The Purpose of Washers on Fastener Assemblies

What is a Washer?

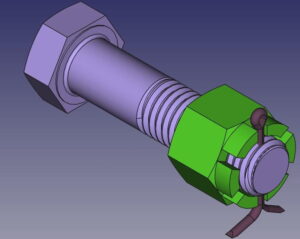

Washers are temporary types of fasteners and unlike the most common ones, they are physically different as they are flattened disc-shaped metal with a hole in the middle. They are often used in conjunction with threaded fasteners like screws, bolts & nuts, threaded studs, etc.

There are various types of washers and even hybrid ones that are innovated to suit certain kinds of applications. But as the variations continue to grow in numbers, their function and purpose stay relatively similar. Some of the benefits that washers provide include load distribution, spacing, absorption of vibration, and liquid protection.

Why Are Washers Used with Fasteners?

Load Distribution

Washers were primarily designed to distribute a load of threaded fasteners within the surface of the application. This method helps in reducing the chances of direct damage to the components which can later on cause failure of the assembly. By eliminating the risk of overloading in fasteners, washers provide an important role in protecting both materials against damage or cracking.

Spacing

A simple solution for problems regarding size difference between threaded fasteners and surface materials is through using washers as spacers. This method is just one example of using washers for temporary spacing until they can get replaced by a proper and permanent spacer.

Vibration Absorption

Vibration isolating washers are made of softer materials like rubber or plastic. This allows them to efficiently work with the constant movements in the assembly. Oftentimes, when bolts and nuts are used in machinery or engines with aggressive vibrations they can break or obtain damage. To prevent the object from being damaged washers are an effective solution for absorbing the vibrations from hard materials.

Liquid Protection

Fasteners are also known to be used in piping and other liquid connections. Usually, these assemblies require a stopper or prevention of ingress of liquids. Just like vibration-damping washers, liquid-sealing washers are made of rubber material to completely provide waterproofing. Other types of sealing washers are also used to seal out water, oil, dust, solvents, and other contaminants.

How to Use Washers?

Washers are easy devices to use, but the first thing to work on is choosing the right thickness. For example, when you are using washers as a waterproof seal a thinner washer will be the best option. It is relatively important to measure the thickness of washers for use as they mainly affect the joint of assemblies.

For installation of washers, they are placed in the bearing surface of the hole before a screw or a bolt. And as the threaded fastener is driven to tighten the washer will be placed between the head and the surface of the application.

2 Main Types of Washers

Here are the two main types of metal or steel washers:

Flat Washers

Flat washers are also called plain washers. They are the basic and most common type of washers that are usually made of metal and used along with bolts and nuts.

These types of washers also mainly help the distribution of load to eliminate the stress and pressure on the other fasteners. They also prevent loosening and further damage to the assembly.

Spring Washers

This type of washer has twisted shape forms designed to provide a preload between two surfaces. Spring washers are also referred to as locking washers, and unlike flat washers, they are placed on the nut side. There are many types of spring washers, the most common are Belleville washers, curved washers, conical washers, and wave washers.

If you are looking for caliber-rated fasteners, custom fasteners, standard washers, OEM washers, and other related fastening products, you may contact us for your inquiries.

We offer wholesale prices of high-quality materials on fasteners for different ranges of applications. Learn more and discover more capabilities from a leading supplier and manufacturer of industrial parts for more than 30 years. Visit us here Prince Fastener Manufacturing Co., Ltd.