When it comes to home improvement and construction projects, the choice of screws might seem like a minor detail. Still, it can make a significant difference in the overall quality and durability of the work. Drywall screws, in particular, play a crucial role in securing wall panels and other materials. Understanding the specifications and features of these screws, including the screw diameter, is essential for both professionals and DIY enthusiasts. In this blog post, we will delve into the world of drywall screws, exploring their sizes, materials, thread designs, and other essential elements that can impact your projects. Whether you’re hanging drywall for a new room or repairing an existing wall, having the right screws—along with the correct screw diameter—can ensure a smooth and successful outcome.

Drywall screw Specifications

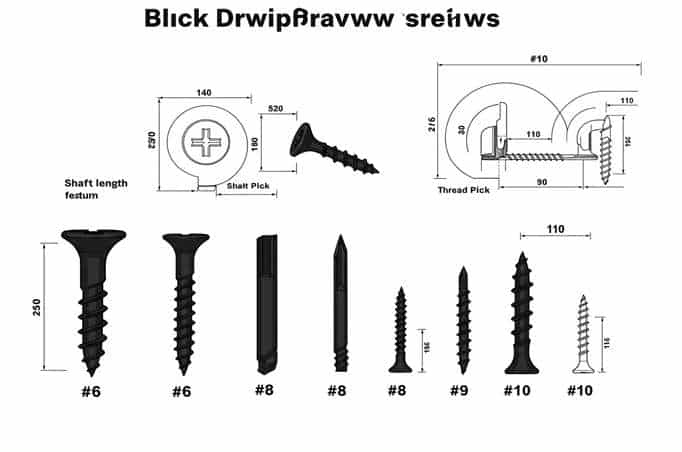

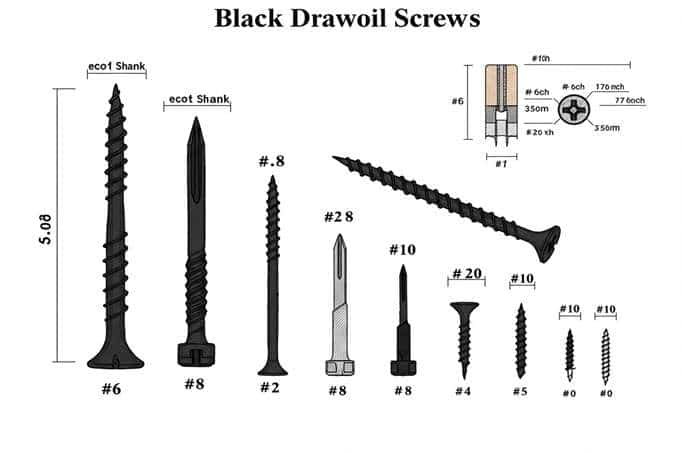

Screw specifications generally consist of two parts: the gauge number and the length. The gauge number indicates the screw diameter, while the length indicates how long the screw is. For example, #6 x 5/8” means the screw has a screw diameter of approximately 3.5 mm and a length of 5/8 inch.

Common drywall screw Sizes and Their Applications

- #6 (3.5 mm):These screws are used for securing thin drywall or lightweight materials. With a screw diameter of 3.5 mm, they are commonly used in home construction, such as in ceiling and wall drywall installations.

- #8 (4.2 mm):These screws are designed for thicker drywall or heavier materials. Their screw diameter of 4.2 mm makes them widely used in construction and decoration, especially when strong fixation is needed.

Length Choices

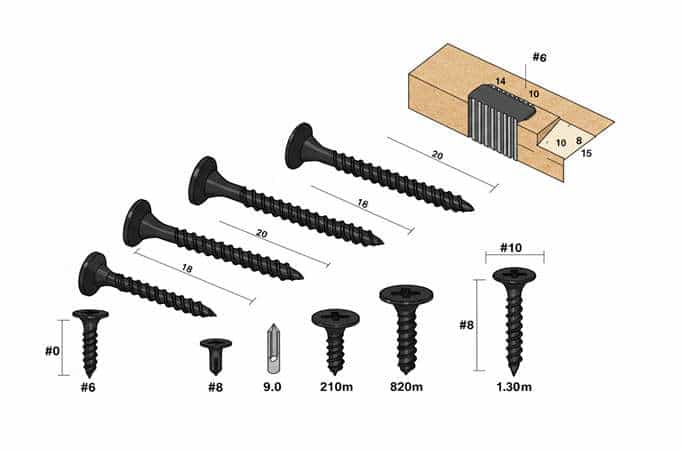

- Short screws (e.g., 5/8 inch):Suitable for securing thinner drywall or lightweight materials. They provide sufficient holding power without penetrating through the material.

- Medium-length screws (e.g., 1 to 1.5 inches):Suitable for most standard drywall thicknesses and heavier materials. These screws provide more remarkable holding power to ensure materials stay securely fixed.

- Long screws (e.g., 2 inches and above):Ideal for thicker drywall or when penetrating through thicker underlying materials. These screws ensure stability under various conditions.

Other Key Elements

- Materials:drywall screws are typically made from carbon steel or stainless steel. Carbon steel screws are heat-treated to improve hardness and strength, making them relatively inexpensive but prone to rusting. These screws are best for dry indoor environments. Stainless steel screws are corrosion-resistant, making them suitable for damp environments or places where rust resistance is essential, but they come at a higher cost.

- Surface Treatments:To ensure corrosion resistance and durability, screws are often treated with coatings such as zinc or nickel plating. Zinc-coated screws provide good corrosion resistance at a lower cost and are the most widely used surface treatment. Nickel-plated screws offer higher corrosion resistance and a more aesthetically pleasing appearance, but they are relatively expensive.

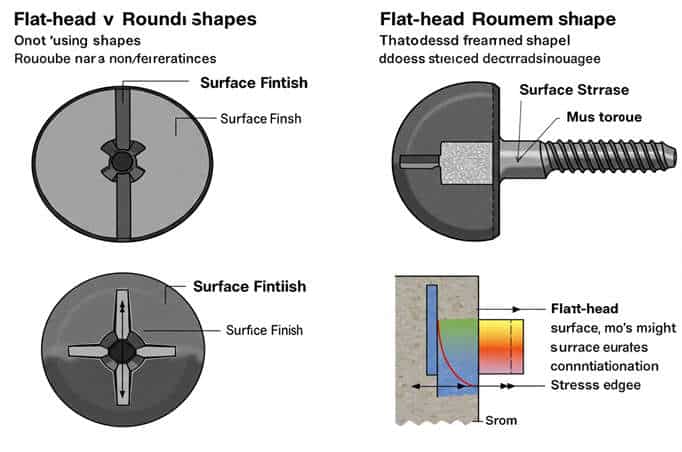

- Head Shape:drywall screws typically come with either flat heads or round heads. Flat head screws are level with the surface of the material after installation, making them ideal for decorative drywall where surface smoothness is essential. Round head screws protrude slightly, which helps distribute stress and reduce pressure on the drywall. These are suitable for thinner drywall materials.

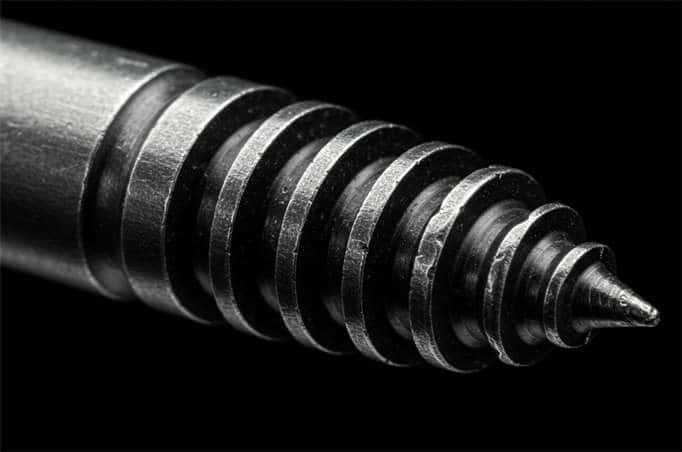

Thread Design of drywall screws

The thread design of drywall screws plays a crucial role in securing the materials. Below are some common types of threads used in drywall screws:

Thread Types

- Self-tapping threads:This is the most common thread design for drywall screw Self-tapping threads allow the screw to create its thread as it is driven into the material. These screws have widely spaced, deep threads that provide excellent grip in soft materials. For example, when securing drywall panels, self-tapping screws can easily grip the drywall and hold it firmly to the studs or other supporting structures.

- Coarse threads:Coarse-thread screws have more significant, more widely spaced threads. These screws are designed to transfer greater torque and allow the screw to penetrate more complex materials more efficiently. Coarse threads offer a deeper grip within the material, providing stronger pull-out resistance. These screws are better for securing drywall in situations where the base material is more complex.

- Fine threads:Unlike coarse threads, fine threads have smaller and tighter spacing. Fine-thread screws are excellent for providing a larger contact area between the threads and the material, which increases friction and offers a more stable grip. Fine-thread drywall screws are ideal for precise installations where a stable and tight fix is crucial, such as in decorative wallboard installations.

Role of Threads

- Increasing Friction:The threads on drywall screws increase the friction between the screw and both the drywall and the underlying material. As the screw is driven in, the threads interact with the material’s surface to create a mechanical locking effect. This friction helps prevent the screw from loosening or falling out under pressure, ensuring the stability of the wallboard. For instance, in environments subject to vibration or impact, such as factory walls or around machinery, threaded drywall screws can better maintain the position of the wallboard and prolong its lifespan.

- Enhancing Joint Strength:Threads improve the strength of the connection between the drywall and the base material. The interlocking threads create a strong bond that can withstand tensile, shear, and other forces. This strength is significant in high-rise building wall installations, where the wallboard must bear pressures from wind, weight, and other environmental factors. Screws with threads provide sufficient holding power to ensure the wallboard stays secure and reliable.

- Ease of Assembly and Disassembly:Compared to flat-headed or unthreaded nails, drywall screws are easier to install and remove. During installation, the threads help guide the screw into the material, making it easier to insert. When wallboards need to be removed or replaced, the threads facilitate a quicker and more efficient disassembly without damaging the drywall or the underlying material.

Thread Precision and Surface Treatment

- Thread Precision:The precision of the thread on drywall screws significantly impacts their performance. High-quality screws ensure smooth and safe insertion, reducing the likelihood of jamming or damaging the material. Precision-threading equipment is typically used during production to ensure the threads are formed accurately, enhancing the quality and functionality of the screw.

- Surface Treatment:To improve corrosion resistance and longevity, drywall screws are often surface-treated. Common treatments include zinc, nickel, and chrome plating. Zinc plating is a cost-effective option, forming a protective zinc layer on the threads to prevent corrosion. Nickel and chrome plating offer superior corrosion and wear resistance but are more expensive. Some specialized coatings like Dacromet also provide excellent corrosion and high-temperature resistance, making them ideal for harsh environments.

Our Range of Drywall Screws

We offer a wide variety of drywall screws with the following specifications:

| Specification Number (Diameter) | Common Standard Length (mm) | Thread Type | Surface Treatment |

|---|---|---|---|

| #6 (3.5mm) | 13, 16, 19, 25, 32, 38, 50 | Coarse/Fine | Black/Grey Phosphate |

| #8 (4.2mm) | 25, 32, 38, 50, 65, 75, 90 | Coarse/Fine | White/Yellow Zinc |

| #10 (4.8mm) | 38, 50, 65, 75, 90, 102, 127, 150 | Coarse/Fine | White/Yellow Zinc |

Drywall screws are more than just fasteners; they are a critical component in ensuring the stability and longevity of your wall constructions. By understanding the various specifications, materials, and thread designs available, including the impact of the screw diameter, you can make informed decisions that will enhance the quality of your projects. Whether you opt for self-tapping screws for their ease of use, coarse threads for more complex materials, or fine threads for precision work, the right choice can make all the difference. Additionally, considering factors like corrosion resistance and surface treatment can extend the life of your screws and the structures they hold together. So, the next time you reach for a dry wall screw, remember the importance of selecting the right one—based on screw diameter—for the job at hand.