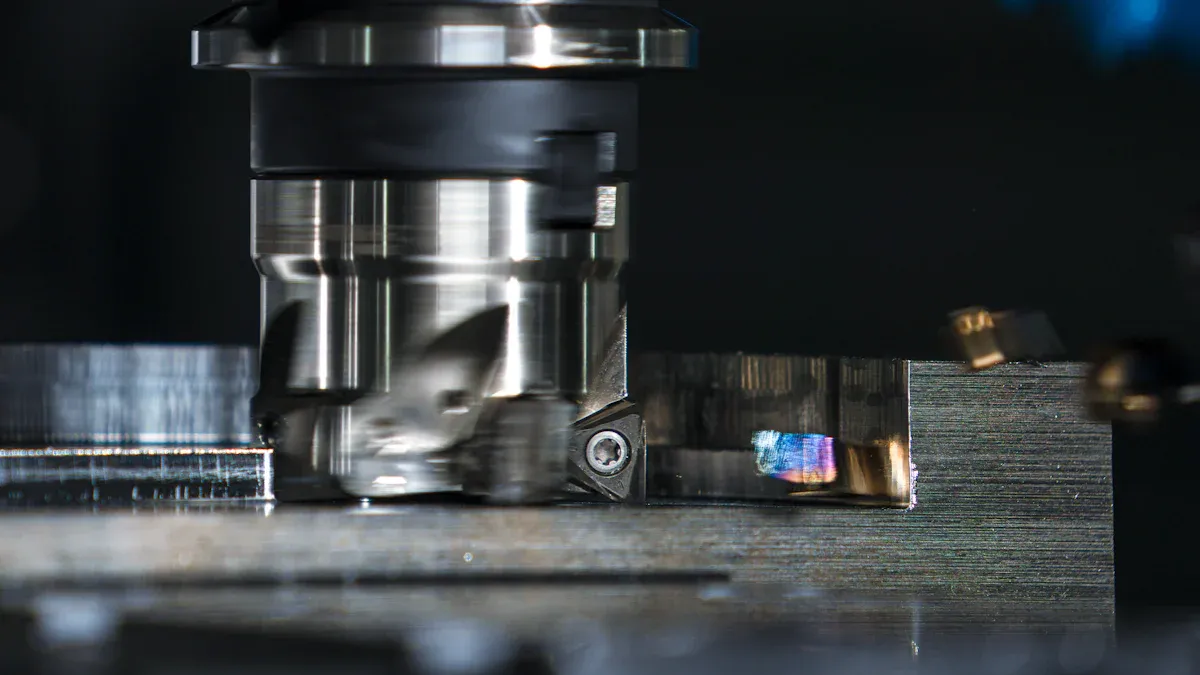

A ball screw changes spinning motion into straight-line motion. It does this with great accuracy and little friction. In 2025, companies use ball screws in CNC machines and robotic arms. They also use them in automated systems for exact and repeatable moves. The world market shows this need:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2023 | 4.5 | N/A |

| 2025 | ~5.14 (estimated) | 7.1 |

Ball screws help cut down on wear and make machines last longer. They also help lower the cost to fix machines. Their design lets them work fast and carry heavy things. This makes them very important in today’s automation.

Key Takeaways

- Ball screws change spinning into straight movement. They have low friction. This helps machines go faster and work better.

- Many industries use ball screws. You see them in cars, planes, hospitals, and factories. They can hold heavy loads and last a long time.

- Lubrication and maintenance are important. They stop ball screws from wearing out. This saves money on repairs. Ball screws work well when cared for.

- Picking the right ball screw is important. You must think about speed, load, and accuracy. This keeps machines safe and working well.

- Ball screws work better than lead screws. They are more efficient. But they need more care and lubrication to last longer.

Ball Screw Basics

What Is a Ball Screw

A ball screw is a device that turns spinning into straight movement. It has a screw shaft and a nut with tiny steel balls. The balls roll in grooves inside the shaft and nut. This rolling makes it easier for the parts to move. It does not use sliding friction, but rolling friction instead. Ball screws have less resistance than other devices like lead screws.

Key features include:

- A screw shaft with spiral grooves

- A nut that holds the balls

- Ball bearings between the nut and shaft

- Special groove shapes, such as gothic arc or semi-circular arc, change how much weight it can hold and how tightly it moves

- Preloading methods help stop looseness, called backlash, and make movement more accurate

Ball screws are special because they work well, last long, and move very precisely. These things make them important in 2025, since machines need to be fast and strong.

How It Works

A ball screw changes spinning into straight movement. The screw shaft has spiral grooves. When the shaft spins, the balls inside the nut roll in the grooves. This rolling pushes the nut in a straight line.

The balls move smoothly and go through a special system. This keeps the movement steady and makes it quieter.

The table below shows how a ball screw works:

| Principle/Aspect | Explanation |

|---|---|

| Basic Operation | The screw shaft spins; balls roll in grooves and move the nut in a straight line. |

| Ball Recirculation | Balls keep moving through a system so motion stays smooth. |

| Lead Angle | This sets how far the nut moves each time the shaft turns. |

| Contact Angle | Usually 20°-40°, helps spread out weight and lowers bending. |

| Preloading | Stops looseness, makes the ball screw stiffer, and spreads out weight better. |

| Lubrication | Needed for smooth movement, less friction, and longer life. |

| Ball Circulation Design | Different designs help balls move better, lower noise, and reduce wear. |

| Efficiency & Load Capacity | Rolling makes less friction than sliding, so it works well and can carry heavy things. |

The lead is the distance the nut moves with each turn. This sets how fast and well the ball screw works. The number and size of the balls decide how much weight it can move and how smooth it works.

Key Applications

Many industries use ball screws in 2025 because they need exact and steady movement.

Some main uses are:

- Automotive: Electric cars, steering, and transmissions

- Aerospace: Plane controls and landing gear

- Medical: Surgery robots, imaging, and rehab equipment

- Industrial Manufacturing: Machine tools, packaging, and moving materials

- Electronics: Making computer chips and robots

- Defense: Control systems and new weapons

- Construction Equipment: Big machines and automation

Ball screws help these industries by giving:

- High accuracy for jobs that need exact movement

- Low friction, so less heat and longer life

- The ability to carry heavy things quickly

- Lower repair costs because there is less wear

The car industry is the biggest user, because electric cars and automation are growing. Planes and medical fields also use ball screws for safety and accuracy. As technology gets better, more industries use ball screws for new things, like clean energy and smart building machines.

Components

Screw Shaft

The screw shaft is the main part of a ball screw. Makers use strong metals like chromium-molybdenum steel. These metals help the shaft last longer and not wear out fast. Sometimes, they use special metals like Invar for science tools. Invar keeps the shaft steady when it gets hot or cold.

How the shaft is made changes how well it works. Some shafts are rolled, which is cheaper but less exact. Others are ground with special tools to make them smoother and more accurate. New ways, like hard whirling, shape tough steel with little heat. This makes the shaft stronger and more precise.

Tip: If the shaft is smoother, it will have less friction and work better.

Nut and Ball Bearings

The nut holds the ball bearings and slides on the shaft. Makers use brass or steel for the nut to make it tough. The balls are made from hard steel or ceramic. These materials keep the balls smooth and strong. This helps lower friction and backlash.

The way the nut and balls are made changes how long the ball screw lasts.

- Stainless steel and hard alloy steel stop rust and wear.

- Nut designs, like outside or inside ball return systems, change the size and make it easier to put together or fix.

- Hard steel balls and smart ways to move them help the ball screw work smoothly and last longer.

- Lubrication and seals keep dirt out and help stop wear.

A good nut and ball system lets the ball screw carry heavy things and move very accurately.

Recirculation Mechanism

The recirculation mechanism keeps the balls moving inside the nut. This system lets the balls go around in a loop so they never get stuck.

Designers use tubes or grooves to guide the balls back to the start. The type of recirculation system changes how loud, fast, and easy to fix the ball screw is.

A good recirculation design helps the ball screw stay quiet and last longer.

Note: Check the system often and use the right oil to help it work well and stop damage.

Performance

Accuracy and Preload

Accuracy and preload play a big role in how well a ball screw works. Preload means pressing the ball bearings tightly between the nut and the screw shaft. This action removes extra space, called backlash, which can cause mistakes when the direction changes.

- Preload reduces lost motion and helps the ball screw repeat the same move every time.

- Higher preload makes the nut stiffer, so the whole system becomes more rigid.

- Most of the stiffness comes from adding preload to a nut that had none before. Raising preload even more gives only a small boost in rigidity.

- Preload can be set using oversized balls, adjustable nuts, or double nut systems.

- Too much preload increases the force inside the ball screw. This means the motor must work harder and the ball screw may wear out faster.

Preload helps keep machines accurate, but it can wear down over time. When this happens, the ball screw loses some of its accuracy and stiffness. Regular checks help keep the preload at the right level.

Lubrication

Lubrication keeps a ball screw running smoothly and helps it last longer. Good lubrication lowers friction and stops dirt from causing damage.

- Grease works well for keeping out dirt and handling high heat.

- Oil is best for fast or very precise machines. It can be sprayed as a mist or used in an oil bath.

- Solid lubricants, like molybdenum disulfide, protect in tough conditions.

Before adding new lubricant, clean the ball screw to remove old grease and dust. Always use the right amount. Too little can cause breakdowns, but too much can make the ball screw get hot and slow down.

Tip: Never run a ball screw dry. Always check for a thin film of lubricant to prevent early wear.

Regular checks and a set schedule for adding lubricant help extend the time between repairs.

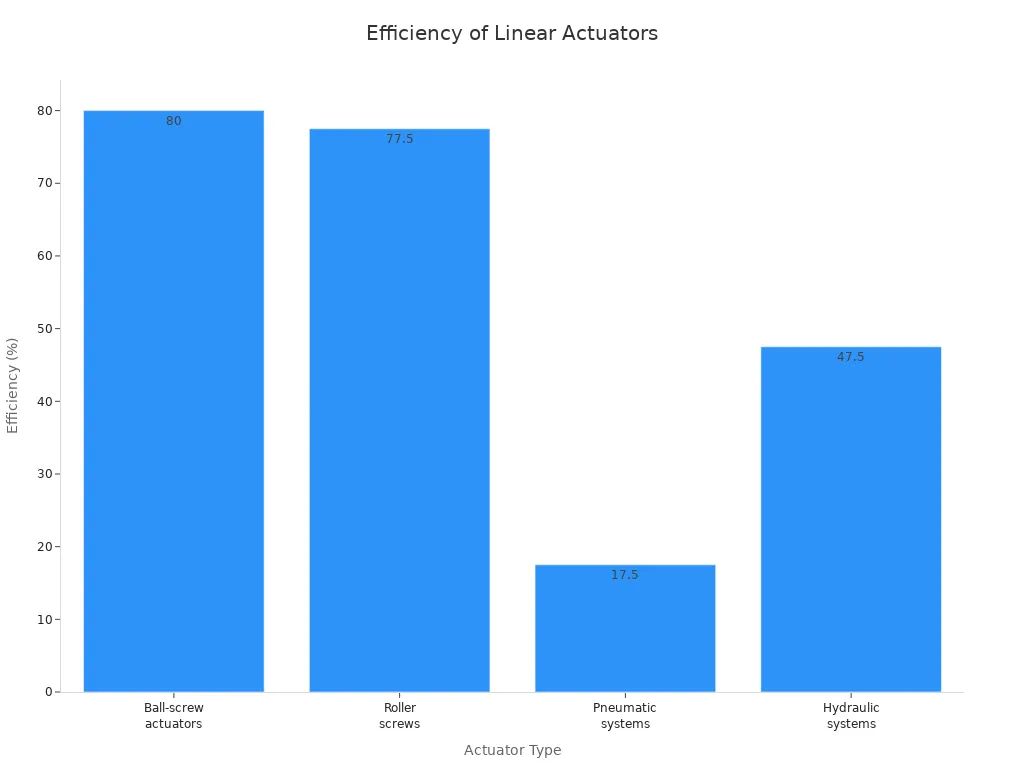

Back-Driving and Efficiency

Ball screws have high efficiency, which means they waste less energy. This also makes them easier to back-drive. Back-driving happens when a heavy load pushes the nut, causing the screw to spin backward. This can be dangerous, especially in machines that move up and down.

Designers use brakes, counterweights, or special springs to stop loads from dropping by accident. They also check the back-driving torque and compare it to friction to see if extra safety parts are needed.

The table below shows how efficient ball screws are compared to other systems:

| Actuator Type | Typical Efficiency Range |

|---|---|

| Ball Screws | 80-90% |

| ACME Screws | 20-40% |

| Roller Screws | 75-80% |

| Pneumatic Systems | 10-25% |

| Hydraulic Systems | 40-55% |

Ball screws work better than most other actuators because their rolling balls lower friction. This makes them a top choice for machines that need to save energy and move with precision.

Types

Ground vs. Rolled

Ball screws have two main types: ground and rolled. The way they make the threads is different. Ground ball screws use a grinding machine for each thread. This makes them very accurate and smooth. It takes more time and costs more money. Rolled ball screws use a rolling process to shape the threads. This way is faster and costs less. But, the threads may not be as perfect.

| Aspect | Ground Ball Screws | Rolled Ball Screws |

|---|---|---|

| Processing Method | Precision grinding for each thread | Cold rolling between dies |

| Surface Finish | Very smooth, visible grinding marks | Shiny, smooth surface with shallower grooves |

| Accuracy | Very high, as tight as 0.0003 inch/foot | Moderate, better than 0.003 inch/foot |

| Cost | Higher due to time and precision | Lower, good for large-scale production |

| Application Suitability | Best for CNC machines and tools needing high precision | Good for general industry and automation |

Ground ball screws are best for machines that need to move very exactly. CNC tools use them a lot. Rolled ball screws are good for most factory machines. They are better when saving money is important.

Precision Grades

Ball screws come in different precision grades. These grades show how close the screw stays to its path. Groups like JIS and ISO set these grades. Higher grades mean the screw is more accurate.

| Precision Grade | Use Case | Lead Accuracy Example |

|---|---|---|

| C0, C1, C3, C5 | High-precision machines | Tightest tolerances |

| C7, C10 | Standard machines, less critical | More error allowed |

Note: Grades from C0 to C5 are used in robots and medical tools. Grades C7 and C10 are used in conveyor belts or packaging lines.

Specialized Designs

In 2025, ball screw makers have new designs for special jobs. Heavy-duty ball screws use smart sensors and AI. These help find problems early and watch loads. Some ball screws use coatings and materials that save energy. Mini ball screws are used in small, fast machines like drones and 3D printers.

| Brand | Special Features in 2025 |

|---|---|

| NSK | High speed, thermal stability, advanced lubrication |

| THK | High rigidity, low noise, smooth movement |

| HIWIN | Thermal compensation, innovative lubrication |

| Bosch Rexroth | High load capacity, system integration |

| Pinsi | High reliability and durability |

| Kuroda | Ultra-high precision for micro-movement |

These new designs help machines work faster and last longer. They also help save energy.

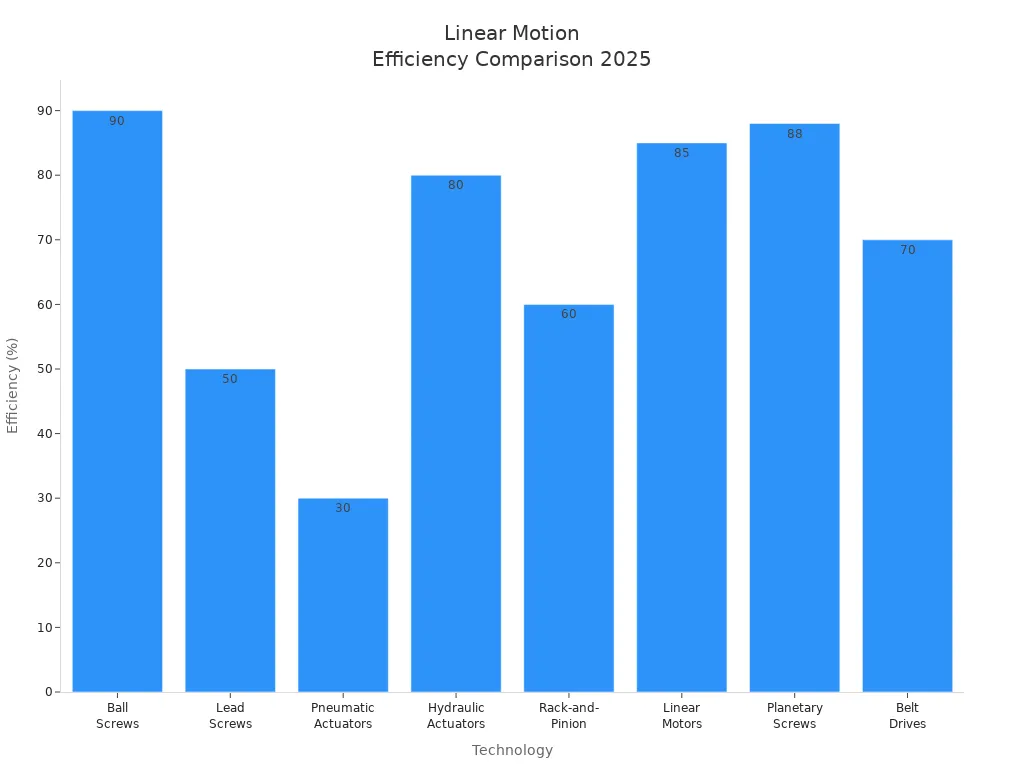

Ball Screw vs. Lead Screw

Efficiency Comparison

Ball screws and lead screws do not work the same way. Ball screws use rolling ball bearings to move the nut. This makes them have less friction and better efficiency. Lead screws use sliding friction between the nut and threads. This makes them lose more energy as heat.

| Feature | Lead Screw Efficiency | Ball Screw Efficiency |

|---|---|---|

| Efficiency | Low (30%-50%) | High (>90%) |

Ball screws are very efficient. They let machines use smaller motors and save power. Lead screws are not as efficient. They are better for slow jobs or when you need self-locking. Ball screws need to be oiled often to keep working well.

Tip: Ball screws are best for fast and accurate machines. Lead screws are good when speed does not matter.

Application Differences

Ball screws and lead screws are used for different things. Ball screws can carry heavy loads and move fast. They are used in planes, robots, and making computer chips. Lead screws are quieter and work well in calm places. They are used in medical tools and small machines.

| Feature/Aspect | Ball Screws | Lead Screws |

|---|---|---|

| Friction Mechanism | Recirculating ball bearings reduce friction | Sliding friction between nut and screw |

| Load Capacity | Higher load capacity | Lower load capacity |

| Speed | Suitable for higher speeds | Suitable for lower speeds |

| Noise | Noisier due to ball recirculation | Quieter, vibration-free |

| Self-locking | No, needs braking system | Yes, self-locking |

| Lubrication | Requires lubrication | Can operate with or without lubrication |

| Typical Applications | Aircraft, robotics, machine tools | Medical devices, OEM products |

Ball screws work best when moving things sideways. Lead screws are better for up and down jobs because they lock in place.

Cost and Maintenance

Ball screws cost more at first because they are made with care and have many parts. They last a long time if you take care of them. You need to oil and clean them often to keep them working. Lead screws cost less and do not need much care. Their simple shape lets them work even if they get dirty.

| Feature | Ball Screws | Lead Screws |

|---|---|---|

| Maintenance | Needs regular lubrication and cleaning | Less frequent maintenance |

| Lifespan | Longer with proper care | Shorter due to more friction |

| Cost | Higher initial cost, lower long-term cost | Lower initial cost, higher wear rate |

Ball screws can save money over time for hard jobs. Lead screws are a good choice for easy or cheap jobs.

Selection and Installation

Sizing

Picking the right ball screw starts with knowing the job. Engineers think about many things. Lead accuracy shows how exact the nut moves. Axial clearance and preload help stop backlash and make it stiffer. Critical speed is how fast the screw can spin before shaking. The nut’s speed changes if the screw is rolled or ground. These things help match the ball screw to what the machine needs for speed, weight, and accuracy.

| Factor Increased | Affected Parameters | Effect Description |

|---|---|---|

| Screw Length | Critical Speed, Compression Load | Both go down as length gets longer |

| Screw Diameter | Critical Speed, Inertia, Load | All go up as diameter gets bigger |

| Lead | Drive Torque, Angular Velocity | Torque goes up, velocity goes down |

| End Mounting Rigidity | Critical Speed, Compression Load | Both go up with stronger mounting |

| Load | Life | Life goes down as load gets heavier |

| Preload | Accuracy, Stiffness, Drag Torque | All go up with more preload |

Engineers also look at the weight, direction, speed, travel length, and where it will be used. They use computer tools and ask makers for help. This makes sure the ball screw will last and work safely.

Installation Tips

Installing the ball screw the right way helps it work well and last longer. Some mistakes are not enough oil, dirt, too much weight, parts not lined up, or going too fast. The table below shows how to stop these problems:

| Common Error | Cause/Explanation | Prevention Method |

|---|---|---|

| Insufficient Lubrication | Metal parts wear out fast | Use the right oil and add it often |

| Contamination | Dirt and dust cause damage | Use seals and clean a lot |

| Overloading | Too much weight bends or breaks the screw | Pick the right size and add safety space |

| Misalignment | Parts wear uneven and rub too much | Use tools to line up and check sizes |

| Excessive Speeds | Heat builds up and hurts the screw | Stay under speed limits and use fast designs |

| Improper Sizing | Wrong size makes it work badly or break | Study needs and ask experts |

| Poor Ball Recirculation | Balls get stuck or blocked | Check and clean the ball path often |

Tip: Always do what the maker says and check if parts line up after fixing.

Troubleshooting

If a ball screw does not work right, workers follow steps to find out why: 1. Check if the power is too high. 2. Measure backlash to see if parts are worn. 3. Look at wipers for missing or broken pieces. 4. Check for rust, pits, or marks in the grooves. 5. Compare wear where the nut moves the most. 6. Make sure the oil system works and oil is clean. 7. Check if parts line up and look for bent or worn slides. 8. Take off the nut and turn it to feel for rough spots. 9. Stop the machine if you see loose balls or parts. 10. Check up-and-down ball screw systems often to stay safe.

Note: Doing regular checks and fixing things fast stops bigger problems and keeps machines working well.

Ball screw technology works well and does not waste much energy. It has low friction and is trusted by many industries. If you take care of ball screws, they last longer. You need to keep them clean and use the right oil. This helps stop breakdowns and saves time. Ball screws are very exact and can lift heavy things. This makes them a good choice over other options.

- Doing things like adding oil and checking if parts line up stops damage.

- New ideas include smart sensors, green materials, and better designs for electric cars and robots.

Learning from guides, classes, and help from sellers keeps users up to date with the best ways to use ball screws.

FAQ

What is the main benefit of using a ball screw?

Ball screws offer high efficiency and low friction. They help machines move with great accuracy. Many industries choose ball screws for jobs that need fast and precise movement.

How often should someone lubricate a ball screw?

Most experts recommend checking and adding lubricant every month. Machines that run fast or carry heavy loads may need more frequent checks. Good lubrication helps prevent wear and keeps the ball screw working well.

Can ball screws work in dirty or wet places?

Ball screws can work in tough environments if they have seals and covers. These parts keep out dirt and water. Regular cleaning and maintenance help ball screws last longer in harsh conditions.

How does someone know if a ball screw needs replacement?

Signs include increased noise, rough movement, or more backlash. A table can help track common warning signs:

| Warning Sign | What It Means |

|---|---|

| Loud noise | Possible damage |

| Jerky movement | Worn parts |

| Backlash grows | Loss of accuracy |

Tip: Replace the ball screw if these problems do not improve after maintenance.