications requiring specific drilling effects.

6. Other Special Types

- Self-Drilling Self-Tapping Screws: The head resembles a drill bit, allowing it to drill into the MaterialMaterial without pre-drilling.

- Tri-Lobular Self-Locking Screws: The threads feature a triangular design, providing a locking function suitable for high-vibration connections.

With this classification, you can select the appropriate セルフタッピングネジ type based on your specific application needs.

Self-Drilling Self-Tapping Screws vs. QUICK FLOW® Plus Screws: A Comparison

While both self-drilling self-tapping screws and QUICK FLOW® Plus screws excel in sheet metal connections, they differ in design, operation, and Application. Here’s a detailed comparison:

1. Design Features

- Self-Drilling Self-Tapping Screws:

- Their tails are drill-shaped, similar to a drill bit, with sharp cutting edges and helical flutes, allowing for independent drilling.

- Suitable for hard metal materials, such as steel, structural colour steel tiles, and thin plates.

- During assembly, they eliminate the need for pre-drilling, completing both drilling and tapping in a single operation.

- QUICK FLOW® Plus Screws:

- Specifically designed for thin sheet metal, they eliminate the need for pre-drilling or punching.

- The self-tapping action occurs through material deformation and work hardening, rather than cutting, to form the threads.

- A twin-lead thread design reduces the number of installation steps and processing time.

2. Installation Steps

- Self-Drilling Self-Tapping Screws:

- Installation is straightforward; you drive them directly into the Material using pneumatic or manual tools.

- They are ideal for areas requiring rapid installation, especially in thin sheet metal.

- QUICK FLOW® Plus Screws:

- Assembly requires no pre-drilling or punching; the screw tip independently forms threads as it penetrates the sheet metal.

- They are suitable for automated installation, boosting efficiency.

3. Applications

- Self-Drilling Self-Tapping Screws:

- Primarily used for fixing steel structural colour steel tiles and thin wood.

- Suitable for areas requiring quick installation in hard materials.

- QUICK FLOW® Plus Screws:

- Widely used in exhaust systems, household appliances, automotive components, and mechanical engineering.

- Especially suited for thin sheet metal connections, enabling lightweight and rapid assembly.

4. Connection Strength

- Self-Drilling Self-Tapping Screws:

- Their integrated drilling and tapping design creates a tighter bond with the Material, resulting in a stronger connection.

- QUICK FLOW® Plus Screws:

- The threads form through cold work hardening, offering high strength and ensuring connection stability and reliability.

5. Cost

- Self-Drilling Self-Tapping Screws:

- Their unit price is lower, and their simple installation process contributes to a lower overall installation cost.

- QUICK FLOW® Plus Screws:

- Their unit cost is higher, but by eliminating pre-drilling or punching, they reduce the number of production steps and overall costs.

If you require rapid installation in hard materials, we recommend self-drilling self-tapping screws because they drill and tap directly, ensuring high assembly efficiency. Suppose you require a lightweight design and need to connect thin sheet metal. In that case, we recommend QUICK FLOW® Plus screws, as they eliminate the need for pre-drilling, simplify the installation process, and are suitable for automation.

How to Use Self-Tapping Screws

When using セルフタッピングねじ, follow the correct installation procedures based on the specific Material and Application to ensure a firm and reliable connection. Here’s a detailed guide:

1. Preparation

- Tool Preparation:

- Screwdriver or Power Drill: Use these to tighten the screws.

- Electric Drill (Optional): If using self-drilling self-tapping screws, an electric drill provides more power.

- Drill Bit (Optional): If using standard self-tapping screws, you must pre-drill holes; therefore, prepare a drill bit with a diameter close to that of the screw’sscrew.

- Material Inspection: Ensure the connecting material surface is smooth, clean, and free of oil, rust, or other residues. Check that the screw model meets the Material’sMaterial’s thickness and strength requirements.

2. Installation Steps

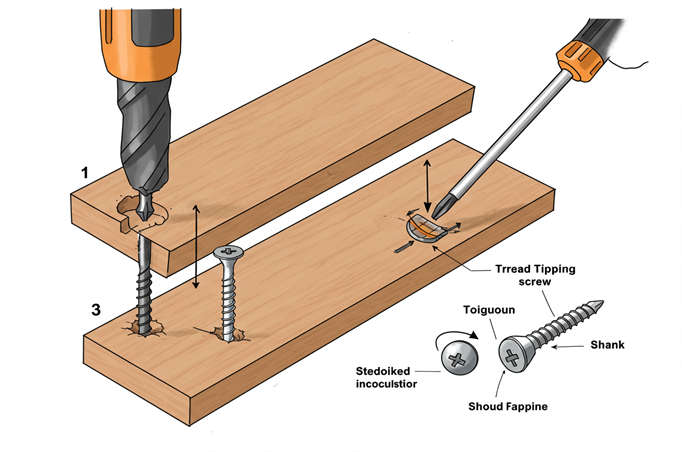

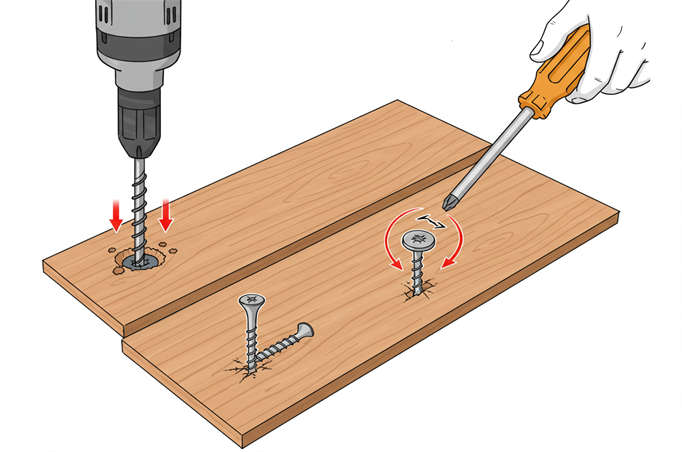

(1) Standard Self-Tapping Screws (Requires Pre-Drilling)

- Mark Installation Position: Mark the screw’s installation position on the connecting MaterialMaterial.

- Drilling: Use an electric drill and an appropriate drill bit to drill a pilot hole at the marked position. The pilot hole diameter should typically be slightly smaller than the screw’s outer diameter (approximately 0.5-1 mm smaller) to ensure smooth screw entry. The drilling depth should match the screw’s thread length.

- Driving the Screw: Align the セルフタッピングネジ with the pilot hole and slowly drive it in with a screwdriver or power drill. Maintain the screw’s perpendicularity during the slow driving process to prevent screw damage. Gradually increase the tightening torque until the screw fully engages the MaterialMaterial and the screw head fits snugly against the workpiece surface.

- Checking the Connection: Ensure the screw is firmly fixed in the MaterialMaterial and not loose. If necessary, gently pull the screw with a wrench or pliers to check its stability.

(2) Self-Drilling Self-Tapping Screws (No Pre-Drilling Required)

- Mark Installation Position: Mark the screw’s installation position on the connecting MaterialMaterial.

- Directly Driving the Screw: Align the self-drilling self-tapping screw with the marked position and drive it in with a power drill or electric drill. Maintain the screw’s perpendicularity during the slow driving process to prevent screw damage. The drill point will automatically drill the hole and tap the threads, and the screw will gradually enter the MaterialMaterial.

- Adjusting Torque: As the screw drills, adjust the tightening torque based on the Material’sMaterial’s hardness. Harder materials may require more torque. Once the screw drills to a certain depth, it will start to engage the MaterialMaterial; you can then slightly reduce the torque to prevent screw damage.

- Checking the Connection: Ensure the screw is firmly fixed in the MaterialMaterial and not loose. The screw head should fit snugly against the workpiece surface.

3. Important Considerations

- Screw Selection: Select the appropriate screw model and length based on the material type (e.g., metal, plastic, wood) and the Material’s thickness. For metal connections, we recommend stainless steel or carbon steel screws; for plastic connections, we suggest plastic screws.

- Assembly Torque: Do not overtighten the screw, as this can damage the screw or the MaterialMaterial. If the screw cannot be driven in, try reducing the tightening torque or check if the screw is correctly aligned with the hole.

- Material Protection: During installation, avoid scratching or damaging the workpiece surface. If necessary, you can add a washer between the screw head and the workpiece surface to minimize damage.

- 環境要因: If using in a humid or corrosive environment, we recommend selecting stainless steel or anti-rust screws.

- Safe Operation: When using power tools, ensure the tool’s power cord or battery is reliable and in good condition. Wear cut-resistant gloves and safety goggles during operation to ensure personal safety.

4. Common Problems and Solutions

- Screw Cannot Be Driven In:

- Verify that the screw is aligned with the hole and that the diameter is suitable. If the hole is too small, you can slightly enlarge it; if the hole is too large, you may need to change the screw.

- Loose Screw: Ensure the screw is entirely driven into the MaterialMaterial and the screw head fits snugly against the workpiece surface. If the screw is loose, you can try using thread locker or a lock washer to prevent loosening.

- Damaged Thread: If the screw thread is damaged, you can try replacing the screw or using a thread repair tool to fix the damaged thread.

By following these steps and precautions, you can standardize the use of セルフタッピングねじ and ensure the firmness and reliability of your connections.

Thank you for joining us on this comprehensive exploration of self-tapping screws. At Prince Fastener, we are committed to providing you with the best fastening solutions and the knowledge to make informed decisions. Self-tapping screws are a testament to innovation and practicality, offering unmatched versatility and ease of use across a wide range of applications.

We hope this blog post has shed light on the various types of self-tapping screws, their unique features, and how to effectively utilize them. Whether you’re working with metal, plastic, or wood, there’s a self-tapping screw designed to meet your specific needs. And when it comes to choosing the right fastening solution, Prince Fastener is here to support you every step of the way.

Remember, the key to a successful fastening project lies in selecting the right screw for the job and following proper installation techniques. If you have any questions or require additional assistance, our team of experts is always available to help. Don’t forget to check out our extensive range of self-tapping screws, available in various materials, sizes, and types to suit every requirement.

Stay tuned for more informative content from Prince Fastener, where we continue to bring you the latest insights and solutions in the fastening industry. Happy fastening, and let’s build a better world together, one screw at a time!

At プリンスファスナー, we 専用 to delivering the best fastening solutions. Do you have more questions about specific applications or screw types?