In the vast landscape of industrial manufacturing, fasteners, and aluminum foil play indispensable roles. As fundamental components for connecting and securing structures, fasteners act as the “joints” of machinery, ensuring the stable operation of entire mechanical systems. They are widely used in construction, automotive, aerospace, and many other sectors. With its lightweight nature, flexibility, excellent thermal and electrical conductivity, and outstanding moisture and oxidation resistance, aluminum foil holds significant importance in packaging, electronics, aviation, and beyond.

In recent years, rapid technological advancements and evolving market demands have sharply focused on the innovative integration of these two materials. The collaboration between the fastener industry and aluminum foil is far from a mere physical combination—it represents a transformative innovation spanning materials, packaging, surface treatments, and application expansions.

From a material innovation perspective, composite fasteners that combine aluminum foil with carbon fiber or plastics offer aerospace and automotive industries solutions that balance strength and lightweight properties. High-precision electronic aluminum foil fasteners meet stringent requirements for precision and conductivity in electronic devices. In packaging, intelligent packaging systems and eco-friendly solutions enhance storage and transportation safety and align with green development principles. Surface treatment innovations, such as aluminum foil coatings and nano-coating technologies, further improve corrosion resistance and protective performance. Emerging fields like new energy vehicles and aerospace provide expansive opportunities for their integration.

Moreover, aluminum foil and fastener materials exhibit complementary characteristics in weight, rigidity, conductivity, and application scenarios. This synergy lays a robust foundation for their deep integration and injects continuous momentum into industrial innovation. Let us explore this groundbreaking partnership’s transformative potential across industries.

How Can the Fastener Industry Leverage Aluminum Foil Innovations?

Material Innovation with Composite Fasteners:

We combine aluminum foil with other materials, such as carbon fiber and plastics, to create unique fasteners. For instance, aluminum foil and carbon fiber composites can enhance fasteners’ strength and corrosion resistance, making them ideal for aerospace, automotive, and other demanding applications.

High-Precision Electronic Foil Fasteners:

We are developing fasteners made from high-precision electronic aluminum foil for electronic products. These fasteners provide excellent precision and high conductivity, meeting the stringent requirements of modern electronics.

Packaging Innovation with Smart Packaging:

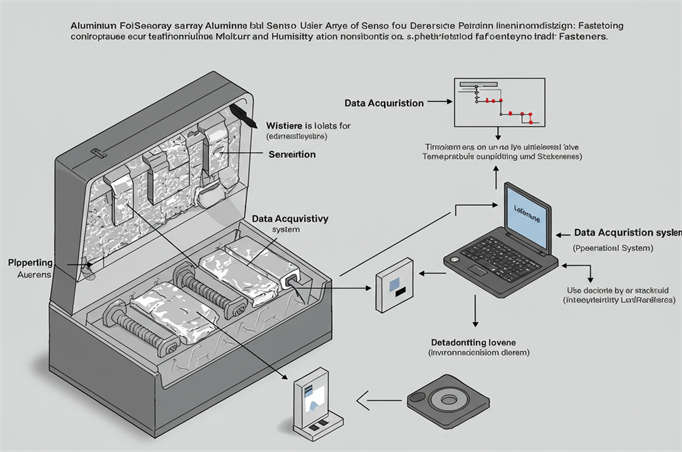

We utilize aluminum foil’s conductive properties to develop smart packaging systems. By integrating aluminum foil sensors into packaging, we can monitor fastener temperature, humidity, and other environmental factors in real time. The data can be sent to user devices through wireless transmission, enabling real-time monitoring of fastener conditions.

Eco-friendly Packaging:

We use biodegradable aluminum foil and reusable foil packaging materials to minimize environmental impact and promote sustainability in the fastener industry.

Surface Treatment Innovation

Aluminum Foil Coating on Fasteners:

We apply aluminum foil coatings to fastener surfaces to improve corrosion resistance and electrical conductivity. For example, coating bolts and nuts with aluminum foil enhances their durability in harsh environments.

Nano-Coating Technology:

By incorporating nanomaterials, we create nano-coatings on aluminum foil to increase surface density and shielding effectiveness. This further enhances fasteners’ maintenance characteristics.

Expanding Main Applications

Electric Vehicle Industry:

We use high-conductivity aluminum foil in the electric vehicle battery pack to develop fasteners that connect and secure battery components. This ensures the battery pack’s efficient operation.

Aerospace Industry:

We develop reinforced fasteners made from aluminum foil to meet the aerospace industry’s need for lightweight and high-performance materials. This helps reduce structural weight while ensuring strong connections and durability.

The Versatility of Aluminum Foil and Fastener Materials

Comparing Material Characteristics:

- Weight and Strength: Aluminum foil is lightweight, with a density of about 2.7g/cm³, much lower than steel and other fastener materials. This makes aluminum foil an ideal choice for applications sensitive to weight. In contrast, materials like steel and titanium offer excellent strength for high-load applications.

- Flexibility and Rigidity: Aluminum foil is flexible, making it easy to shape into various forms. This is ideal for applications requiring adaptability. Fastener materials generally require higher rigidity to ensure connection stability and precision.

- Thermal and Electrical Conductivity: Aluminum foil has good thermal and electrical conductivity, about two-thirds that of copper per unit volume, making it widely used in electronics. Fastener materials’ conductivity requirements vary based on their applications. For example, some electrical equipment needs fasteners with excellent conductivity, while others prioritize mechanical performance.

Complementary Range of Applications

- Packaging Protection: Aluminum foil is widely used in packaging, acting as a standard product fastener. Its moisture resistance, anti-oxidation, and insulation properties maintain the integrity of fasteners during storage and transportation. Fasteners in engineering, automotive, and machinery are critical in connecting and securing parts, ensuring product quality and performance at each stage.

- Electronics and Electrical Applications: Aluminum foil is a conductive material or heat dissipation component in electronic devices. They can provide effective electrical connections and heat dissipation when combined with fasteners. For example, aluminum foil can be used to create conductive tracks on circuit boards, while standard fasteners secure the components in place, ensuring the system’s efficient operation.

- Aerospace and Automotive Applications: In the aerospace industry, aluminum foil creates lightweight parts and insulation panels, integrated with high-strength fasteners to reduce aircraft weight while maintaining structural strength and safety. In the automotive industry, aluminum foil is ideal for insulating and conducting components in battery packs. At the same time, standard fasteners are used to connect and secure vehicle components, improving performance and reliability.

Complementary Manufacturing Processes

- Shaping and Forming: Aluminum foil is easy to cold-form and hot-forge, allowing it to be shaped into various components using processes like stamping and extrusion. Fastener manufacturing involves forging, cutting, and cold-forming, which can benefit from mutual learning and collaboration, enhancing production efficiency and product quality.

- Surface Treatment: Aluminum foil can undergo surface treatments such as anodizing to improve corrosion resistance and wear resistance. Fastener materials also undergo similar surface treatments like electroplating or chemical plating, changing surface properties to extend their lifespan and stability.

Complementary Performance Features

- Strength and Capacity: While aluminum foil has relatively low strength, it can enhance its load-bearing capacity through composite designs or special engineering techniques. Fastener materials need to be strong and hard enough to support working loads. In specific applications, combining aluminum foil with other materials can optimize theirboth performance.

- Corrosion Resistance: Aluminum foil has excellent corrosion resistance, as it forms a dense oxide layer when exposed to air, preventing further oxidation. Fastener materials’ corrosion resistance varies, with stainless steel and aluminum alloy fasteners offering strong protection. In harsh environments, aluminum foil and fasteners can work together to provide better protection.

- Thermal Properties: Aluminum foil has a high thermal conductivity, making it ideal for heat dissipation and thermal management. Fasteners must maintain stable performance in high-temperature environments. Combining aluminum foil with heat-resistant alloys can improve heat control and enhance system performance.

Collaborations in the Electronics Sector Between Aluminum Foil and Fasteners

1. Dow and Carbice’s Thermal Interface Material Partnership:

Dow collaborated with Carbice, a carbon nanotube technology company, to develop innovative thermal interface materials (TIMs) that enhance the performance and stability of electronic products. This fusion of Dow’s expertise in silicone and Carbice’s carbon nanotube technology provides effective thermal management solutions for electric vehicle batteries and mobile devices, including GPUs.

2. Aluminum Foil for Heat Dissipation in Electronics:

In electronic devices, aluminum foil is commonly used as a heat-dissipation material, working with fasteners to achieve better thermal conductivity. For example, aluminum foil can create thermal pads or heat sinks on circuit boards. Fasteners are then used to secure these components, facilitating rapid heat transfer and ensuring efficient system performance.

3. Aluminum Foil and Fasteners in Electromagnetic Shielding:

Aluminum foil is also employed in electronic devices to protect them from electromagnetic interference. Fasteners secure the aluminum foil shielding, ensuring proper contact with other components. This combination is widely used in communication devices, computers, and other electronic products, safeguarding devices from external interference and preventing internal radiation leakage.

This collaboration exemplifies how aluminum foil and fasteners work together in the electronics sector. They provide effective solutions for heat dissipation, electromagnetic shielding, and other critical functions, driving the advancement of electronic technology.

The innovative integration of aluminum foil and the fastener industry marks a profound industrial revolution. From composite materials and innovative packaging to nano-coating technologies and cross-sector applications, every dimension showcases the immense potential of this collaboration.

In electronics, case studies like Dow and Carbice’s thermally conductive interface materials, aluminum foil-based heat dissipation solutions, and electromagnetic shielding applications demonstrate how their synergy enhances device performance and reliability. These advancements push the boundaries of electronic technology and drive the industry toward higher standards.

As technology evolves and market demands diversify, this partnership will unlock further opportunities. Advanced composite materials tailored for specific industries, intelligent and sustainable packaging systems, and cutting-edge surface treatments will redefine fastener performance. In sectors like new energy vehicles and aerospace, aluminum foil’s lightweight and conductive properties will continue to optimize structural efficiency and safety.

Ultimately, the fusion of aluminum foil and fasteners will leave a lasting imprint on industrial history, steering manufacturing toward greater efficiency, sustainability, and intelligence. Together, they will forge a future where innovation and practicality converge, paving the way for human progress.