At Prince Fastener, we are dedicated to being at the forefront of the fastener industry, providing innovative and reliable solutions for all your industrial needs. This comprehensive blog post delves into stainless steel lag bolts, a crucial component in countless mechanical, construction, and engineering applications.

As experts in the field, we understand the significance of selecting the right fastener for your specific project requirements. Stainless steel lag bolts, with their exceptional strength, corrosion resistance, and durability, have become a preferred choice across various sectors, including aerospace, automotive, and marine industries. We aim to equip you with in-depth knowledge about these versatile fasteners, from their material composition and performance characteristics to their diverse applications and future trends. Whether you’re a seasoned professional or new to the industry, this blog aims to serve as a valuable resource, guiding you in making informed decisions regarding stainless steel lag bolts.

Product Definition and Structural Types

Stainless steel lag bolts are custom-made fasteners with a square head, requiring the use of nuts for assembly. The square head design allows easy tightening with a wrench, preventing rotation. These bolts are primarily used in mechanical, construction, chemical, and aerospace industries. Stainless steel is known for its high corrosion resistance and toughness, making it ideal for use in various challenging environments. These bolts are highly corrosion-resistant, making them suitable for humid, high-temperature, or chemically corrosive settings. Depending on the specifications, these bolts are available in C-class (practical) and higher performance grades, such as A2-70 and A4-80.

Materials and Characteristics

Standard Materials: 304 stainless steel is the most common material, containing 18% chromium and 8% nickel, providing good corrosion resistance, heat resistance, and processability. 316 stainless steel, with 16%-18% chromium and 10%-14% nickel, includes molybdenum, which enhances its corrosion resistance compared to 304, especially in environments with chlorine ions, such as marine environments.

Functionality: Stainless steel lag bolts offer high strength and toughness, enabling them to withstand significant tension and pressure. They also feature excellent oxidation resistance and high-temperature durability, preventing oxidation deformation even in high-temperature environments, thus making them applicable across a wide temperature range.

Applications

Steel Structure Connections

In steel structure projects like factories, warehouses, and bridges, stainless steel lag bolts connect steel beams, columns, and other components, ensuring the structure’s stability and load-bearing capacity.

Mechanical Equipment Assembly

These bolts are primarily used in vehicles, motorcycles, machine tools, and other mechanical manufacturing to connect components and ensure equipment’s regular operation and safety.

Pipe Fixation

Stainless steel lag bolts are ideal for securing various pipes, such as water or gas pipelines, preventing misalignment or vibration during operation.

Specifications and Sizes

Thread Size: This is generally represented by thread specifications such as M6, M8, M10, and M12, with the number indicating the external diameter of the bolt in millimeters. Typical lengths range from 10mm to 200mm, with custom lengths available depending on requirements.

Head Size: The size of the head corresponds to the bolt specification. Typically, larger bolt sizes have proportionally larger heads. The thickness of the head is determined by the bolt’s grade and its usage requirements.

Standards and Grades:

- National Standards: GB/T 35-2013 (Small Square Head Bolts), GB/T 8-2021 (Square Head Bolts C-class), GB/T 868-2013 (Interchangeability of Hexagonal Head Bolts and Small Square Head Bolts).

- International Standards: DIN 21346-1989 (Wooden Shaft Guide Square Head Bolts), JIS B 1182-1995 (Square Head Bolts), ISO 4026:1992 (Hexagonal Head Bolts and Square Head Bolt Head Sizes).

Surface Treatment

- Polishing: This process enhances the bolt’s surface, improving its appearance and boosting corrosion resistance to a certain degree.

- Passivation: The bolt’s surface undergoes a chemical treatment to form a dense oxide layer, improving corrosion resistance and extending service life.

Advantages

- High Corrosion Resistance: These bolts are ideal for use in extreme environments such as high humidity and acid or alkaline conditions. This reduces maintenance frequency and costs.

- Distinctive Appearance: With a smooth surface and uniform color, they are widely used in architectural decoration, home appliances, and other areas requiring high aesthetic standards.

- Good Compatibility: Stainless steel lag bolts are biocompatible, making them suitable for medical equipment, food machinery, and other health-related fields.

Industry Outlook and Challenges

Development Trends

- Smart Integration: Integrating innovative sensor technologies allows for real-time monitoring of bolt conditions, enhancing safety.

- New Materials: High-performance stainless steel alloys, such as 316 and duplex stainless steel, are being developed to enhance corrosion and wear resistance, especially for offshore and space engineering applications.

Smart Manufacturing and Technologies

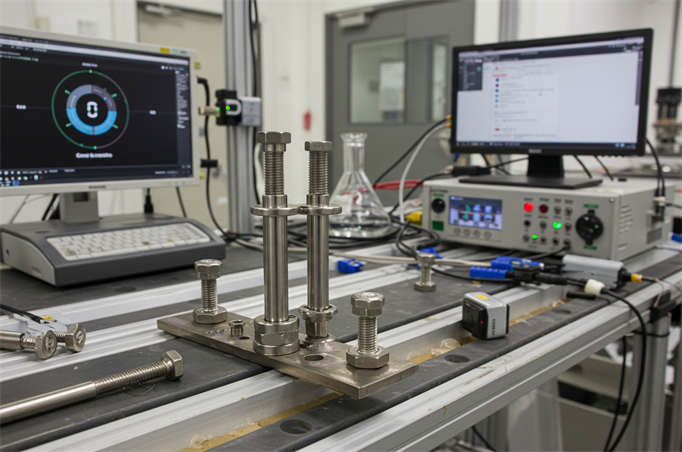

- Smart Sensors: By incorporating IoT sensors, bolt preload, stress levels, and corrosion conditions can be monitored. This enables fault warnings and dynamic management, thus improving system safety.

- Automated Manufacturing: Introducing automatic cold-heading machines and AI-driven visual inspection systems increases production efficiency and accuracy.

Market Expansion

- New Energy and High-end Manufacturing: High-strength stainless steel lag bolts are gaining traction in the manufacturing of electric vehicle batteries and solar power systems, particularly in applications where durability is key, such as battery packs and window connections.

- Underwater and Aerospace Engineering: Custom bolts designed to withstand extreme temperatures and pressures are used in underwater vehicles and spacecraft.

Green Infrastructure and Urban Development

- Sustainable Buildings: Stainless steel square head bolts are increasingly used in prefabricated housing, bridge structures, and subway tunnels, replacing traditional carbon steel to extend service life. For example, the Hong Kong-Zhuhai-Macau Bridge used 8200 tons of duplex stainless steel rebar.

- Water Supply and Environmental Projects: The widespread use of stainless steel pipes and bolts in water supply system renovations is expected to increase market penetration significantly in the next decade.

Industry Ecosystem Improvements

Green and Low-carbon Transition

- Environmental Technologies: Promoting acid-free passivation and photovoltaic-powered workshops can reduce wastewater discharge and carbon footprints. For instance, Dongming Corporation plans to reduce the carbon footprint of its components by 40% by 2025.

- Recycling: RecyclingRecycling stainless steel scrap, especially duplex stainless steel, helps minimize lifecycle costs. Duplex steel’s recyclability makes it a favored choice for coal industry equipment, extending its service life to 30 years.

Standardization and Globalization

- International Standards Compliance: To cater to global markets, products should meet international standards such as DIN, ANSI, and JIS. Dongming, for example, offers over 20 varieties of M12 hexagonal bolts, ensuring compatibility with foreign markets.

- Supply Chain Integration: Industry leaders, such as Qingdao Steel and Tai Steel, optimize supply chains through digital platforms, as China accounts for over 60% of global stainless steel production.

Market and Competitive Landscape

Demand Growth and Regional Breakdown

- Market Expansion: The global market is expected to grow at a compound annual growth rate (CAGR) of 6%, reaching a market size of $8.22 billion by 2030, with Asia (especially China) as the primary growth driver.

- Branding and Smart Solutions in the Western Market: Developed countries focus on high-end products with a branding and innovative technology emphasis, whereas they also drive consumption of mid-range products through infrastructure demands.

Industry Consolidation

- Industry Leaders: Companies that lead in technology standards, such as patents and intelligent production lines, dominate the market. For instance, Dongming and Tenda Technology hold over 70% of the domestic high-end market share.

- Small Enterprises: Small and medium enterprises (SMEs) should focus on differentiation (such as custom services) or pivot to niche market segments.

Challenges and Solutions

- Technical Barriers: Companies must improve R&D for advanced materials (e.g., high-nitrogen stainless steel) and enhance manufacturing processes by increasing cooperation between industry, academia, and research institutions.

- Cost Control: Fluctuating raw material prices (such as nickel and chromium) pose risks to profitability. Companies can mitigate this by hedging or entering long-term contracts to stabilize supply.

- International Trade Barriers: Anti-dumping policies and differing technical standards may hinder exports. Companies should strengthen local production and compliance certifications to navigate these challenges.

Stainless steel square head bolts will evolve in performance, intelligence, and ecological impact. Technological innovations and market demand will reshape the industry, with companies focusing on material research, smart manufacturing, and global expansion to maintain a competitive edge while addressing environmental regulations and cost pressures.

As we conclude this detailed exploration of stainless steel lag bolts, we at Prince Fastener remain committed to advancing the fastener industry through innovation and excellence. The future of stainless steel lag bolts is promising, with ongoing technological advancements and expanding applications driving their demand. We are excited to be part of this evolution and look forward to contributing to developing more efficient and reliable fastening solutions.

At Prince Fastener, we don’t just provide products; we offer expertise and support to ensure your projects succeed. We invite you to explore our extensive range of stainless steel lag bolts and experience the quality and reliability that Prince Fastener stands for. For more information or to discuss your specific requirements, please don’t hesitate to contact us. Let’s build a stronger, more sustainable future with Prince Fastener.