In the current era of rapid fastener industrial development, fasteners are critical as the cornerstone of connecting and maintaining machinery and equipment. However, with the intensification of market competition, how to effectively control the cost of fasteners has become the key to improve the competitiveness of enterprises. In this paper, we will discuss in depth the methods of fastener costing to provide a clear cost management framework to help enterprises occupy a favourable position in the fierce market competition.

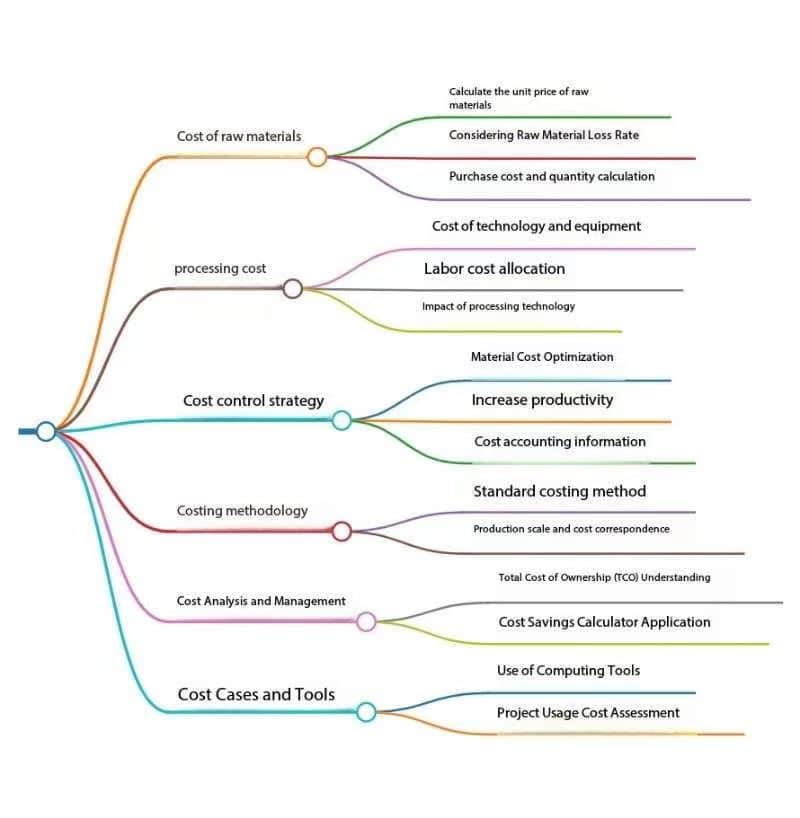

Detailed description of fastener costing methods

Fasteners are common key components in various industries, and their extensive use drives the huge potential of the fastener market. However, how to clearly measure the cost of fasteners is a headache. In this article, we will explain in detail a feasible fastener costing method to help enterprises better save costs and improve their operating ability.

1. Calculate the material cost of fasteners

Material cost is the premise of fastener cost, including the commodity cost of raw materials, processing costs and other costs. Enterprises need to measure this cost in all aspects to ensure that each cost can be measured well. At the same time, suitable raw materials should be established based on the type and specification of fasteners to improve work efficiency and product quality. This is the premise of fastener cost, including product cost and consumption. Steel, stainless steel, copper and other different materials have different procurement costs, should be based on specific material prices and application quantities of measurement

2. Fastener production cost calculation

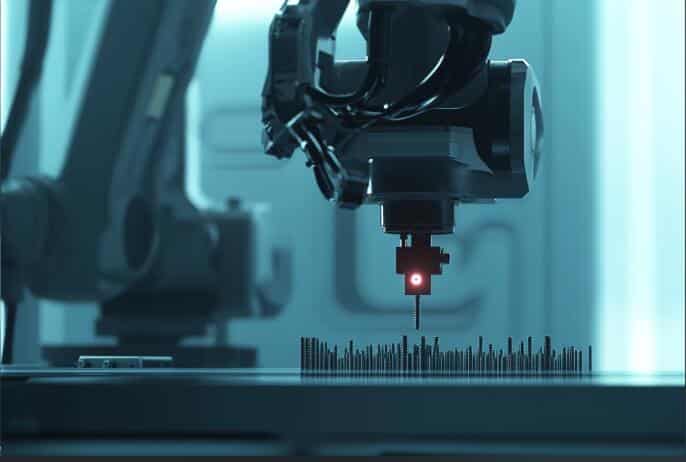

The cost of goods refers to all the costs incurred in the production process of fasteners, including manpower costs, equipment depreciation costs, energy costs and so on. Enterprises should calculate such cost efficiently based on the condition of production line. The key to the profitability of the enterprise is to arrange the production resources scientifically, improve the working efficiency and minimise the cost. The production process of fasteners is subject to a number of procedures, and the process fee, equipment service fee and labour cost of each procedure should be measured in detail. Costs are based on fastener appearance, dimensions, and production processes.

3. Measuring the Cost of Fastener Quality

The quality of fasteners is closely related to the service life and safety of the product, so quality costing is critical. Quality costs include quality inspection costs, after-sales costs, etc. Enterprises need to accurately measure such costs in order to improve product quality and customer satisfaction. At the same time, the establishment of a perfect quality management system to reduce the quality problems caused by the enterprise’s competitiveness is of great significance.

4. Calculating environmental costs

With the progress of society, environmental protection is getting more and more attention. Enterprises need to calculate environmental costs, including waste disposal costs, environmental renovation costs and so on. Reducing environmental costs is not only conducive to improving corporate image, but also helps to reduce business risks and create a good environment for sustainable development.

5. Cost management and reduction

Manipulating and reducing the cost of fasteners is a key factor in improving corporate profitability. The company reduces raw material cost, commodity cost and quality cost by formulating reasonable cost control measures. Meanwhile, sound supply chain, sound logistics system, improve supply efficiency and manipulate cost. In addition, the company can also make use of technological innovation and technical improvement to improve work efficiency, manipulate costs and improve product quality.

6. Human Resources cost:

Contains immediate work and indirect labour. Immediate labour refers to the wages of workshop workers, and indirect work will involve costs and expenses, etc. Labour costs are generally allocated in proportion to working hours

Fasteners are an indispensable and important component of modern industrial production, widely used in machinery, cars, electronics, aviation and other fields. Cost measurement is a very important part of the fastener procurement process. In this article, we will explain the costing method of fasteners in detail to help you improve the efficiency of procurement cost control.

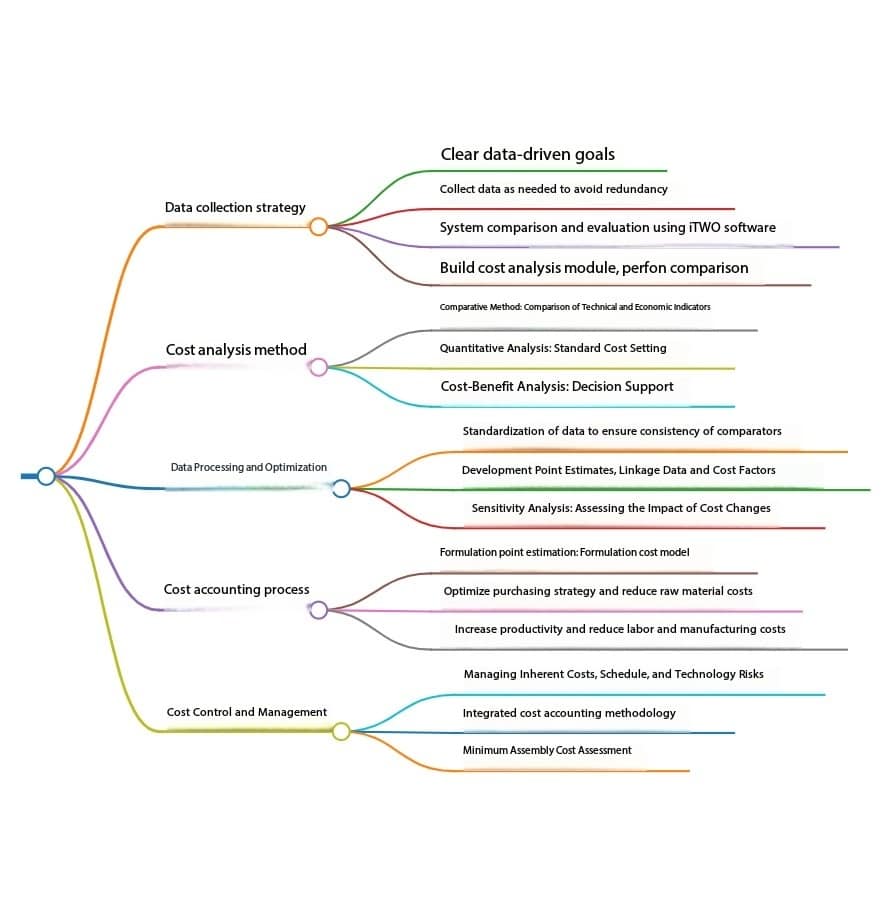

In fastener costing, effective collection and analysis of information is a key step to ensure cost management and optimise purchasing decisions.

Below are the detailed steps and approaches:

1. Define data-driven objectives:

First and foremost, data analysis objectives must be clearly defined, which is beneficial to avoid data redundancy and improve profiling efficiency. For example, establish what cost elements need to be analysed, such as raw material costs, processing costs, costs during the period, etc.

2. Collect data on demand:

Collecting data based on profiling objectives ensures the relevance and accuracy of the data. For example, timely activity data can be obtained through production records, purchasing records, engineering models, etc.

3. Selection of costing methods:

Selection of appropriate costing methods is crucial. For example, the life-cycle costing method helps companies to grasp the cost of fastener plans more effectively. In addition, the specification cost method can be used to guide the actual cost control based on the development of standard costs.

4. Application of Cost Analysis Methods.

Several cost analysis methods, such as comparative method, sensitivity analysis, risk assessment, etc., are selected to expose cost differences and find the causes. This method helps companies discover cost drivers and develop appropriate control measures.

5. Information Planning:

Improve the degree of informationisation in management and accounting, integrate costing methods and improve the overall cost measurement level. For example, data analyses using big data platforms can clearly show the relationship between data trends and plant machine operations.

6. Gradual improvement:

Through regular costing profiling, continuously improve the procurement plan and production process to reduce raw material procurement costs and labour commodity costs. At the same time, simulation and modelling techniques are used to select the most appropriate torque system.

Based on the above process, enterprises can effectively collect and analyse the cost data of fasteners, so as to achieve cost management and improve the procurement decision-making objectives.

Fastener procurement countermeasures: how to improve efficiency and manipulate costs?

Fasteners are common key components in various fields, including bolts, nuts, washers and so on. The selection of suppliers in the industry chain and procurement countermeasures are particularly important to the production efficiency and cost management of enterprises. In this article, we will introduce some efficient fastener procurement countermeasures to help you improve efficiency and reduce costs.

1. Explore reliable fastener suppliers

Exploring reliable fastener suppliers is the key to improving fastener procurement efficiency. Reliable fastener suppliers should have the following characteristics:

– Quality Assurance: The agent should have ISO9001 and other relevant quality system certifications and be able to provide relevant quality inspection reports of the products.

– On-time supply: the agent should be able to supply on time to ensure that your production schedule is not affected.

– Intimate service: the agent should be able to provide timely technical support and after-sales service to help you deal with things and provide solutions.

Compare with several dealers and choose a service provider that is both reliable and can meet your requirements, which greatly improves your purchasing efficiency. A reliable service provider is a key factor in ensuring successful fastener shopping. Explore reputable and experienced agents and establish a long-term relationship with them to ensure quality and supply reliability. At the same time, the agent must respond quickly to meet your emergency requirements.

2. Fastener Demand Forecasting and Management

Based on past sales records and industry outlook, a reasonable demand forecast can help you better manage fastener inventory and purchase quantities. If you can immediately foresee the future requirements, you can be able to shop according to the plan and avoid overstocking or undersupply.

At the same time, it is also necessary to establish and improve the inventory management system, timely tracking of supplies, timely inspection of inventory to ensure inventory accuracy. Prevent property waste and inventory hold-up caused by improper inventory management.

3. Fastener bulk purchasing and supplier exploration

Bulk purchasing is an important way to reduce the cost of fastener goods. Based on the discussion with suppliers, you can get more discounts and discounts by developing different purchasing programmes based on your needs.

It is also important to create long-term partnerships with your suppliers. Based on maintaining a good relationship with your suppliers, you can get more support and incentives, including emergency order processing, flexible delivery arrangements, and so on. This can help you solve emergency situations and improve work efficiency.

4. Technological innovation and process improvement

Fastener procurement is a complex process that involves multiple links and processes. Through technological innovation and process improvement, you can improve procurement efficiency and manipulate costs.

For example, the application of e-procurement system can simplify the procurement process and improve the transparency and efficiency of procurement. Sharing statistical information with suppliers leads to better communication and rapport.

In addition, considering the use of standardised fastener specifications and materials can reduce procurement costs. Selecting cost-effective fastener brands and models can reduce procurement costs while ensuring quality.

In modern manufacturing, fasteners are an integral part of maintaining and connecting every component. It is vital for companies to explore fastener procurement countermeasures that can improve efficiency and reduce costs. In this article, we will introduce some simple and effective ways to help you achieve success in fastener procurement.

5. Develop a clear procurement programme

Before purchasing fasteners, it is important to develop a clear procurement programme. This includes establishing the types and quantities of fasteners needed, as well as their estimated delivery dates. By planning ahead, you can better control your inventory and reduce purchasing costs.

6. Harmonise purchasing methods

Centralising fasteners in one or more channels can help you get better prices and service. Scattered purchasing with multiple agents can increase product costs. According to the unified purchasing method, you can better manage supplier relationships and bargain quickly and reasonably.

7.Regular evaluation of suppliers

Evaluating distributors on a regular basis is an important step in ensuring their stability and quality. Evaluation criteria may include on-time delivery, product quality, after-sales service, and so on. Through the evaluation, you can clarify whether you need to change the distributor and what level of improvement is needed to improve the efficiency of the industry chain.

8.Application of e-procurement system

In the procurement process, the application of e-procurement system greatly improves the efficiency. This system can help you manage purchase orders, track delivery status, and monitor inventory in real time. With automated processes and real-time dynamics, you can better manage the procurement process and make timely corrections.

9. Explore substitution or design optimisation

Sometimes the cost of fasteners can be reduced by exploring substitutions or optimising designs. Work with your suppliers to explore if there are alternative materials or designs that are cheaper and more affordable. These types of improvements can help you reduce purchasing costs while always maintaining product quality and reliability.

10. Research the industry outlook immediately

The fastener market is a highly competitive and rapidly changing market. Researching the industry outlook immediately can help you grasp new technologies and trends, as well as the pricing and benefits of different agents. Based on the market trends, you can correct your purchasing strategy in time to get the best purchasing results.

The conclusion is based on exploring reliable service providers, formulating a clear sourcing plan, unified sourcing methods, rating agents immediately, applying e-procurement systems, exploring alternatives or optimising designs, researching industry outlooks immediately, improving fastener sourcing efficiency, and manipulating costs. Applying this strategy can also help you stay competitive and successful in a competitive market.

With the detailed costing methods and sourcing strategies described above, companies can more accurately control the cost of fasteners, thereby improving overall economic efficiency. In the ever-changing market environment, continuous optimisation of cost management can not only improve profitability, but also enhance the competitiveness of your business in the marketplace. Remember, cost control is a continuous process that requires enterprises to continuously explore and innovate. By implementing effective costing and purchasing strategies, enterprises can move forward steadily in the fastener market and achieve sustainable development.