Welcome to the Prince Fastener knowledge hub, where every turn of a countersunk screw is treated as precision engineering in miniature. For more than 25 years we have shipped over two billion fasteners to 42 countries, yet the countersunk screw remains one of the most requested—and most misunderstood—components in our catalog. Designers love its flush, “invisible” silhouette; production managers worry about the extra machining step; quality teams argue over the ideal 90° vs. 100° head angle.

In this definitive guide, we unpack every layer of the countersunk screw so you can specify, source and install it with total confidence. You will learn why NASA insists on countersunk titanium screws for satellite panels, how Apple hides them under 0.15 mm of anodised aluminium, and why our robotic vision system inspects each cone to ±0.05 mm before shipment. We will show you torque tables for carbon-fibre composites, salt-spray data for 316L stainless, and a free downloadable CAD library that covers M1.4 to M20 in both coarse and fine threads.

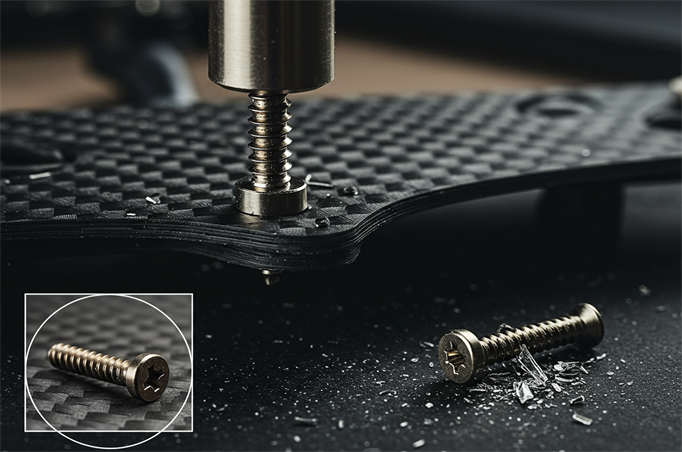

Whether you are building a drone arm that must survive 10 g crashes, a yacht deck that must laugh at 1,000-hour salt fog, or a consumer product that has to feel seamless in the hand, the countersunk screw is often the only fastener that satisfies the brutal trinity of strength, space and beauty.

By the end of this article, you will know exactly when to choose it, how to machine the perfect cone seat, and what pitfalls to avoid so your assembly does not end up with cracked CFRP or a costly cosmetic recall. So tighten your mental torque wrench—Prince Fastener is about to take you on a deep dive into the world of the countersunk screw, where millimetres matter and invisible excellence is always the goal.

At Prince Fastener, we know that understanding every fastener is key to professional results. Let’s decode the countersunk screw.

What is a Countersunk Screw?

A countersunk screw features a head designed to be conical or flat-conical. After installation, its top sits flush with or slightly below the workpiece surface, creating a seamless appearance. Here are its core characteristics and applications:

Key Features

Head Shape of countersunk screw:

- We design the head with a 90° or 120° cone angle (90° is most common) to match a pre-drilled, conical countersink hole. This ensures the screw top does not protrude from the surface.

- The top of the head may include slotted, Phillips, or hex drive types, facilitating tool operation.

Purpose:

- Flush Surface Requirement: We use these screws in applications like furniture, moulds, and mechanical casings where protruding screws could scratch surfaces or detract from aesthetics.

- Tight Fit: The conical surface contacts the workpiece, providing a larger contact area, distributing pressure, and preventing loosening.

Distinctions from Standard Screws

- Flat Head Screw: A flat head screw has a flat top that sits flush with the surface, whereas a countersunk screw embeds its entire head within the workpiece.

- Pan Head/Round Head Screws: These visibly protrude from the surface, while a countersunk screw remains completely hidden.

Common Types

- Countersunk Machine Screws: We use these for metal parts, requiring a threaded hole.

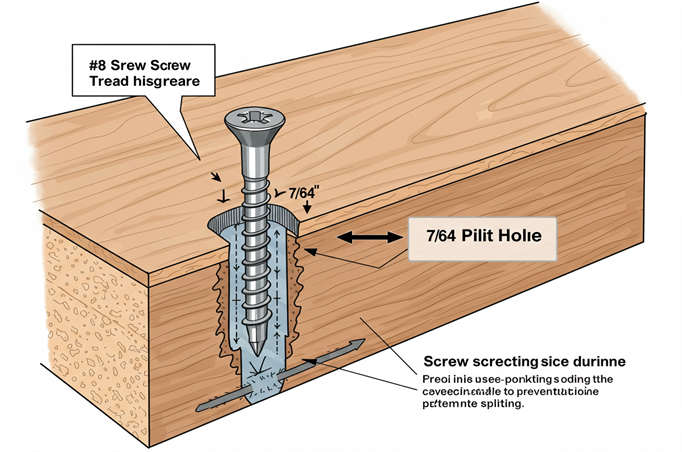

- Countersunk Wood Screws: They have a pointed tip, allowing us to drive them directly into wood.

- Countersunk Self-Tapping Screws: We use these for plastic or thin metal sheets, eliminating the need for pre-tapping.

Installation Considerations

- Pre-Drill Countersink Hole: The hole diameter must be slightly larger than the screw head diameter, and the cone angle must match (e.g., 90°).

- Tightening Force: Overtightening can deform the conical surface or crack the workpiece.

A countersunk screw achieves “invisible” fastening through its conical head design, balancing functionality and aesthetics. It is the preferred choice for precision assemblies and applications with high aesthetic demands.

Why Use Countersunk Screws?

We use countersunk screws for core reasons that we summarise as “three flats, three protections, and three aesthetics”—namely, flat surface, flat resistance, and flat stress; scratch prevention, anti-loosening, and corrosion prevention; and aesthetic appeal, concealment, and design matching. Let’s elaborate:

1. Functional Requirements: Must Be “Hidden”

Avoid Interference:

- In sliding components (like guide rails, molds), precision machinery, or human contact areas (like furniture edges), a protruding screw head creates a physical obstacle. A countersunk screw fully embeds into the workpiece, eliminating the risk of protrusion.

- Example: 3D printer platforms, or the slide grooves in aluminium profile frames.

Reduce Air/Fluid Resistance:

- Aerospace and racing car components require extremely flat surfaces; any protrusion increases turbulent drag. A countersunk screw maintains a streamlined surface.

- Example: Aircraft fairings, F1 racing car carbon fibre underbodies.

2. Mechanical Optimisation: Distribute Stress, Prevent Loosening and Cracking

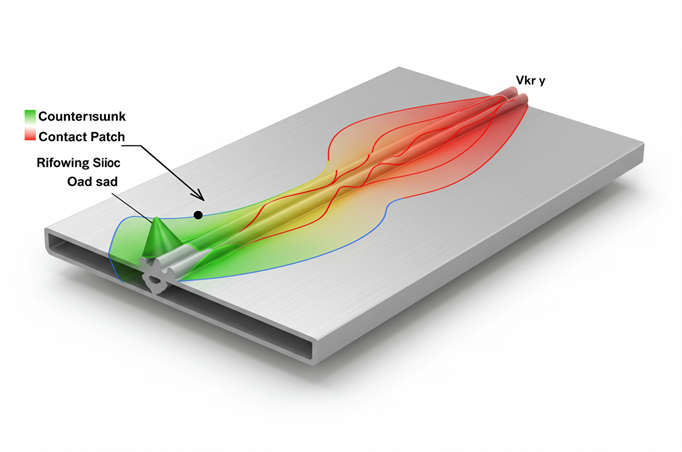

Conical Surface Pressure Distribution:

- The conical head of a countersunk screw creates a large contact area with the countersink hole. Compared to the line contact of a flat head screw, this significantly reduces localised pressure, preventing cracking in plastics or brittle materials (such as ceramics, composite materials).

- Example: Carbon fiber connections in drone propellers.

- The conical fit generates a wedge-locking effect, making it more resistant to loosening in vibrating environments than flat-head screws.

- Example: Aluminum cover plates for motorcycle engine casings.

3. Aesthetics and Industrial Design: Concealment and Symmetry

Visual Simplicity:

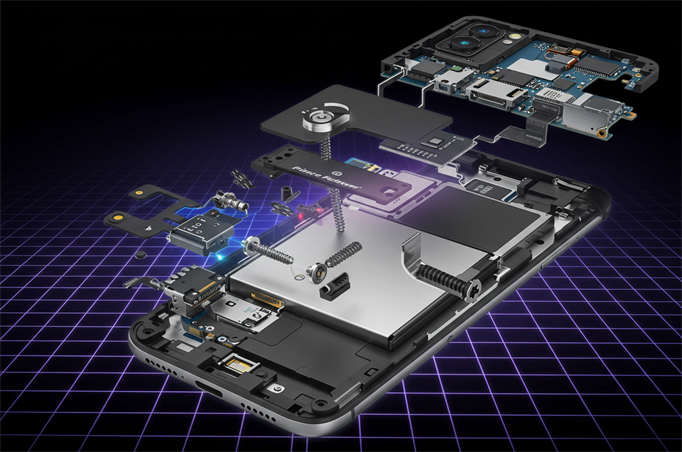

- Consumer electronics (like MacBook back covers, phone mid-frames) demand invisible screws. A countersunk screw can be completely hidden, even achieving a “disappearing” effect through anodizing or painting.

- Example: iPhone bottom screws (though not countersunk, they pursue a similar concept).

Symmetrical Assembly:

- For components requiring bilateral symmetry (like high-end knife handles, musical instruments), countersunk screws allow both sides to be flat, avoiding the protrusion of traditional nuts.

- Example: Neck connections on custom guitars.

4. Special Scenarios: Sealing and Corrosion Protection

Sealing Requirements:

- In food machinery or chemical equipment, a countersunk screw combined with a sealing ring creates a crevice-free surface, preventing bacterial growth or chemical residue.

- Example: Covers of stainless steel reaction vessels in pharmaceutical factories.

Corrosion Protection Design:

- In marine environments, we can fill countersink holes with epoxy adhesive, completely covering the screw head and preventing seawater contact with the threads, thus avoiding corrosion.

- Example: Stainless steel fasteners on yacht decks.

When Not to Use Countersunk Screws?

- Frequent Disassembly: Countersink holes can wear out, potentially leading to a loose fit later.

- Thick Materials or Blind Holes: Countersink hole processing can significantly weaken the workpiece’s strength (e.g., thin iron plates).

- Low-Cost Scenarios: Standard pan head screws do not require pre-processing of countersink holes, making them more economical.

A countersunk screw is a “function-first” solution. When a flat surface, structural strength, or aesthetic concealment becomes a rigid requirement, it is almost always the only choice.

Benefits of Using Countersunk Screws

At Prince Fastener, we know the advantages of countersunk screws offer significant benefits for your projects.

1. Flat: Truly “Zero Protrusion”

- Scenario: Any sliding, stacking, abutting, or hand-held areas—drawer slides, mould parting lines, phone mid-frames, bicycle stems.

- Principle: A 90° (or 100°/120°) conical head creates a surface-to-surface fit with the pre-drilled countersink hole, making the screw itself part of the workpiece’s contour.

- Case Study: Laptop D-shell: If we used pan head screws, the bottom would bulge, causing the laptop to “teeter-totter” on a table. With countersunk screws, the entire bottom surface can accept a foot pad as thin as 0.3 mm.

- Note: The countersink hole angle must match the screw angle; a 2° difference will cause an edge to lift.

2. Stable: Transforms “Point Loading” into “Surface Loading”

- Scenario: Brittle, low-strength, or fibrous materials—carbon fibre plates, ceramic substrates, 3D printed PLA parts, aluminium profile end faces.

- Principle: The conical contact area (≈π(R²-r²)/sin(θ/2)) is 3-10 times larger than that of a flat washer of the same diameter. This drastically reduces localized pressure, preventing chipping and cracking.

- Case Study: FPV drone arm: We used M3 titanium countersunk screws on a 4 mm thick carbon plate. It withstood repeated crashes without hole cracks. If we had used pan head screws, the hole edges often fractured into a “moon shape.”

- Note: You must recalibrate torque based on the countersunk screw’s “conical friction coefficient”; otherwise, overtightening may still cause cracking.

3. Hidden: Dual Physical and Visual Concealment

- Scenario: Human/skin contact, aesthetic parts, casings requiring film application/painting—watch backs, snowboard bindings, car interiors.

- Principle: After the head sinks in, we can apply a 0.1-0.2 mm thick paint layer or waterslide decal over it, achieving a “screw-less” visual effect. This also prevents clothing or skin from being scratched.

- Case Study: Apple MacBook bottom case: Countersunk screws with anodised grey finish and laser polishing make the fastening points almost invisible to the naked eye.

- Note: If future disassembly is needed for repair, you must incorporate a “hidden pull tab” or pre-drill disassembly holes; otherwise, you risk damaging the painted surface.

4. Efficient: Saves Processes, Thickness, and Weight

- Scenario: High-volume thin-walled parts, weight-sensitive industries—phone mid-frames, LED light boxes, spacecraft brackets.

- Principle: No need for extra washers, nuts, or hole plugs. The screw’s inherent thickness is incorporated into the workpiece thickness, potentially reducing overall thickness by 0.3-1 mm.

- Case Study: A particular brand’s 5G phone mid-frame: Switching to countersunk screws reduced the overall device thickness from 8.1 mm to 7.65 mm. The saved 0.45 mm perfectly accommodated a larger battery.

- Note: Countersink hole processing requires single-step forming (stamping, CNC, in-mould injection). Initial mould costs are slightly higher, but unit costs become lower in high-volume production.

5. Protective: “Three-Proof” (Scratch, Loosening, Corrosion)

5-1 Scratch Protection:

- Scenario: Conveyor belt side panels, baby crib railings, snowboard bindings.

- Principle: No protruding points, preventing clothing or packaging film from snagging or tearing.

5-2 Anti-Loosening:

- Scenario: High-vibration environments—motorcycle engines, drone motor mounts.

- Principle: The conical surface creates a “wedge-locking” effect. The cone absorbs radial displacement during vibration, making it more reliable than a pan head screw with a spring washer.

5-3 Corrosion Protection:

- Scenario: Coastal areas, chemical, and food equipment.

- Principle: You can fill the countersink hole with epoxy or silicone, completely covering the screw head and forming a “secondary seal.” This increases salt spray test life by 2-4 times.

- Comprehensive Case Study: Yacht deck 316 stainless steel countersunk screws: We applied marine-grade sealant before driving them in, resulting in no rust spots for five years. Ordinary hex head screws rusted within half a year.

6. Aesthetic: The “Invisible Punctuation” of Industrial Design

- Scenario: High-end consumer electronics, luxury goods, car interiors, architectural curtain walls.

- Principle: Achieves minimalism, symmetry, and a sense of integrity through “no visible fasteners.” The screw itself becomes part of the CMF (Colour-Material-Finish) system.

- Case Study: Dyson hairdryer handle: Countersunk screws with anodised gray and laser brushing seamlessly integrate with the body. Using ordinary screws would disrupt the streamlined design.

- Note: You must control colour consistency, angle consistency, and surface brushing direction; otherwise, “invisible” becomes “conspicuous.”

In a Nutshell:

The six benefits of countersunk screws are not isolated: “Flatness” brings “stability,” “stability” allows for “thinness,” “thinness” promotes “concealment,” “concealment” satisfies “aesthetics,” and “protection” is a continuous side effect. This is why when any “extreme requirement” regarding appearance, strength, or space arises, engineers first consider countersunk screws.

What’s the Difference Between Countersunk Screws and Standard Screws?

At Prince Fastener, we highlight the key differences between countersunk screws and standard screws.

| Feature | Countersunk Screw | Pan Head/Cylindrical Head Screw (as examples) |

| 1. Head Shape | 90° (or 100°/120°) conical, like a “funnel” | Round or cylindrical, clearly protruding |

| 2. Height After Installation | Head fully recessed into the workpiece, 0 protrusion on the surface | Head exposed, height = head thickness |

| 3. Hole Type Requirement | Must pre-drill a “conical countersink hole” | Only requires a straight or threaded hole |

| 4. Tightening Tool | Must match the hole’s angle, otherwise edges will lift | No angle requirement, highly versatile |

3 Hidden Performance Differences:

1. Force Distribution:

- Countersunk: Large conical contact area → distributes pressure, suitable for brittle/thin-walled materials.

- Standard: Point or line contact → high localised pressure, thin plates easily bulge.

2. Anti-Loosening Capability:

- Countersunk: Conical wedge-locking effect, more resistant to loosening in vibrating conditions.

- Standard: Requires additional spring washers or thread locker.

3. Aesthetics and Safety:

- Countersunk: No surface protrusion, can be painted or covered with film, prevents scratching.

- Standard: Protrusion easily snags, bumps, requires decorative caps.

One-Sentence Conclusion:

Countersunk screw = a specialised “embedded” fastener; Standard screw = a general-purpose “exposed” fastener.

If your design requires a perfectly flat surface, deals with easily cracked materials, or demands minimalist aesthetics, you must choose a countersunk screw. Otherwise, a standard screw is more convenient and cost-effective.

If you have read this far, you already understand why the countersunk screw is not just another fastener—it is a strategic design element that unlocks flatter surfaces, lighter structures and cleaner aesthetics. At Prince Fastener, we turn that understanding into a daily reality. Our ISO 17025–accredited lab runs 48-hour, 240-hour and 1,000-hour salt-spray cycles so you can quote exact corrosion life to your customers. Our seven-axis CNC cone-seat machining centres hold a 0.02 mm positional tolerance across production lots of 100,000 pieces.

And our VMI bins in Houston, Rotterdam and Dubai keep countersunk screws within 48 hours of any global assembly line. Ready to put this expertise to work? Click the link below to download our interactive RFQ pack: it includes STEP files for every countersunk screw profile we manufacture, torque guidelines for dissimilar materials, and a one-page quality agreement template that protects you from hidden costs. Need prototypes yesterday?

Ask for our “10-Piece Airfreight” program—no MOQ, no tooling fee, just ten flawless countersunk screws on your desk in three days. Prefer to test before you commit? We will laser-mark your part number on free samples and include a QR-coded test report that traces material heat, coating thickness and thread flank angle back to the exact coil of wire. From aerospace brackets that demand 0.1 g weight savings to architectural façades that must hide every fastener from the naked eye, Prince Fastener has delivered the countersunk screw that makes the impossible look effortless.

Tell us your surface finish, your vibration spectrum, your target lifecycle—and we will return a countersunk screw solution that is invisible on the outside, invincible on the inside. Because when the world demands flat, flawless and forever, Prince Fastener delivers the countersunk screw that disappears—except in performance.