You want the best cold headed fasteners for your job. Top companies like Morton Manufacturing, Ideal Fasteners, and Grandeur Fasteners, Inc. are known for their AS9100 and NADCAP certifications. These companies make many fasteners and offer custom options. The table below lists top companies and their certifications. Pick a supplier with lots of experience and good customer reviews for the best results.

Manufacturer | Certifications Held |

|---|---|

Morton Manufacturing | |

Ideal Fasteners | AS9100, NADCAP |

Grandeur Fasteners, Inc. |

Key Takeaways

Pick manufacturers that have important certifications like AS9100 and ISO 9001. These certifications show the fasteners are good and reliable.

Find companies that make custom fasteners. Custom fasteners help you get parts that fit your needs.

Choose suppliers who have a history of good quality control. Good testing and careful making create strong and useful fasteners.

Think about how the supplier helps customers and how fast they answer. Good support fixes problems fast and keeps your projects going.

Top Manufacturers 2025

STALCOP Metal Forming LLC

STALCOP Metal Forming LLC makes cold headed fasteners with great accuracy. They help many industries like power, electric cars, and airplanes. STALCOP has lots of products, such as fuse parts, transformer pieces, terminals, and connectors. They know how to work with copper, steel, aluminum, nickel, brass, silicon bronze, and stainless steel. If you work with cars, you can get custom OEM parts like starter terminals and battery connectors.

Specialty/Offering | Description |

|---|---|

They make parts for power, electric cars, planes, and machines. | |

Product range | Their products include fuse parts, transformer pieces, terminals, connectors, and cables. |

Industry focus | They help companies with electrical power, heat control, and special parts. |

Material expertise | They use copper, steel, aluminum, nickel, brass, silicon bronze, and stainless steel. |

Automotive innovation | They make custom OEM parts for cars, like starter terminals and battery connectors. |

Chicago Nut & Bolt, Inc.

Chicago Nut & Bolt, Inc. is known for making cold headed fasteners with advanced tools. You can buy cold-formed, hot-forged, or CNC fasteners. They make small and big orders. Their team uses special machines and extra steps to make sure every part is strong and accurate. Chicago Nut & Bolt can design custom parts for tough jobs and fill orders of any size.

Custom parts for any size and volume

ISO-certified, RoHS compliant, and meets SAE, ASME, or ASTM standards

Production Capability | Description |

|---|---|

Types of Nuts | They make hex, square, through, round, countersunk, flanged, and socket headed nuts. |

Materials Used | They use Inconel®, titanium, nickel, copper, brass, bronze, aluminum, stainless steel, and carbon steel. |

Services Offered | They offer drilling, knurling, tapping, thread grinding, rolling, warehousing, prototyping, and packaging. |

Production Runs | They make prototypes, small runs, and large runs. |

Compliance | Their parts meet SAE, ASME, ASTM standards, are RoHS compliant, and ISO-certified. |

Delivery Options | They offer JIT delivery, emergency, and rush services. |

The Fastron Co.

The Fastron Co. makes cold headed fasteners that are high quality and precise. They have a strong reputation because they focus on zero defects and deliver on time. Many buyers trust Fastron to meet their needs and provide reliable fasteners for important jobs.

The Fastron Co. is known for always making quality fasteners and being precise. Many people trust them for cold headed fasteners.

KD Fasteners, Inc.

KD Fasteners, Inc. has one of the biggest selections of cold headed fasteners. You can order washers, nuts, hex bolts, studs, machine screws, self-tapping screws, and more. KD Fasteners makes custom fasteners and handles both big and small orders. They use many materials and offer different finishes and extra steps, like drilling holes and nylon patching.

Product Lines | Customization Options |

|---|---|

Washers | They make fasteners to your print. |

Nuts | They can use many types of materials. |

Hex bolts | They do big orders and small orders. |

Studs | They offer different plating choices. |

Machine screws | They can drill holes as a secondary step. |

Self-tapping screws | They do nylon patching and passivation. |

Thread forming screws |

|

Socket screw products |

|

Rivets |

|

Self-drilling screws |

|

Lock washers |

|

Anchors |

|

Sems screws |

|

Weld screws and nuts |

|

Dry wall screws |

|

Custom fasteners (e.g., Flange bolts) |

|

American Bolt Corporation

American Bolt Corporation is known for making quality cold headed fasteners. You can trust their products because they are part of NTA’s QSV program and test their fasteners’ strength. Since 2006, they have worked with NTA to improve quality, so they are a good choice for your projects.

Participates in NTA’s QSV program

Certified bending yield strength

Quality control partnership with NTA since 2006

Fastco Industries

Fastco Industries makes lots of cold headed fasteners and keeps quality high. Their manufacturing is steady, so you get the same results every time. Fastco controls how tools are made, so they can make custom fasteners. Their tub tracking system helps find parts quickly, and regular maintenance keeps machines working well. The PLEX ERP system connects all their processes for better management and quality.

Strategy | Description |

|---|---|

Predictability in Manufacturing | They make sure every batch is the same and check quality. |

Greater Control of Tooling Creation | They can make custom and precise fasteners. |

Tub Tracking for Improved Parts Location | Their system helps find and manage parts fast. |

Superb Preventative Maintenance | They fix machines before problems happen. |

Advanced PLEX ERP System | Their system helps manage everything and keep quality high. |

Bar coding for efficiency

Just-in-time delivery

Attentive customer service

TFG USA

TFG USA helps many industries like cars, planes, defense, electronics, and consumer products. Their cold headed fasteners have strict quality checks. TFG USA has ISO 9001 certification and offers good prices and clear communication. People trust them because they are reliable.

Automotive, aerospace, defense, electronics, consumer products

ISO 9001 certified

Known for quality management and good prices

Ideal Fasteners

Ideal Fasteners is known for great customer service and technical help. You get high-quality cold headed fasteners and expert advice. Their lab tests steel framing fasteners for free, showing they care about customers. Ideal Fasteners focuses on service, quality, and advice, so you get certified products and quick delivery. Their team helps keep your production running smoothly.

“I never try to sell anything… I just help people and they buy from me.”

— Ideal Fasteners representative

Abbott

Abbott has reached many goals in the cold headed fastener business. You benefit from their 75 years of making fasteners and their worldwide reach. Abbott invests in U.S. factories with new CNC machines, making precise fasteners for over 50,000 customers. Trade journals have shared Abbott’s story, showing their focus on quality and new ideas.

Achievement/Recognition | Description |

|---|---|

They celebrated 75 years in September 2023, showing leadership in fasteners. | |

Featured in Link Magazine | A trade journal wrote about Abbott’s story and focus on quality and new ideas. |

Global Reach | They have partner factories and warehouses around the world. |

Investment in U.S. Manufacturing | They built a new CNC factory to make precise parts. |

Service to Over 50,000 Customers | Abbott serves many customers and cares about service. |

Cold Headed Fasteners: Quality and Reliability

Certifications

It is important to look for strong certifications when picking cold headed fasteners. These certifications mean the company follows strict rules. They also show that the fasteners are reliable. Many top companies have AS9100, NADCAP, or ISO 9001:2015 certifications. These standards help you trust the fasteners you buy. You might also see certificates for plating, heat treating, or materials. Some companies give you a Certificate of Conformance with your order. This paper proves your fasteners meet all the rules. You can ask for inspection papers like DIN EN 10204 to track your fasteners. These steps help you feel sure about what you buy.

Quality Control

You want fasteners that work right every time. The best companies use advanced machines to make cold headed fasteners. These machines are very precise. On the factory floor, you will see cold heading machines. They use special dies and punches to shape the fasteners. This keeps them strong. After making the fasteners, workers test them for size and strength. They also check how well they work. Vision sorting uses cameras and computers to find tiny flaws. Only perfect fasteners get sent to you. Companies also test for tensile strength, hardness, and fatigue. These tests make sure your fasteners can handle hard jobs. You get fasteners that last and do what you need.

Advanced cold heading machines help make fasteners precise.

Testing stations check size, strength, and how well they work.

Vision sorting uses cameras to find small problems.

Regular tests check tensile strength, hardness, and fatigue.

Industry Compliance

You want fasteners that follow all the rules for your industry. The best companies meet standards like ISO 898-1, ASTM A574, SAE J429, and NAS/AN/MS. These rules help you know your fasteners are safe. Companies also follow ISO 9001:2015 and QS 14000 for quality and the environment. You can ask for lot traceability and dates on your fasteners. Some companies use Statistical Process Control to keep quality high. You may see first articles, PPAP, DFAR, and RoHS compliance. These steps show that quality and rules go together. You get fasteners that fit your project and follow all the rules.

Aspect | Details |

|---|---|

ISO Certification | Meets ISO 9001:2015 for fasteners you can trust. |

Quality Control Measures | Uses strict testing and checks for every batch. |

Inspection Documentation | Gives you inspection reports so you can track your fasteners. |

Tip: Always ask your supplier for certifications and inspection papers. This helps you make sure your fasteners are right for your job.

Comparison Table

When you pick cold headed fasteners, you want to know how each company is different. The table below lets you see important things fast.

Manufacturer | Product Range | Quality Standards | Reliability | Customer Service | Global Reach |

|---|---|---|---|---|---|

STALCOP Metal Forming LLC | Wide, custom parts | ISO, AS9100 | High | Responsive | North America |

Chicago Nut & Bolt, Inc. | Large, custom runs | ISO, SAE, ASTM | High | Fast, flexible | USA |

The Fastron Co. | Precision, zero-defect | AS9100, NADCAP | Very high | Trusted, helpful | USA |

KD Fasteners, Inc. | Largest selection | ISO, custom standards | High | Quick, reliable | USA |

American Bolt Corporation | Quality, tested | NTA QSV, ISO | High | Attentive | USA |

Fastco Industries | Custom, consistent | ISO, PLEX ERP | Very high | Efficient, JIT delivery | USA |

TFG USA | Multi-industry | ISO 9001 | High | Clear communication | USA, global |

Ideal Fasteners | Certified, tested | AS9100, NADCAP | High | Expert advice | USA |

Abbott | Broad, precise | ISO, CNC quality | Very high | Global support | Worldwide |

Product Range

You need cold headed fasteners for lots of jobs. Some companies, like KD Fasteners, Inc., have many choices. You can get washers, nuts, bolts, screws, and special parts. STALCOP Metal Forming LLC and Abbott make custom fasteners for special needs. If you want perfect parts, The Fastron Co. and Fastco Industries focus on zero-defect fasteners.

Quality Standards

Quality is important when you buy fasteners. Most top companies have ISO certifications. Some, like Ideal Fasteners and The Fastron Co., have AS9100 and NADCAP for airplane jobs. American Bolt Corporation works with NTA’s QSV program to test strength. You can trust these companies to follow strict rules for cold headed fasteners.

Reliability

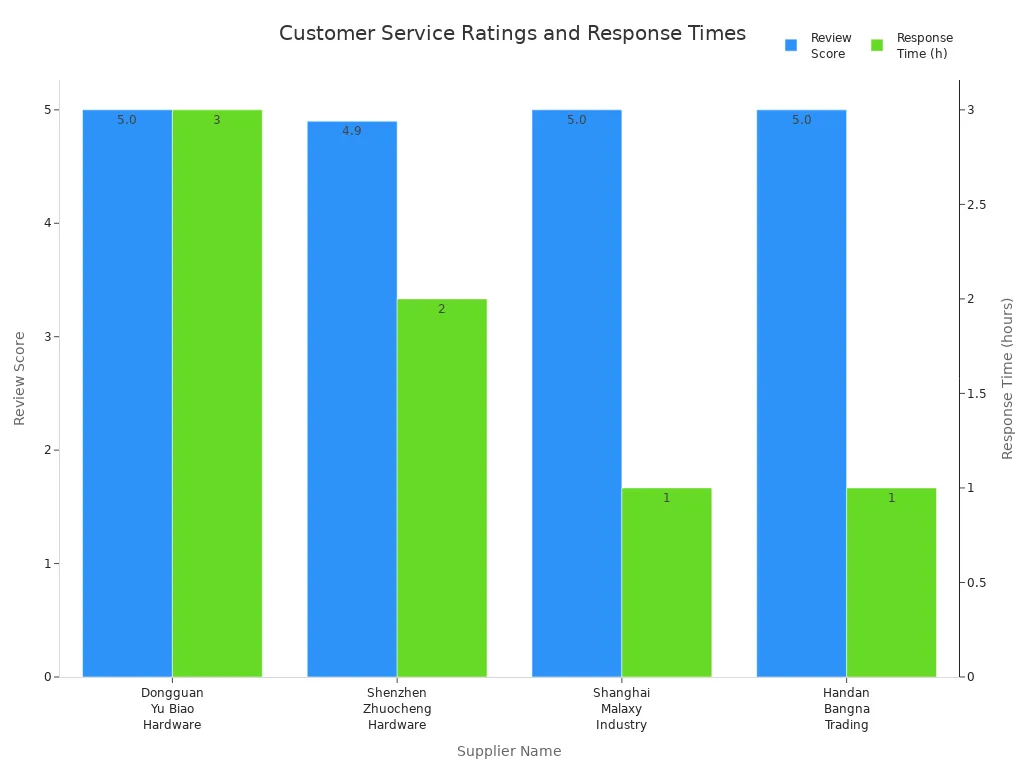

You want fasteners that work every time you use them. Fastco Industries uses smart systems to keep batches the same. The Fastron Co. and Abbott are known for being reliable. You can see high reorder rates and on-time delivery in the customer service table below.

Supplier Name | Review Score | Response Time | On-Time Delivery | Reorder Rate |

|---|---|---|---|---|

Dongguan Yu Biao Hardware Co., Ltd. | 5.0/5.0 | ≤3h | 93.5% | 38% |

Shenzhen Zhuocheng Hardware Co. Ltd. | 4.9/5.0 | ≤2h | 99.7% | 33% |

Shanghai Malaxy Industry Co., Ltd. | 5.0/5.0 | ≤1h | 99.6% | 19% |

Handan Bangna Trading Co., Ltd. | 5.0/5.0 | ≤1h | 100.0% | 20% |

Customer Service

You want quick answers and good help when you order cold headed fasteners. The table above shows top suppliers reply in less than three hours. You see high review scores and strong reorder rates. Fastco Industries and Ideal Fasteners give expert advice and fast delivery. Abbott helps over 50,000 customers all over the world.

Tip: Pick a supplier with fast replies and high review scores for the best results.

Global Reach

If you need fasteners in many places, look for companies with worldwide networks. Abbott and TFG USA help customers everywhere. The table below shows how some companies reach lots of countries and keep delivery distances short.

Manufacturer | Total Warehouse (Sq M) | Countries Served | Avg Distance to Customer (km) |

|---|---|---|---|

Ruihua Hardware | 950,000 | 165 | 290 |

Nestlé | 2,500,000 | 186 | 450 |

PepsiCo | 2,200,000 | 200+ | 380 |

Unilever | 1,900,000 | 190 | 420 |

JBS | 1,800,000 | 150 | 520 |

You can see that global reach helps you get cold headed fasteners fast, no matter where you work.

Choosing a Supplier

Key Factors

When you pick a supplier for cold headed fasteners, look at a few main things. You want a company that can make parts fast and right. This means they have strong manufacturing skills. Good product quality is very important. Bad fasteners can break and cost you more money. Price matters too. Try to find fair prices, but do not pick the cheapest if it means bad quality. Good customer service helps you fix problems and get answers quickly.

They can make custom cold headed fasteners.

They make high-quality products with no defects.

Their prices are fair for cold headed fasteners.

They give good support when you need help.

Tip: Do not choose a supplier just because they are cheap. Low prices can mean bad quality or slow shipping.

Customization

Sometimes you need special fasteners for your job. The best suppliers let you pick different materials, finishes, and sizes. Some companies help you design cold-headed bolts for your project. They use cold heading to make parts that fit your needs.

Manufacturer | |

|---|---|

Slidematic | Makes cold headed specials, screw machined parts, rivets, and springs. They help you save money with design analysis. |

Grandeur Fasteners | Makes custom fasteners from many materials. They have in-house tooling and design for special jobs. |

Addison Fasteners | Lets you pick drive styles, materials, finishes, and special products for tough jobs. |

Suppliers like Slidematic answer you fast and give personal help. Grandeur Fasteners uses many materials and makes tools in their own shop. Addison Fasteners can make your order quickly and lets you order small or big amounts.

Lead Times

You want your cold headed fasteners to arrive on time. How long it takes depends on what you order. Standard cold-headed bolts can come in one day or up to three weeks. Big orders can take up to fourteen weeks if it is your first time. Custom orders take longer and depend on what you need. If you order from another country, it can take up to twenty-six weeks because of shipping.

Order Type | Typical Lead Time |

|---|---|

Standard Parts | 1 day to 3 weeks (depends on how many you order) |

High Volume Standard Parts | 12 to 14 weeks (first-time order) |

Custom Orders | Time changes a lot based on what you want |

Overseas Suppliers | 24 to 26 weeks (includes shipping time) |

Note: If a supplier makes their own tools, they can make custom cold headed fasteners faster.

Warranty

You want to know your fasteners will last a long time. Many suppliers give a limited lifetime warranty for cold headed fasteners. This covers rust and defects if you use them the right way. You must follow the supplier’s rules for putting them in. The warranty is usually only for the first person who buys them. If you have a problem, you need to send the broken fasteners, pictures of your project, and your receipt. The warranty does not cover damage from using them wrong or from accidents.

Limited lifetime warranty for cold headed fasteners

Covers rust and defects if used the right way

Only the first buyer gets the warranty

You need proof of purchase and photos for claims

Tip: Always read the warranty rules before you buy cold headed fasteners.

You have lots of good choices for cold headed fastener makers. The table below shows what each company does best:

Manufacturer | Experience | Quality Control Measures |

|---|---|---|

Chicago Nut & Bolt | Many years making fasteners | They make parts that work well for important jobs. |

Stalcop | Over 100 years together | They use CNC machines and special ways to build parts. |

To pick the right company, try these steps:

Decide what parts you need and how many.

Look for companies that check their fasteners for quality.

See what services, certificates, and help they offer.

Talk to your favorite companies about your project.

Pick the one that fits what you want.

You can start looking now by asking these trusted companies for prices.

FAQ

What are cold headed fasteners?

Cold headed fasteners are metal parts shaped without heat. They are made at room temperature. You get bolts, screws, and rivets that are strong. This way of making fasteners saves metal. It also helps make parts with exact shapes.

How do I know if a manufacturer is reliable?

Check if the company has ISO 9001 or AS9100 certificates. Read what other customers say about them. Ask for reports that show their parts are tested. Good companies answer your questions fast. They also send your order on time.

Can I order custom cold headed fasteners?

Yes, you can ask for custom fasteners. Many companies let you pick the material, size, and finish. You can send your own design to them. If you need help, they can help you with the design.

What industries use cold headed fasteners?

Cold headed fasteners are used in cars and airplanes. You also find them in electronics and buildings. These parts are good for jobs that need strong connections.

How long does it take to get my order?

How long it takes depends on your order. Small orders can come in a few days. Big or special orders may take weeks. Ask your supplier when your fasteners will arrive.