In manufacturing, design, and engineering, precision and adaptability are not just advantages—they are necessities. Whether you’re building industrial machinery, designing furniture, or developing medical devices, the components that hold your products together must meet exact specifications. That’s where custom screws come into play.

At Prince Fastener, we understand that off-the-shelf fasteners often fall short when addressing unique challenges. From specialized head shapes and thread designs to material requirements for extreme environments, custom screws are the solution that ensures your project’s success.

But what exactly makes custom screws stand out?

Custom screws are engineered to match your exact needs, whether you require high-strength alloys for aerospace applications or corrosion-resistant materials for marine environments. They can be tailored to fit specific design aesthetics, enhance durability, or optimize performance in ways standard fasteners cannot.

In this blog, we’ll explore the versatility of custom screws, from their applications across industries to the benefits they offer in terms of performance, longevity, and cost efficiency. We’ll also dive into material choices like stainless steel, titanium, and copper alloys and surface treatments such as galvanization that can elevate your project’s durability and appearance.

Whether you’re an engineer, a designer, or a screw manufacturer, custom screws are more than just fasteners—they’re critical components that enable innovation. At Prince Fastener, we’re here to help you turn your vision into reality with precision-engineered solutions.

Read on to discover how custom screws can transform your next project.

What Are Custom Screws?

Custom screws are specially designed and manufactured screws that are tailored to meet the specific needs of the user. These non-standard screws are created with unique head shapes, slot designs, materials, and specifications to meet the particular demands of various applications, smart devices, and environmental conditions.

Applications of Custom Screws

Industrial Field

Used in machinery, automotive components, aerospace engineering, and other scenarios that require high precision and special specifications.

Home Decoration

Used for furniture connection, fixation, and decoration, enhancing the aesthetics and extending the furniture’s lifespan.

Medical Machinery

Custom screws are essential for high precision and adherence to material standards in medical machinery.

Construction Industry

Applied in building components such as bolts, fasteners, etc.

Advantages of Custom Screws

Accurate Fit

Designing screws according to specific applications ensures a perfect match with components.

Enhanced Performance and Longevity

By optimizing the design and material selection, custom screws can offer improved durability and lifespan.

Personalized Design

Custom designs, including pattern processing, meet the client’s unique requirements.

Strengthen Brand Competitiveness

In-home decoration design, custom screws highlight the uniqueness of the brand.

Considerations for Custom Screws

Setting Specifications

Users must provide detailed design drawings or samples, specifying materials, surface treatments, and other factors.

Material Selection

Based on their applications, choose the most suitable materials, such as stainless steel, carbon steel, copper, etc.

Surface Treatment

Options like plating, galvanization, and others can enhance the corrosion resistance and appearance of custom screws.

Production Time

Custom screws often have longer production times, so proper planning is necessary.

The Custom Screw Service Process

1. Requirement Communication

Customers provide the specifications, including design, materials, and other requirements.

2. Solution Development

Screw Manufacturers create a custom solution based on the customer’s needs and provide a price quote.

3. Order Confirmation

Once the customer confirms the solution, the order is placed for production.

4. Production and Delivery

Screw Manufacturers follow the plan and deliver the products on time.

For specific customization needs, you can consult professional screw manufacturers like Prince Fastener.

Standard Material Options for Custom Screws

Material selection for custom screws is diverse, as different materials are suitable for various applications and technical requirements. Below are standard material options and their advantages:

1. Carbon Steel

Characteristics: Cost-effective, good physical properties, high strength.

Applications: General industrial use, such as machinery, building components, etc.

Surface Treatment: Often requires galvanization or blackening to improve corrosion resistance.

2. Stainless Steel

Common Types:

- 304 Stainless Steel: Good corrosion resistance, suitable for general corrosive environments.

- 316 Stainless Steel: Excellent corrosion resistance for marine or strong acid/alkali environments.

- Characteristics: Strong corrosion resistance, aesthetic appearance, good physical properties.

- Applications: Food processing equipment, medical machinery, chemical equipment, etc.

3. Carbon Steel

Characteristics: High toughness, suitable for high-load and special-use applications.

Applications: Automotive components, aerospace engineering, heavy machinery, etc.

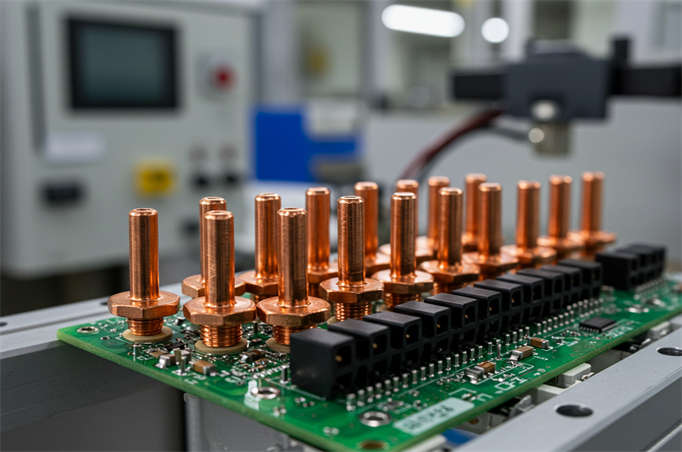

4. Copper Alloys

Types:

- Copper: Aesthetic, corrosion-resistant, good conductivity.

- Red Copper: High toughness, wear-resistant.

- Characteristics: Good corrosion resistance, excellent conductivity, suitable for harsh environments.

- Applications: Electrical equipment, decorative purposes, instruments, etc.

5. Aluminum Alloys

Characteristics: Lightweight, good corrosion resistance, moderate strength.

Applications: Aerospace engineering, automotive light-weighting, electronics, etc.

6. Titanium

Characteristics: High toughness, strong corrosion resistance, and lightweight.

Applications: Aerospace engineering, medical devices, high-end industrial equipment, etc.

7. Polyester/Plastic

Characteristics: Lightweight, sound insulation, chemical corrosion resistance.

Applications: Electronic devices, home decor, decorative purposes, etc.

8. Other Special Materials

Examples: Ceramics, fiberglass, etc., used for unique requirements.

Common Material Selection Issues

- Environmental Conditions: Based on the usage scenario, choose materials with appropriate resistance to corrosion, heat, etc.

- Processing Performance: Select suitable materials based on the screw’s load-bearing requirements.

- Cost Control: Choose materials that offer a good balance of performance and cost based on the budget.

- Surface Treatment: Options like galvanization or nickel plating can further enhance the screw’s aesthetics and performance.

If you have specific customization needs, you can select the material based on these characteristics and requirements.

Benefits of Zinc Plating for Custom Screws

Zinc plating is a standard surface treatment for screws and offers several key advantages:

1. Improved Corrosion Resistance

Principle: Zinc plating forms a protective zinc layer on the surface of the screw, preventing direct contact with external factors (e.g., air, water, acid), thus reducing the likelihood of corrosion.

Galvanic Protection: If the zinc layer is scratched or damaged, zinc corrodes first, protecting the screw’s base material, typically carbon steel or other metals.

Applications: Zinc-plated screws are ideal for use in humid and corrosive environments, such as outdoor equipment, construction components, and automotive parts.

2. Enhanced Aesthetics

Zinc-plated screws have a smooth and polished surface, making them suitable for decorative applications.

3. Increased Wear Resistance

The zinc layer increases the screw’s surface hardness, reducing wear and scratches, especially in high-friction or high-load environments.

4. Cost Efficiency

Zinc plating is relatively inexpensive compared to more complex surface treatments (e.g., nickel or chrome plating), making it ideal for large-scale production.

5. Stronger Adhesion

Zinc plating bonds firmly to the base material, providing lasting protection and durability.

6. Environmental Friendliness

Zinc-plated screws are recyclable, aligning with environmental sustainability standards.

7. Versatility

Zinc plating can be applied to a variety of screw materials, including carbon steel and high-alloy steel, to meet most industrial and consumer requirements.

How to Lower the Cost of Custom Screws

Cost savings for custom screws can be achieved through a variety of strategies, including improving design and processes, optimizing supply chains, and material selection. Below are key strategies and suggestions:

1. Design and Process Optimization

- Mold and Standard Design: Using the screw manufacturer’s existing molds or similar product models can avoid the additional cost of creating custom molds.

- Simplify Design and Structure: Reducing complex features (e.g., thread or head shapes) can decrease processing difficulty and improve efficiency.

2. Production Management

- Batch Production and Order Collaboration: Pooling orders to achieve economies of scale. For example, combining orders from multiple customers to lower unit costs.

- Flexible Minimum Order Quantities (MOQ): Set up tiered pricing (e.g., $0.1 per unit for 10,000 pieces, $0.06 per unit for 100,000 pieces).

3. Automation and Equipment Upgrade

- Introduce Automation: Multi-position cold-heading machines can increase daily output and reduce labor costs.

- Optimize Supply Chain: Implement ERP systems to reduce human errors and improve supply chain response speed.

4. Material and Procurement Optimization

- Select Cost-effective Materials: Choose domestic alternatives (e.g., carbon steel replacing titanium) to reduce costs by over 50%.

- Bulk Procurement: Negotiate long-term contracts with steel mills to lock in prices and avoid market fluctuations.

5. Quality Control and After-Sales Support

- Preventive Inspection: Conduct rigorous initial inspections to avoid rework or defects in mass production.

- Strategic Partnerships: Build long-term relationships with core fastener suppliers to optimize custom parameters and improve efficiency.

By implementing these strategies, screw manufacturers can significantly reduce the cost of custom screws while ensuring quality and performance.

For custom screw solutions, you can trust Prince Fastener to deliver high-quality, cost-effective products tailored to your needs.

From industrial machinery to medical devices, custom screws are the unsung heroes that ensure your designs function flawlessly. By choosing the right materials, optimizing designs, and leveraging advanced manufacturing techniques, you can create fasteners that meet your specifications and exceed expectations.

At Prince Fastener, we specialize in turning complex requirements into reliable, high-performance solutions. Our expertise spans everything from material selection and surface treatments like galvanization to cost-saving strategies such as mold reuse and process optimization. We work closely with clients to understand their unique challenges and deliver custom screws that align perfectly with their goals.

Whether you need screws for high-stress applications, decorative purposes, or cost-sensitive projects, our team is equipped to handle every step—from initial design to mass production. We believe that the right fastener isn’t just a component; it’s a foundation for success.

Ready to elevate your next project? Contact Prince Fastener today to discuss your custom screw needs. Our team of experts is here to help you design, manufacture, and deliver the perfect fasteners for your application.