In the world of fasteners, hex-head fasteners stand out for their versatility and reliability. From construction sites to automotive manufacturing, these fasteners play a crucial role in holding things together. This blog post explores the various types, materials, and applications of hex-head fasteners, highlighting their benefits and providing tips for selecting the right one for your needs. Whether you’re a professional in the field or a DIY enthusiast, understanding the nuances of hex-head fasteners can make a significant difference in your projects.

Overview of Hex Head Fasteners

Hex head fasteners (such as screws and bolts) are characterized by their hexagonal heads, which allow for rapid tightening using tools like wrenches and nuts.

Classification

By Head Type:

- External Hexagonal Bolt: Features a hexagonal head and is typically tightened using tools like wrenches.

- Internal Hexagonal Bolt: Has a hexagonal hole in the head, requiring an internal hex key for operation.

By Thread Type:

- Coarse Thread Hex Head Bolt: Has a larger pitch between threads, suitable for general tightening environments.

- Fine Thread Hex Head Bolt: A smaller pitch between threads is ideal for situations requiring precise adjustments.

By Use:

- Hex Head Connecting Bolt: Primarily used to connect two or more components.

- Hex Head Tightening Bolt: Used to secure components in place.

By Thread Coverage:

- Complete Thread Bolt: The entire shaft is threaded, suitable for high-strength connections.

- Half Thread Bolt: Only part of the shaft is threaded, balancing strength and assembly efficiency.

By Function:

- Self-Drilling Hex Screws (Tek Screws): Equipped with a drill bit, eliminating the need for pre-drilled holes, suitable for copper sheet assemblies.

- Internal Hexagonal Bolt: Features a recessed head commonly used in precision machinery and furniture.

- High Toughness Large Hex Bolts: Used for steel structure connections, such as bridges and building frames.

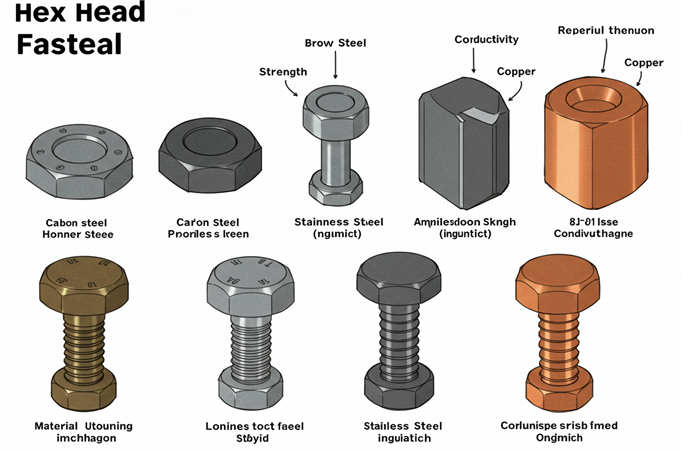

Materials

Hex head fasteners are typically made from carbon steel, carbon alloy steel, stainless steel, and other materials.

- Carbon Steel: Cost-effective, suitable for general environments.

- Carbon Alloy Steel: It is high-strength and ideal for high-toughness connections.

- Stainless Steel: Excellent corrosion resistance, perfect for damp or corrosive environments.

- Surface Treatments: Hot-dip galvanizing, Dacromet coating, and other treatments enhance durability, especially outdoors or in high-humid environments.

Specifications

Hex head fasteners are generally described by their thread diameter and length. For example, the M8 Hex Head Fastener × 20 indicates a thread diameter of 8mm and a length of 20mm. Different standards for hex head fasteners, such as GB/T 5780-2016, DIN 601, and ISO 4014, provide detailed specifications and tolerances.

Applications and Benefits of Hex Head Fasteners

Construction Industry

Hex head bolts, especially those with high toughness (Grade 8.8 and above), ensure seismic performance in steel structure connections (e.g., bridges and building frames).

Automotive Industry

Critical for engine components and chassis fasteners, hex bolts, and flange nuts enhance the stability of contact surfaces under high vibrations.

Furniture & Home Appliances

Internal hex screws are used for assembling cabinets and metal frames, combining aesthetic appeal with strength. Self-drilling hex screws (Tek screws) optimize copper sheet installation.

Electrical and Electronic Equipment

Used in distribution box grounding bolts, transformer joints, and stainless steel plates to prevent electrochemical corrosion. Copper bolts are used to connect conductive components.

Urban Railways & Heavy Machinery

Dacromet-coated bolts are selected for subway segment connections to withstand damp environments. High-toughness large hex bolts are used at key nodes of bridges and mining equipment.

Aerospace & Instrumentation

Countersunk internal hex bolts reduce friction, and lightweight materials like aluminum or titanium alloys are used. When combined with torque wrenches, they allow precise control of pre-tensioning forces.

Machinery Manufacturing

Hex head fasteners secure and position parts in various machine manufacturing, such as automobiles, machine tools, and ships.

Electronics & Electrical Equipment

Used to assemble electronic products and electrical equipment, such as computers, mobile phones, and home appliances, ensuring internal components are securely fixed.

Railway Transportation

Hex fasteners connect railway tracks and cars, ensuring operational stability and safety.

Energy Industry

Hex head fasteners are used to install and maintain wind and solar power generation equipment, ensuring efficient system operation.

Selection Recommendations

Scenario Compatibility:

- Outdoor and high-humidity environments should use stainless steel or coated bolts.

- For vibration-prone applications, choose tightening design models.

Tool Compatibility:

- External hex bolts are operated with socket wrenches.

- Internal hex bolts require Allen keys (e.g., H3/H4).

Specification Marking:

- Example: M12 × 50, with a 12mm diameter and 50mm length, features a half-thread design to balance strength and assembly efficiency.

Advantages of Hex Head Fasteners

- Stable Tightening: The hex head design provides a more significant stress area, more effectively transferring tightening force, ensuring connection stability.

- Ease of Maintenance: Hex head fasteners are typically operated with wrenches, making them easy to rotate and tighten, facilitating maintenance and replacement.

- Convenient Replacement: Standardized sizes and specifications make replacement easy, reducing maintenance costs.

- High Toughness: Typically made from high-strength materials, hex head fasteners can withstand significant tension and pressure, ideal for high-toughness applications.

- Corrosion Resistance: Available in stainless steel and other corrosion-resistant materials, suitable for damp or corrosive environments.

- Reusable: Hex head fasteners can generally be reused, reducing maintenance costs.

- Rational Design: The hex head design helps prevent loosening, ensuring reliable connections.

Materials Used for Hex Head Fasteners

Hex head fasteners are made from various materials to meet different application requirements. Here are some common materials and their properties:

Metal Materials

- Carbon Steel: One of the most common materials for hex head fasteners, offering good strength and toughness at a relatively low cost. Carbon steel is classified into low-carbon, medium-carbon, and high-carbon steel, with different strengths.

- Carbon Alloy Steel: Alloying elements, such as chromium-molybdenum steel (e.g., SCM435), enhance the strength and toughness, making it suitable for high-toughness connections.

- Stainless Steel: Known for excellent corrosion and heat resistance, suitable for damp or corrosive environments. Standard stainless steel grades include SUS302, SUS304, and SUS316.

- Copper: Copper and its alloys have good electrical conductivity and corrosion resistance. They are often used for electrical equipment and decorative parts.

Non-Metallic Materials

- Plastic: Plastic fasteners are lightweight, corrosion-resistant, and insulative, suitable for non-structural connections and decoration. Common materials include polyamide (PA), polycarbonate (PC), and polypropylene (PP).

- Ceramics: Structural ceramics offer high toughness, wear resistance, and sound insulation properties, making them suitable for high-temperature, high-pressure, and corrosive environments. For example, alumina ceramics (CA) are excellent in heat and corrosion resistance.

Composite Materials

- Glass Fiber Reinforced Plastic: These materials combine the advantages of plastic and fiberglass, offering high strength, low weight, and good corrosion resistance. They are suitable for the aerospace and automotive industries.

Special Alloys

- Nickel-Based Alloys: For example, Inconel 718 offers excellent heat and corrosion resistance and is used in the aerospace and energy industries.

- High-Temperature Alloy Steel: For example, A286 offers strong high-temperature strength and corrosion resistance, making it suitable for standard parts in high-temperature environments.

When choosing materials for hex head fasteners, it is essential to consider the specific use case and technical performance requirements. For example, carbon and alloy steel are commonly selected in engineering and machinery manufacturing. In contrast, stainless steel is more suitable for environments in the chemical and food industries, which require corrosion resistance.

Benefits of Hex Head Fasteners

Overall Design and Installation Advantages

- All-Around Assembly Convenience: The hex head offers six faces for force application, making it suitable for assembly in tight spaces. The larger tool contact area makes it less prone to slippage.

- Efficient Torque Transfer: The hex head design increases the stress area for tools, allowing for higher load-bearing capabilities. The torque transfer capacity is more potent than that of Phillips or slotted screws, reducing the risk of thread stripping.

- Reliability and Tightening: Self-locking nuts or elastic washers (e.g., nylon locking nuts) integrated with the hex head prevent loosening, reducing the chances of vibration-induced loosening. High-toughness models (e.g., Grade 14.9) enhance tightening effectiveness through optimized thread precision.

Stable Tightening Performance

- The hex head design provides a more significant stress area, ensuring efficient torque transfer and stable connection.

- Made from high-strength materials like carbon steel, alloy steel, and stainless steel, hex head fasteners can withstand significant tension and pressure, ideal for high-toughness connection applications.

Easy Installation and Maintenance

- Tool Compatibility: Hex head fasteners are commonly operated with wrenches, making them easy to rotate and tighten, reducing operation time.

- Standardized Specifications: Hex head fasteners come in standardized sizes, making replacement easy and reducing maintenance costs.

Corrosion Resistance

- Stainless steel versions offer excellent corrosion resistance and are suitable for damp or corrosive environments. Coatings like galvanizing or nickel plating further enhance corrosion resistance, forming protective layers against corrosive substances.

Cost-Effectiveness and Precision

- Thanks to their standardized production, hex head fasteners are cost-efficient, particularly in large-scale applications.

- Reusable fasteners help lower maintenance costs, especially in scenarios requiring frequent disassembly.

Hex head fasteners are essential in many industries, offering stability, durability, and ease of use. Their diverse materials and designs make them suitable for various applications, from high-intensity construction to delicate electronic devices. By considering factors like the environment, required strength, and compatibility with tools, you can choose the most appropriate hex head fastener for your specific needs. These fasteners’ economic and maintenance advantages further solidify their importance in both industrial and everyday settings. Whether securing a skyscraper or assembling furniture, hex head fasteners are a reliable choice.