How Fastener Design Impacts the Efficiency of Fastening Assembly and Disassembly

Manufactured fasteners have come a long way from traditional features to the most innovative designs of head style, drive, threading, and others. Unknown to many, the characteristics and designs of a fastener play an important role in connectivity and efficiency. Their complex features influence the ease of installation process and removal or disassembly of fasteners as well as their overall performance in applications. Here is the significance of fastener design in assemblies and how they can provide impact in unique ways:

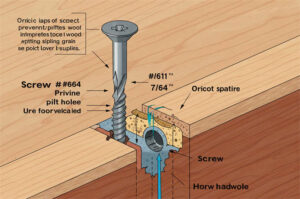

Fastener threads have two common types of coarse and fine threads which provide varying properties. Coarse threads in fasteners can be installed easily and faster yet it may compromise grip strength resulting in gradual loosening in time. Fine threads provide better strength in holding connections but are slower in assembly times thus they are often applied with the use of powered tools.

Other features within the shank or body of fasteners like thread profile, pitch, and direction also impact the ease of engagement and disengagement processes during use. Therefore, these considerations are essential to deciding on industries that require crucial features for precision and reliability.

Head style has several variations in common fasteners which are often overlooked as an important part that determines proficiency in installation and removal. For example, hex head screws are the most common among the head styles and offer versatility and torque transmission in general fastening since they can be used with readily available tools in any household. While specialized head style provides assembly features suitable for application environments and security.

Coating and material also influence the major requirements of fasteners such as corrosion resistance, abrasion, and chemical resistance. These features affect the life span of a fastener in use which directly contributes to the ease of its removal during replacements or repair.

Other fastener designs and configurations also influence their performance in different assemblies of industries. In automotive and construction, most fastening systems require solutions that can provide structural integrity and vehicle safety. Fastener failure can result in unpleasant accidents that can put the safety of workers and consumers at risk. Thus, thoroughly inspecting details in the simple parts of systems such as fastener devices can provide the main program of a project.

Prince Fastener Manufacturing Co., Ltd. offers a wide variety of fasteners for many industrial applications in manufacturing, furniture making, vehicle assembly, and more. We also manufacture custom fasteners for specific requirements and customer designs. When needing expert and technical support for fastening systems we ensure to provide the best experience and satisfaction of our services. Contact us today for your inquiries and fastener needs.