Fastener Suppliers for Marine Applications: Meeting Saltwater Challenges

What are Saltwater Challenges for Fasteners?

The marine industry requires fasteners that can withstand constant challenges in their environment. Marine equipment needs effective components that are highly corrosion-resistant and are specifically designed and manufactured for saltwater. Under several conditions, some of the challenges that fasteners will likely encounter include the following:

- Corrosion – Saltwater can cause extreme corrosion which leads to rust and corroding of fasteners. When fasteners are more exposed to this environment they will eventually go weak and fail over time.

- Galvanic corrosion – this process occurs whenever two different materials of fasteners get in contact with electrolytes found in saltwater. The event causes the failure of the weaker metal to corrode right away and leaves it to ultimately fail.

- Crevice corrosion – crevices are small gaps between metals or other components that get infiltrated by saltwater and eventually weaken in the long run.

- Stress corrosion cracking – saltwater has a lot of environmental and temperature issues that put fasteners under high levels of stress. During the incident, small cracks will form in the body of fasteners and will cause them to fail due to weakened structure.

There are several ways to prevent the failure of marine fasteners due to saltwater corrosion. Typically, the products can be manufactured under specific requirements that can withstand the different kinds of corrosion in saltwater environments. Some of the most common materials highly resistant to corrosion are stainless steel and titanium. Moreover, they may also have coatings that can provide an extra layer of protection in fasteners. And lastly, it is best to have expert advice from professionals to increase the chances of preventing the said failure of the components and identify the proper steps to maintain the safety of assemblies.

Marine Grade Fasteners

Marine-grade fasteners are essential for saltwater applications because of their specific design which can sustain and withstand harsh environments. Most often, stainless steel and titanium fasteners are used for marine equipment and applications such as boats, docks, offshore plants, structures, etc. for their ability to resist types of saltwater corrosion.

Stainless steel fasteners are alloy steel that contains at least 10.5% chromium which provides great resistance to corrosion. The available grades for stainless steel fasteners that are mostly used in marine applications are 304 and 316. Each stainless steel grade contains different abilities which depend on its use. While titanium fasteners are also another option used in marine applications for their high strength-to-weight ratio and corrosion resistance.

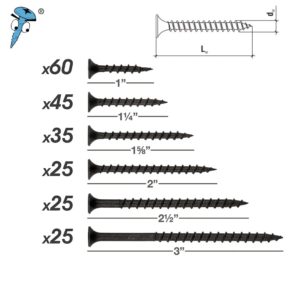

Additionally, there is a variety of range of fasteners in types like bolts, nuts, screws, washers, rivets, and different sizes. A protective coating like zinc plating, epoxy, and Teflon can be an additional precaution for corrosion. It is very important to choose marine-grade fasteners for saltwater environments to secure the safety of different assemblies and prevent failures on fasteners.

How can Prince Fastener provide help?

Prince Fastener is a professional manufacturer and supplier of marine fasteners. The company has complex capabilities to meet the demands of custom fasteners and specific requirements of every range of assembly applications. With over 35 years of extensive experience in the industry, Prince Fastener can ensure high-quality components that can withstand saltwater corrosion.

Contact us today to know about what we can offer.