Welcome to Prince Fastener, your trusted partner in construction hardware. Whether you’re building skyscrapers, bridges, or residential structures, one thing remains constant: the critical role of construction screws in ensuring stability, durability, and safety. At Prince Fastener, we understand that every screw, bolt, and anchor is more than just a fastener—it’s a vital component that holds your project together, literally and figuratively.

In today’s fast-paced construction industry, choosing the right construction screws can make all the difference. From stainless steel screws designed to withstand harsh coastal environments to high-strength anchors for concrete and masonry, the variety of fasteners available can be overwhelming. That’s why we’ve created this comprehensive guide—to help you navigate the world of construction screws, understand their applications, and make informed decisions for your next project.

At Prince Fastener, we pride ourselves on offering a wide range of construction screws tailored to meet the unique demands of modern construction. Whether you need screws for exterior applications, structural connections, or specialized installations like curtain walls and metal frameworks, our products are engineered to deliver exceptional performance. In this blog, we’ll explore the different types of construction screws, their specifications, and how to select the perfect solution for your project.

But we don’t stop at just providing products. We believe in empowering our customers with knowledge. By understanding the key factors that influence the performance of construction screws—such as material strength, corrosion resistance, and installation techniques—you can ensure that your projects stand the test of time. Whether you’re a contractor, architect, or DIY enthusiast, this guide will equip you with the insights to choose the correct fasteners for your needs.

Join us as we delve into the fascinating world of construction screws, uncovering their critical role in modern construction and how Prince Fastener can be your go-to source for reliable, high-quality solutions.

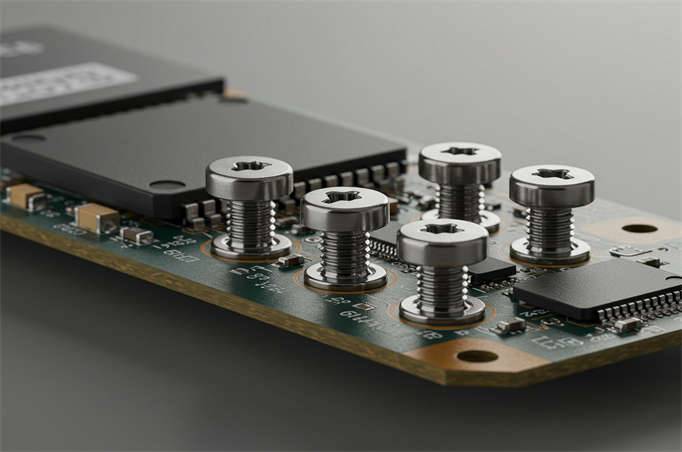

Construction screws play a crucial role in connecting, securing, and reinforcing structures in building construction. Depending on the application scenarios and wall materials, construction screws can be classified into several types:

Types of Construction Screws

- Standard Screws: These are the most common construction screws, widely used to connect wood, metal, and plastic. They consist of a screw and a nut.

- Self-Tapping Screws: Suitable for metals or plastics, these screws can cut threads into the material.

- Self-Drilling Screws: Designed to drill holes and tap threads in one go, providing strong engagement, saving time, and improving efficiency.

- Drywall Screws: Used to attach drywall to wooden or metal studs, these screws are more profound than standard screws and have higher thread positions and lengths.

- Masonry Screws: These screws are designed to fit into rigid materials like concrete, CMU, mortar joints, and bricks, typically made of stainless or carbon steel.

- Wood Screws: Used for connecting wood components, generally made of brass, steel, or bronze.

- Stainless Steel Bolts: Known for their corrosion and oxidation resistance, stainless steel bolts are perfect for harsh environments.

- Expansion Bolts: These use the friction generated by the expansion of a metal sleeve within a drilled hole, ideal for securing to concrete, walls, and other hard surfaces.

- Chemical Anchor Screws: Combine the use of adhesives with anchor fixation in concrete, offering excellent load-bearing capacity.

- Hook Head Screws (T-type or L-type screws): These screws have a hook or T-shaped head for easy suspension or positioning.

- Self-Tapping Screws: These screws feature a pointed tip, allowing them to create their hole and thread in materials like metal, wood, or plastic without the need for pre-drilling.

Applications of Construction Screws

- Steel Structure Connections: Used to link steel components, ensuring the stability and safety of buildings.

- Concrete Structure Connections: Stainless steel bolts are commonly used in concrete structures due to their high corrosion resistance.

- Wood Structure Connections: Wood screws provide stable connections for wooden components.

- Curtain Wall Systems: Stainless steel bolts secure curtain wall panels and connect various parts of the system.

- Bridge Construction: These screws are used to connect different parts of a bridge, including the ground, bridge piers, and towers.

Specifications of Construction Screws

- M3: Diameter 3mm, pitch 0.5mm, head diameter 5.5mm.

- M4: Diameter 4mm, pitch 0.7mm, head diameter 7mm.

- M5: Diameter 5mm, pitch 0.8mm, head diameter 8.4mm.

- M6: Diameter 6mm, pitch 1.0mm, head diameter 10mm.

- M8: Diameter 8mm, pitch 1.25mm, head diameter 13.1mm.

- M10: Diameter 10mm, pitch 1.5mm, head diameter 16mm.

This information serves as a reference. When selecting screws, always consider the actual requirements and environmental standards.

Key Considerations for Selection and Installation

- Material Matching: Opt for stainless steel bolts in humid environments (e.g., bathrooms).

- Hole Requirements: For concrete/walls, make sure the drilled hole is slightly more profound than the screw, and clean up any debris.

- Gypsum Board: Use specific gypsum board screws to prevent damage to internal structures.

- Safety Operations: Always wear safety goggles and operate within the recommended torque range to avoid thread stripping.

For more detailed parameters (e.g., screw specifications, tensile strength), refer to the product standards or fastener manufacturer’s specifications.

Which Construction Screws Are Suitable for Outdoor Use?

When working outdoors, it’s essential to choose screws that are resistant to corrosion and have the necessary strength. Here are the best types of screws for outdoor use:

- 304 Stainless Steel Bolts: These bolts are suitable for general environments and freshwater settings, offering strong corrosion resistance and aesthetic appeal.

- 316 Stainless Steel: This type, with added molybdenum, offers superior corrosion resistance, especially in marine environments or areas with high chloride content.

- Coated Carbon Steel Screws: Zinc-coated or otherwise treated carbon steel screws provide enhanced corrosion resistance, suitable for general outdoor use.

- Self-Tapping or Self-Drilling Screws: Stainless steel self-tapping or self-drilling screws are ideal for metal curtain walls, metal roofs, and other assemblies, enabling easy penetration and tightening in different materials.

- Expansion Bolts or Chemical Anchors secure concrete or walls. They are ideal for outdoor curtain walls or structural connections.

Recommended Scenarios

- Coastal or High-Corrosion Environments: Prioritize 316 stainless steel bolts or coated carbon steel screws.

- General Outdoor Environments: 304 stainless steel bolts or galvanized carbon steel screws will suffice.

- Assembly of Metal Structures or Curtain Walls: Self-tapping or self-drilling screws are effective choices.

Select the right screws based on specific project requirements and environmental conditions to ensure long-term stability and durability.

Can Construction Screws Bear Weight?

The weight that construction screws can handle depends on their specifications, materials, and installation methods. Here’s an overview of the load-bearing capacity of various screws:

- M10 Expansion Bolt: Can generally handle over 50kg of tensile force when installed in concrete.

- M8 Standard Bolt: Can support about 720kg of weight when vertically loaded.

- M12 Standard Bolt (Grade 4.8): Can handle a maximum tensile force of 26100N (approximately 2660kg), with the actual capacity depending on the material and diameter.

- High-Tensile Bolts (e.g., Grade 12.9 or 8.8): These bolts have higher tensile strength; for instance, Grade 8.8 bolts have a tensile strength of 800MPa, and Grade 12.9 bolts have 1080MPa, making them suitable for heavy-duty applications.

- M12 Expansion Bolt: Generally handles 2660kg of weight, with variations depending on material and installation method.

Factors Affecting Load-Bearing Capacity:

- Material Strength: Higher-strength steel bolts support more weight.

- Installation Method: Proper tightening and secure assembly affect the load-bearing capacity.

- Stress Direction: Tensile forces in the vertical direction are usually easier to withstand than shear forces.

- Substrate Strength: The load-bearing capacity varies depending on whether the screw is installed in concrete, walls, or hollow bricks.

Are Construction Screws Stronger than Deck Screws?

Construction screws tend to be stronger than deck screws, considering the following factors:

- Material: Construction screws come in a variety of materials, including high-strength steel grades like 8.8, 10.9, and 12.9. These offer excellent tensile and shear strength.

- Deck Screws: Typically made from stainless steel or copper, deck screws excel in corrosion resistance but may not have the same tensile strength as high-grade construction screws.

- Design: Construction screws often feature deeper threads, providing better grip and stability for heavy-duty applications.

- Purpose: While deck screws are ideal for securing decking materials, construction screws are designed for heavy-duty structural connections, requiring higher strength.

In summary, construction screws are typically stronger in material strength and design, making them better suited for load-bearing applications. However, deck screws offer superior corrosion resistance, particularly in wood construction.

Construction Screws for Structural Frameworks

Construction crews are essential in the building industry, providing reliable connections for various structural applications. Here are the key specifications, materials, and uses:

- Specifications (M12 to M30): The screw size depends on the required connection strength.

- Materials: Carbon steel is commonly used for general construction, while high-strength alloy steel is ideal for demanding environments requiring more excellent wear resistance, such as Grade 8.8 and 10.9 bolts.

- Applications: Construction screws are widely used in precast concrete frame structures, improving assembly efficiency and saving construction time.

Due to their versatility, construction screws provide reliable connection solutions for the construction industry, enhancing structural integrity and performance.

How to Calculate the Preload Force of Construction Screws?

You can calculate the preload force (F) of construction screws using two key methods:

- Based on Torque:

- 𝐹=𝑑𝑇×𝐾F=dT×K

- Where:

- 𝐹F: Preload force (in Newtons or pounds)

- 𝑇T: Torque (in Newton-meters or pounds-feet)

- 𝐾K: Torque coefficient (typically between 0.13 and 0.2, depending on surface treatment and lubrication)

- 𝑑d: Diameter of the screw (in meters or inches)

- Based on Bolt Strength:

- 𝐹=0.7×𝐴×𝜎𝑦F=0.7×A×σy

- Where:

- 𝐹F: Preload force (in Newtons or pounds)

- 𝐴A: Tensile stress area of the screw (in square millimeters or square inches)

- 𝜎𝑦σy: Tensile strength of the bolt material (in MPa or pounds per square inch)

- 0.7: Safety factor to ensure preload does not exceed the bolt’s compressive strength

For example, if you need to calculate the preload force for an M10 screw with a torque of 50 Nm and a torque coefficient of 0.2, the formula would be:

𝐹=0.0150×0.2=10,000 NewtonsF=0.0150×0.2=10,000 Newtons

If the tensile stress area (A) of the screw is 78.54 mm² and the tensile strength (𝜎𝑦σy) is 600 MPa:

𝐹=0.7×78.54×600=33,070.8 NewtonsF=0.7×78.54×600=33,070.8 Newtons

Key Considerations:

- Torque Coefficient: The torque coefficient’s selection has a significant impact on the calculation. It must be chosen according to the bolt’s surface treatment and lubrication conditions.

- Safety Factor: A safety factor is usually introduced to ensure the bolt does not fail under load.

These formulas help you precisely calculate the preload force of construction screws, ensuring reliable connections and safety in your construction projects.

At Prince Fastener, we’re not just selling construction screws—we’re providing peace of mind. From stainless steel screws for corrosive environments to high-strength anchors for structural connections, every product in our portfolio is designed with precision, durability, and performance in mind. As we conclude this guide, we hope you’ve gained valuable insights into the diverse world of construction screws and how they contribute to the success of your projects.

Selecting the right construction screws isn’t just about meeting immediate requirements; it’s about ensuring long-term reliability. Whether working on a residential building, a commercial complex, or an industrial structure, the proper fasteners can make your project safer, more efficient, and more cost-effective. At Prince Fastener, we offer solutions that cater to the most demanding applications, from coastal environments to heavy-duty structural connections.

We understand that every project is unique, which is why we provide a comprehensive range of construction screws to suit various materials, loads, and environmental conditions. Our team of experts is always ready to assist you in choosing the perfect fasteners for your specific needs. Whether you require stainless steel screws for exterior applications, self-tapping screws for metal frameworks, or chemical anchors for concrete structures, we’ve got you covered.

At Prince Fastener, quality and innovation go hand in hand. Our commitment to excellence is reflected in every product we offer, ensuring you can trust our construction crews to perform under pressure. As you embark on your next construction project, remember that the correct fasteners are the foundation of success.

Thank you for choosing Prince Fastener as your construction partner. We look forward to helping you build stronger, safer, more sustainable structures. Contact us today to discover how our premium construction screws can elevate your projects to new heights.