Prince Fastener:How to Distinguish Stainless Steel Screws, Galvanized and Nickel-plated Screws?

From the appearance, the method of distinguishing stainless steel screws, galvanizing and nickel -plated screws is to see the color of the screw. The color of the stainless steel screw is close to the original color of the iron. In addition, it can also be distinguished from stainless steel screws, galvanized and nickel -plated screws with magnets, oxidatives, and strong acidic alkali.

Standard screws include bolts, screws, screws, nuts, machine screws, self -attack screws, pads, sales, rivets, and ten categories. It is a basic part that is widely used in all aspects, and its function is to play a solid effect. The connection form can be divided into detachable connections (using screw fasteners such as bolts, nuts and other threads) and permanent connection (using rivet connection).

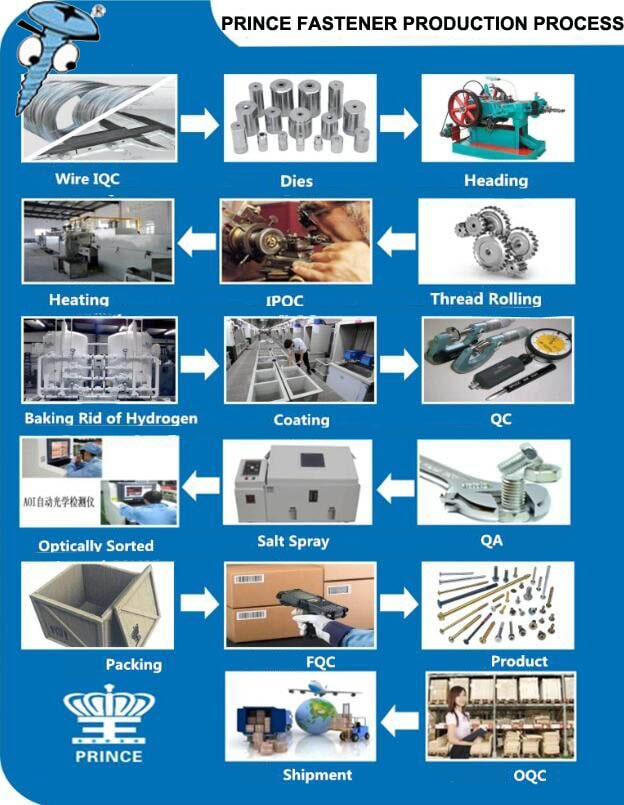

The production process of the screw is as follows:

How to distinguish stainless steel screws, galvanized and nickel -plated screws from appearance?

First distinguish by color:

Stainless steel is the original color of iron.

Galvanized screws are white, color, black.

Nickel -plated screws are silver.

1. Stainless steel screws are made of stainless steel. The color of stainless steel is mainly iron and carbon alloy, so the color is close to the color of the iron;

Prince Fastener: How to distinguish stainless steel screws, galvanized and nickel -plated screws?

2. The surface of galvanized screws has white zinc, zinc, black zinc, etc., so the color of galvanized screws is generally white, color, and black;

3. The color of nickel -plated screws is related to nickel, and it generally presents very bright silver.

Prince Fastener: How to distinguish stainless steel screws, galvanized and nickel -plated screws?

Divide stainless steel screws, galvanized and nickel -plated screws other methods

1. Division with magnets: Stainless steel is generally not magnetic, and stainless steel screws cannot be adsorbed by magnets. Galvanized and nickel -plated screws can be adsorbed by magnets.

2. Division of oxidant: Metal nickel has a strong passivation ability. When plating, it can quickly generate a layer of extremely thin passivation on the surface. Zinc, there is nothing to do on the surface of stainless steel, which can be distinguished in a strong oxidant.

3. Differentiated with strong acid and strong alkali: stainless steel contain chromium and nickel. It has a strong corrosion resistance. It is not corroded by strong acid and strong alkali. There is a layer of passivation film on the surface of the nickel -plated screws. The fastest corrosion.

Summarize:

From the appearance, the method of distinguishing stainless steel screws, galvanizing and nickel -plated screws is to see the color of the screw. The color of the stainless steel screw is close to the original color of the iron. In addition, it can also be distinguished from stainless steel screws, galvanized and nickel -plated screws with magnets, oxidatives, and strong acidic alkali.

In addition, hot -dip galvanized screws have the following advantages:

1. Low treatment costs: The cost of hot -dip galvanizing and rust -proof is lower than the cost of other paint coatings;

2. Streaming durability: In the suburban environment, the standard thermal galvanized rust -proof thickness can be maintained for more than 50 years without having to repair it; in urban or offshore areas, the standard hot -dip galvanized rust -proof layer can be maintained for 20 years without having to repair it without repairs without repair ;;

3. Good reliability: The galvanized layer and steel are a combination of metallurgy, which becomes part of the steel surface, so the durability of the coating is more reliable;

4. Strong toughness of the coating layer: Galvanized layer forms a special metallurgical structure. This structure can withstand mechanical damage during transportation and use;

5. Comprehensive protection: Each part of the plating can be plated with zinc, even in the depression, the sharp corner and the hidden place, it can be fully protected;

6, time -saving and effort: Galvanizing process is faster than other coating construction methods, and it can avoid the time required to paint on the construction site after installation.

In addition, the mechanical performance level of galvanized screws can reach 8.8 levels, while stainless steel screws can only be -70 at most, such as A2-70 and A4-70, which is equivalent to level 7, which is lower than galvanized screws.

Therefore, the use of galvanized screws is wide than stainless steel screws, and the amount is more than stainless steel screws.

However, it should be noted that the galvanized screws cannot be completely replaced by stainless steel screws. It is not better than stainless steel screws in corrosion resistance. Therefore, the appropriate material should be selected according to the occasion of use.

For stainless steel screws, galvanized and nickel -plated screws, everyone may encounter the following problems.

Question: Ask the masters in electroplating. Why do screws generally specify 3-5 microns, but galvanized membranes have a thickness of 5-8 microns? Will it affect the normal? Detailed and specific

Answer 1: The thickness of the plating layer is not stipulated, and it is determined according to customer requirements or salt mist requirements. If the coating is thick, of course, it will affect the general regulation. The key is that the prelude to control the thread tolerance. Galvanizing salt and fog is stronger than nickel -plated anti -corrosion capacity.

Answer 2: The thickness and electroplating type depends on the conditions and environment of the customer’s use. The judgment standard for thickness and corrosion resistance is determined by the buyer and the seller.