Ready to learn what makes a Torx screw stand out? Here are four quick facts you should know:

- El star-shaped design lets you apply more torque and reduces the chance of stripping the screw head.

- You get better grip and comfort, which means less hand fatigue during long projects.

- Torx screws work in many industries, from cars to electronics, because they deliver reliable fastening.

- You save money on bulk purchases, with prices as low as $0.01 per piece for large orders.

| Fast Fact | Por qué es importante |

|---|---|

| Star shape | More torque, less damage |

| Comfort | Easier, longer use |

| Versatilidad | Used in many fields |

| Cost savings | Lower expenses for big projects |

Try these facts when you tackle your next DIY task. You might find your work gets easier and faster!

Tornillo Torx

¿Qué es un tornillo Torx?

Torx es una unidad de tornillo con diseño de estrella en la cabeza de los tornillos. Es comúnmente conocido por diferentes nombres como seis lóbulos o estrella, mientras que se llama hexalobular como su nombre ISO.

Los tornillos Torx pueden tener unidades internas y externas, pero generalmente se encuentran dentro del zócalo de la cabeza para impulsar el tornillo durante la instalación o extracción. La unidad Torx puede soportar una fuerza de torsión alta que probablemente dañará o fatigará el tornillo cuando se coloca sobre la superficie de los materiales.

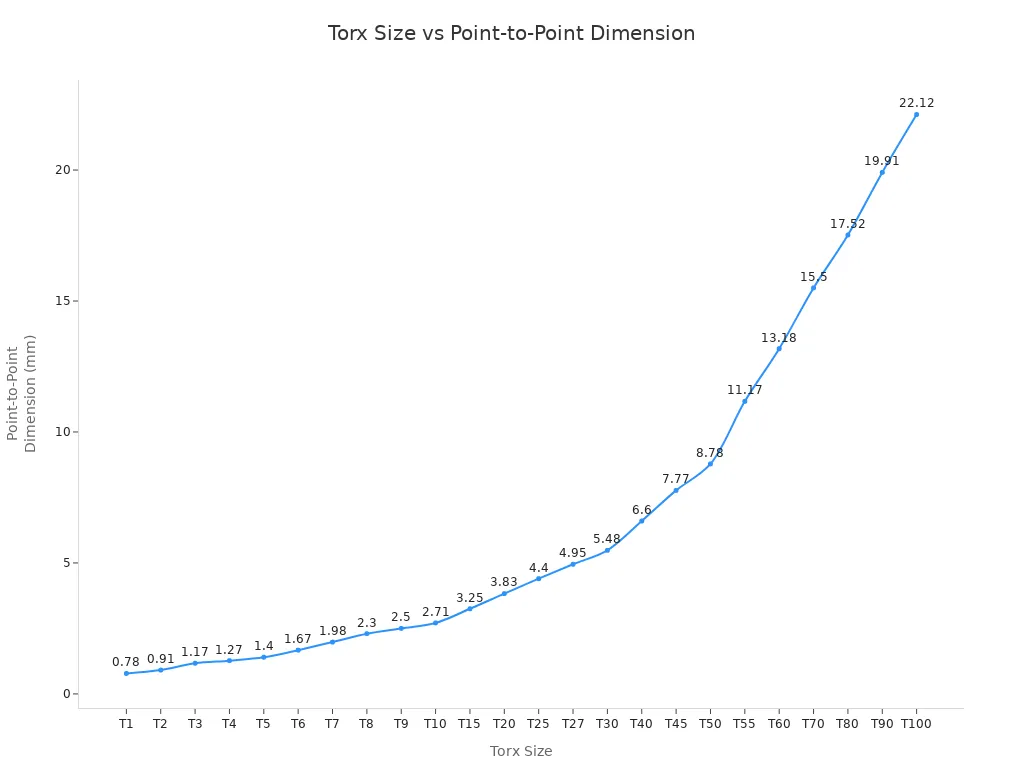

Tamaños de tornillos Torx

Tamaño torx | Tamaños de puntos métricos |

T1 | 0,81 mm |

T5 | 1,42 mm |

T10 | 2,74 mm |

T15 | 3,27 mm |

T20 | 3,86 mm |

T30 | 5,52 mm |

T40 | 6,65 mm |

T50 | 8,83 mm |

T60 | 13,25 mm |

T70 | 15,51 mm |

T80 | 17,54 mm |

T90 | 19,92 mm |

T100 | 22,13 mm |

Destornillador Torx

Herramientas torx

Cuando se trabaja con tornillos Torx, es importante utilizar la unidad y el tamaño de herramienta Torx correspondientes. Hay varias herramientas que se pueden utilizar para la instalación y extracción de tornillos Torx. Los siguientes son los destornilladores Torx conocidos;

Torx de seguridad – se llaman Torx de seguridad debido al pin adicional en el centro de la cabeza del zócalo. Este pin requiere la herramienta correspondiente que es un pin Torx o Torx de seguridad. Esta característica permite que los tornillos Torx sean a prueba de manipulaciones y adecuados para áreas de aplicación que necesitan seguridad.

torx estándar – tener la unidad de 6 puntos que se adapta a los puntos de seis lóbulos de los tornillos Torx. Facilitan la colocación de tornillos Torx durante la instalación o extracción.

Diferentes tipos conocidos de materiales para tornillos Torx

Material | Tipos de tornillos Torx |

Aleación de acero |

|

Acero inoxidable |

|

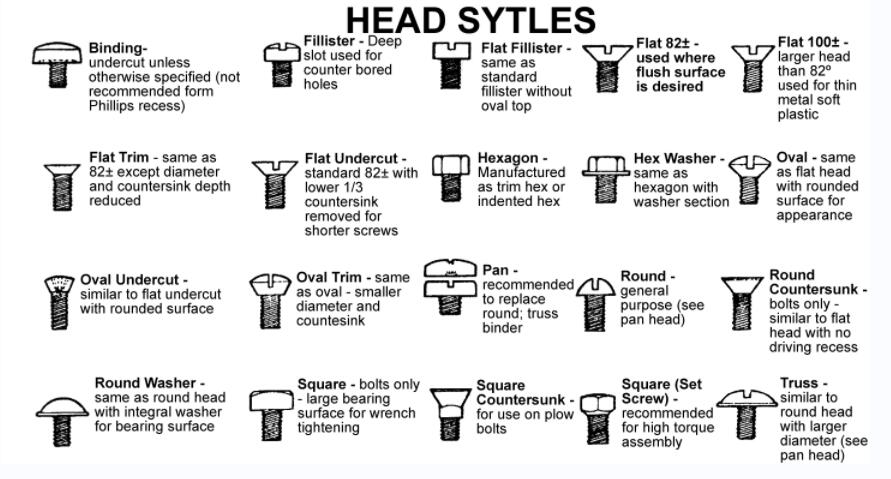

Tipos de cabeza de tornillo

La cabeza de los tornillos tiene varios tipos de estilos de cabeza disponibles para diferentes tipos de tornillos. Los siguientes son los tipos comunes de cabezas de tornillo:

Principales conclusiones

- Torx screws have a star shape. This shape gives a strong grip. It helps stop damage to the screw and tool.

- Using the right Torx driver size is important. It lets you use more force safely. It stops the screw head from getting stripped.

- Torx screws are used in cars and electronics. They are also used in aerospace and construction. They hold tight and last a long time.

- Security Torx screws have a special pin. This pin stops people from tampering. You need a special driver to remove them.

- Picking Torx screws and drivers helps with DIY projects. It makes work easier, faster, and more reliable.

Torx Screw Design

Star Shape

A Torx screw has a special six-point star shape. This shape is not just for looks. It lets you use more force without slipping or breaking the screw. Here are some reasons why this star shape is helpful:

- The six points spread the force across the screw and tool.

- You can use more torque and not strip the screw head.

- El rounded parts help stop damage to the screw and tool.

- The shape gives a strong grip, so the screwdriver does not slip.

- You get better control and can line things up easily, even in small spaces.

- The star shape is great for jobs that need high precision, like in cars, electronics, and airplanes.

- Your tools and screws will not wear out as fast, so they last longer.

Consejo: The star shape also helps machines on assembly lines. Machines can put in Torx screws fast and right, which saves time and lowers mistakes.

Estilos de cabeza

Torx screws have many head styles. Each style works best for a certain job or industry. Here is a table to show the most common types and where you might use them:

| Torx Head Style | Description & Features | Aplicaciones típicas |

|---|---|---|

| torx estándar | Six-point star, good torque transfer, stops cam-out | Cars, bikes, computers, electronics, DIY projects |

| Torx más | Squarer lobes, stronger, lasts longer | High-torque and heavy-duty uses |

| Torx TTap | Tapered tip, thin walls, cuts threads in plastics and composites | Enclosures, housings |

| Torx de seguridad | Pin in the middle for extra safety | Car ignition systems, high-security areas |

| External (Inverted) Torx | Head looks like a Torx bit, used with a socket | Motors, gearboxes, tight spaces |

| AudiTorx | Break-away drive for tamper-proof fastening | industria ferroviaria |

Puede pick the head style that fits your project. For example, use Security Torx if you need more safety. If you work in a small space, try External Torx.

Cam-Out Resistance

Torque Transfer

You want a screw that stays put when you turn it. The Torx screw gives you that advantage. Its star-shaped pattern lets you apply more force without the tool slipping out. This means you can tighten or loosen screws with less risk of stripping the head. The design spreads the force across six points, so you get a strong grip every time.

- Torx screws maintain a better grip on the driver, even when you use high torque.

- The star shape reduces the risk of slippage and cam-out, especially in tough jobs like construction or auto repair.

- Many users say Phillips screws strip easily, but Torx screws rarely do.

- Experts recommend Torx as the standard drive because it performs better than Phillips.

The Ultimate Guide to Fastener Drives explains that the six-point star shape allows for higher torque and superior resistance to cam-out. You get more control and less damage to your screws and tools.

Tool Fit

Picking the right tool for your Torx screw matters. If you use a bit that fits perfectly, you lower the chance of stripping the screw head. The best fit happens when the driver reaches the base of the screw socket. This lets the force spread along the whole wall of the screw recess.

- Using a bit that is too big or too small causes poor seating and increases the risk of stripping.

- A proper fit means the driver bottoms out fully, giving you even torque and less chance of cam-out.

- Ill-fitting bits can damage both the screw and the tool, leading to extra costs and frustration.

- Matching the screwdriver bit size exactly to the Torx screw size makes your work faster and more effective.

Tip: Always check the size before you start. A snug fit keeps your screws and tools in good shape and helps you finish your project with less hassle.

Usos comunes

Industries

Torx screws are used in many fields because they hold things tightly. Here are some main places where you will find them:

- Automotive manufacturing: Car makers use Torx screws to put cars together. These screws can handle a lot of force and do not strip easily. This helps keep cars safe and strong.

- Electronics manufacturing: Companies use Torx screws in computers and phones. The screws help keep small parts safe and stop people from opening the devices.

- Aerospace: Airplane makers pick Torx screws because they stay tight even when things shake or move.

- General industrial applications: Factories and machine makers use Torx screws for equipment that needs to stay together for a long time.

- Construction: Builders use these screws in furniture, cabinets, and metal work.

North America uses the most Torx screws. Europe and Asia Pacific use them too, but not as much. Car and factory work use about 45% of all Torx screws. Electronics and appliances use about 35%. Airplanes and other uses make up the last 20%.

Aplicaciones

You can find Torx screws in many things you use every day. Here are some examples:

- Electronic devices like laptops and game consoles

- Home appliances such as washing machines and fridges

- Car parts, including engines and dashboards

- Furniture and cabinets

- Factory machines and tools

- Airplane parts

- Security equipment and public machines

- Medical and telecom devices

People who work with these things like Torx screws for many reasons:

- The six-point star shape lets you use more force without ruining the screw.

- The tight fit stops slipping and makes tools and screws last longer.

- The shape spreads out the force, so nothing gets damaged.

- You get more control and less chance of breaking things, which is important for careful work.

Tip: If you fix electronics or cars, using a Torx screw can help you do a better job and avoid mistakes that cost money.

Sizes and Security

Tamaños de tornillos Torx

Torx screws come in many sizes. Each size is made for a certain job. The size number, like T6 or T40, shows how wide the star shape is from point to point. If the number is small, the screw is small. If the number is big, the screw is bigger and can take more force.

Here is a table that lists common Torx sizes, their measurements, and where you might use them:

| Tamaño torx | Point-to-Point (mm) | Typical Use | Max Torque (Nm) |

|---|---|---|---|

| T6 | 1.67 | Electrónica | 0.75 – 0.9 |

| T10 | 2.71 | Small devices | 3.7 – 4.5 |

| T15 | 3.25 | Automotor | 6.4 – 7.7 |

| T20 | 3.83 | Automotor | 10.5 – 12.7 |

| T25 | 4.4 | Uso general | 15.9 – 19 |

| T30 | 5.48 | Maquinaria | 31.1 – 37.4 |

| T40 | 6.6 | Heavy duty | 54.1 – 65.1 |

Pick the right size for your job. T10 is good for electronics. T20 and T25 are used in cars and machines. Using the right size stops the screw from getting ruined and keeps your work safe.

Tip: Check the size before you start. A good fit means less damage and better results.

Security Features

Some Torx screws have extra security features. You might see a small pin or bump in the middle of the screw head. This stops normal Torx drivers from turning the screw. You need a special security Torx driver to use these screws.

Security Torx screws help stop theft, tampering, and damage. You often see them in public places, electronics, cars, and outdoor gear. Here are some places where you might find tamper-resistant Torx screws:

- Public benches, bathroom stalls, and lamp posts

- License plates and electrical boxes

- Security systems and cleanrooms

- Car parts that need extra safety

- Robots, drones, and self-driving vehicles

These screws help keep important things safe. They make it harder for people to open or break things without permission. Use security Torx screws when you want to protect valuable or sensitive items.

Note: Security Torx drivers work on both regular and security Torx screws. Standard drivers cannot turn security screws.

You now know why these four facts matter for your next project.

- The star-shaped design gives you a strong grip and reduces damage.

- Puede utilizar higher torque for tough jobs in cars, electronics, and woodworking.

- Choosing the right screwdriver size saves time and keeps your work safe.

- Many users say Torx screws make repairs easier and last longer.

Try these tips and see how your DIY tasks become smoother and more reliable.

Preguntas más frecuentes

What makes Torx screws better than Phillips screws?

You get more grip with Torx screws. The star shape lets you use more force without stripping the head. You finish jobs faster and avoid damage.

How do you choose the right Torx size?

Check the screw head for a size mark like T10 or T25. Match your driver to that number. Using the correct size keeps your screw and tool safe.

Where do you find Torx screws at home?

Verás Torx screws in electronics, furniture, and appliances. Look inside game consoles, laptops, and kitchen machines. Many DIY kits use Torx screws for strong holds.

Can you use a regular screwdriver on a Torx screw?

No, you need a Torx driver. Regular screwdrivers slip and damage the screw. A Torx driver fits the star shape and gives you better control.

What is a security Torx screw?

A security Torx screw has a pin in the center. You need a special driver to turn it. These screws protect devices from tampering and theft.