When you need something to hold very strong in building work, a bolt screw is usually better than a regular screw. Bolt screws provide more holding power and strength, making them ideal for building structures that must support heavy weight. Screws, on the other hand, are great when you need to install them quickly or when space is limited. The table below explains why workers choose bolt screws or screws for different tasks:

| Reason | Bolt Screw | Screws |

|---|---|---|

| Strength | Perfect for heavy-duty jobs and frames | Suitable for light jobs, not for large frames |

| Installation | Requires nuts, more effort to install | Faster and easier, no nuts needed |

| Material Compatibility | Works well with metal, wood, and frames | Best for wood, plastic, and light metals |

If you need assistance selecting the right fastener, a reliable screw supplier can guide you through your project.

Key Takeaways

- Bolts hold things together very tightly. They work well for big building jobs. You can take bolts out or change them easily.

- Screws go in faster than bolts. They are good for small jobs or places that are hard to reach. Screws cannot hold as much weight as bolts.

- Use bolts for large things like steel frames or heavy machines. Use screws for wood, drywall, or quick repairs.

- Bolts need more tools and take longer to put in. Bolts last a long time and do not need much fixing.

- Always pick the right fastener for your job. Make sure it is strong enough and made from the right material. This keeps your project safe and helps it last.

Bolt Screw Differences

Design

Bolts and screws look different from each other. Bolts have a smooth part and need a nut to hold things together. Screws have threads all the way down and make their own threads when you put them in. This makes screws simple to put in and take out, especially with a drill or screwdriver.

Here is a table that shows how bolts and screws are not the same:

| Aspect | Bolts | Screws |

|---|---|---|

| Thread Length | Partially unthreaded shank | Threads along entire length |

| Fastening Method | Needs nut (sometimes washers) | Self-tapping or into pre-tapped holes |

| Installation Tools | Wrench or socket | Screwdriver or power drill |

| Load Capacity | High, for heavy loads | Lower, for lighter loads |

| Clamping Force | High, due to nut tightening | Lower, no nut involved |

| Adjustability | Easy to adjust and disassemble | Less adjustable, more permanent |

| Typical Applications | Structural, machinery, automotive | Woodworking, electronics, lighter assemblies |

| Installation Speed | Slower, more steps and tools | Faster, simpler installation |

The way threads are made is important too. Rolled threads are tough and last a long time. This helps in hard building jobs. Screws use V-threads to lock in place easily. Bolts can use Acme or buttress threads for more strength and to move power. Picking the right thread keeps your project safe and strong.

Tip: If you want to take out and change your fastener later, bolts are better. Screws are good for quick jobs that stay in place.

Function

Bolts and screws hold things together in different ways. Bolts need nuts and sometimes washers. The bolt goes through the material, and the nut tightens on the other side. This makes a strong hold and spreads the weight out. Bolts are used where you need lots of strength and safety.

Screws dig into the material and hold with their threads. You do not need a nut. Screws are great for fast jobs and for wood, drywall, or thin metal. You can put screws right into the material, and they work well for lighter things.

- Bolts give strong holding power and can handle heavy things.

- Screws are easy to put in and take out, so they are good for projects that need to be changed quickly.

- Bolts need holes made first and special tools like wrenches.

- Screws usually just need a screwdriver or drill.

Applications

Bolts and screws are used in many building jobs, but each one is best for certain things.

- Used in big jobs like steel beams, concrete anchors, and large wood frames.

- Common in building, machines, and factories.

- Needed when you want a strong, adjustable, and shake-proof hold.

- Examples: Carriage bolts, lag bolts, and hex bolts.

Screws:

- Used in lighter jobs like woodwork, drywall, and putting furniture together.

- Good for projects that need to be done fast and need medium strength.

- Common types are wood screws, drywall screws, deck screws, and machine screws.

- Special screws, like concrete or masonry screws, go into brick or concrete after you drill a hole.

Here is a quick list of where you might use each fastener:

- Bolts: Deck posts, steel frames, machines, car parts.

- Screws: Cabinets, drywall, metal roofs, electric panels, outdoor decks.

If you need to pick between a bolt screw and a regular screw, think about how much weight your project needs to hold and how easy you want it to be to put together. Bolts are best for heavy jobs, while screws are great for lighter, faster work.

Strength

Bolt Screw Strength

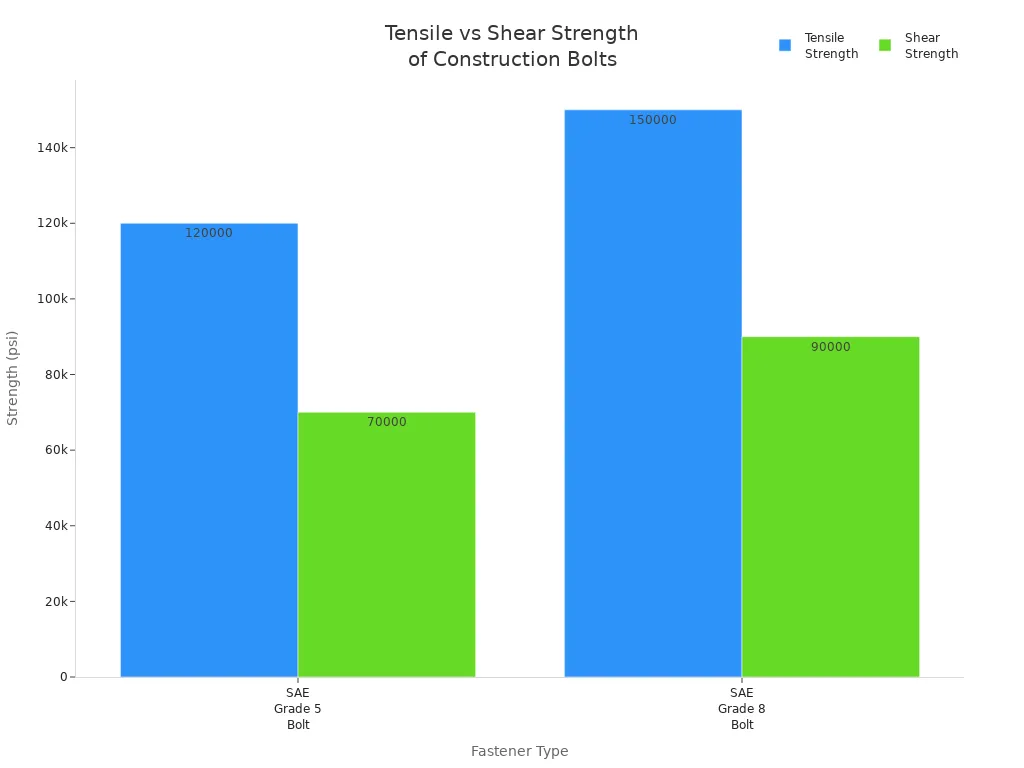

When you choose fasteners for construction, you want to know how much weight they can hold and how strong they are. Bolts and screws have different strengths. Bolts, especially high-grade ones, have very high tensile and shear strength. This means they can handle a lot of pulling and sideways forces. For example, a Grade 8 bolt can reach a tensile strength of 150,000 psi and a shear strength of about 90,000 psi. Screws, like lag screws, do not have standard strength ratings. Their strength can change a lot depending on the material and size.

Here is a table that shows the difference in strength between common bolts and screws:

| Fastener Type | Tensile Strength (psi) | Shear Strength (psi) | Notes |

|---|---|---|---|

| SAE Grade 5 Bolt | 120,000 | ~70,000 | Shear strength about 60% of tensile strength |

| SAE Grade 8 Bolt | 150,000 | ~90,000 | High strength carbon steel bolt |

| ASTM A325 / A490 | N/A | N/A | Structural bolts with published values, follow similar shear-to-tensile ratio |

| Stainless Steel Bolt | N/A | ~60% of tensile | Similar shear-to-tensile strength ratio applies |

| Lag Screws | N/A | N/A | Usually ungraded, no standardized tensile or shear strength values available |

Note: Bolts have clear strength ratings, so you can trust them for heavy-duty jobs. Screws do not always have these ratings, so you need to be careful when using them for important tasks.

Bolts also give you more clamping force. This means they squeeze materials together tightly when you use a nut. Screws rely on their threads to grip the material, so they do not squeeze as hard. You should use bolts when you need a strong, secure hold, like in steel frames or heavy machinery.

- Bolts work best for high load-bearing and structural jobs because they have more clamping force and strength.

- Bolts give you a secure hold and are great for construction and machines.

- Screws have lower clamping force. They work well for lighter loads and quick jobs.

- Screws are easier to install, but they do not hold as much weight.

- You can adjust or remove bolts by taking off the nut, which makes them reliable for big projects.

Here is a table that compares bolts and screws in structural uses:

| Feature | Bolts | Screws |

|---|---|---|

| Material | High-strength steel, stainless steel | Stainless steel, copper, brass, plastic |

| Application | Critical engineering structures | Light structural, decorative parts |

| Hole requirements | Pre-drilled clearance hole for nut | Threaded hole or self-tapping |

| Clamping force | High | Usually low |

| Reliability | High | Low |

| Load carrying capacity | High (larger diameter possible) | Low (limited by smaller diameter) |

| Strength | Stronger | Weaker |

Load Capacity

The load capacity of a fastener tells you how much weight it can safely hold. Bolts come in different grades, and each grade has its own strength. For example, SAE Grade 2 bolts are for light jobs, while SAE Grade 8 bolts can handle very heavy loads, up to 150,000 psi. Screws, especially lag screws, do not have these clear grades. Their load capacity depends on the material, size, and how you install them.

| Bolt Grade/Class | Approximate Strength (psi) | Typical Applications |

|---|---|---|

| SAE Grade 2 | 60,000 – 74,000 | Household repairs |

| SAE Grade 5 | 105,000 – 120,000 | Automotive, military, machinery |

| SAE Grade 8 | Up to 150,000 | Heavy machinery, aerospace |

| ISO Class 8.8 | Comparable to Grade 5 | Automotive, machinery |

| ISO Class 10.9 | Comparable to Grade 8 | Heavy machinery, industrial |

| ISO Class 12.9 | Strongest metric grade | Critical applications, engines |

| ASTM A307 Grade A | 60,000 | Non-critical construction |

| ASTM A307 Grade B | Up to 100,000 | Piping, flanged joints |

You may wonder about lag bolts and structural screws. Structural screws are made from heat-treated steel, so they can be as strong as or even stronger than lag bolts. They also cause less wood splitting and do not need pre-drilling. You can use structural screws for decks and frames, and they often replace lag bolts in these jobs. Lag bolts still work best for very thick materials and the heaviest loads, like supporting machines or buildings.

Tip: If you need to hold up a lot of weight or build something that must last, pick a bolt screw with a high grade. For lighter jobs or quick fixes, a screw may be enough.

You should always match the fastener to your project. Bolts give you more strength and safety for big jobs. Screws help you finish lighter work quickly. Knowing the difference helps you build safer and stronger structures.

Installation

Tools

When you install bolts, you need more than just your hands. You must use a wrench or socket for the bolt head and another tool for the nut. Sometimes, you also need washers. This means you often work with two tools at once. Screws are much simpler. You only need a screwdriver or a power drill. You can finish the job faster because you do not have to hold a nut or use extra parts.

Here is a quick comparison:

- Bolts: Wrench, socket, sometimes washers, and a nut.

- Screws: Screwdriver or drill.

Tip: If you want to save time and use fewer tools, screws are the better choice.

Complexity

Bolts take more steps to install. You must line up the bolt, add a washer if needed, and then thread on the nut. You tighten both sides, which can be tricky in tight spaces. Screws are easier. You just drive them in. You do not need to reach both sides of the material.

Key points to remember:

- Bolts have more parts and steps.

- Bolts take longer to install.

- Screws go in quickly and easily.

If you work in a small space, bolts can be hard to use. You need room for both the bolt and the nut. Screws fit into tight spots with no problem.

Adjustability

You might need to adjust or remove fasteners later. Bolts make this easy. You just loosen the nut and pull out the bolt. Screws can be harder to remove, especially if they get stripped. Stripped screws happen when you use the wrong tool or too much force. You may need special tools or extra effort to get them out.

Note: Bolts are better if you plan to take things apart or make changes in the future. Screws can get damaged and may be tough to remove if not installed carefully.

Choosing the right fastener helps you finish your project faster and makes future repairs easier. Bolts give you more control for adjustments. Screws offer speed and simplicity for quick jobs.

Material Use

Wood

Wood is used a lot in building. Picking the right fastener makes your project safer. Construction screws are best for wood frames and strong joints. These screws have sharp threads and tough steel. They grip wood tightly and hold heavy things. You can use them for frames, floor joists, and other parts that need strength. Their Torx or square heads let you turn them without slipping.

Deck screws are good for decks and fences outside. They do not rust and have sharp threads. This helps them go into treated wood without stripping. But deck screws are not as strong as construction screws. If you need to hold a lot of weight, use construction screws.

| Feature | Deck Screws | Construction Screws |

|---|---|---|

| Primary Use | Decking, fencing (outdoor) | Framing, heavy-duty wood joints |

| Material | Stainless steel, corrosion-resistant | Hardened steel, high strength |

| Thread Design | Sharp, coarse threads | Aggressive threads for strong grip |

| Head Type | Bugle head | Torx or square drive |

| Strength & Application | Weather-resistant, lighter loads | Load-bearing, structural connections |

Tip: For wood frames or jobs that hold weight, use construction screws or structural wood-to-wood screws. These can replace lag bolts and make your work faster and safer.

Metal

Metal jobs need fasteners that hold heavy loads and stop movement. Bolts give the most holding power and keep things tight. You use bolts for steel beams, metal frames, and big jobs. Bolts need nuts and washers, so putting them in takes more time and space.

Screws for metal are quicker and easier to use. You drive them right into the metal. Screws are best for lighter jobs or when you might need to take them out later. Screws do not hold as much weight as bolts.

- Bolts make strong, safe connections for heavy metal work.

- Screws are fast to put in and good for lighter jobs.

- Always pick the right fastener for the load and metal type.

- Use coatings that stop rust if your project gets wet.

Note: The fastener you pick changes how strong and long-lasting your metal project is. Use bolts for strength, and screws for quick jobs or when you need to adjust things.

Other Materials

Sometimes you need to fasten composite, masonry, or concrete. Each one needs a special fastener. Here is a quick guide:

| Fastener Type | Suitable Material | Application / Notes |

|---|---|---|

| Expansion Anchors | Grout-filled concrete block | Used for heavy jobs; they expand in the hole to hold tight |

| Sleeve Anchors | Hollow masonry | Hold the back of thin walls; good for hollow blocks |

| Cast-in Anchorages | Grouted concrete or masonry | Put in while building walls; includes bolts and plates |

| Screw Anchors | Masonry, concrete | Easy to use; best for light or temporary jobs |

| Wall Ties | Composite masonry walls | Connect brick or block layers for strength and sharing weight |

Wall ties are important in composite masonry. They join layers so the wall is stronger. Always follow building rules for how far apart and deep to put them.

Tip: For concrete or masonry, use anchors or wall ties made for that material. This keeps your building safe and strong for a long time.

Cost

Price

When you plan a construction project, you need to think about the price of fasteners. Bolts and screws have different costs. Bolts usually cost more than screws at the start. High-strength bolts use more metal and need special coatings. Screws are cheaper and easier to find in most stores.

Many things can change the price of fasteners. You might see prices go up because of:

- Rising costs for steel, aluminum, and other metals.

- Tariffs on imported fasteners, sometimes up to 25% or more.

- Supply chain problems, like delays or shortages.

- Rules that require you to buy American-made fasteners, which can cost more.

- Higher demand for fasteners when more people build things.

- Fewer discounts when prices go up or when you buy less.

These changes can make your project cost more. If fastener prices rise, your whole budget can go over. You may also face delays if you cannot get the fasteners you need.

Tip: Always check fastener prices before you start your project. This helps you avoid surprises and keeps your budget on track.

Labor

Labor costs matter as much as the price of the fastener itself. Bolts take longer to install. You need to drill holes, use nuts and washers, and tighten everything with tools. Screws go in faster with a drill or screwdriver. This saves time and money on simple jobs.

However, bolts can save you money over time. They last longer and need less maintenance. Screws may loosen or rust, so you might need to replace them more often. This adds to your labor costs later.

Here is a table to help you compare long-term costs:

| Aspect | High Strength Bolts | Traditional Fasteners (Screws) |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance Cost Over Time | 30–50% less (better durability) | Higher (more replacements needed) |

| Failure Rate | Low | High |

| Inspection Frequency | Less frequent | More frequent |

| Downtime | Less | More |

If you want to save money in the long run, bolts may be the better choice for big projects. Screws work well for quick jobs but can cost more in repairs and replacements over time.

Pros and Cons

Bolts

Bolts give you strong and secure connections in construction. You can use them for heavy-duty jobs and structural work. Here are some key pros and cons to consider:

Pros:

- High load capacity makes bolts perfect for supporting heavy structures.

- Secure fastening keeps your project safe and stable.

- Versatility allows you to use bolts with wood, metal, and concrete.

- Many types exist, such as anchor bolts, U-bolts, and eye bolts, each with special uses.

- Bolts are reusable. You can remove and reinstall them if you need to make changes.

- Accessories like Nord-Lock washers help bolts resist vibration and loosening.

Cons:

- Installation takes more time because you need to use nuts, washers, and sometimes special tools.

- You must access both sides of the material to install bolts, which can be hard in tight spaces.

- Some bolts, like stud bolts or threaded rods, are harder to handle and cost more.

- Bolts can corrode if you do not use the right coating or material.

- You need to follow precise steps for installation, especially with anchor bolts.

Tip: Choose bolts when you need maximum strength and plan to adjust or repair the structure in the future.

Screws

Screws work well for many construction projects, especially when you want quick installation and easy removal. The table below shows the main pros and cons of common screw types:

| Screw Type | Pros | Cons |

|---|---|---|

| Drywall Screws | Cost-effective; less likely to strip | Brittle; can rust over time |

| Wood Screws | Strong grip; versatile; less brittle | More expensive; may need pre-drilling |

General Pros:

- Screws have strong holding power because of their threads.

- You can remove and reuse screws easily, which helps with repairs.

- Screws resist pulling out, making them reliable for many jobs.

General Cons:

- You need different screwdrivers or drill bits for each screw type.

- Power tools are usually required, so you must keep batteries charged.

- Screws can break if you use too much force or the wrong type.

Screws give you flexibility and speed, but bolts offer more strength for heavy-duty needs.

Decision Guide

Project Type

Choosing the right fastener depends on your project. You need to think about what you are building, how much weight it must hold, and what materials you use. Here are some scenarios to help you decide:

- Heavy Structures: If you build a deck, steel frame, or support beam, use bolts. Bolts give you the strength and safety you need for big jobs. You often need more than one bolt to stop parts from moving or bending. Pick the right bolt grade and size for the load.

- Medium Loads: For projects like fences, outdoor furniture, or wooden frames, you can use lag screws or structural screws. These fasteners work well for wood and give good holding power. Make sure you choose the right length and thread type for the material.

- Lightweight Projects: If you put together cabinets, drywall, or small metal parts, screws are a good choice. Screws are easy to install and remove. They work well for jobs that do not need to hold much weight.

- Special Materials: For concrete, brick, or masonry, use anchors or special screw types. These fasteners are made to grip hard materials and keep your project safe.

- Outdoor or Wet Areas: Pick fasteners made from stainless steel or with special coatings. These materials stop rust and last longer in tough weather.

Tip: Always match the fastener to the job. Think about the load, the number of fasteners, and the environment.

You now know bolts give you the best strength for heavy-duty construction. Screws work well for lighter, quick jobs. Your choice depends on the load, material, and how you plan to install the fastener. Use this table to help you decide:

| Choose Bolts When… | Choose Screws When… |

|---|---|

| You need high strength | You want fast, easy installation |

| Vibration resistance matters | The load is light |

| Reuse is important | Space is limited |

Tip: Always check the standards and match the fastener to your project needs for safe, lasting results.

FAQ

What is the main difference between a bolt and a screw?

A bolt needs a nut to hold things together. A screw makes its own threads in the material. You use bolts for heavy jobs and screws for lighter, faster work.

Can you use screws instead of bolts for heavy-duty projects?

You should not use screws for heavy-duty projects. Bolts give you more strength and safety. Screws can break or loosen if you use them for big loads.

How do you choose the right fastener for wood?

Pick construction screws for wood frames and decks. Use bolts if you need extra strength, like for beams or posts. Always match the fastener to the weight and type of wood.

Do bolts or screws last longer outdoors?

Bolts last longer outdoors if you pick stainless steel or coated types. Screws can rust or loosen faster. Always choose weather-resistant fasteners for outdoor projects.