En la entrada de blog de hoy, nos adentramos en el mundo del tornillos de cabeza cilíndricaun componente versátil y esencial en diversas aplicaciones. En Prince Fastener, somos conscientes de la importancia de la calidad y la fiabilidad. cuando se trata de tornillería. Nuestro compromiso con la excelencia nos impulsa a ofrecerle información exhaustiva sobre las características, usos y ventajas de los tornillos de cabeza cilíndrica. Tanto si se dedica a la ingeniería mecánica como a los sistemas eléctricos, la construcción o incluso los proyectos de bricolaje, estos tornillos desempeñan un papel crucial a la hora de garantizar conexiones seguras y duraderas. A medida que exploremos los intrincados detalles de los tornillos de cabeza cilíndrica, desde su exclusivo diseño de cabeza hasta sus precisas especificaciones de rosca, descubrirá por qué son la opción preferida de profesionales y aficionados por igual. Acompáñenos mientras desentrañamos el potencial de los tornillos de cabeza cilíndrica y cómo pueden mejorar la eficacia y longevidad de sus proyectos.

En Sujetador PríncipeEstamos orgullosos de ofrecer una comprensión global de nuestros productos. Los tornillos de cabeza cilíndrica, un componente estándar común caracterizado por su cabeza redondeada, ejemplifican nuestro compromiso con la calidad y la funcionalidad. Explore a continuación las complejidades de estos versátiles elementos de fijación.

Prince Fastener detalla la excelencia estructural de los tornillos de cabeza cilíndrica

Diseño de cabezas: La integración estética de Prince Fastener

La cabeza en forma de arco de nuestros tornillos de cabeza cilíndrica les permite adaptarse perfectamente a las superficies adyacentes, una característica crucial cuando el atractivo visual es primordial. Piense en el montaje de un mueble de madera: la cabeza del tornillo se alinea perfectamente con los contornos de la madera.. A diferencia de tornillos de cabeza plana que crean una superficie plana distinta o tornillos avellanados que se empotran por completo, nuestras cabezas de relleno ofrecen una conexión armoniosa y visible.

Precisión en la rosca: El cierre Prince garantiza un encaje fiable

Nuestros tornillos de cabeza cilíndrica cumplen las normas más estrictas especificaciones de rosca. La rosca, elemento esencial del tornillo, engrana con el material para establecer una sujeción segura y duradera. Mantenemos rigurosos controles sobre el paso de rosca, el diámetro y todos los demás parámetros relevantes. Normalmente, la longitud de la rosca corresponde a la longitud total del tornillo, lo que garantiza un engranaje suficiente para una fuerza de fijación óptima.

Prince Fastener ilustra el amplio espectro de aplicaciones de los tornillos de cabeza cilíndrica

Sector mecánico: Prince Fastener facilita el montaje robusto de maquinaria

Encontrará nuestros tornillos de cabeza cilíndrica indispensables en el montaje de una amplia gama de maquinaria y equipos. En la conexión de piezas de transmisión críticas, como ejes de engranajes a cajas de cambios, estos tornillos proporcionan una fijación fiable. Su diseño de cabezal circular simplifica ambos instalación y desmontaje, permitiendo que las llaves y herramientas estándar las agarren y giren con facilidad.

Además, nuestros tornillos de cabeza cilíndrica aparecen con frecuencia en uniones diseñadas para soportar fuerzas cortantes específicas. Por ejemplo, en la construcción de ligeras estructuras de acero, unen de forma fiable chapas de acero y otros materiales, evitando cualquier movimiento no deseado o desalineación bajo tensión.

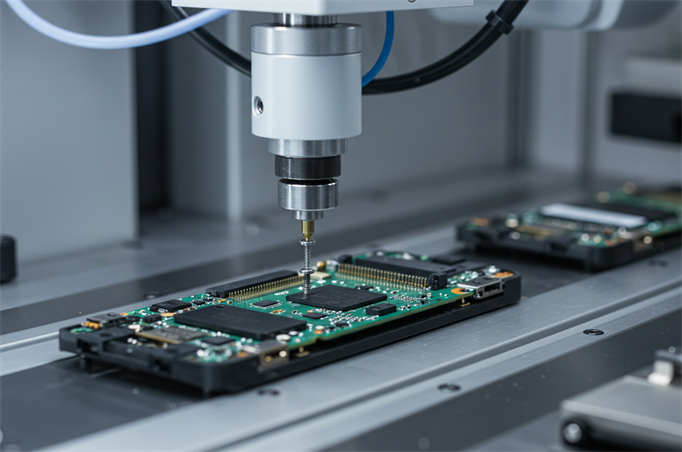

Industria eléctrica: La fijación Prince asegura componentes eléctricos vitales

En el sector eléctrico, nuestros tornillos de cabeza cilíndrica desempeñan un papel fundamental en el montaje y la fijación seguros de dispositivos eléctricos. Cuando se trata de asegurar placas de circuitos, estos tornillos fijan firmemente las placas al chasis y a diversas carcasas. La forma de su cabeza evita eficazmente la presión indebida sobre los componentes sensibles de la placa, al tiempo que proporciona una fuerza de sujeción estable y constante, garantizando la fiabilidad operativa de la placa de circuitos dentro del equipo.

Usos arquitectónicos y decorativos: El cierre Prince mejora la estética y la integridad estructural

En aplicaciones de construcción y decoración, nuestros tornillos de cabeza cilíndrica resultan muy útiles para fijar diversos materiales de acabado. Por ejemplo, cuando se instalan techos de cartón yeso, estos tornillos fijan de forma fiable las placas a la estructura subyacente. La cabeza redondeada proporciona un punto de contacto visualmente más atractivo en la superficie de la placa de yeso, lo que minimiza el impacto visual. cualquier posibles daños y garantizar una fijación firme y duradera.

Prince Fastener describe las opciones de materiales y especificaciones de los tornillos de cabeza cilíndrica

Selección de materiales: Prince Fastener ofrece soluciones a medida

Prince Fastener ofrece una amplia gama de materiales para nuestros tornillos de cabeza cilíndrica, lo que le permite seleccionar la opción perfecta para sus necesidades específicas:

- Acero al carbono: Un material rentable y muy utilizado para tornillos de cabeza cilíndrica, que ofrece buenas propiedades mecánicas generales. Podemos ajustar su dureza y resistencia mediante diversos tratamientos térmicos como el temple y el revenido. Encontrará estos adecuado para montajes mecánicos generales, construcción y fines decorativos. Para mejorar su resistencia a la corrosión, a menudo aplicamos tratamientos superficiales como el galvanizado.

- Acero inoxidable: Nuestros tornillos de cabeza cilíndrica de acero inoxidable presentan una resistencia superior a la corrosión y a las altas temperaturas. Su resistencia inherente a la oxidación los hace ideales para entornos exigentes, incluidos entornos húmedos o químicamente corrosivos. Entre las calidades más comunes se incluyen el acero inoxidable 304, conocido por su excelente rendimiento general, y el acero inoxidable 316, que ofrece una resistencia aún mayor a la corrosión. mayor Resistencia a la corrosiónespecialmente en aplicaciones marinas y de procesamiento químico.

- Acero aleado: Para aplicaciones que requieren una mayor resistencia, dureza y resistencia al desgaste, ofrecemos tornillos de cabeza cilíndrica de acero aleado. Estos materiales pueden soportar cargas e impactos significativos y a menudo se someten a tratamientos térmicos especializados para maximizar sus características de rendimiento.

- Aleaciones de cobre: Incluidos el latón y el bronce, estas aleaciones ofrecen un buen desgaste y resistencia a la corrosión, junto con excelente conductividad eléctrica. A menudo los encontrará utilizados en equipos eléctricos o como elementos de fijación resistentes a las chispas en entornos potencialmente explosivos. El atractivo color de los tornillos de aleación de cobre también los hace adecuados para aplicaciones decorativas.

- Nylon: Como plástico ligero, resistente al desgaste y con buenas propiedades aislantes, el nailon es una opción excelente para tornillos de cabeza cilíndrica en dispositivos electrónicos que requieren aislamiento o en estructuras mecánicas ligeras.

Opciones de especificación: El cierre Prince ofrece un dimensionamiento de precisión

Las especificaciones de nuestros tornillos de cabeza cilíndrica se centran principalmente en el diámetro y la longitud:

- Especificaciones de diámetro (roscas métricas): Denotamos el diámetro de nuestros tornillos de cabeza cilíndrica utilizando designaciones de rosca métrica como M2, M3, M4, M5, M6, M8, M10 y M12. La "M" indica una rosca métrica, y el número siguiente representa el diámetro exterior nominal en milímetros. Por ejemplo, un tornillo M3 tiene un diámetro exterior nominal de 3 mm. El diámetro adecuado depende en gran parte en función del tamaño y los requisitos de resistencia de los componentes que vaya a unir y de la carga que deba soportar la conexión. Los diámetros más pequeños, como M2 a M4, se utilizan a menudo en electrónica pequeña o mecánica de precisión, mientras que los diámetros más grandes, como M8 a M12, se utilizan a menudo en electrónica de precisión. común en maquinaria general y construcción.

- Especificaciones de longitud: Ofrecemos una amplia gama de longitudes para nuestros tornillos de cabeza cilíndrica, que suelen oscilar entre unos pocos milímetros y varios centímetros. Común Las longitudes incluyen 5 mm, 10 mm, 15 mm, 20 mm, 25 mm, 30 mm, y se extienden hasta 100 mm, 150 mm y más. Para seleccionar la longitud correcta, hay que tener en cuenta el grosor de los materiales. estar unido y el necesario profundidad de roscado para garantizar una conexión segura y estable. Por ejemplo, cuando se unen dos placas de 5 mm de grosor, una longitud de tornillo de 15-20 mm suele ser adecuada para proporcionar un encaje adecuado de la rosca.

Prince Fastener Explica las Funciones Únicas de los Diseños de Rosca y Cabeza de Relleno

Prince Fastener destaca los atributos especiales del cabezal Fillister

- Eficaz Punto de aplicación de la fuerza: La cabeza redondeada de nuestros tornillos de cabeza cilíndrica suele incorporar un accionamiento Phillips, ranurado o hexagonal interno. Este diseño proporciona un punto de contacto fiable para herramientas como destornilladores o llaves, facilitando el apriete y afloje eficaz del tornillo. Por ejemplo, en el montaje mecánico, un destornillador Phillips encaja con seguridad en la ranura transversal de un tornillo de cabeza cilíndrica, lo que permite eficaz aplicación del par de apriete o desmontaje.

- Instalación y desmontaje simplificados: La forma circular de la cabeza facilita intrínsecamente la alineación del tornillo con el orificio receptor durante la instalación. En comparación con los tornillos de cabeza plana o avellanada, es menos probable que las cabezas de relleno se enganchen en los bordes o queden demasiado al ras de la superficie, lo que contribuye a un proceso de instalación y extracción más suave. La forma redondeada guía eficazmente el tornillo en el orificio, reduciendo la resistencia y la posibilidad de desalineación.

- Mayor atractivo estético: En aplicaciones en las que el aspecto visual es una consideración, como muebles de madera y carcasas de equipos electrónicos, el cabezal de relleno sirve como un elemento de fijación relativamente atractivo. Su superficie lisa y ligeramente elevada evita el aspecto plano de las cabezas planas o la necesidad de rebajes avellanados, lo que mejora la estética general del producto acabado.

- Pivote versátil o elemento de posicionamiento: En cierta estructuras y dispositivos mecánicos, el cabezal de llenado puede funcionar como punto de giro o como componente de posicionamiento. Su forma le permite interactuar eficazmente con otras piezas, proporcionando apoyo o permitiendo la ubicación precisa de elementos dentro del conjunto, contribuyendo así a la estabilidad y precisión generales de la estructura.

Prince Fastener detalla las funciones distintivas de la rosca Fillister

- Conexión de apriete seguro: La rosca es el elemento fundamental de nuestros tornillos de cabeza cilíndrica, meticulosamente diseñados para encajar firmemente con las roscas internas de un orificio receptor. Al apretar, la fricción y el enclavamiento mecánico entre la rosca del tornillo y las roscas internas del orificio crean una conexión robusta y duradera entre los componentes unidos. Este mecanismo de apriete resiste eficazmente ambos fuerzas axiales y radiales, garantizando la estabilidad y fiabilidad del conjunto durante el funcionamiento. Por ejemplo, en la conexión de piezas de máquinas, la rosca de un tornillo de cabeza cilíndrica sujeta firmemente varios componentes entre sí, evitando que se aflojen o se desplacen durante el funcionamiento.

- Ajuste preciso de la posición de los componentes: La parte roscada de nuestros tornillos de cabeza cilíndrica es ideal para ajustar con precisión la posición de los componentes conectados. Al girar el tornillo, puede moverlo con precisión hacia delante o hacia atrás dentro del orificio roscado, lo que permite realizar ajustes precisos de las piezas unidas. Esta característica es especialmente valiosa en maquinaria e instrumentos de precisión; por ejemplo, en el ajuste de equipos ópticos, los tornillos de cabeza cilíndrica pueden utilizarse para posicionar con precisión las lentes para un enfoque óptimo.

- Acción de bloqueo fiable: En aplicaciones en las que evitar el aflojamiento es fundamental, se puede utilizar la rosca de nuestros tornillos de cabeza cilíndrica junto con varios mecanismos de bloqueoComo tuercas de seguridad, arandelas de seguridad o insertos de nailon. Estos dispositivos suplementarios mejoran la fricción entre el tornillo y la pieza de acoplamiento o impiden físicamente la rotación del tornillo, aumentando así la estabilidad de la conexión y evitando que se afloje debido a vibraciones, impactos u otros factores. Por ejemplo, en entornos de alta vibración como los motores, el uso de tornillos de cabeza cilíndrica con características de bloqueo garantiza la integridad de las conexiones de componentes críticos.

- Transmisión eficiente de potencia o movimiento: En cierta En los sistemas de transmisión mecánica, la parte roscada de un tornillo de cabeza cilíndrica puede servir para transmitir potencia o movimiento. Un ejemplo excelente es un gato de tornillo, en el que la rotación del tornillo de cabeza de relleno, a través de su acoplamiento con una rosca de soporte, convierte el movimiento giratorio en movimiento lineal para la elevación o el ajuste. Del mismo modo, en los codificadores rotativos o en los conjuntos de husillo y tuerca, la rosca de un tornillo de cabeza cilíndrica desempeña un papel crucial en la transmisión de una fuerza motriz precisa.

Elija Prince Fastener para sus necesidades de tornillos de cabeza cilíndrica

En Prince Fastener se dedican para ofrecerle tornillos de cabeza cilíndrica de alta calidad diseñados para un rendimiento óptimo, diversas aplicaciones y especificaciones precisas. Nuestra amplia selección de materiales y tamañosjunto con nuestro profundo conocimiento de sus funcionalidades únicas, hace su socio de confianza para todas sus necesidades de fijación. Póngase en contacto con Prince Fastener hoy mismo para descubrir cómo nuestros tornillos de cabeza cilíndrica pueden mejorar la fiabilidad y la estética de sus proyectos.

En Prince Fastener, nos enorgullecemos de ofrecer una amplia gama de tornillos de cabeza cilíndrica para satisfacer diversas necesidades industriales y comerciales. Nuestro amplio inventario incluye tornillos fabricados con diversos materiales, como acero al carbono, acero inoxidable, acero de aleación, aleaciones de cobre e incluso nailon, cada uno de ellos diseñado para cumplir requisitos específicos en cuanto a fuerza, resistencia a la corrosión y durabilidad. Con nuestros tornillos de cabeza cilíndrica de alta calidad, puede garantizar una fijación precisa y segura. soluciones de fijación para sus aplicaciones. Nosotros se dedican a apoyar sus proyectos con orientación profesional y productos fiables. Tanto si necesita ayuda para seleccionar derecha especificaciones de tornillos o necesita soluciones personalizadas, nuestro equipo de expertos está aquí para ayudarle. Gracias por elegir Prince Fastener como su proveedor de confianza de tornillos de cabeza cilíndrica y otros componentes de fijación. Esperamos a formar parte de su éxito y contribuir a la resistencia y estabilidad de sus construcciones y ensamblajes. Explore hoy mismo nuestra gama de productos y experimente la diferencia de Prince Fastener.