The #10 screw diameter measures exactly 0.190 inches, which equals 4.83 millimeters. You will notice that screw sizes can seem confusing at first. To help, see how #10 compares to other popular choices:

| Screw Size | Diameter (inches) |

|---|---|

| #8 | 0.164 |

| #10 | 0.190 |

| #12 | 0.216 |

Choosing the right screw diameter makes your project much stronger. Studies show that the correct screw can raise stability rates above 90%. If you match the screw to your project, you avoid weak joints and costly mistakes.

Key Takeaways

- The #10 screw diameter measures 0.190 inches (4.83 mm), making it a strong choice for medium to heavy-duty projects.

- Always use a screw size chart to compare different screw sizes. This helps you select the right fastener for your material and job.

- Consider the material you are working with. Thicker screws are better for harder materials, while thinner screws work well for softer ones.

- Match the screw size to the weight it needs to hold. For heavy jobs, use #10 or #12 screws for a secure hold.

- Double-check measurements in both inches and millimeters to avoid mismatched parts and ensure a strong connection.

#10 Screw Diameter

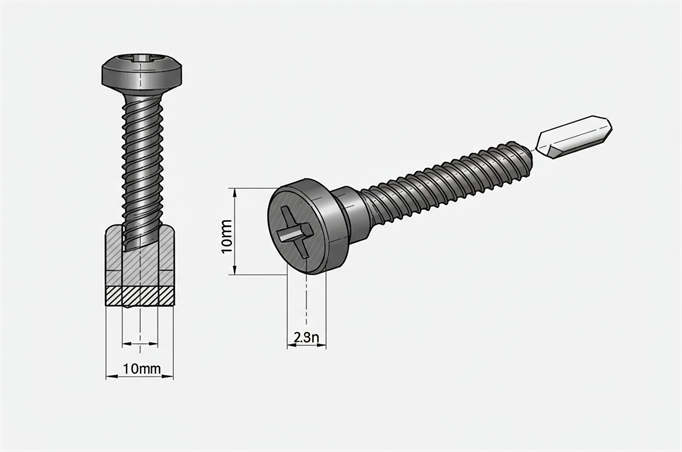

Measurements in Inches and Millimeters

You often see both imperial screw sizes and metric screw sizes when you shop for fasteners. The #10 screw diameter stands out as a common choice for many projects. You measure this screw at 0.190 inches in diameter. In metric screw sizes, this equals 4.83 millimeters.

Here is a quick reference table for you:

| Screw Size | Diameter (inches) | Diameter (mm) |

|---|---|---|

| #10 | 0.190 | 4.83 |

You can use this table to compare the #10 screw diameter with other sizes. When you work with wood, metal, or plastic, knowing the exact screw diameter helps you pick the right fastener. Many builders and DIYers prefer to check both imperial screw sizes and metric screw sizes before starting a project. This habit helps you avoid mistakes and ensures a strong hold.

Tip: Always double-check the #10 screw diameter in both inches and millimeters. This step saves you time and prevents mismatched parts.

Gauge System Overview

You might wonder why screws have numbers like #10 or #8. The gauge system started in the 19th century. Factories needed a way to make parts that fit together every time. Joseph Whitworth in England and William Sellers in America both helped create standards for screw threads. Their work made it possible for you to find screws that match your needs, no matter where you shop.

The gauge number tells you the thickness of the screw. A higher number means a thicker screw. For example, the #10 screw diameter is larger than a #8 but smaller than a #12. This system works for both imperial screw sizes and metric screw sizes. When you understand the gauge system, you can choose the right screw for your project with confidence.

You will see that metric screw sizes use millimeters instead of gauge numbers. Still, the idea stays the same. You match the screw diameter to your material and the job you want to do. This knowledge helps you build strong, safe, and lasting projects.

Common Screw Sizes

Size Chart Comparison

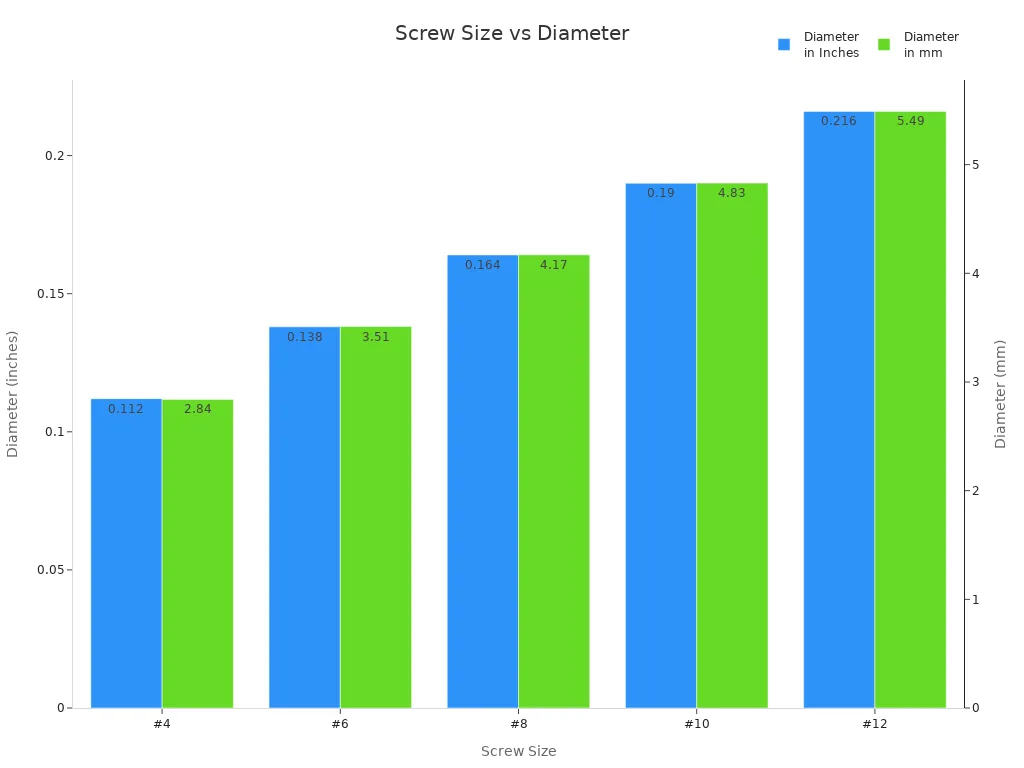

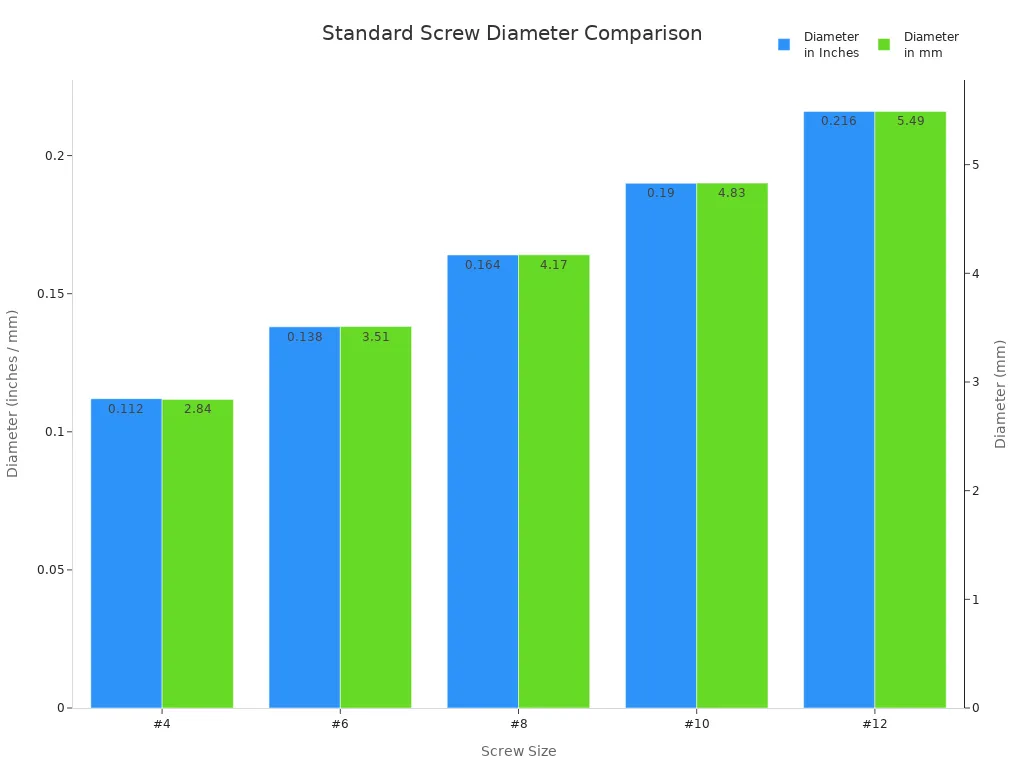

You often see many different screw sizes when you start a project. Knowing the right size helps you choose the best fastener for your job. The most common screw sizes include #4, #6, #8, #10, and #12. These sizes work well in woodworking, metalworking, and construction. You can find them in many lengths, so you always have options.

Here is a screw size chart that compares these popular choices:

| Screw Size | Inch Decimal | Nearest Fraction | Metric Equivalent |

|---|---|---|---|

| #4 | 0.112 in. | 7/64″ | 2.84 mm |

| #6 | 0.138 in. | 9/64″ | 3.51 mm |

| #8 | 0.164 in. | 5/32″ | 4.17 mm |

| #10 | 0.190 in. | 3/16″ | 4.83 mm |

| #12 | 0.216 in. | 7/32″ | 5.49 mm |

You can also see the differences in this chart:

This screw size chart helps you compare the thickness of each screw. You can see that as the number goes up, the screw gets thicker. For example, a #4 screw is much thinner than a #12 screw. You should always check the screw size chart before you buy screws for your project.

You will notice that the most common screw sizes in woodworking and construction are #6, #8, and #12. These screws come in many lengths, so you can pick the right one for your needs. The screw size chart above shows you the exact measurements in both inches and millimeters. This makes it easy to match the screw to your material.

Tip: Always use a screw size chart when you plan your project. This step helps you avoid mistakes and makes your work stronger.

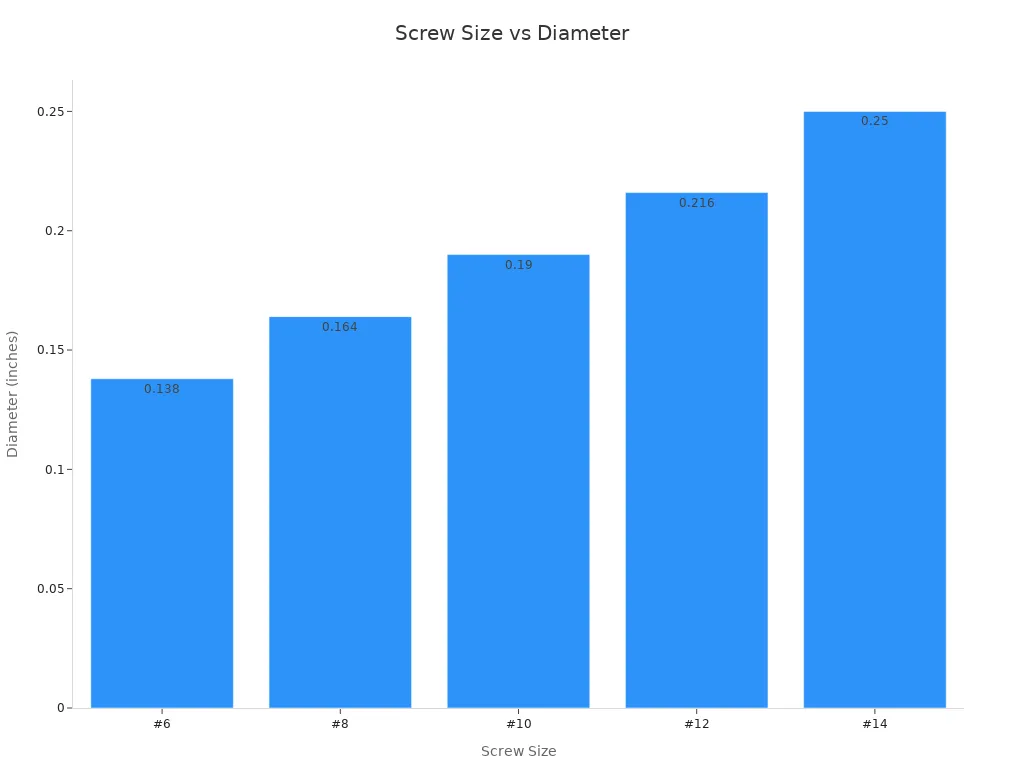

#10 vs #8 vs #12

You might wonder how the #10 screw compares to the #8 and #12 screws. These three sizes are very popular in many projects. Each one has its own strengths and best uses.

- The #8 screw has a diameter of 0.164 inches (4.17 mm). You often use this screw for light to medium tasks, like joining thin wood or attaching hardware.

- The #10 screw measures 0.190 inches (4.83 mm). This screw gives you more holding power than a #8. You can use it for medium to heavy-duty jobs, such as building furniture or framing.

- The #12 screw is even thicker at 0.216 inches (5.49 mm). You use this screw when you need extra strength, like in heavy construction or when joining thick materials.

You can see the differences in this chart:

When you compare these screws, you notice that the #10 screw sits right in the middle. It gives you a balance of strength and size. The #8 screw works well for smaller jobs, while the #12 screw handles the toughest tasks.

You should also know that the holding strength of a screw does not depend only on its size. The design of the screw, the type of head, and the thread pattern all play a role. Sometimes, a #10 screw can even outperform a #12 screw if it has a better design. Different manufacturers may also make screws that perform differently, even if they have the same size.

Here are some practical differences between these screw sizes:

- #8 screws are easy to drive and remove. You use them for cabinets, trim, and light fixtures.

- #10 screws give you more grip. You use them for shelves, frames, and medium furniture.

- #12 screws offer the most strength. You use them for heavy-duty projects, like deck building or attaching thick boards.

You can see that choosing the right screw size makes your project safer and stronger. Always match the screw to your material and the job you want to do. The screw size chart helps you make the best choice every time.

Note: The most common screw sizes for woodworking and construction are #6, #8, #10, and #12. You will find these screws in many lengths, so you can always find the right one for your project.

Screw Size Differences

Holding Strength

You want your project to last, so you need to think about holding strength. The holding strength of a screw depends on more than just its size. The design of the screw, the material you drive it into, and the length all play a big part. When you use the right screw, you help your project resist pullout forces. If you use a screw that is too short or thin, it might not hold well. The way you prepare the pilot hole also matters. A well-prepared hole lets the screw grip better. The torque you use when driving the screw can change how tightly it holds. If you use too much force, you might strip the hole. If you use too little, the screw may not stay in place. Each of these factors works together to give you the best holding strength.

Tip: Always match the screw to your material and make sure you use the right length for the job. This step helps you get the strongest hold.

Typical Applications

You will see that different screw sizes work best for different jobs. The #10 screw is a favorite for heavy-duty woodworking and deck framing. You use it when you need more strength than a #8 screw can give. The #12 screw is even stronger and works well for structural connections and timber framing. The #8 screw is great for general-purpose use and moderate strength needs in woodworking or light metal work.

Here is a table to help you choose the right screw for your project:

| Screw Size | Typical Applications |

|---|---|

| #8 | General-purpose use, moderate strength woodworking, light metal fabrication |

| #10 | Heavy-duty woodworking, deck framing |

| #12 | Structural connections, timber framing |

You can see that picking the right screw size makes your work safer and longer-lasting. When you know the differences between screw sizes, you can choose the best one for each task. Always check the job and the material before you pick your screw.

Choosing Screw Size

Material Considerations

Think about what your material is before picking a screw. Wood, metal, and plastic all need different screw sizes and types. Harder materials, like metal or hardwood, need thicker screws for a better hold. Softer things, such as pine or drywall, work with thinner screws. How dense and hard your material is changes how much weight the screw can hold and how well it stays in place.

Here is a table to help you know what to check in your material:

| Material Property | Impact on Screw Choice |

|---|---|

| Density | Changes how much weight the screw can hold and what size you need |

| Hardness | Shows how strong the material is and if it is good for certain jobs |

You also need to think about the screw’s own features. Use this screw size reference table to help you pick:

| Property Type | Description |

|---|---|

| Screw Length | Should be as long as the top piece plus two-thirds of the bottom piece. |

| Gauge | Means the outside thread width; thicker things need a higher gauge. |

| Thread Coarseness | Thicker threads grip better, which helps keep the screw in place. |

| Material Choice | Different metals, like carbon steel or stainless steel, change how strong the screw is and if it rusts. |

Tip: Always measure how thick your materials are before picking a screw. This helps you stop splitting or stripping.

Load and Strength

You want your project to be strong and safe. The right screw size guide helps you pick a screw that can hold the weight. For light jobs, like trim or hinges, a #6 screw works well. For heavier things, like drywall or deck frames, use a #10 or #12 screw.

Here is a screw size reference table with common uses:

| Screw Size | Common Uses | Notes |

|---|---|---|

| #6 x 1″ | Light wood work, trim | Good for inside jobs with less force |

| #8 x 1-1/4″ | Cabinets, putting furniture together | Great for joining wood inside |

| #10 x 1-1/2″ | Drywall to studs, heavy frames | Strong hold without breaking the wood |

| #12 x 2″ | Metal brackets, strong hardware | Needed for extra grip strength |

When you pick a screw, think about how much weight it will hold. Use the halfway rule: the screw should go at least halfway into the bottom piece for a tight grip. Make the screw longer for heavy things or for materials that break easily.

Here are some quick tips for matching screw sizes to your job:

- Use thin threads for thin metal so the screw does not bend.

- Pick longer screws for heavy jobs in brick or stone.

- Choose deck screws that are longer if you live where it rains a lot.

- Always measure how thick your material is first.

- Bigger screws are not always better. Match the screw to your material and job.

Note: The right screw size guide makes your project safer and helps it last longer. Always check a screw size reference table before you begin.

You can see that the #10 screw stands out for medium-duty jobs, while #6 and #8 screws work best for lighter tasks. The #12 screw handles heavy-duty needs. Check this table for a quick comparison:

| Screw Size | Diameter (inches) | Common Uses |

|---|---|---|

| #6 | 0.138 | Light wood joinery, trim, hinges |

| #8 | 0.164 | Cabinets, furniture assembly |

| #10 | 0.190 | Shelves, heavy brackets |

| #12 | 0.216 | Metal brackets, structural hardware |

Always match the screw diameter to your project. This step helps you avoid weak joints or damage. For best results, use a screw size chart and measure your materials before you start.

FAQ

What does the “#” mean in screw sizes like #10?

The “#” symbol shows the gauge or thickness of the screw. A higher number means a thicker screw. You use this system to compare screw sizes quickly.

Can you use a #10 screw in place of a #8 screw?

You can use a #10 screw if you need more strength. Make sure the hole and material can handle the larger size. Always check the fit before you start your project.

How do you measure screw diameter?

You measure screw diameter across the outer threads. Use a ruler or caliper for accuracy. Always check both inches and millimeters for the best match.

Why do some screws use millimeters instead of gauge numbers?

Metric screws use millimeters to show diameter. Many countries use this system. You may see both systems in stores. Always match the screw to your project’s needs.