How Fastener Suppliers Can Help Your Business Reduce Waste and Costs

Fastener manufacturing has been running the supply chain for more industry demands. Nowadays, the products require improvement and sustainability as well as means of having concerns for environmental issues. Many fastener manufacturers have resided to eco-friendly supplies to help and support a cleaner and better world. There are quite a few discussions of how these organizations play their role in managing the reduction of harmful materials and elements while keeping their business running.

Let’s take on some of the ways that fastener suppliers can help many businesses in reducing waste and the costs of products.

Causes of Waste Costs in the Fastener Industry

In every manufacturing business, the waste of materials is a common problem leading to a shortfall. The few most recognized cause of waste in organizations are as follow;

- Overproduction of materials/goods

- Scraps/rejects

- Inappropriate Process

- Disorganization

Surely, the instances above can be prevented with proper management of the system and processes within the company. Today, there are many variables to consider to achieve a successful and functioning business. The help of experts and other organizations can offer their services to help to maintain the balance of production processes, financial insights, inventory management, and others.

Importance of Waste Reduction for Fastener Business

As the world evolves to the use of advanced technology, the number of waste disposal grows along with it. Fortunately, concerns with the environment have been raised to a notch, making the manufacturers and organizations take action to reduce and take control of wastes in industrial manufacturing. Waste reduction in a fastener business has been slowly implemented by many companies to help in supporting the green world.

The importance of waste reduction in fastener business can;

- conserve natural resources and energy (i.e. raw materials)

- save money on supplies and production costs

- reduce the costs of disposing of wastes

- meet the demands of many eco-friendly conscious customers/industries

- not taking part in increasing the environmental issues and burden

- boost employee morale by allowing them to help in an environmental cause

- reduce the risk of potential liability for solid waste issues in the future

How to Reduce Manufacturing Wastes and Cut Costs of Fasteners

There are several ways for reducing manufacturing waste of fasteners that can provide environmental benefits while keeping the business in line with good principles and values. The most common way of taking part in eco-friendly production is to imply the use of recyclable materials that can reuse in manufacturing or even with assemblies to reduce a carbon footprint.

- Plan the production properly. For any business, sustainability is important to keep the flow running efficiently. And to maintain sustainability every production process should be planned according to what products are usually purchased.

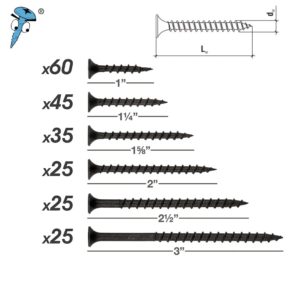

- Choose a standard design of fasteners and cut a variety of types and sizes for your inventory to eliminate the overstocking of products that may not get sold right away.

- Choose multi-function fasteners as they can do more than just hold parts together but perform efficiently for shear and other assembly operations.

- Reduce excessive use of packaging materials for fasteners. The usual choice of packaging for the components is reusable materials like paper, plastic, and other less hazardous materials.

Overall, there can be further ways to lessen the harmful effects on the environment while having a healthy and successful business. The key is to follow a good management system that allows a productive and beneficial process for everyone and the environment.

Contact us for your fastening concerns and needs.