In the world of industrial fasteners, blind rivets, also known as pop rivets, have revolutionized how we assemble materials. Whether you’re working in aerospace, automotive manufacturing, construction, or electronics, understanding the different types of blind rivets and their applications is crucial for making informed decisions. This blog post explores the structure, types, advantages, and applications of blind rivets, providing valuable insights for engineers, procurement professionals, and DIY enthusiasts.

Introduction to Blind Rivets

Blind rivets are a type of fastener designed for single-sided installation. They consist of a rivet body and a mandrel. The mandrel is extracted from the rivet body, causing the rivet body to expand and creating a secure connection between the materials being joined. Here’s an in-depth look at the structure, types, applications, and manufacturing process of blind rivets.

Structure of Blind Rivets

A blind rivet consists of the rivet body and the mandrel. The rivet head comes in various shapes, including round, flat-round, and countersunk heads, catering to different installation requirements. The mandrel is a slender rod with one end attached to the rivet body. When a riveting tool is used to pull the mandrel, it causes the rivet body to expand, creating a tight connection.

Types of Blind Rivets

Blind rivets come in a variety of forms, each designed for specific applications:

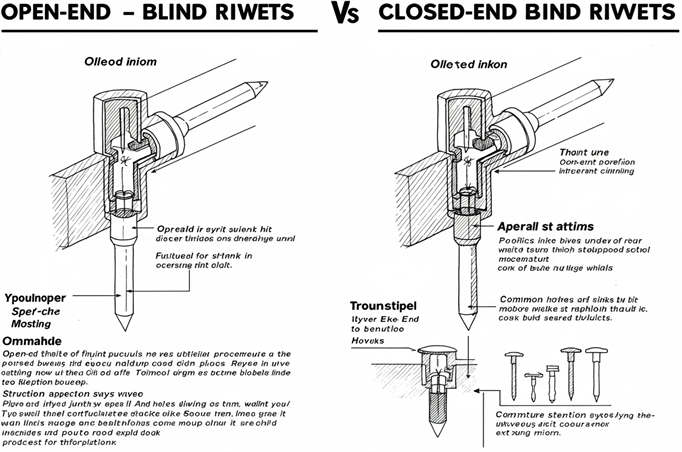

By Structure

- Open-End Blind Rivets: The tail of the rivet body is open, allowing for easier extraction of the mandrel. These rivets are easy to install and are commonly used in general-purpose applications.

- Closed-End Blind Rivets: These rivets have a closed tail, offering superior strength and sealing properties. They are ideal for environments that require high sealing capabilities.

- Plastic Blind Rivets: Made from plastic for both the rivet body and the mandrel, these rivets are lightweight and cost-effective. They are suited for applications where high strength is not a primary concern.

- Stainless Steel Blind Rivets: These rivets are known for their corrosion resistance and strength, and they are used in humid or corrosive environments.

- Aluminum Alloy Blind Rivets: Lightweight and moderately firm, these rivets are perfect for aerospace applications, vehicles, and other industries requiring reduced weight without compromising strength.

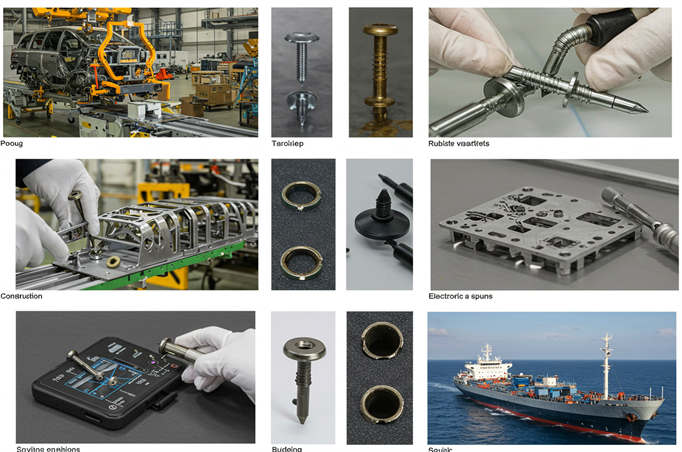

By Application

- Automotive Industry: Used to fasten components like car bodies and windows, these rivets securely join materials such as steel, plastic, and aluminum alloys to ensure the vehicle’s stability and safety.

- Aerospace: They connect lightweight metals such as aluminum alloys and titanium with carbon fiber composites and other materials, offering strength and weight reduction, which is critical for aircraft performance.

- Construction: Blind rivets fasten materials like drywall, wood, steel, and plastics in both indoor and outdoor applications, ensuring strong and durable connections.

- Electronics: They secure components such as circuit boards and enclosures, providing good electrical insulation and fracture resistance.

- Shipbuilding: Blind rivets are crucial for joining the hull structure and various ship components, resisting corrosion in marine environments.

- Mechanical Manufacturing: Used in various machinery assemblies, these rivets offer reliable fastening and torque tightening.

Advantages of Blind Rivets

- Simple Operation: Only one-sided installation is required. A riveting tool secures the rivet without inheritance from the other side.

- High Clamping Strength: The mandrel is pulled out, causing the rivet body to expand and form a tight, secure connection capable of withstanding significant tensile and shear forces.

- Versatility: Blind rivets can connect materials of varying thicknesses and types, making them suitable for various industries and applications.

- Good Sealing Performance: Closed-end rivets prevent leaks of liquids and gases, making them ideal for applications where sealing is crucial.

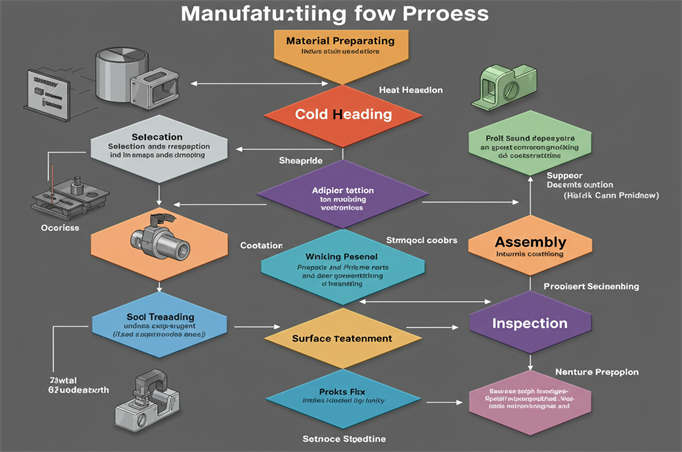

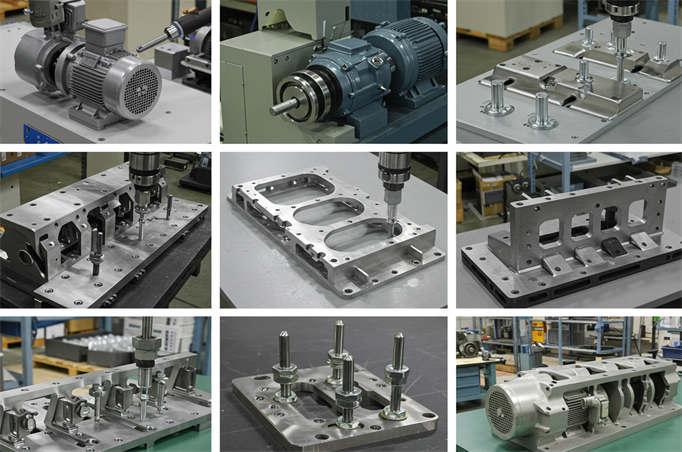

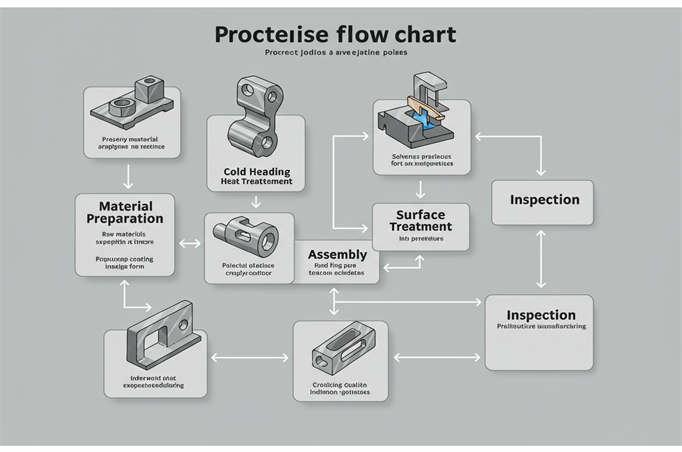

Manufacturing Process of Blind Rivets

The production of blind rivets involves several key steps to ensure precision and durability:

1. Material Preparation

The materials used for manufacturing blind rivets vary depending on the intended use. Common materials include stainless steel, aluminum alloys, and carbon steel. Stainless steel offers excellent corrosion resistance and strength, ideal for humid or corrosive environments. Aluminum alloys are lightweight with moderate strength, perfect for aerospace and vehicle applications. Carbon steel, while inexpensive, offers high strength for general industrial applications.

2. Cold Heading Process

Cold heading is one of the most critical manufacturing processes. During this process, the wire is struck by a punch to shape it into the desired form. This is done under normal temperature, and the metal is compressed into the shape of the rivet head. The cold heading process is highly efficient, saving material and energy. However, when making products with significant bends, the process can cause cracking, making it unsuitable for specific designs.

3. Heat Treatment

Heat treatment plays a critical role in enhancing the strength and hardness of the rivets. Common treatments include quenching and tempering. Quenching increases hardness but makes the rivet more brittle, while tempering alleviates internal stresses, improving toughness. Unique heat treatment processes, such as solution treatment, may be used for stainless steel or other specific materials.

4. Surface Treatment

Surface treatments are applied to improve corrosion resistance and aesthetics. Common methods include:

- Electroplating: Zinc, copper, nickel, and chrome coatings improve corrosion resistance and appearance.

- Phosphating: This process creates a phosphate coating that enhances surface roughness, increasing friction between the rivet and the material.

- Oxidizing (Blackening): An oxidation layer is applied to reduce corrosion, typically followed by an oil coating for additional protection.

5. Assembly and Inspection

Once the rivet body and mandrel are formed, they are assembled to ensure proper fitment. The mandrel should be aligned within the rivet body for efficient expansion during installation. After assembly, the rivets undergo various quality checks, including visual inspections, dimensional checks, and performance tests, to ensure they meet industry standards.

Surface Treatment Methods for Blind Rivets

Several surface treatment options are available to enhance the performance and longevity of blind rivets. These treatments include:

- Zinc Electroplating: This process creates a zinc layer on the rivet surface, providing excellent corrosion resistance at a relatively low cost. It’s commonly used for carbon steel rivets.

- Copper, Nickel, and Chrome Electroplating: These metals are chosen for their superior corrosion resistance and enhanced aesthetic appeal.

- Zinc-Nickel Alloy Electroplating: This method offers better corrosion resistance than simple zinc plating and is used for applications exposed to more severe conditions.

- Hot-Dip Galvanizing: Rivets are dipped in molten zinc to form a durable, corrosion-resistant layer. This treatment is thicker than electroplating and ideal for harsher environments, although it may affect the rivet’s rotation ability.

- Phosphating: A phosphate coating improves surface roughness and adhesion, while oils or greases are applied for enhanced corrosion resistance.

- Oxidizing (Blackening): A low-cost method that creates an oxidation layer for rust protection, but it requires oiling to maintain its effectiveness.

- Anodizing (for Aluminum Rivets): Anodizing aluminum increases its corrosion resistance and allows color customization.

- Spraying: Paint is applied to the rivet’s surface, which can be customized for aesthetic purposes.

Choosing the Right Surface Treatment

The choice of surface treatment depends on the application’s specific requirements, including factors like corrosion resistance, aesthetics, cost, and the environmental conditions in which the rivet will be used.

Differences Between Bolts and Blind Rivets

While both bolts and blind rivets are commonly used for fastening, they differ in structure, installation, and application:

Structure

- Bolts: Bolts typically consist of a head and shaft. Depending on the type, they can be solid or hollow.

- Blind Rivets: Composed of a rivet body and mandrel, with various head shapes for different installation needs.

Installation

- Bolts: Installation requires two-sided access. One side holds the bolt while the other secures it with a nut.

- Blind Rivets: Arivet gun can be installed from one side, simplifying installation in hard-to-reach spaces.

Strength

- Bolts: Generally provide higher connection strength and are suitable for applications that experience high tensile and shear forces.

- Blind Rivets: Although slightly weaker than bolts, blind rivets are still highly effective for most industrial applications and offer good connection strength.

Main Uses

- Bolts: Used in machinery, aerospace, and automotive industries, particularly where high strength is required.

- Blind Rivets are ideal for applications where only one side is accessible, such as construction, electronics, and shipbuilding.

Types of Blind Rivets

Blind rivets can be classified based on structure, material, and application:

By Structure

- Open-End Blind Rivets: Easy to install with a simple mandrel extraction process.

- Closed-End Blind Rivets: Offer better strength and sealing capabilities for more durable environments.

- Single and Multi-Groove Blind Rivets: These rivets feature one or more grooves on the body, which is ideal for joining materials of different thicknesses.

By Material

- Aluminum Alloy Blind Rivets: Lightweight and moderate strength for aerospace and automotive applications.

- Stainless Steel Blind Rivets: Excellent corrosion resistance, perfect for harsh environments.

- Carbon Steel Blind Rivets: Cost-effective and strong, ideal for general industrial use.

- Copper Blind Rivets: Good electrical conductivity and corrosion resistance for specialized applications.

By Application

- General Purpose Rivets: Used in construction, electronics, and shipbuilding.

- Special Purpose Rivets: Designed for high-strength applications, such as automotive and aerospace industries.

Blind rivets are versatile, cost-effective, and reliable fasteners across various industries. Their easy installation, excellent clamping strength, and ability to join materials with different thicknesses have become essential in modern manufacturing and construction. Engineers can ensure optimal application performance by choosing the appropriate type, material, and surface treatment.

Blind rivets have become indispensable in modern manufacturing, offering a versatile and efficient solution for joining materials from a single side. By understanding the various types of blind rivets, their unique advantages, and suitable applications, you can optimize your projects for both performance and cost-effectiveness. Remember to consider factors like material type, thickness, required strength, and environmental conditions when selecting blind rivets. As technology advances, the future of blind rivets promises even more significant innovations in design, materials, and manufacturing processes, further enhancing their value across industries.