Exploring Plated and Coated Fasteners: What You Need to Know

Fasteners are essential components in various industrial, commercial, and household settings. Almost every machine, manufacturing, and construction project consists of fastener devices to form a joint that incorporates a functional assembly through qualities of durability, corrosion resistance, aesthetics, and various conditions.

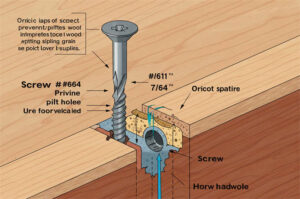

As a crucial part of securing structures, fasteners such as screws and bolts face several challenges that expose their integrity leading to potential safety hazards. To enhance the durability of fasteners, protecting them from vulnerability through some methods like plating and coating improve their overall performance and appearance to make them more resistant to galling and corrosion. This process is vital to some conditions that require extreme resistance to high levels of corrosive elements, temperature, and other conditions, they also benefit a large portion of involvement in fastening.

The Difference Between Plated Fasteners and Coated Fasteners

Plated fasteners such as zinc, nickel, chrome, and cadmium have an increased corrosion resistance that improves aesthetics. This method by fastener manufacturers is done through the deposition of metallic materials onto the surface of fasteners in various electrochemical processes. It provides a thin layer of protective barrier against common damages like corrosion and wear.

Whereas, coated fasteners act as a shield in the fastener surface through methods of powder coating, painting, and application of polymers. These coatings offer versatile colors, textures, and thicknesses that additionally provide a layer of protection from harmful elements in the environment.

Read More: Fastener Platings, Finishes, & Coatings

The Benefits of Enhancing Fasteners

Here are some helpful advantages of plated and coated fasteners that benefit different kinds of applications:

- Corrosion Resistance: In some cases, the natural corrosion resistance of fasteners cannot withstand certain levels of environmental conditions thus plated and coated fasteners can adapt naturally to challenges within corrosive elements that can harm and weaken the integrity of fasteners.

- Enhanced Aesthetics: Coated fasteners is a preferable option to customize the materials of surrounding appearance and match it accordingly to the needs of visual look, hence it can enhance overall structure and aesthetic.

- Reduce Maintenance: Plated and coated fasteners reduces the regular maintenance or replacement of assemblies since they prevent chances of corrosion and wear.

- Extended Lifespan: The coating and plating on fasteners is known to offer a protective layer that decreases the rate of damage on the material of the fastener hence they can have a longer lifespan or durability to withstand harsh conditions.

- Application Diversity: Various industries with hybrid requirements like construction, automotive, aerospace, electronics, military, and more can find more use of plated and coated fasteners for their extreme benefits in applications.

Contact us for inquiries about fasteners and fastening essentials, and get high-quality custom fasteners for your next project from a reliable manufacturer and supplier!