You will find hex head bolts work best for most projects. These bolts fit standard wrenches and sockets, so you can install them quickly. Square head bolts help when you need to work in tight or blind spots. Before you choose a machine bolt, look at where you plan to use it. Think about how much torque you need and if you want the fastener to show. Each project has its own needs.

Key Takeaways

- Hex head bolts work well for most jobs. They fit with common tools. This makes them fast and simple to put in.

- Square head bolts are best for small or hidden spaces. They have a bigger surface to grip. This helps you use more force. They are good for tough jobs.

- Think about where you will use the bolts. Stainless steel and galvanized bolts do not rust easily. They are good for wet or chemical places.

- Use the checklist to pick the right bolts. Make sure the bolts fit your project’s needs. Check for the right material, strength, and if you can see them well.

- Always check if your bolts are tight. It is easier to see if square head bolts are tight. Hex head bolts can be harder to spot and need more checking.

Machine Bolt Comparison

Quick Table

You can use this table to compare hex head and square head machine bolt options. It shows how each type works in different situations. This helps you choose the best types of bolts for your project.

| Feature | Hex Head Machine Bolt | Square Head Machine Bolt |

|---|---|---|

| Head Shape | Six-sided | Four-sided (square) |

| Tool Compatibility | Standard wrenches and sockets | May need adjustable or manual tools |

| Installation Speed | Fast and easy | Slower, may need more effort |

| Torque Application | Good, suitable for most tasks | Greater torque, ideal for heavy-duty |

| Visibility | Less visible, blends in | Easy to inspect visually |

| Typical Uses | Construction, machinery, automotive | Woodwork, restoration, blind areas |

| Surface Area | Smaller | Larger, grips better in wood |

| Accessibility | Best for open spaces | Useful in tight or blind spots |

Tip: You should look at this table before you pick a machine bolt. It helps you see which types of bolts fit your needs.

Key Differences

When you compare machine bolt types, you notice several important differences. These differences affect how you use bolts in your project.

- Hex head bolts have a six-sided head. You can use standard tools like wrenches and sockets. This makes installation fast and easy. You save time on most machine projects.

- Square head bolts have a four-sided head. You may need adjustable or manual tools. Installation takes longer. These bolts work well in tight or blind areas where you cannot see the fastener.

- Square head bolts give you a larger surface area. You can apply more torque. This helps when you need heavy-duty fastening or want to grip wood tightly.

- Hex head bolts blend in with most machines. They do not stand out. Square head bolts are easy to inspect. You can see if they are tight.

- You find hex head bolts in construction, machinery, and automotive work. Square head bolts are common in woodwork, restoration, and places where you need to check tightness often.

- If you want speed and tool compatibility, hex head machine bolts are the best choice. If you need more torque or work in a tight spot, square head machine bolts help you.

Note: You should think about the environment and visibility before you choose between different types of nuts and bolts. Each machine bolt type has its own strengths.

You see that the types of bolts you pick can change how your machine project turns out. You should match the machine bolt to your tools and the job you need to do. When you know the key differences, you make better choices for your project.

Hex Head Bolts Overview

Definition

You see hex head bolts in many projects because they offer a strong and reliable way to fasten materials. These bolts have a hexagonal head, which means you get six flat sides. This design lets you grip the bolt easily with a wrench or socket. You can use hex bolts for repair work, construction, and machinery. The machine threads on these bolts help you create a secure hold. You find that hex head bolts work well when you need to tighten parts with precision. The straight shank gives you a stable connection, and the head shape makes installation simple.

Tip: You should choose hex head bolts when you want fast installation and easy tool access.

Materials and Sizes

You can pick hex bolts made from different materials to match your project needs. Most hex head bolts come in anti-corrosion stainless steel, alloy steel, or carbon steel. These materials help prevent rust and keep your bolts strong over time.

- Anti-corrosion stainless steel

- Alloy steel

- Carbon steel

You find hex head bolts in many sizes. The diameter and head width change based on what you need. Here is a table that shows common size ranges for hex bolts:

| Material Type | Size Range (Diameter) | Head Width Range |

|---|---|---|

| Inch Series | 1/4″ to 2″ | 7/16″ to 3-1/8″ |

| Metric | M4 to M64 | 7mm to 95mm |

Industry standards help you pick the right hex head bolts for your job. Heavy hex bolts have a chamfered head, and the diameter matches the maximum width across the flats. You see that length tolerances change with the diameter and length of the bolt. Heavy hex bolts give you extra strength and durability. You can find bolts with blunted or pointed tips, depending on your application.

Note: You should check the size and material before you buy hex bolts. This helps you get the best fit and strength for your project.

Square Head Bolts Overview

Definition

You often see square head bolts in projects that need strong fastening and easy inspection. These bolts have a four-sided head, which gives you a large gripping surface. You can turn them with a wrench or pliers, even when you work in tight spaces. The square shape helps you apply more torque, so you get a secure fit. You find square head bolts in woodwork, restoration, and places where you want to check tightness quickly. The simple design makes these bolts easy to spot and adjust.

Tip: Choose square head bolts when you need to fasten materials in areas with limited visibility or space.

Materials and Sizes

You can select square head bolts made from different materials to match your project needs. Steel is the most common choice because it offers strength and durability. Silicon bronze is another option, especially when you want resistance to corrosion. You find these bolts in both imperial and metric sizes, so you can pick the right fit for your job.

Here is a table that shows the most common materials and size ranges for square head bolts:

| Material | Size Range (Imperial) | Size Range (Metric) |

|---|---|---|

| Steel | #1 to 6 | M4 to M30 |

| Silicon Bronze | #1 to 6 | M4 to M30 |

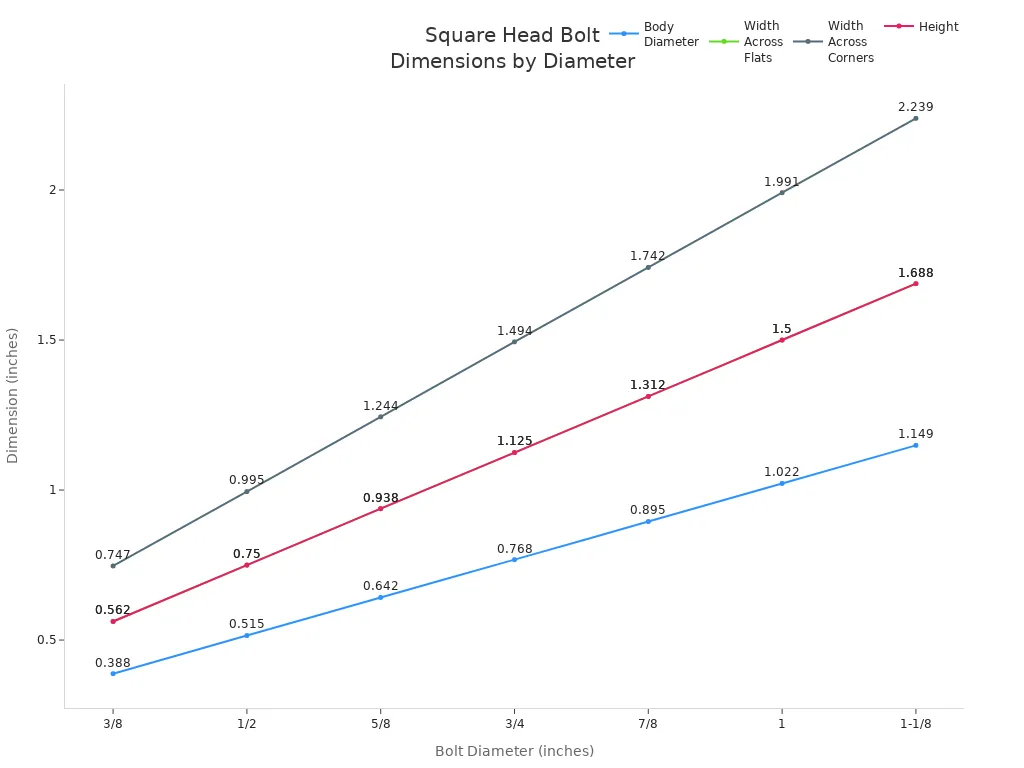

Industry standards help you choose bolts with the right dimensions and tolerances. You can look at the table below to see typical measurements for square head bolts:

| Bolt Diameter | Body Diameter | Width Across Flats | Width Across Corners | Height |

|---|---|---|---|---|

| 3/8 | 0.388 | 9/16 | 0.562 | 0.747 |

| 1/2 | 0.515 | 3/4 | 0.750 | 0.995 |

| 5/8 | 0.642 | 15/16 | 0.938 | 1.244 |

| 3/4 | 0.768 | 1-1/8 | 1.125 | 1.494 |

| 7/8 | 0.895 | 1-5/16 | 1.312 | 1.742 |

| 1 | 1.022 | 1-1/2 | 1.500 | 1.991 |

| 1-1/8 | 1.149 | 1-11/16 | 1.688 | 2.239 |

You should check the material and size before you buy bolts. This helps you get the right strength and fit for your project. Square head bolts give you flexibility in choosing the best option for your needs.

Design Differences

Head Shape

You notice the head shape makes a big difference when you work with bolts. Hex head bolts have six flat sides. This design lets you grip the bolt easily with a wrench or socket. You get a secure hold, which helps you apply torque without slipping. If you use the wrong tool or do not engage the wrench fully, you risk stripping the hex socket. You should use full-length hex drivers to prevent this problem. Strain-hardened fasteners also help you get better torque. Avoid ball-end hex drivers because they can strip the hex at low torque.

- Hex head bolts give you more tool options and faster installation.

- The six-sided shape helps you turn the bolt in tight spaces.

- You get better grip and control, which means less chance of damaging the bolt.

Square head bolts have four sides. The large, flat surfaces make it easy to grip with a wrench or pliers. You can apply more torque, which is useful for heavy-duty jobs. The square shape also helps you work in blind spots where you cannot see the bolt head.

Tip: Choose the head shape that matches your tools and the space you have to work in.

Appearance

The look of bolts matters, especially in projects where you want a certain style. Hex head bolts blend in with modern machines and construction. You see them in places where you want a clean, simple look. These bolts do not stand out, so they work well when you want the fastener to be less visible.

Square head bolts give you a classic, antique look. You often see them in restoration work or historic buildings. The large head surface area keeps the bolt tight under stress, which helps maintain the strength of old furniture or structures. The robust design also gives you a strong grip and makes the bolt easy to inspect.

- Square head bolts match period hardware in restoration projects.

- Their appearance adds character and authenticity to historic work.

- You get both style and strength when you use square head bolts.

Note: Pick bolts that fit the style and strength needs of your project. The right appearance can make your work look professional and authentic.

Installation and Tools

Torque Application

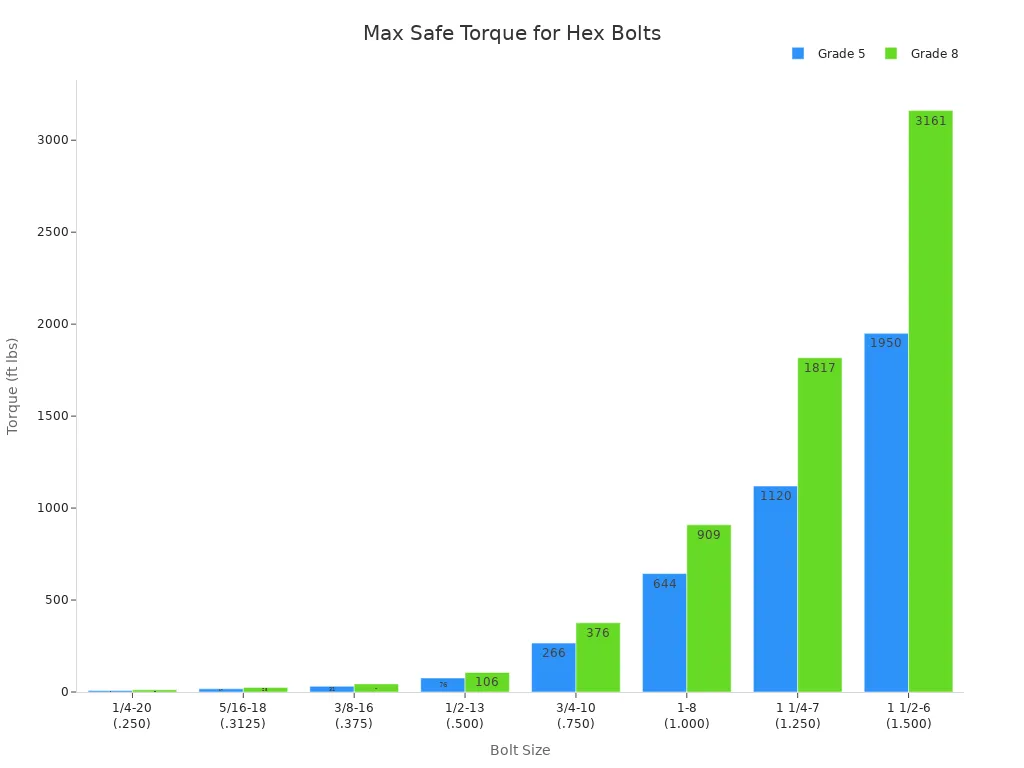

You need to know how much force you can safely use when tightening bolts. Hex head bolts let you apply strong torque because their six-sided heads fit snugly with wrenches. This design helps you avoid slipping and makes tightening easier. You can see the maximum safe torque for different bolt sizes in the table below. The numbers show how much force you can use for Grade 5 and Grade 8 bolts.

| Bolt Size | Grade 5 Torque (ft lbs) | Grade 8 Torque (ft lbs) |

|---|---|---|

| 1/4-20 (.250) | 8 | 12 |

| 5/16-18 (.3125) | 17 | 25 |

| 3/8-16 (.375) | 31 | 44 |

| 1/2-13 (.500) | 76 | 106 |

| 3/4-10 (.750) | 266 | 376 |

| 1-8 (1.000) | 644 | 909 |

| 1 1/4-7 (1.250) | 1120 | 1817 |

| 1 1/2-6 (1.500) | 1950 | 3161 |

Square head bolts also let you use high torque. Their large, flat surfaces give you a strong grip. You find these bolts helpful when you need to fasten wood or work with heavy-duty materials. The square shape helps you tighten bolts in places where you cannot see the head.

Tip: Always check the sizing and compatibility of your bolts before you start. This helps you avoid damage and keeps your project safe.

Tool Compatibility

You want to use tools that make your job easier. Hex head bolts work with most standard wrenches and sockets. You can install or remove these bolts quickly. The six-sided design means you do not need special tools. You save time and effort on every project.

Square head bolts need a different approach. You often use adjustable wrenches or pliers. These bolts work well in tight or blind areas. You can grip the head from different angles. This makes square head bolts a good choice when space is limited or when you need to check the tightness often.

- Hex head bolts: Best for fast installation and easy tool use.

- Square head bolts: Useful for hard-to-reach spots and visual checks.

Note: Choose bolts that match your tools and workspace. The right choice helps you finish your project faster and with less trouble.

Strength and Durability

Load Capacity

You want to make sure your project can handle the weight and force it will face. Load capacity tells you how much force bolts can hold before they fail. Hex head bolts give you strong load capacity because their design spreads force across six sides. This shape helps you tighten bolts without slipping. You often see hex head bolts used in heavy machinery and construction because they support large loads.

Square head bolts also offer good load capacity. Their wide, flat sides let you grip them tightly. You can use these bolts in woodwork and restoration projects where you need extra strength. The large surface area of square head bolts helps prevent the bolt from pulling through soft materials like wood.

Tip: Always check the size and grade of bolts before you start your project. Bigger bolts and higher grades give you more load capacity and better durability.

Here is a quick table to help you compare load capacity:

| Bolt Type | Typical Load Capacity | Best Use Cases |

|---|---|---|

| Hex Head | High | Machinery, construction |

| Square Head | Moderate to High | Woodwork, restoration |

Performance

You need bolts that perform well over time. Durability matters when your project faces stress, vibration, or changing weather. Hex head bolts show strong durability because their shape resists wear and tear. You can use coarse-thread hex head bolts for better resistance to loosening under vibration. The deeper threads grip tightly and stay secure, even when your project moves or shakes. Fine-thread hex head bolts give you higher tensile strength, but they may loosen more easily if your project vibrates a lot. You might need extra washers or locking nuts to keep them tight.

Square head bolts also offer good durability, especially in wood or older structures. Their large heads make it easy to check tightness and adjust as needed. You can trust square head bolts to hold up in restoration work, but you may need to inspect them more often if your project faces heavy vibration.

- Hex head bolts: Best for projects with repeated stress or vibration.

- Square head bolts: Good for woodwork and places where you need to check tightness often.

Note: Choose bolts that match your project’s needs for durability and performance. The right bolts help your work last longer and stay safe.

Corrosion Resistance

Material Options

You want your bolts to last in tough environments. The material you choose makes a big difference. Some bolts resist rust and corrosion better than others. Stainless steel and hot-dip galvanized bolts stand out for their strong protection. You see these options used in places with lots of moisture or chemicals.

Here is a table that shows how different materials protect your bolts:

| Material | Corrosion Resistance Description |

|---|---|

| Stainless Steel | Excellent corrosion resistance, ideal for marine and outdoor use. |

| Hot-Dip Galvanized | Zinc coating provides long-term corrosion protection in exposed areas. |

Stainless steel bolts work well when you need to fight rust. You can use them near water, in outdoor projects, or in places with chemicals. Hot-dip galvanized bolts have a zinc layer that shields them from rain and harsh weather. You see these bolts on fences, bridges, and outdoor machinery.

- Stainless steel bolts: Best for wet or salty areas.

- Hot-dip galvanized bolts: Good for places with changing weather and rough conditions.

Tip: Choose bolts with high corrosion resistance if your project faces moisture or chemicals.

Environmental Suitability

You need to match your bolts to the environment. If you work near the ocean or in rainy places, stainless steel bolts give you the best protection. These bolts do not rust easily. You can trust them for docks, boats, and outdoor furniture. Hot-dip galvanized bolts also help in tough spots. The zinc coating keeps your bolts strong even when exposed to rain or mud.

You see that some bolts work better in dry, indoor spaces. Regular steel bolts cost less, but they may rust if you use them outside. You should check the weather and location before you pick your bolts. If you want your project to last, use bolts that fit the environment.

- Use stainless steel bolts for marine and outdoor jobs.

- Pick hot-dip galvanized bolts for construction in exposed areas.

- Avoid regular steel bolts in wet or salty places.

Note: Always think about where you will use your bolts. The right choice keeps your project safe and strong.

Typical Applications for Hex Bolts and Square Head Bolts

Common Uses for Hex Head Bolts

Hex head bolts are used in many industries. They are strong and can be used in lots of ways. You see them in construction, manufacturing, and car projects. People use these bolts to hold steel, wood, and concrete together. Factories use hex head bolts to build machines and equipment. Car mechanics use them to attach engine parts and frames. Farmers use hex head bolts on tractors and trailers. These bolts are also good for fixing and repairing things. You can use them again because they last a long time.

There are different hex head bolts for different jobs. Standard hex bolts are for general building and machines. Heavy hex bolts are stronger and used for big bridges and buildings. Hex lag bolts are best for joining wood to wood or wood to metal, like in decks and fences. Flange hex bolts help stop bolts from coming loose when things shake. Metric hex bolts are used in places that use metric sizes, like some car and machine factories.

Tip: Pick hex head bolts when you need a strong and reliable fastener for many jobs.

Common Uses for Square Head Bolts

Square head bolts are important in old buildings and big factories. Builders use these bolts to hold steel beams and columns together. This makes buildings safer and stronger. Machines need square head bolts to keep their parts lined up and working right. Car makers use square head bolts to build engines and frames. These bolts are also good for ships because they do not rust easily.

Railroads use square head bolts to keep rails and other parts in place. Wooden bridges and decks need these bolts to hold beams and frames tight. Power towers use square head bolts to hold up wires. Wind turbines and solar panels use these bolts to stay strong. Big machines and projects like dams and highways need square head bolts for safety.

| Application Area | Description |

|---|---|

| Structural Steel Connections | Holds steel beams and columns together. |

| Machinery Assembly | Keeps machine parts lined up. |

| Automotive Industry | Used to build engines and frames. |

| Marine Applications | Stops rust in ship parts. |

| Railroad Infrastructure | Holds rails and parts in place. |

| Wooden Structures | Fastens beams and frames in bridges and decks. |

| Electrical Transmission Towers | Holds up wires in power towers. |

| Renewable Energy Installations | Keeps wind turbines and solar panels strong. |

| Heavy Machinery | Builds mining and construction equipment. |

| Infrastructure Projects | Secures parts in bridges, dams, and highways. |

People pick square head bolts for fixing old buildings. These bolts make old homes strong and look real. You get a classic style for old projects. You can use both old and new tools to install them. Square head bolts are also good for fixing machines in restoration work.

Pros and Cons of Hex Head Bolts

Advantages

You will find many reasons to choose hex head bolts for your project. These bolts make your work easier and faster. The hex shape gives you six flat sides, so you can grip the bolt with a wrench or socket from many angles. This design helps you install or remove hex bolts quickly, even if you need to work fast.

- The hexagonal head lets you use standard tools like wrenches or ratchets. You do not need special equipment.

- You get a firm grip on the bolt, which makes installation and removal simple.

- Hex head bolts help you finish jobs faster because you can turn them easily from different positions.

- You can use hex bolts in many projects, from building machines to fixing cars.

- These bolts work well in places where you need strong and reliable fasteners.

Tip: If you want to save time and avoid tool problems, pick hex head bolts for most jobs.

Disadvantages

Hex head bolts also have some drawbacks. You may face problems in certain situations. If you work in a tight space or cannot see the bolt head, you might struggle to use hex bolts. The head can get stripped if your tool slips, especially in hard-to-reach spots. This makes removal difficult.

- Removing hex bolts becomes hard if the head gets stripped, especially in low visibility or tight areas.

- You might over-tighten the bolt when using a hex key or impact driver. This can cause problems in small or confined spaces.

- Hex head bolts can rust in places with high humidity or chemicals. Corrosion makes maintenance harder and can weaken the bolts.

Note: Always check your workspace and the environment before you choose hex head bolts. Some projects need different bolts for better results.

Pros and Cons of Square Head Bolts

Advantages

Square head bolts have many good points, especially for old buildings. These bolts have a big head, so you can grip them easily. It is simple to tighten or loosen them. You can use wrenches or pliers, even if space is tight. The shape lets you use more force without slipping.

- Square head bolts give you a better grip for fixing old things.

- You can use them with other old fasteners in buildings. This keeps your project looking real.

- The classic shape fits well with old styles. Your restoration work looks better.

- In old building repairs, square head bolts help keep the right look.

- You can see these bolts easily, so checking if they are tight is simple.

Tip: Pick square head bolts if you want your project to look old and stay strong. They are great for fixing antique furniture or restoring old places.

Disadvantages

There are some problems with square head bolts in new buildings. These bolts do not always work with modern tools or ways of building. You might need to use adjustable wrenches or hand tools, which can slow you down.

- Square head bolts are mostly used for making furniture. You do not see them much in new buildings.

- These bolts are good for electrical work in small spaces. But they are not common in big building jobs.

- It can be hard to find square head bolts in regular stores. New projects often need hex head bolts because they are faster to use.

- The big head can get in the way if you work where there are lots of bolts.

- Square head bolts do not match modern styles. They can stand out and change how your project looks.

Note: Make sure square head bolts fit your tools and style before you start. You might need another type for new projects.

Choosing the Right Machine Bolt

Selection Checklist

You want your project to go well. Picking the right bolts is important. Use this checklist to help you pick between hex head bolts and square head bolts for your machine work.

- Project Environment

- Will your bolts get wet, touch chemicals, or get very hot or cold?

- Stainless steel or galvanized bolts are best for outside or tough places.

- Material Compatibility

- Are you joining wood, metal, or plastic?

- Hex head bolts work with metal, concrete, and plastic.

- Square head bolts hold wood tightly.

- Strength and Durability

- Does your project need to be very strong?

- Hex head bolts are stronger for heavy-duty machine jobs.

- Ease of Installation

- Can you reach the bolt easily?

- Hex head bolts go in fast with regular tools.

- Square head bolts help in tight or hidden spots.

- Vibration Resistance

- Will your machine shake or move a lot?

- Square head bolts stay tight because of their shape.

- Aesthetic Needs

- Do you want the bolts to blend in or stand out?

- Hex head bolts look modern and blend in.

- Square head bolts look classic and are easy to see.

- Visibility and Access

- Can you see and reach the bolt when you put it in or check it?

- Square head bolts are easier to check by looking.

Tip: Always pick bolts that match your project’s place, how easy they are to see, and how you will put them in. This helps you avoid problems later.

Here is a table to help you compare important things when picking bolts and nuts for your machine project:

| Factor | Square Head Bolts | Hex Head Bolts |

|---|---|---|

| Material Use | Best for wood-to-wood and wood-to-metal jobs | Good for metal, concrete, and plastic |

| Strength and Durability | Medium strength, good for fixing old things | Stronger, best for tough jobs |

| Ease of Installation | Easy in wood, tight spaces | Fast with regular tools, slower in hidden spots |

| Vibration Resistance | Very good because of the square shape | Might need extra help to stay tight |

| Aesthetic Considerations | Classic, easy to check | Modern, not easy to see |

Project Scenarios

You need to think about your own machine project before you pick a bolt. Here are some common examples to help you choose:

- Outdoor Construction

- You build a deck or fence.

- Use galvanized hex head bolts for weather and strength.

- Woodworking or Restoration

- You fix old furniture or work on a historic building.

- Square head bolts match the look and are easy to check.

- Heavy Machinery Assembly

- You put together a machine that gets a lot of stress and shaking.

- Hex head bolts give a strong hold and last longer.

- Tight or Blind Installations

- You work where you cannot see the bolt head.

- Square head bolts help you grip and tighten without seeing.

- Marine or Chemical Environments

- You put bolts near water or chemicals.

- Stainless steel hex head bolts do not rust and last longer.

Here is a table that shows how the environment changes your choice:

| Factor | Description | What to Consider |

|---|---|---|

| Environmental Conditions | Wet, chemicals, or very hot or cold places | Use stainless steel or galvanized bolts outside |

| Visibility | Need to check bolts or hide them | Square head bolts for easy checks, hex for hiding |

| Installation Constraints | Hard to reach or tight spaces | Square head bolts for grip, hex for fast tools |

Note: Always look at what your project needs before you pick bolts. The right bolts save time and keep your machine safe.

You see that every project is different. When you think about the place, how easy it is to see, and how hard it is to put in bolts, you make better choices. Picking the right bolts helps your machine work well and last longer.

You will find hex head bolts work best for most projects. These bolts give you strong clamping pressure and fit standard tools, making installation easy. When you work in tight spaces, square head bolts can help, but they need more room for your wrench. Use the checklist and comparison table to match bolts to your needs. For unique projects, talk with hardware professionals about material, strength, thread type, torque, and finish. The right bolts keep your project safe and strong.

FAQ

What makes hex head bolts easier to install?

You can use standard wrenches or sockets with hex head bolts. The six-sided shape lets you grip the bolt from many angles. This design helps you finish your project faster and with less effort.

When should you choose square head bolts?

You should pick square head bolts for tight spaces or restoration work. The large head gives you a strong grip. You can check the tightness easily, which helps in old buildings or wood projects.

Are bolts made from stainless steel good for outdoor use?

Stainless steel bolts resist rust and corrosion. You can use them for outdoor jobs, near water, or in places with chemicals. These bolts last longer and keep your project safe in tough environments.

Can you use bolts for both wood and metal projects?

You can use bolts for wood, metal, or concrete. Hex head bolts work well for metal and concrete. Square head bolts grip wood tightly. You should match the bolt type to your material for best results.

How do you check if bolts are tight enough?

You should use a wrench to check the tightness of bolts. Square head bolts are easy to inspect because you can see the head clearly. Hex head bolts blend in, so you may need to check them more often.