How to Choose the Right Wood Screws

Deciding what type of screw to use in woodworking can be tedious. In the traditional use of screws, few options were available in choices. The development of technology and complex requirements in fastening has made millions of alternatives to saturate the commercialization of screws. Today, many individuals who work with DIY-ing wood materials or projects usually encounter the same confusion on what type of screw to use and the right size of screw to choose.

Steel screws are mostly preferred in woodworking projects because of their strength. And sure enough, there’s a variety of choices, but what can be the factors affecting the versatility of wood screws? Let’s narrow down the general guidelines to help us decide the type of wood screw for an application.

Types of Screws And Screw Material

Screws can be made in different types of metal, among the most common are stainless steel, carbon steel, brass, bronze, aluminum, etc. Stainless steel screws are the most popular and sought-after material in woodworking. They are strong, inexpensive, and readily available in a vast range of sizes from hardware and fastener suppliers.

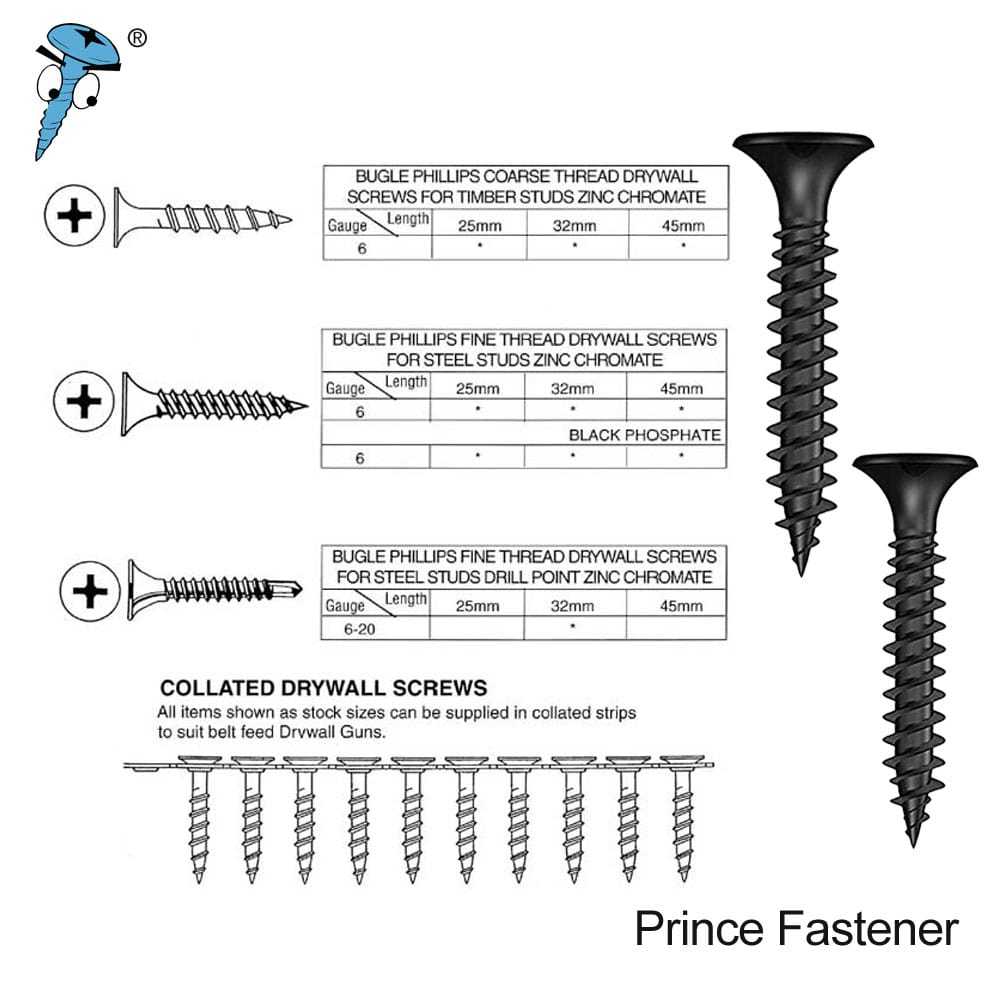

Other interior projects also use drywall screws for plasterboard, softwood, wallboard, etc., its tapered sharp points have made the installation of the screws much easier by drilling them into the wood surface without the need for a pre-drilled hole. Relatively, drywall screws are black phosphate and also a much cheaper choice than old-fashioned wood screws.

A different kind of woodworking screws that are typically used in construction and hardwood materials are called production screws. These screws are designed to penetrate difficult surfaces in some cases – metal materials. They are comprised of durable materials that can withstand high torque and impact from power drilling tools. In some markets, these screws are also referred to as multipurpose screws or construction screws, with overall corrosion-resistant features.

All screws can be subjected to enhance their quality through different types of plating or coating. This method increases the strength, durability, and corrosion resistance ability of the screws. For a corrosive environment that can rust the metal screws, the best materials are silicon bronze and stainless steel, while certain grades of screws can prevent other failures such as breakage due to exposure to salt elements.

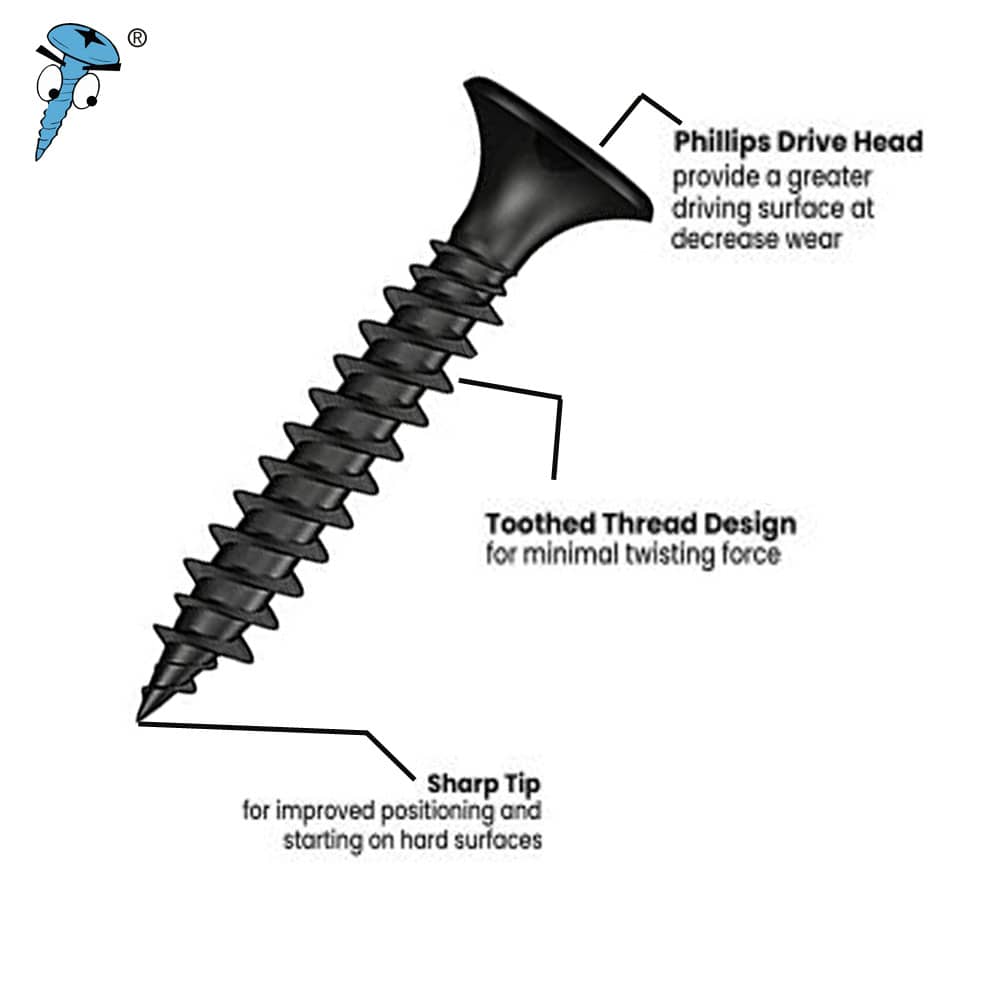

Know the Wood Screw Head Types

A big part of the confusion is what type of head-in wood screws are best to use for interior projects. There are many kinds of head with different varieties of drives, which also proposes necessary functions. Some of the known head types are the following;

A flat head screw with a tapered and countersinking head is best for sitting flush on the wood surface.

Slothead screws are the main and common variety of head-on wood screws with a simple slot feature.

Pan Head Screws provide better holding power through their flat bearing.

Round Head Screws are half-dome headed yet lay flat underside, often used for a decorative finish.

Truss Head and Washer Head Screws offer a flat bearing surface and wide head.

Phillips Head Screws propose a better advantage than slot head screws. They can be used in many wooden materials and secure the assembly.

Square drive or Robertson screws. its square head design reduces the risk of slippage during installation.

Determine the Size And the Length of the Screws

Screw sizes are extremely important to acknowledge. They can determine how much your screw can hold, the thicker its size the greater its holding capacity. Pre-loading the screws with twice the weight of the external load can help ensure your screws will not fail in application. Screw length is the overall height of the screws. The length of the screw should be able to pierce enough in the two objects (at least half of the bottom material) to secure the joint.

If you want to know more about the technicality and directly ask your inquiries, you may contact experts and professionals for help. Our services are available for any kind of fastening! Contact us today and discover the great deal we can offer.