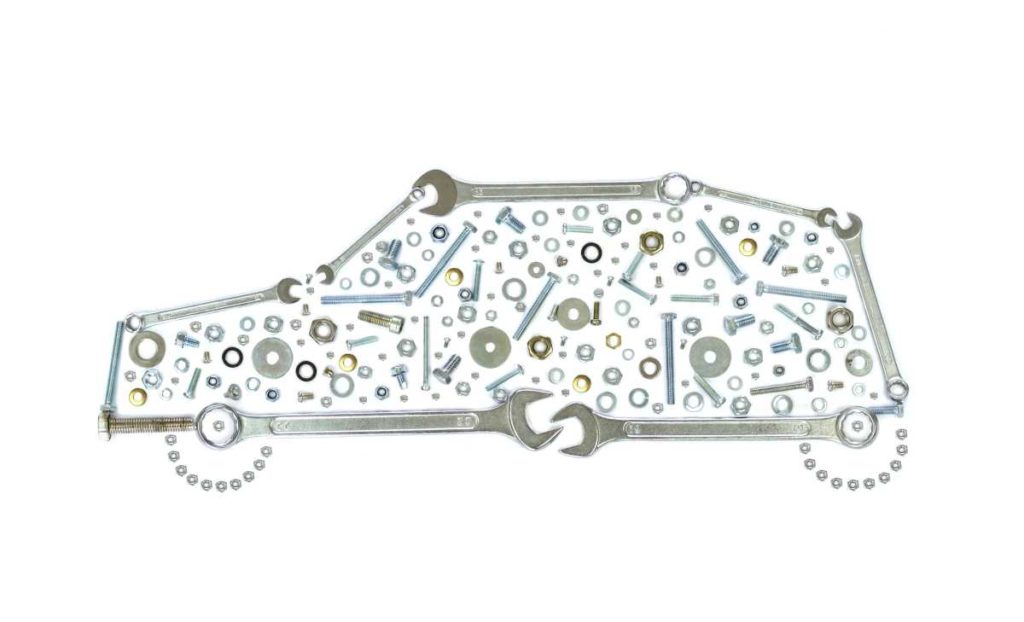

In today’s fast-moving and highly competitive industrial era, product performance, quality and reliability have become the key factors for enterprises to win. With the continuous advancement of technology and the increasing diversity of market demands, traditional standardised parts can no longer fully meet the individual needs of specific industries and application scenarios. As a result, custom fasteners, also known as non-standard parts, have emerged and become a significant force driving various industries forward. With their unique specifications, shapes, materials and characteristics, these parts, manufactured to specific needs, designs or applications, provide the perfect solution for a wide range of complex and challenging engineering projects. From aerospace to automotive, from building construction to medical devices to electronics and marine technology, custom fasteners are used everywhere to improve product safety and performance and drive technological innovation and industrial upgrades. Today, let’s dive into the world of custom fasteners and discover how they are revolutionising various industries.

What do you mean by custom fasteners?

Customised or non-standard parts are standard parts that do not conform to standard specifications or general norms and are generally manufactured according to a particular must, design or application. The standard part may have unique specifications, appearance, materials, screws or other characteristics to meet specific engineering, installation or manufacturing requirements.

Role in multiple industries

The effectiveness of custom fasteners in various industries is as follows:

Meeting special requirements: Many industries, such as aerospace engineering and the automotive sector, face specific technical properties. custom fasteners can be designed and manufactured to such standards to ensure the safety and reliability of the system. For example, aerospace’s lightweight and high-strength standard parts are necessary to improve fuel efficiency and equipment.

Improvement of equipment: custom fasteners can improve the overall performance of equipment, especially in high-temperature, high-pressure or high-impregnation environments. Oil rigs, nuclear power equipment and other special equipment must bear extreme standard parts to ensure long-term efficient operation.

Promote technological innovation: With the advancement of technology, the design and production technology of customised fasteners is also pioneering innovation. For example, the development of 3D printing technology promotes the completion of standard parts with complicated shapes, improves production efficiency and reduces costs.

Widely used industries: custom fastener are commonly used in many industries, including construction, car, electronics, medical and so on. They are the essential components of machines and equipment and play a leading role in ensuring structural stability and safety.

Adapting to market shifts: With the diversification of market demands, custom fasteners can respond quickly to specific customer requirements and provide convenient solutions. This type of customisation not only improves productivity but also helps companies save on costs.

Generally speaking, the role of custom fasteners in various industries must be addressed to meet unique technical requirements and promote the industry’s overall development and technological progress.

A brief overview of the versatility of custom fasteners

The multi-purpose performance of custom fasteners is as follows:

Adaptability: custom fasteners are designed for different applications and natural standards to meet different materials, temperatures and pressure compounds.

Diversity in size and appearance: standard parts can be built in various sizes and shapes to meet specific installation specifications or space constraints.

General Material Types: customized fastener can be built in various materials, including but not limited to stainless steel, carbon steel, aluminium, titanium, plastics, etc., to accommodate different corrosion resistance and strength net weight regulations.

Surface treatment options: customized fasteners can be galvanised, nickel plated, anodised, phosphate, and several other surface treatments to enhance corrosion resistance, wear resistance or aesthetics.

Load carrying capacity: custom fasteners can be designed with different load carrying capacities to suit different loading requirements, from light to light.

Flexibility in interface standards: custom fasteners can be designed with various interface standards such as live flange, welded, riveted or bonded to meet different installation specifications.

Safety and Reliability: Customized fastener can be designed to meet unique testing standards and certification requirements, ensuring safety and reliability in critical applications.

Cost Efficiency: While the initial cost of custom fasteners may be higher than standard parts, they can provide better performance and longer life, reducing the total cost of ownership.

Design innovation: custom fasteners can incorporate innovative designs such as clamping action, tightening designs or integrated constructions to improve product performance and user experience.

Rapid Market Response: Customised fastener suppliers can respond quickly to actual customer needs, reducing product project schedules and accelerating product release dates.

This versatility makes custom fasteners an integral part of many industries, especially in those applications where performance, safety and reliability are critical.

Understanding Custom Fasteners

Many types of custom fasteners can be designed and manufactured to meet the needs of specific industrial projects. The following are some common types of custom fasteners.

Custom bolts:

These can include stainless steel bolts, nickel alloy bolts, titanium bolts, aluminium alloy bolts, copper bolts, shoulder bolts, U-bolts, etc.

Custom nuts:

stainless steel nuts, nickel alloy nuts, titanium nuts, aluminium alloy nuts, brass nuts, etc.

Custom Nuts & Rods.

Custom nuts & rods: will include stainless steel connecting sleeve, nickel alloy screw thread round rod, titanium connecting sleeve, aluminium alloy hollow nut, purple copper screw thread, etc.

Custom Screws:

Custom screws: including custom machine screws, shoulder screws, thumb screws, ladder screws, etc.

Customised screws

Custom precision shafts and bushings: precision shafts and bushings are made according to exhaustive regulations

Custom piping and flanges:

Custom piping and flanges are made according to special piping or live flange regulations.

Customised gaskets and brackets:

Including customised gaskets and rings, customised bolts, customised precision machined components, etc.

Non-Standard Parts:

The standard parts may be customised.

Non-standard parts: The standard parts may have unique specifications, shapes, materials and screws to meet specific engineering, installation or manufacturing requirements.

Aerospace engineering standard parts:

Aerospace engineering standard parts have a wide range of varieties, including bolts, studs (screws), nuts, single-sided standard parts, unique standard parts, pipe fittings connectors and so on.

Industrial custom fasteners:

this standard part applies to the current selection of planning, materials, specifications, and sometimes even features and standards designed specifically for the relevant requirements of various industrial areas

The custom fasteners are suitable for the automotive industry.

The custom fasteners are suitable for the automotive, electrical, electronic, mechanical, and other industries. They can be carried out according to the specific requirements of the customer’s material type, specification customisation and surface processing.

The manufacturing process of custom fasteners

The critical factors of the production and processing process are as follows:

Design and planning:

Before production begins, the designer must develop product specifications based on the customer’s needs, including data such as specifications, materials and strengths. Communication at this stage is vital to ensure that the finished product meets expectations.

Raw Material Purchase:

Choosing quality raw materials is a prerequisite for production, and commonly used materials include carbon steel, stainless steel, and aluminium alloys. Material selection is directly related to the durability of the fastener.

Processing and moulding:

Cold head: The cold head machine will produce raw materials fasteners in the original state to ensure their physical properties.

Heat treatment: change the organisational structure of the material based on quenching, hardening and other processes to improve hardness and strength.

CNC machining: Precise machining using machining centres and milling machines to ensure screw threads and holes are accurate.

Surface treatment: To ensure the corrosion resistance and appearance of fasteners, common surface treatments include zinc plating, nickel plating and phosphating. This solution creates a protective layer that enhances the service life of standard parts.

Quality control: Strict quality testing is carried out at different stages of production, including physical and chemical mechanical properties testing, to ensure that the products comply with the regulations.

Packaging: Finally, the standard parts are packaged and prepared for shipment according to the quality tests to ensure they are not damaged during transport.

Applications of Custom Fasteners

Custom fasteners are used in various industries, with unique designs and production techniques enabling them to meet the needs of distinctive sectors. Below are some examples of essential industry applications:

Automotive industry:

The automotive sector requires many standard parts to assemble various car parts, including the engine, chassis, body, etc. The standard parts should be highly wearable. The standard parts should be highly resistant to wear and abrasion to cope with the various loads in vehicle operation. With the development of electric vehicles and autonomous driving technology, the regulations on fasteners are also changing. They must be lighter and have higher strength custom fasteners to improve fuel efficiency and performance.

Aerospace Engineering:

The aerospace engineering industry demands high-standard parts, so they must operate in extreme temperature and pressure environments. Aerospace engineering standards are typically made from other materials, such as titanium, which is lightweight and robust. The standard parts are also heat-resistant, corrosion-resistant and fatigue-resistant.

Construction & Infrastructure:

The standard parts are usually made of titanium and other materials in engineering and infrastructure.

Construction and infrastructure: In the field of engineering and infrastructure, standard parts are used to connect and fix various structural components such as bridges, high-rise buildings and industrial facilities. The standard parts should have high wear resistance and durability to ensure the stability and safety of buildings and infrastructure.

Special equipment

Such as oil drilling rigs, nuclear power equipment, marine technology facilities, etc., generally work in extreme environments and must be customised to cope with high temperatures, high pressure, high corrosion, high vibration and other specifications.

Medical Machinery:

Medical machinery: Medical machinery, especially equipment requiring high cleanliness, such as magnetic resonance, ultrasound, x-ray, etc., can use customised plastic or special alloy standard parts to ensure the efficacy and safety of the system.

Electronics:

In electronic equipment, standard parts must have specific conductivity or insulating properties to ensure the proper functioning of the circuits and the user’s safety.

Marine technology:

In the marine technology industry, customised marine corrosion specifications are essential to ensure the safety and stability of equipment in salt spray and humid environments over long periods.

Customised fasteners for versatility and stability.

The versatility and adaptability of custom fasteners make them an integral part of this industry. Unique designs and machining processes can be tailored to meet distinctive industries’ needs, increasing the equipment’s effectiveness and stability.

Advantages of using custom fasteners

The use of custom standardised fasteners offers the following advantages:

Improved safety:

Custom fasteners can be designed to meet unique testing standards and certification requirements, ensuring safety and reliability in critical applications.

Improved characteristics:

Customised standards can be tailored to meet actual usage needs, providing better load-carrying capacity, fatigue and corrosion resistance, improving overall machine performance.

Reduced maintenance costs:

the durability and longevity of customised fasteners reduce the frequency of replacement, thus reducing maintenance costs.

Optimised design:

Custom fasteners can incorporate creative designs such as clamping action, tightening designs or integrated structures to improve product performance and user experience.

Strong adaptability:

For different industries and application scenarios, custom fasteners can be adapted to various materials, temperatures and pressure compounds.

Improve work efficiency:

custom fasteners can reduce the improvement and maintenance of the installation process and improve work efficiency.

Reduced total cost of ownership:

Although the initial cost of custom fasteners may be higher than standard parts, they can provide better performance and longer service life, thus reducing the total cost of ownership.

Enhance brand image:

Using custom made fasteners can enhance the professionalism and uniqueness of a product, improving the image of a company.

Meet special requirements:

custom fasteners can meet the specific requirements of particular industries or applications, such as lightweight, highly wear-resistant materials and unique surface treatments.

Responding quickly to the market:

Custom fasteners manufacturers can react rapidly to customer needs, reducing product project schedules and accelerating product release dates.

Improved compatibility:

custom fasteners ensure perfect compatibility with existing equipment and systems, avoiding difficulties caused by inconsistent specifications or appearance.

Increased customer satisfaction:

Providing custom fasteners that meet specific needs increases customer satisfaction and satisfaction rates.

In short, the versatility and adaptability of custom fasteners make them an indispensable part of many industries. Unique design and manufacturing techniques can meet the needs of unique industries and improve the effectiveness and stability of equipment.

Custom standard fasteners hurt various industries. Last relevant thoughts

The impact of customized fasteners on various industries is evident, improving the safety and performance of products and driving technological innovation and productivity. The following are the last thoughts about customized fastener in various industries:

Promote technological innovation:

The development of custom fasteners has promoted the use of new materials, designs and processing techniques, such as high-strength materials and 3D printing technology, which has significantly improved the characteristics and production efficiency of fasteners.

Meeting specific requirements:

With the development of industrial diversification, the market’s need for fasteners has become more individual and personalised. Manufacturers must provide fast and flexible customisation services to meet customers’ detailed regulations on product quality, specifications and features.

Promoting industrial upgrading:

Using customised fasteners promotes industrial upgrading in related industries, especially in the automotive, aerospace engineering, construction and machinery manufacturing sectors. This standard component is generally a crucial part of high-end manufacturing, and the quality and advantages of the product have a decisive impact.

Improve competitiveness:

Based on the custom specification, the enterprise can provide more personalised solutions according to different customer needs to improve its competitiveness in the market.

The company’s competitiveness in the marketplace is enhanced by its customised specifications.

Applying sustainable development: in an environment of increased global environmental awareness, manufacturers of customised fasteners are striving to improve the environmental performance of their goods, such as using environmentally friendly materials and optimising machining processes, to meet the market demand for sustainable products.

Improve product quality and reliability: Using customised fasteners improves products’ overall quality and stability, especially in aerospace engineering and the automotive industry, where the quality and performance of standardised parts are highly demanded.

Promote the development of the industrial chain: the development of the custom fastener industry promotes the overall development of upstream raw materials and downstream application industry, constituting a closely linked and jointly developed industrial chain.

Solving the market test: Customised fastener production helps enterprises deal with challenges such as industry competition, improved quality standards and upgraded environmental protection requirements through technological innovation and product upgrading to maintain competitiveness.

Capture Market Opportunities.

Seize market opportunities: With the prevalence of emerging markets for global manufacturing upgrading, the customised fastener industry is facing substantial market opportunities. The company can meet the market demand and gain market share through product upgrading, technological innovation and branding.

Promote green production: In the ‘Industrial Area Carbon Peak Implementation Plan’, the Ministry of Industry and Information Technology attaches importance to the layout of the essential components of ‘carbon reduction’ and promotes the ecological production of the fastener industry, which is conducive to the sustainable development of the field.

Generally speaking, custom fasteners have far-reaching significance for various industries, improving product quality and characteristics and promoting the technological progress and market competitiveness of the whole industrial chain. With the continuous development of technology and changing market demands, custom fasteners will continue to play a vital role in various industries.

Related information: