Choosing the right stainless steel carriage bolts matters for your project’s success. You want bolts that resist rust and hold strong over time. Different materials can react with each other, so you need to check if your bolts match your other parts. Think about where you will use the bolts. Wet or outdoor places need extra protection. Your project’s needs help you pick the best option.

Key Takeaways

- Pick stainless steel carriage bolts for strong fasteners. They do not rust and last outside or in wet places. – Choose the right bolt size, thread, and grade for your project. Think about what materials you use, how much weight it holds, and where it will be. – Use 304 stainless steel for most projects. Use 316 grade if there is saltwater or strong chemicals. – Put in bolts with the right tools. Drill the right holes. Use washers to protect surfaces and keep bolts tight. – Stop rust by keeping bolts clean. Use lubricants. Do not mix metals that do not work well together.

Key Factors

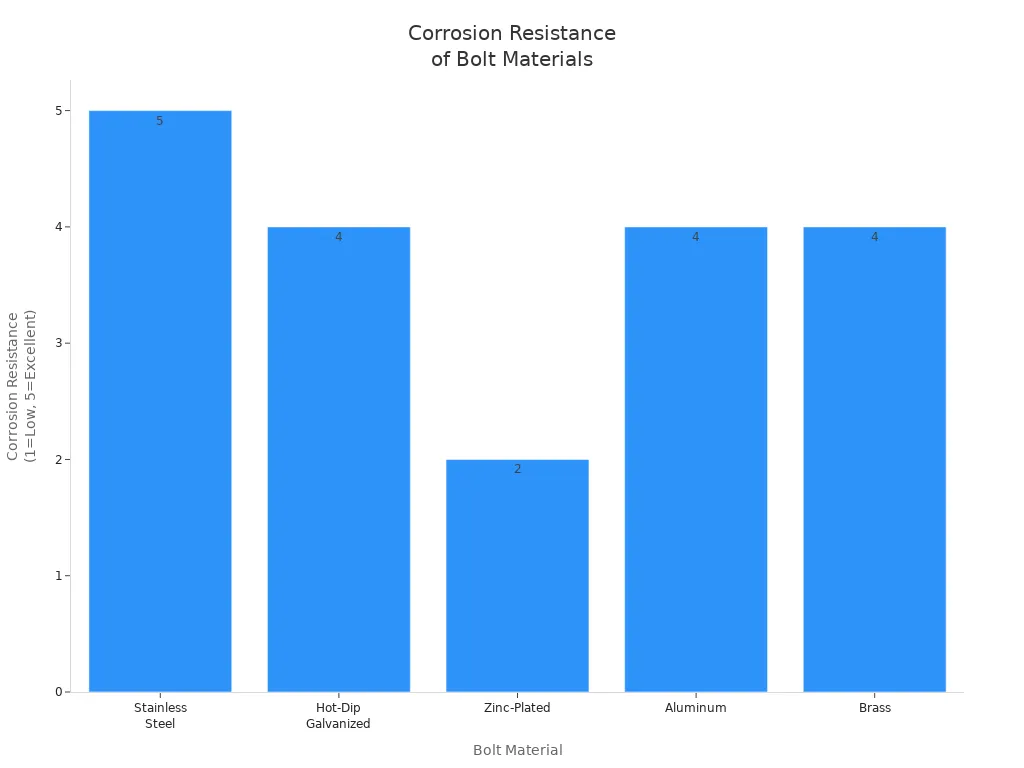

Corrosion Resistance

You want your carriage bolts to last a long time. This is important if you use them outside or near water. Stainless steel bolts are great because they do not rust easily. They also do not corrode like many other materials. That is why people pick them for outdoor, marine, or wet places. Stainless steel has chromium. This makes a shield on the bolt. The shield keeps the bolts strong and shiny, even in tough weather.

- Stainless steel bolts are good for marine, food, and outdoor jobs.

- Carbon steel bolts need a coating so they do not rust.

- Aluminum and brass bolts do not rust much but are not as strong.

| Bolt Material | Corrosion Resistance | Suitability for Outdoor Use | Notes on Durability and Cost |

|---|---|---|---|

| Stainless Steel | Excellent because of the chromium layer | Best for tough outdoor and marine places | Very strong; costs more |

| Hot-Dip Galvanized | Better than zinc; thick zinc coating | Good for tough outdoor places | Strong but not as much as stainless steel |

| Zinc-Plated | Basic help from a thin zinc layer | Okay for mild or medium outdoor use | Not good in lots of water or salt |

| Aluminum | Good | For lighter jobs | Not as strong as steel bolts |

| Brass | Good | For looks or light jobs | Not as strong as steel bolts |

Strength

You need bolts that can hold up your project. Stainless steel carriage bolts are very strong. Most common ones, like Class 70, can reach about 700 MPa. This means they do not break or stretch easily.

Tip: Pick the right class for your job. Class 70 bolts work for most things. Class 80 bolts are even stronger.

Application

Think about where and how you will use your bolts. Stainless steel carriage bolts are best for wet, salty, or chemical places. You see them in marine work, playgrounds, outdoor furniture, and farm tools. They are strong and do not rust, so they are good for heavy loads and hard jobs.

- Use stainless steel bolts for outdoor buildings, marine work, and big machines.

- Pick them when you need strength and long life.

- They are also good for cars and farm work.

Choosing the right bolt keeps your project safe and strong.

Carriage Bolts Overview

Design Features

A stainless steel carriage bolt has a special shape. The head is round and smooth. There is no slot or drive on the head. You cannot use a screwdriver or wrench on it. Right under the head is a square neck. This square part pushes into wood or metal. It stops the bolt from spinning when you tighten the nut. You only need to hold the nut, not the head, to put it in.

- The round head looks nice and does not catch on things.

- The square neck keeps the bolt from turning.

- You can put the bolt in from one side, which is simple.

- Stainless steel does not rust, so these bolts are good outside or in wet places.

- Carriage bolts are different from hex or flange bolts because their heads have no edges or flanges.

| Feature | Carriage Bolt | Other Bolt Types (e.g., Hex, Flange) |

|---|---|---|

| Head Shape | Smooth, round, domed head with no drive | Hex bolts have hexagonal heads; flange bolts have flanges |

| Neck Design | Square section beneath head to prevent turning | Usually no square neck; rely on head shape for grip |

| Installation | Can be installed from one side; square neck embeds in material | Usually require holding head with tools |

| Material (Stainless Steel) | Corrosion resistant, ideal for marine/coastal use | Varies; may not always offer same corrosion resistance |

Tip: The square neck is what makes carriage bolts special. It keeps the bolt steady while you tighten the nut.

Common Uses

Stainless steel carriage bolts are used in many jobs. People pick them when they want strong bolts that do not rust and look nice.

- Builders use them for decks, fences, and outdoor furniture.

- Water plants, railroads, and farms use them for wet or tough work.

- You can use them to join wood to metal, wood to wood, or metal to metal.

- The smooth head and square neck are good for places where safety and looks matter, like playgrounds or benches.

- Carriage bolts are also good for security because you cannot take them out from the head side.

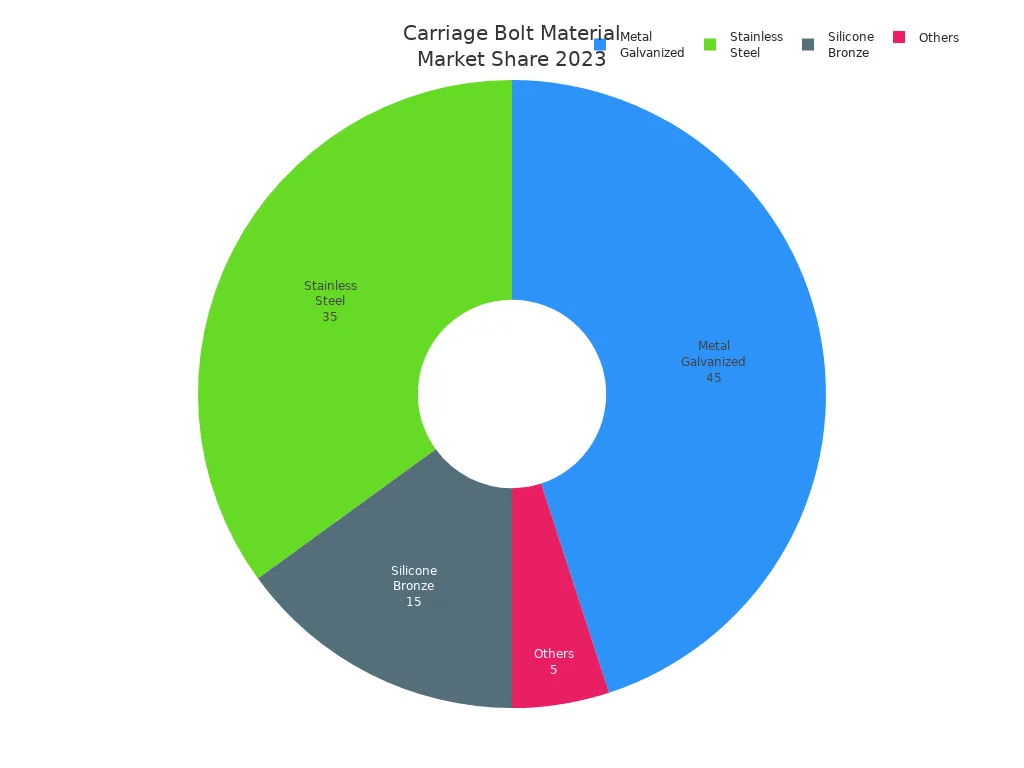

Stainless steel carriage bolts make up 35% of the carriage bolt market. Only galvanized bolts have a bigger share.

You can count on these bolts for strength and a clean look. They work well in wet places or where you need a bolt that is hard to remove.

Why Stainless Steel

Benefits

Stainless steel carriage bolts give you lots of good things. These bolts last longer than most others. You do not need to take care of them much. Here are some main benefits:

- They do not rust in wet or salty places.

- They are strong and work for big jobs.

- The round head and square neck make them easy to put in.

- Stainless steel bolts follow world rules for quality.

- You save money because you do not replace them often.

Note: Stainless steel carriage bolts cost more at first. But you spend less fixing or changing them. Over time, you save money compared to other bolts.

Look at this table to see how stainless steel bolts compare:

| Feature | Stainless Steel Carriage Bolts | Galvanized Carriage Bolts | Zinc-Plated Carriage Bolts |

|---|---|---|---|

| Corrosion Resistance | Best; fixes itself if scratched | Good; thick zinc layer | Not much; thin zinc layer |

| Strength & Durability | Very strong; good for big jobs | Strong, but not as much as stainless steel | Not very strong; good for small jobs |

| Longevity | Lasts longest; needs little care | Okay; coating can wear off | Short life; only for inside use |

| Ideal Applications | Marine, chemical, tough outdoor, heavy work | Outside building, fences | Inside jobs, furniture |

| Cost | Costs most at first, saves money later | Medium cost | Cheapest |

Stainless Steel Grades

There are two main types of stainless steel carriage bolts: 304 and 316. Both are strong, but they work best in different places.

| Property/Aspect | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Yield Strength | Same as 316 | Same as 304 |

| Tensile Strength | Same as 316 | Same as 304 |

| Corrosion Resistance | Good for most jobs | Best for saltwater and strong chemicals |

| Chemical Composition | No molybdenum | Has molybdenum (up to 3%) |

| Best Use | Most outdoor, indoor, and light chemical places | Marine, coast, or chemical plants |

304 stainless steel is good for most jobs inside or outside. Pick 316 stainless steel if you need extra help against saltwater or strong chemicals. Both types are strong, so choose based on where you use them.

Types of Carriage Bolts

Standard

You will find standard carriage bolts in many projects. These bolts have a smooth, rounded head and a square neck under the head. The square neck fits into a hole and keeps the bolt from turning when you tighten the nut. Standard carriage bolts work well in wood and metal. You can use them in construction, woodworking, and outdoor furniture. They hold beams, join wood pieces, and fasten parts in fences or decks. The design helps stop vibration and keeps the bolt tight.

- Smooth, round head for safety and looks

- Square neck for self-locking in wood or metal

- Used in building, furniture, and outdoor structures

Flanged

Flanged carriage bolts have a built-in washer under the head. The flange spreads the load over a larger area. This helps protect the material and gives extra grip. You can use flanged bolts when you want to avoid damage to wood or metal. They work well in softer materials or when you need more holding power. The flange also helps keep the bolt steady during tightening.

Tip: Choose flanged carriage bolts if you want to prevent the bolt from sinking into soft wood.

Security

Security carriage bolts help stop theft or tampering. You will see these bolts in public places, playgrounds, or anywhere you want extra safety. Security features make it hard to remove the bolt without special tools.

| Security Feature | Description |

|---|---|

| Square Neck Locking | The square neck fits tight and stops the bolt from turning. |

| Trident™ Nut | Needs a special tool to remove, thanks to its unique shape. |

| Break-Away Nut | The nut breaks off after tightening, leaving a piece you cannot remove with normal tools. |

| Double-Action Protection | Uses both a driver-less bolt and a special nut for extra security. |

You can use security carriage bolts for benches, gates, and equipment that must stay safe.

Specialty

Specialty carriage bolts meet unique needs. You may need extra strength, better grip, or special shapes for your project. Here are some common types:

| Specialty Carriage Bolt Type | Distinguishing Characteristics | Application/Benefit |

|---|---|---|

| Mushroom Head | Large, mushroom-shaped head for more surface area | Better load-bearing for heavy materials |

| Ribbed Neck | Ridges on the neck for extra grip and vibration resistance | Keeps bolts tight in moving parts |

| Tension Control (TC) Bolts | Oval neck shears off at set torque | Ensures the right tension every time |

| Grade 8 | Made from heat-treated alloy steel | Handles heavy-duty jobs and resists corrosion |

You can pick specialty bolts when your project has special demands. Stainless steel options give you strength and corrosion resistance for tough jobs.

Choosing the Right Bolt

Selecting the right carriage bolt for your project keeps your work safe and strong. Follow these steps to make the best choice:

Project Requirements

Start by thinking about what your project needs. Ask yourself these questions:

- What materials will you join? (wood, metal, or both)

- How much weight will the bolts hold?

- Do you need bolts that are easy to install or remove?

- Will the bolts show, and do you care about how they look?

You should also check if your project has special rules or standards. Some jobs, like building decks or playgrounds, must follow local codes. Always match the bolt type to your project’s needs.

Tip: Write down your project’s main needs before you shop for bolts.

Environment

The place where you use the bolts matters a lot. Moisture, salt, heat, and chemicals can damage bolts over time. If you work near the ocean, in a wet area, or with chemicals, pick bolts that resist rust and corrosion.

- Use 316 grade for saltwater or harsh chemicals.

- Use 304 or 18-8 grade for most outdoor or indoor jobs.

- For very tough places, like oil platforms or chemical plants, 2205 duplex stainless steel bolts last longer and need less maintenance.

High humidity and salty air can cause bolts to rust faster. Stainless steel bolts resist this damage better than most other types.

Note: Bolts that resist corrosion save you money and time on repairs.

Size and Thread

You must pick the right size and thread for your bolts. The size includes the diameter and length. The thread is the spiral part that lets you screw the nut on.

- Match the bolt length to the thickness of the materials you join.

- Pick the right diameter for strength and safety.

- Choose coarse threads for wood and soft materials.

- Choose fine threads for metal or when you need a tighter fit.

Here is a table to help you:

| Bolt Size (Metric) | Diameter | Thread Pitch | Best Use |

|---|---|---|---|

| M6-1.0 | 6 mm | 1.0 mm | Light wood or metal |

| M8-1.25 | 8 mm | 1.25 mm | Medium loads |

| M10-1.5 | 10 mm | 1.5 mm | Heavy-duty connections |

| M12-1.75 | 12 mm | 1.75 mm | Very heavy loads |

Tip: Always check your project plans or ask an expert if you are not sure about the size.

Material Compatibility

You need to make sure your bolts work well with the materials you use. Some metals can react with each other and cause corrosion. For example, if you use stainless steel bolts with aluminum in wet places, the aluminum can corrode faster.

To prevent this:

- Use plastic or rubber washers between the bolt and the other metal.

- Add coatings or primers to protect the materials.

- Check if your project needs special fasteners for mixed materials.

If you join large aluminum parts with stainless steel bolts, watch for signs of corrosion and do regular checks.

Callout: Always separate different metals with a barrier to stop corrosion.

Load Needs

Think about how much weight or force your bolts must hold. The bolt grade tells you how strong it is. For most jobs, 18-8 stainless steel bolts work well. They have a minimum yield strength of 65,000 psi and a tensile strength up to 150,000 psi. For bigger loads or harsh places, use higher grades like 316 or even 2205 duplex.

Here is a quick guide:

| Bolt Grade | Yield Strength | Tensile Strength | Best Use |

|---|---|---|---|

| 18-8 (304) | 65,000 psi | 100,000-150,000 psi | Most outdoor/indoor jobs |

| 316 | Similar | Similar | Saltwater, chemicals |

| 2205 Duplex | Higher | Higher | Marine, chemical plants |

Tip: Never use a bolt with a lower strength than your project needs.

Step-by-Step Guide to Choosing Stainless Steel Carriage Bolts:

- Identify your project’s needs and any rules you must follow.

- Check the environment for moisture, salt, or chemicals.

- Pick the right bolt size and thread for your materials.

- Make sure the bolt material matches or is safe with your other materials.

- Choose the right grade for the load and environment.

- Look for certified, high-quality bolts from trusted suppliers.

- If possible, test a sample bolt before buying many.

By following these steps, you can choose the best carriage bolt for your project and make sure your work lasts.

Installation Tips

Tools

You need the right tools to install bolts well. First, drill a hole that matches the bolt’s size. This helps the square neck fit tight and keeps the bolt from spinning. Use a drill for the hole. Use a hammer if you need to push the bolt in. Use a wrench or socket set to tighten the nut. Always use washers to spread out the force and protect the surface. Do not use pliers or adjustable wrenches. They can hurt the bolt or nut.

Checklist for tools:

- Drill with correct bit size

- Hammer (if needed)

- Wrench or socket set

- Washers and nuts

Tip: Make sure the hole is lined up before you put in the bolt. This helps your connection stay strong.

Tightening

Tightening bolts the right way keeps your project safe. Use a wrench or socket set to turn the nut. The square neck holds the bolt steady. Push with even pressure. Do not tighten too much, or you could damage the threads or the material. For important jobs, use a torque wrench and follow the maker’s rules. Tighten until the bolt head is flat with the surface. If there is a lot of shaking, use lock washers or lock nuts to keep bolts tight.

Corrosion Prevention

You want your stainless steel bolts to last long. Keep bolts clean and dry before and after you put them in. Use thread lubricant to stop seizing and make tightening easier. You can use anti-seize compounds or spray zinc-based lacquer for more protection. In tough places, use a coating or sealant. Check and clean bolts often to stop rust.

Ways to prevent corrosion:

- Use corrosion-resistant bolts and washers

- Put on protective coatings or lubricants

- Keep surfaces clean and dry

- Check bolts often

Mistakes to Avoid

Many problems happen because of simple mistakes. Do not use the wrong tools or skip drilling holes first. Do not tighten bolts too much or too little. Always use washers to protect surfaces. Pick the right stainless steel grade for your area. Keep parts clean and make sure they sit flat. Do not forget about corrosion, especially near the ocean.

Common mistakes: Using bad fasteners, mixing wrong materials, or not following torque rules can make bolts loose or break.

You can make your project safer and stronger by choosing the right stainless steel carriage bolts. Match the bolt type and grade to your application for the best results. Follow these steps for success:

- Select bolts with the right size, grade, and finish for your needs.

- Install bolts using proper tools and techniques.

- Inspect and maintain bolts regularly.

If you feel unsure about selection or installation, ask a trusted supplier or expert for advice.

FAQ

What grade of stainless steel carriage bolt should you use outdoors?

You should use 304 or 18-8 stainless steel for most outdoor jobs. For areas near saltwater, pick 316 stainless steel. This grade gives you the best protection against rust and corrosion.

Can you use stainless steel carriage bolts with treated wood?

Yes, you can use stainless steel bolts with treated wood. Stainless steel resists the chemicals in treated wood. This helps prevent rust and keeps your project strong for years.

How do you stop stainless steel bolts from seizing during installation?

Tip: Always use an anti-seize lubricant on the threads before tightening. This stops galling and makes it easier to remove the bolt later.

Do stainless steel carriage bolts need washers?

You should use washers with carriage bolts. Washers spread the load and protect the surface. They also help keep the nut tight and prevent damage to wood or metal.