Concrete Screws

Fasteners are not limited to any type of application, they can be used in wood, metal, plastic, and concrete materials. And while there are many variations of fasteners, the importance of knowing the capabilities of each type is relevant to all situations.

Using fastener screws in concrete surfaces may be one of the hard workpieces in fastening. Fortunately, fastener manufacturers are able to provide solutions in concrete or masonry assembly.

Another known term for concrete screws is masonry screws. These screws have accurate features and precision for drilling into concrete or any solid material alike.

Prince Fastener carries a wide variety of concrete screws in size, shape, and form. We can also manufacture according to design or drawing from customers.

Self-tapping Masonry Screws

Self-tapping screws are known for their ability to tap on surfaces without the need for pre-drilling because of their special point ends. The features of self-tapping screws vary by type.

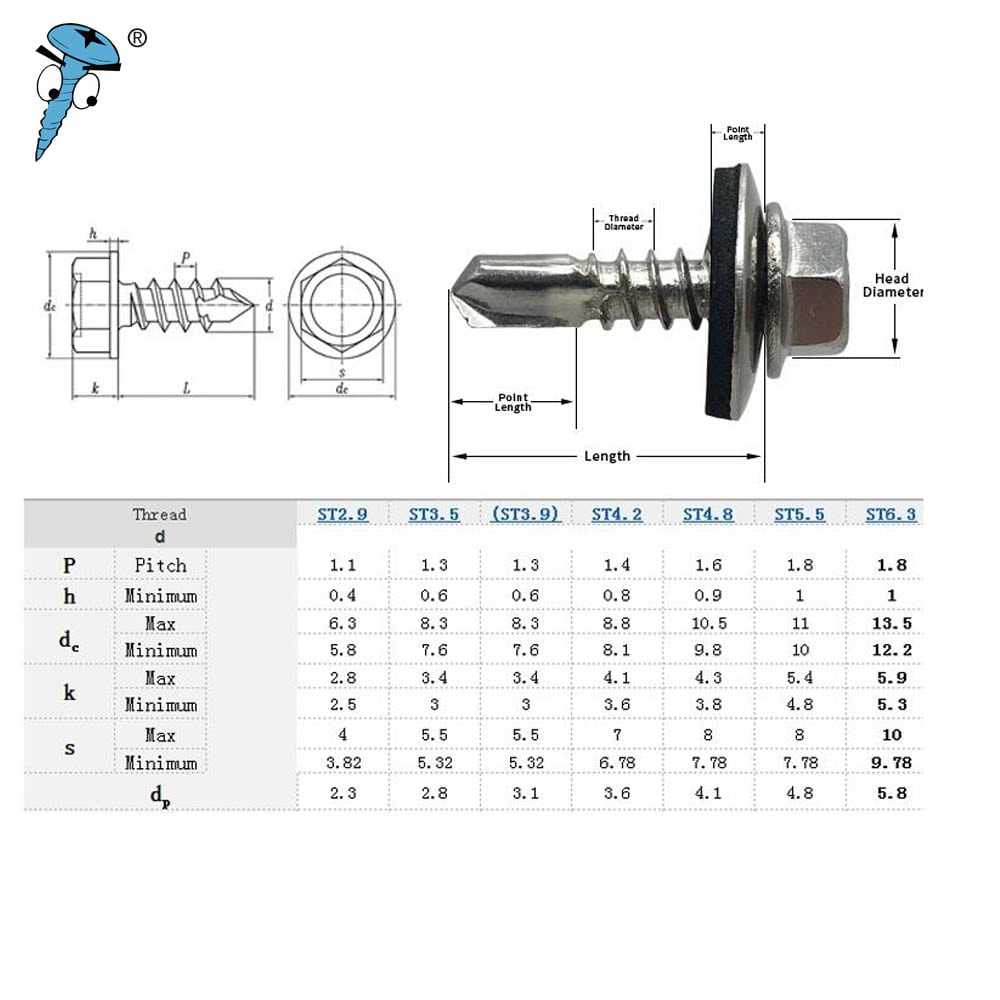

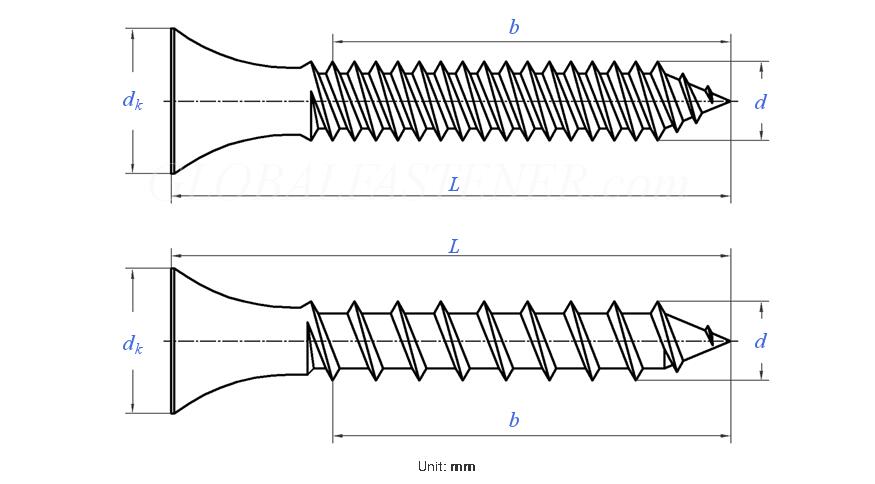

The self-tapping masonry screws have coarse threads and usually hex heads. They can have full or partial threading in the shank depending on the application need. More specifications of self-tapping masonry screws can be according to the following choices below:

Specifications

Material | Carbon steel, Stainless steel, Alloy, Aluminum, Titanium, Brass *We can manufacture according to customer request* |

Size | M4-M20 *We can manufacture according to customer request* |

Head Type | Hex, Pan, Countersunk, Round, Truss, Half-countersunk, Button, Binding, Cheese, Fillister *We can manufacture according to customer request* |

Drive Style | Phillips, Slotted, Six-lobe, Square, Pozidriv, Triangle, Spanner, Clutch, Y-type, S-type *We can manufacture according to customer request* |

Standard | GB, ANSI, ASME, DIN, JIS, UNI, NF, ISO *We can manufacture according to customer request* |

Finishing | Galvanizing, Chromium Plating, Phosphating, Electrophoresis, Dacro, Hot Embroidery, Passivation, Polish *We can manufacture according to customer request* |

Advantages of Self-tapping Masonry Screws

- Eliminates the need for pre-drilling a pilot hole

- Strong and reliable metal component that can be used in common materials

- Self-tapping masonry screws have thread-forming and thread-cutting features

- A device widely used in concrete, masonry, brickwork, blockwork, and others

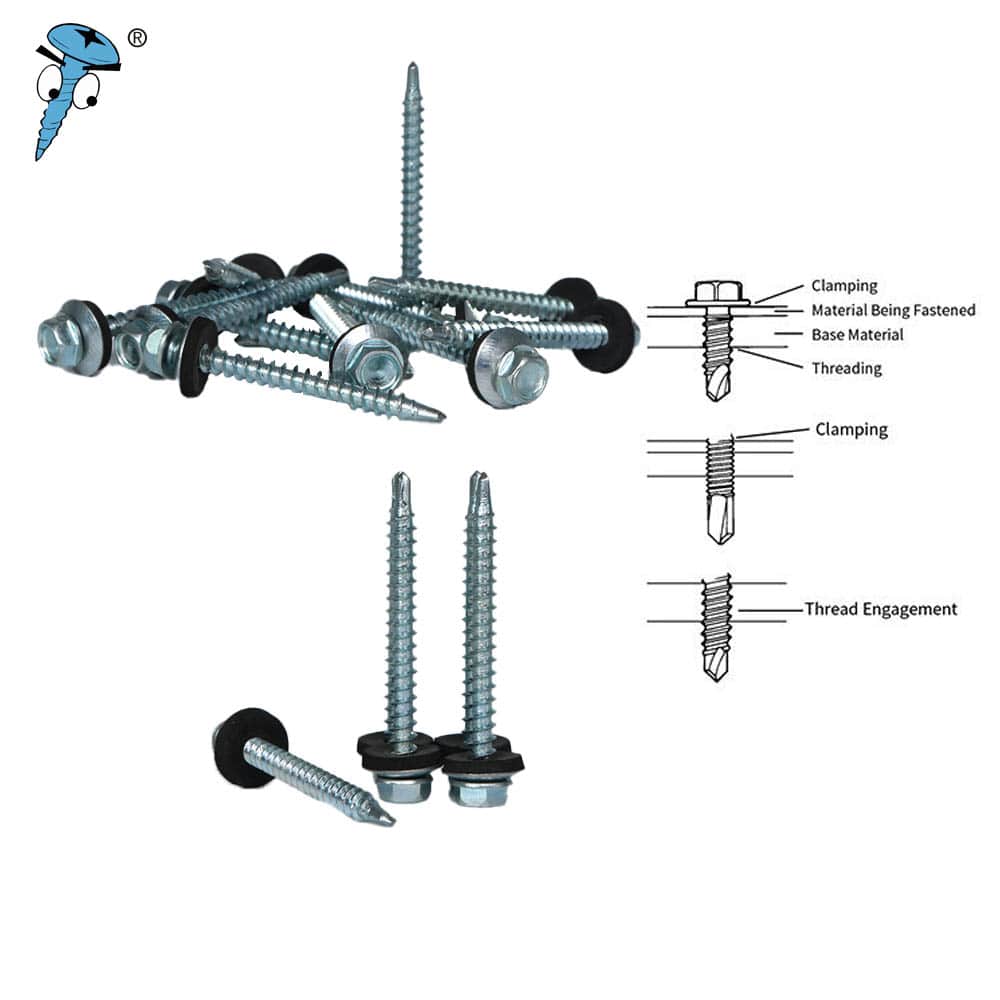

Self-drilling Screws for Concrete Applications

Self-drilling screws are different from self-tapping screws for having integrated blunt point end that easily penetrate any kind of surface material, especially concrete or metal sheets.

Prince Fastener’s self-drilling screws are available in;