Fastener Manufacturer Suppliers for Wholesale Distributors: A Guide to Finding the Best Fastener Supplier

What is Fastener Manufacturing?

Fasteners have vast types and forms that bring a similar purpose in their applications which is to affix/join materials and objects together. The most commonly known fasteners are bolts, screws, nuts, washers, rivets, studs, nails, and more. They are manufactured through several processes called to die, head forming, threading, heat treatments, surface treatment, and other tests to achieve their final form.

Fastener manufacturing takes place in facilities with equipment and types of machinery that is capable of performing the said processes. Some critical factors that are needed most in fastener production are efficiency, quality system, ability to meet the number of orders, etc. Moreover, fastener manufacturers primarily source the different industries that essentially need the products for commercialization, industrial use, structural projects, building projects, and more. It is not only convenient for customers to purchase directly from manufacturers and suppliers but it is also advantageous for reasons of budget-friendly, security in quality, traceability, customization of features, excellent service, and variety of choices.

Fastener Manufacturing Process

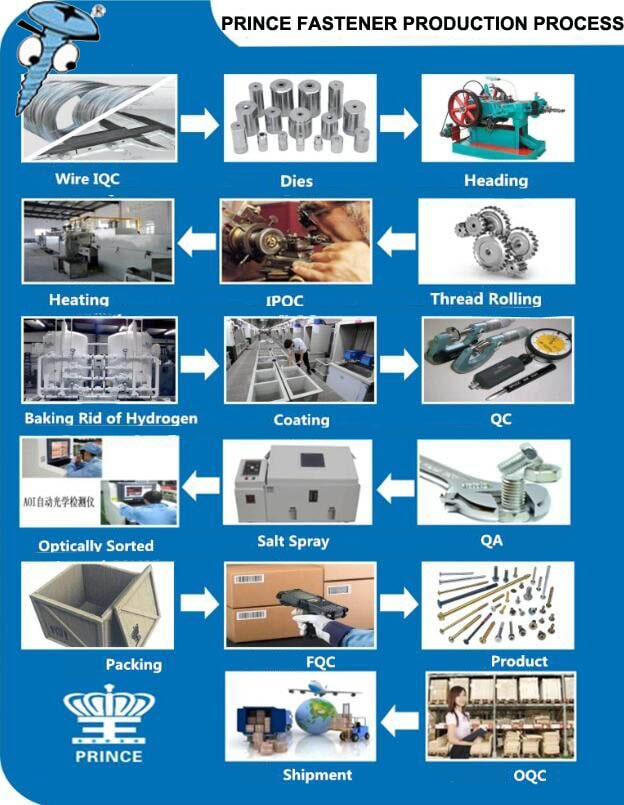

Every product is created from raw material through a series of processes before it becomes its final form. For fasteners, they are firstly made from a wire which can be any type of steel, stainless steel, titanium, aluminum, brass, and plastic. The wire is inserted in different machines that cut, form, and mold its body accordingly to its type. For example, screws undergo head forming and thread forming for shaping their external body and for certain methods like heat treatment and surface treatment (i.e. coating, finishing) for additional qualities.

Heat treatment is the process of heating the fasteners at high temperatures and cooling them afterward to eliminate properties and achieve modification in the material to become stronger, durable, malleable, and rigid. While surface treatment is adding a coating or finishing to the surface of fasteners for them to have an extra layer of protection, high corrosion resistance, or sometimes for decorative appearance.

Finding The Right Fastener Supplier

Having to find the right supplier can sometimes be a tedious job especially when there are a vast of requirements for your project. The industry of fasteners is known to have a large and competitive market yet some customers still have difficulties in finding the right fastener supplier that can meet the demands and needs of their application. With this, we come up with simple steps that can help individuals or organizations find the accurate company for them.

How to find a reliable and best fastener supplier?

- Know your type of application. It is critical to determine the type of your application because it is the primary factor that affects the success of landing on the right supplier. Know what kind of application you are dealing with by recognizing the material of the application, environmental issues, conditions, and others. Once you get clear with the demands of your application, it will be easier to discuss this with the supplier.

- Gather ideas and do research. Research is important since it will allow you to have general and basic ideas about what you should be looking for. Watch some videos about fastening tips and tricks or read informative articles online that will help in identifying the accurate factors that will suit your needs. Collecting opinions and bits of advice from experts is another useful knowledge especially when you have a critical application.

Read here: What are quick tips and tricks for using fasteners?

- Find a reputable company. With thousands of fastener companies online it is easier to inquire from multiple sources in a single day. The industry is filled with competitiveness wherein most suppliers have a quick response rate for inquiries. Therefore, you should prepare and keep standards when you look for a supplier. Some of the major qualities to look for are reliability, excellent customer service, high-quality products, good reviews from previous customers, variety of inventory, capability in custom manufacturing, and efficient shipping, and delivery time of goods.

- Discuss your needs and demands. When you have the finalized list of your needs and demands keep it in mind to openly discuss them with the supplier. A good supplier will most likely keep up to reasonable specifications of products and terms given by the customer. For example, if your application needs high corrosion resistance and durability, suppliers should be able to recommend the right fastener and explain why it is best suited for the assembly.

- Keep more options and connections. The good thing about having a vast option in the industry is you can keep a wide option for your needs. With every supplier, there are also different qualities they possess, plus having another supplier can also benefit you when problems occur. Certain problems include delays in shipment or availability of the product you need.

Many suppliers can accommodate the needs and demands of your application but it is also important to look for a company with values, principles, and deep understanding in fastening to achieve a sustainable, safe, and secured assembly as well as a successful transaction.

Fastener Materials

Having to know the materials of your components is likely to influence the strengths of your assembly. The following are some common materials used in fasteners with their broad definitions:

Stainless Steel – is the most common material of fasteners with high corrosion resistance, strength, non-magnetic properties, and durability, and applicable in most surface applications. There are different grades and types of stainless steel depending on carbon content, hardness, and other characteristics.

Aluminum – this material on fasteners is highly corrosion resistant with lightweight properties which is why they are mostly preferred in aerospace applications. However, aluminum has reactive elements that can cause failure and damage to the surface once they are wrongly used. Aluminum alloys are made up of manganese, silicon, iron, magnesium, and zinc which primarily gives it strength and corrosion resistance.

Brass – has a golden yellow appearance which gives a decorative look in applications. They are also highly corrosion-resistant and electrically conductive which is ideal for electrical-related applications like electronics, appliances, and household projects.

There are a few more available materials of fasteners which has high corrosion resistance that is good for standard applications in consumer products or projects. This includes a variety of steel (carbon steel, mild steel, hardened steel), alloy, silicon bronze, and nylon. Each material possesses its own characteristics that are designed to fit the kinds of assembly.

In addition, coatings also increase the features and abilities of fasteners, making them function effectively in applications. Frequently available coatings of fasteners are zinc plating, hot dip galvanizing, chrome plating, plain finish, color coating, etc.

Industries and Applications of Fasteners

Fasteners are essential in everyday products and structures that help the modern world function effectively. Whether it is consumer products like gadgets, appliances, and garments or large-scale applications in machinery, automotive, industrial manufacturing, infrastructures, equipment, and many others, these useful commodities play a crucial role in connecting the objects. The following are the common industries that use different kinds of fasteners;

- Aerospace

- Automotive

- Agriculture

- Building and Construction

- Engineering

- Electrical

- Energy and petrochemical

- Industrial manufacturing

- Medical

- Marine and Mining industry

- Military

Metal Fasteners Wholesale Distributor

Prince Fastener Manufacturing Co., Ltd is a renowned fastener supplier from China that specializes in standard and non-standard fasteners. With great capabilities to meet the demands and specifications of fasteners through custom manufacturing, the company can serve a wide range of applications and industries in the market. We follow standards in ISO, DIN, JIS, ASTM, and more. We can provide accurate solutions for most of your fastening needs including a variety of bolts, screws, nuts, washers, rivets, studs, nails, anchors, etc.

Send us a message for your fastening needs and we will gladly accommodate your inquiry within 24 hours. We supply wholesale, bulk, and a minimum order of a complete range of fasteners!