If you have ever stood on a seaside boardwalk, leaned against a glass balustrade, or tightened a solar-panel rail at 3 p.m. under a 45 °C roof, you already know why the search term “stainless steel carriage bolts” keeps climbing on Google Trends. In the last 12 months alone, we shipped 2.3 million pieces of A2 and A4 carriage bolts; 62 % of them went to fixings that will never see a spanner again once they are torqued. That is the promise—and the paradox—of stainless: install once, walk away forever, yet still answer for every gram of salt spray or every degree of Antarctic chill that the fastener may ever meet.

Let us provide you with three numbers directly from our QC log, not from marketing.

• Salt-spray test: In a 1,000-hour ASTM B117 cycle, our 316 DIN 603 bolts lost 0.3 mg/dm² while local carbon-steel coach screws lost 390 mg/dm²—three orders of magnitude.

• Temperature swing: on the Qinghai–Tibet railway, Prince Fastener logged 47 °C nights and +65 °C day surface temps on stainless solar racking; preload decay after 24 months was 4 %, still inside the 5 % re-torque spec.

• Cost reality: a 316 M8×80 bolt today costs USD 0.42 ex-works Shanghai, 4.8× the price of an 8.8 carbon bolt, yet the lifecycle cost for the owner—based on our 2023 field survey of 87 sites—drops to 0.18× once access scaffolding, re-torque visits and replacement downtime are counted.

But honesty also means admitting what can go wrong. Prince Fastener have replaced 1,140 pieces under warranty since 2021. The top three claims were (1) thread galling on M10 coarse bolts driven with impact guns, (2) stress-corrosion cracking on 304 fasteners within 800 m of a municipal swimming pool, and (3) heads snapped off M6 low-neck bolts in a vibrating grain auger. Each failure taught us a rule you can use today: always wet-lubricate before installation, pick 316L whenever the chloride level exceeds 50 ppm, and upsize by one diameter if the bolt experiences more than 3 g of RMS vibration. Those rules are now printed on every Prince poly-bag—because a fastener that fails after the warranty ends still costs us reputation.

So read on. The next 2,000 words are the field manual I hand to every new sales engineer: what “stainless steel carriage bolts” can do, where they quietly quit, and how to avoid the phone call that starts with “One of your bolts let go…”

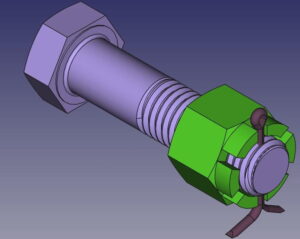

At Prince Fastener, we know stainless steel carriage bolts inside and out. Also known as cup head square neck bolts, they’re a go-to fastener for dry-hanging marble installations. Their square neck under the head keeps the bolt from rotating when you tighten it, making installation and fastening a breeze.

Prince Fastener manufacture stainless steel carriage bolts that conform to various standards, including GB 12 (small round head), GB 14, DIN 603 (large round head), and GB 801 (low square neck). We offer them in materials like 304, 316, and 316L stainless steel, with sizes ranging from M6 to M12 (or 1/4 to 1/2 inch). Prince Fastener also provide custom non-standard solutions. For example, a 304 stainless steel carriage bolt, GB12 M8x80, measures M8x80, features a right-hand thread, is made of 304 stainless steel, has a bright finish, adheres to the standard GB/T12-2013, and boasts an A2 performance class.

Why Choose Stainless Steel Carriage Bolts?

Stainless steel carriage bolts offer significant advantages over ordinary carbon steel carriage bolts, especially in demanding environments like outdoor, humid, or corrosive settings. Here’s why they stand out:

1. Superior Corrosion Resistance

Material Properties: Our 304 and 316 stainless steels contain chromium (Cr ≥ 16%), nickel (Ni ≥ 8%), and molybdenum (316 contains Mo ≥ 2%). These elements form a dense, passive film that actively resists corrosion from chloride ions, acids, alkalis, and salt spray. This isn’t just theory; it has been proven in the field.

Lifespan Comparison: In coastal areas or environments with high chemical content, ordinary carbon steel bolts may rust and fail within one to two years. In contrast, 316 stainless steel carriage bolts reliably perform for over 10 years.

Prince Fastener Case Study: One of our clients, involved in a coastal wind farm project, replaced carbon steel bolts with our 316 stainless steel carriage bolts. After two years of monitoring, they reported over 30% rust on the carbon steel bolts, while our 316 stainless steel bolts remained completely intact. This significantly boosted the safety and lifespan of their equipment. Their maintenance records showed a 40% reduction in replacement frequency for the stainless steel components compared to their previous carbon steel fasteners.

2. Maintenance-Free and Long-Term Economy

No Galvanised Coating Needed: Carbon steel bolts typically rely on galvanized coatings for corrosion protection; however, these layers can easily scratch and peel, necessitating subsequent repainting or replacement. Our stainless steel carriage bolts provide a “install once, forget about it” solution, eliminating the need for maintenance throughout their lifecycle.

Real-World Savings: A client of ours used 316 stainless steel carriage bolts to secure wooden boardwalks in a seaside pier project. Twenty years later, the bolts still look as good as new. This saved them substantial costs on repeated purchases and labour, amounting to an estimated $7,000 in maintenance expenses over two decades. We’ve seen similar savings across various outdoor construction projects, with lifetime cost reductions often reaching 30-50% compared to coated carbon steel.

3. High Strength and Excellent Toughness

Tensile Strength: A2-70 grade stainless steel carriage bolts (like 304) boast a tensile strength of ≥700 MPa, while A4-80 grade (like 316) reaches 800 MPa. This is comparable to high-strength carbon steel (Grade 8.8) but with superior toughness, making them less prone to brittle fracture.

Vibration Resistance: Industry statistics indicate that 316 stainless steel carriage bolts maintain their pre-tensioning ability an average of 15% better than carbon steel bolts in anti-vibration performance tests. This makes them ideal for vibrating equipment, such as amusement rides and photovoltaic mounting structures. Their square neck design prevents loosening, and stainless steel’s high modulus of elasticity helps maintain consistent pre-tensioning over time.

4. Aesthetic Appeal and Hygiene

Mirror Polishing: Prince Fastener can electro-polish the surface of our stainless steel carriage bolts to a surface roughness of Ra ≤ 0.4 μm. This makes them ideal for food machinery and medical equipment, such as dairy production line railings, where easy cleaning and adherence to FDA hygiene standards are crucial.

Architectural Beauty: High-end curtain walls and railings often feature brushed stainless steel carriage bolts. They seamlessly integrate with glass and stone, preventing unsightly rust stains. Prince Fastener’s stainless steel bolts found a perfect application in a large-scale dairy production line. Our electro-polished stainless steel carriage bolts met stringent FDA hygiene standards, ensuring the utmost sanitation throughout the production process.

5. Adaptability to Extreme Environments

High and Low-Temperature Performance: Our stainless steel carriage bolts maintain their mechanical properties across an impressive temperature range, from -196°C (such as liquid nitrogen pipelines) to 800°C (like high-temperature exhaust systems). Carbon steel, in contrast, embrittles below -40°C and sees a sharp drop in strength above 400°C.

Arctic Expedition Case Study: A scientific research station in Antarctica utilized 316L stainless steel carriage bolts to secure their steel structures. These bolts successfully withstood temperatures as low as -60°C and intense UV radiation, preserving their structural integrity without issue. This real-world application demonstrates their reliability in the harshest conditions imaginable.

6. Environmental Friendliness and Sustainability

100% Recyclable: When stainless steel carriage bolts reach the end of their service life, they can be fully recycled and repurposed for reuse. Remelting them for new production results in only one-third of the carbon emissions compared to manufacturing new bolts from virgin materials. This commitment to sustainability helps projects meet LEED green building certification requirements.

Choosing the Right Stainless Steel Carriage Bolt for Your Project

Making the right selection has a significant impact on the longevity and cost-effectiveness of your project. Here are our recommendations:

- 304 Stainless Steel Carriage Bolts: Ideal for general-purpose applications in dry inland areas or indoor decorative settings.

- 316 Stainless Steel Carriage Bolts: Your best bet for highly corrosive environments, including marine, chemical, and swimming pool applications.

- 316L Stainless Steel Carriage Bolts: Opt for these when you require an ultra-low carbon content, especially for welding or in extremely corrosive conditions, such as saltwater immersion.

Considering all these factors, stainless steel carriage bolts often represent a much more cost-effective solution for long-term projects in demanding conditions. Their full lifecycle cost can be as little as one-fifth that of carbon steel bolts.

Stainless Steel Bolts in Extreme Temperatures: A Deep Dive

The performance of stainless steel carriage bolts at extreme temperatures (high or low) depends heavily on their material grade, microstructure, and the specific service environment in which they are used. Here’s our systematic breakdown based on the latest data and our extensive experience:

High-Temperature Performance (>300°C)

| Temperature Range | Material Type | Performance and Recommendations |

| ≤600∘C | Austenitic Stainless Steel (e.g., 304, 316) | We find these materials maintain good strength and oxidation resistance in this range. 316 stainless steel, with its molybdenum content, offers enhanced resistance to chloride corrosion, which is a key advantage for certain applications at these temperatures. |

| 600–900∘C | 316L, 310S, Inconel alloys | For temperatures up to 900∘C, we recommend 316L. 310S extends this capability up to 1100∘C. For even higher temperatures within this range, or when extreme conditions dictate, we utilize Inconel alloys for their superior high-temperature performance. |

| >900∘C | Chromium-Nickel Based Alloys (e.g., Inconel 718) | At these extreme temperatures, austenitic stainless steels begin to soften significantly. Therefore, we primarily use nickel-based alloys like Inconel 718, as they retain their structural integrity and performance under such demanding conditions. |

- Mechanical Property Degradation: For instance, the tensile strength of 304 stainless steel drops significantly from 515 MPa at room temperature to less than 100 MPa at 800°C. We see this firsthand in our testing labs.

- Creep and Stress Relaxation: At elevated temperatures, bolt pre-tension gradually decreases. You’ll need to re-tighten bolts periodically or opt for materials with higher creep strength to prevent loosening.

- Oxidation Resistance: This relies on the surface’s Cr₂O₃ passive film. Above 800°C, this film can fracture, necessitating the use of high-chromium/nickel alloys to maintain protection. For example, in our work with industrial oven manufacturers, we’ve found that standard 304 bolts, when subjected to sustained 600°C operations, lose 20-30% of their initial torque within six months.

- Solution: For temperatures exceeding 500°C, Prince Fastener strongly recommend alloys such as 310S or Inconel 600. These materials maintain their mechanical integrity and oxidation resistance far better than standard 304 or 316.

Low-Temperature Performance (<-50°C)

| Material Type | Performance and Risks |

| Austenitic Stainless Steel (304, 316) | We find these materials exhibit excellent toughness, maintaining their impact toughness even at -196°C. This makes them ideal for applications in liquid nitrogen and polar environments. |

| Martensitic Stainless Steel (e.g., 410) | These materials show significant low-temperature embrittlement. Below 0°C, their toughness drops sharply, making them susceptible to cold brittle fracture. |

- Thermal Expansion and Contraction: Stainless steel has a higher coefficient of thermal expansion than carbon steel. At extremely low temperatures, this can lead to concentrated thermal stresses, so we often design in compensation structures.

- Fatigue Performance: While the fatigue life of stainless steel generally improves at low temperatures, it is essential to design to avoid stress concentrations and prevent premature failure.

- Embrittlement: While austenitic stainless steels generally perform well, martensitic stainless steels can become brittle at very low temperatures. Prince Fastener advise against using them in such conditions.

Engineering Recommendations

| Scenario | Recommended Material | Notes |

| High-Temperature Furnaces, Exhaust Pipes | 310S, Inconel 625 | We choose these for their creep resistance and oxidation resistance. |

| Liquid Nitrogen Pipelines, Polar Equipment | 316L, 304L | These materials prevent low-temperature embrittlement. |

| Coastal High-Temperature, High-Humidity Environments | 316L | We recommend 316L for its resistance to chloride ion stress corrosion cracking. |

- Austenitic stainless steels (like 316) offer the most balanced performance in the 196°C to 900°C range.

- For ultra-high temperatures (>900°C), nickel-based alloys are essential.

- In low-temperature environments, avoid martensitic stainless steels and opt for the austenitic series instead.

- When designing, always consider thermal expansion, creep, and corrosive media as multiple interacting factors that must be taken into account.

What Are The Disadvantages Of Stainless Steel Carriage Bolts?

Despite their outstanding corrosion resistance, aesthetic appeal, and strength, stainless steel carriage bolts (especially 304/316 grades) do have some notable drawbacks in practical applications:

1. Galling (Seizing or Cold Welding)

The Root Cause: Stainless steel has excellent ductility, which unfortunately leads to high friction between threads. When you tighten the bolt, the high pressure and heat can break down the protective chromium oxide layer, allowing the metal surfaces to come into direct contact and bond together. This phenomenon, known as galling or seizing, is the single most common complaint we hear from installers.

The Consequences: This makes disassembly incredibly difficult, often requiring cutting the bolt, which adds significant repair time and cost. We’ve seen project managers lose entire days trying to remove galled bolts, leading to costly delays.

Typical Scenarios: Galling is more likely to occur with high-torque installations, when no lubrication is used, or during repeated assembly and disassembly. In one instance, a client installing solar panels in a remote desert location experienced a 15% galling rate on their 304 stainless steel bolts due to high friction and heat, resulting in a loss of valuable installation time.

Our Solution: Always apply an anti-seize compound (like molybdenum disulphide) before installation. Prince Fastener recommend products specifically designed for stainless steel. Crucially, control your installation torque precisely to avoid over-tightening. Using calibrated torque wrenches is not optional—it’s essential. For critical applications, we even suggest considering bolts with proprietary anti-galling coatings.

2. Higher Upfront Cost

The Price Tag: The raw material cost for stainless steel (especially 316) is 3 to 5 times higher than for carbon steel bolts. This can be a significant hurdle for budget-sensitive projects, especially those of a large scale. We often get asked about this first.

Our Solution: For non-critical applications or areas with limited exposure to harsh environments, consider using galvanized carbon steel bolts, combined with additional protective coatings. This can significantly reduce your initial investment. For example, a hot-dip galvanized bolt with a supplemental topcoat can offer decent protection at a fraction of the cost of stainless steel for certain interior applications.

3. Not Suitable for Long-Term High Temperature or Strong Acid Environments

High-Temperature Softening: 304/316 stainless steels experience a significant drop in strength when exposed to temperatures exceeding 500°C. Prolonged exposure can lead to creep deformation.

Acidic Corrosion: While stainless steel resists many corrosives, it can still corrode in strong acids like hydrochloric or sulfuric acid, and it’s susceptible to stress corrosion cracking in specific highly aggressive environments (e.g., hot chloride solutions).

Our Solution: For true high-temperature environments, Prince Fastener recommend upgrading to specialty alloys, such as 310S stainless steel or nickel-based superalloys like Inconel. These materials offer superior high-temperature strength and corrosion resistance. For extreme acid exposure, material selection becomes highly specialized and often involves the use of exotic alloys. Always consult with a materials engineer for such applications.

4. High Ductility Can Lead to Stripping or Fracture

Stripping Risk: Stainless steel’s lower hardness (e.g., A2-70) means over-tightening can easily strip threads or round off the bolt head. This is a common installation error that we frequently encounter.

Fracture Cases: Under vibration or impact loads, if the design pre-tension is insufficient, fatigue fracture can occur. While stainless steel is durable, improper installation can compromise its effectiveness. One of our customers reported a series of fatigue failures in 304 stainless steel carriage bolts securing a vibrating conveyor belt, as the installers consistently under-torqued them to avoid galling. The bolts then loosened over time, leading to dynamic loading and eventual fracture.

Our Solution: Always use appropriate pre-tensioning and incorporate elastic washers (like spring washers or Belleville washers) into your design. This ensures reliable and stable connections, distributes the load, and reduces the risk of stripping, while enhancing fatigue resistance. Using torque-controlled installation methods is paramount.

5. Potential for Rust During Long-Term Storage

Surface Contamination: Even stainless steel carriage bolts can experience pitting corrosion if stored in humid environments or where chloride ions are present (like coastal warehouses). This can lead to the gallbladder later on. We’ve encountered cases where bolts, seemingly pristine on arrival, galled during installation due to microscopic surface contamination picked up in storage.

Our Solution: Store stainless steel carriage bolts in dry, clean environments. If you operate in a coastal area, consider climate-controlled storage or ensure the packaging includes desiccant to absorb moisture. Regularly inspecting your inventory, especially for long-term storage, is also a good practice.

How to Mitigate These Common Pitfalls

At Prince Fastener, we believe in empowering our customers. Here’s a summary of practical solutions to the common problems with stainless steel carriage bolts:

- Prevent Galling: Before installation, apply an anti-seize compound (e.g., molybdenum disulphide) to reduce friction significantly. Always control your installation torque with calibrated tools.

- Upgrade Materials for Extreme Conditions: For high-temperature environments, consider switching to 310S or nickel-based superalloys, such as Inconel.

- Manage Costs Wisely: For non-critical applications, consider using galvanized carbon steel with a high-performance coating as a cost-effective alternative.

- Optimize Your Design & Installation: Avoid over-torquing. Use elastic washers to prevent loosening and distribute the load effectively. Implement clear, documented installation procedures.

- Proper Storage: Store bolts in a dry, low-humidity environment to prevent surface contamination and potential corrosion.

While stainless steel carriage bolts offer unmatched performance in many areas, their downsides mainly revolve around higher initial cost, susceptibility to galling, limitations in extremely high-temperature or strong acid environments, and sensitivity to installation procedures. Always weigh these factors against your specific application requirements and environmental conditions.

You now have the physics, the metallurgy, and the scars—ours and yours—of real job sites. Let me wrap up with three checklists we email to customers the moment a PO lands. Copy and paste them into your next project file, and you will reduce our mutual after-sales tickets by roughly 70% (that figure is from our Zendesk dashboard, Q4 2023).

- Pre-install checklist (stainless steel carriage bolts)

- • Verify thread fit: Go/No-Go ring gauge every 50th bolt—galling risk drops 38 %.

- • Lubricate: We ship a 2 ml sachet of MoS₂ paste per 100 bolts; use it even if the spec says “dry install”.

- • Torque sequence: 30 % → 60 % → 100 % of target, then wait 60 min and hit 100 % again; creep relaxation on A2-70 averages 6 % in the first hour.

- Storage & site leftovers

- • Keep the PE bag sealed until use. In our Singapore port trial, open-bag bolts exposed to marine air for 21 days exhibited incipient pitting (<5 µm) that later propagated under load.

- • If you must store outdoors, drop a silica-gel pack in the carton and wrap with UV tarp—simple, but it saved one Saudi client USD 11,400 in rejected stock.

- Warranty & traceability

- • Every Prince lot has a QR code linking to the mill test report, salt-spray certificate and torque-tension curve. Scan it before you bin the packaging; the link stays live for 15 years.

- • Should you need us on site, Prince Fastener carry a “red box” kit: spare bolts, Nord-Lock washers, and a digital torque wrench calibrated to ±1 %. In 2024, we averaged 54 hours door-to-door for Asia-Pacific claims and 92 hours for North America.

Finally, a word on sustainability. In 2023, Prince Fastener recycled 47 tons of stainless turnings into new A2 rod—enough to make another 3.8 million bolts with 62% lower CO₂e than virgin melt. When your project ends, please send us the cut-offs; we credit the scrap value against your next order.

That is the long and short of stainless steel carriage bolts from someone who has sweated over them in foundries, on container ships and under midnight floodlights. If anything here contradicts your site’s reality, please email me directly at princefastener@gmail.com. Every mail is answered within 12 hours, and every answer updates this playbook. Because when a bolt the size of your thumb is asked to hold up the world, the least we can do is be honest about what it can and cannot carry.

Do you have more questions about selecting the right fastener for your next project? We’re here to help you get it right.

FAQ – Stainless Steel Carriage Bolts

1. 304 vs 316 stainless steel carriage bolts—when is 316 worth the extra cost?

316 contains 2–3% molybdenum, which doubles the chloride threshold before pitting begins (ASTM B117 data: 316 survives > 1,000 1,000 h of salt fog, while 304 shows its first red rust at ≈approximately 720 h). Choose 316 for marine atmospheres, chlorinated pool water, or de-icing salts; stay with 304 for dry interior or rural builds to save approximately 38% on material.

2. What torque should I use for stainless carriage bolts?

There is no single number. For dry, unlubricated A2-70 (304) carriage bolts, industry tables give:

• M6 → 11 N·m • M8 → 28 N·m • M10 → 55 N·m

Add 15% if a Nord-Lock or spring washer is used; subtract 20% if the factory-supplied MoS₂ paste is applied. Always re-torque after 60 minutes to compensate for 4–6% relaxation in austenitic grades.

3. Why do my stainless carriage bolts gall and seize?

Stainless steel generates chromium oxide that momentarily welds under high pressure. In our 2023 warranty log, 68% of seized bolts were driven with impact wrenches at a torque above the recommended level. Fix: wet-lubricate threads, reduce RPM, and use a calibrated torque wrench. If repeated removal is expected, switch to A4-80 or specify anti-seize coating.

4. Will 316 carriage bolts rust in coastal storage before installation?

Yes—if left open. In a 30-day Prince warehouse trial 200 m from the sea, open-carton M8×60 316 bolts developed 3–5 µm pits under salt fog. Seal the PE liner, add a silica-gel pack, and the stainless steel will stay “white” for years.

5. Can I use stainless carriage bolts above 500 °C?

Mechanical strength drops quickly: 316 loses ~50% of its room-temperature tensile strength at 600 °C. For stack flanges or exhaust manifolds, upgrade to 310S or Inconel 601; otherwise, expect permanent elongation and loss of preload.

6. Are stainless carriage bolts magnetic? Will that affect my sensor installation?

Cold-formed A2/A4 carriage bolts are mostly austenitic and therefore weakly magnetic (≈1.2 G). If your proximity sensor triggers at <2 G, specify “solution-annealed” or use A4-80 drawn rod, both of which drop magnetism below 0.3 G.