Double-headed Screws

Variations of screws have been developed to suit different kinds of fastening applications. One of the best-innovated solutions used in creating hidden joints between two objects is double-headed screws.

What are double-ended screws?

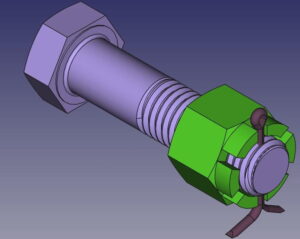

Double-ended screws go by different names around the industry, some of the commonly known names are double-headed screw, dowel screw, and double-threaded screw. This fastener consists of two threaded ends and unthreaded center that can be inserted in two surfaces which then create a hidden joint.

Some double-ended screws have particular designs in threading, for instance, the usual dowel screws have thread-forming-type on both ends (i.e. single threading) that easily goes into wood surfaces. While an assembly between wood and metal surfaces needs two types of threading on the double-ended screws which feature a machine screw thread and the common wood screw thread on the other side.

How do double-ended screws work?

Application use and installation of double-ended screws

Dowel screws or double-ended screws are used to connect a fixed link between objects usually in large buildings, construction, mining machinery, steel structures, and more. When installing double-ended screws they require a pre-drilled pilot hole, both ends can have standard right-hand threading for working clockwise which can be tightened by locking pliers or driver tools.

Common projects that need double-ended screws:

- Finial installation (apex of a roof, pinnacle ornament, canopy)

- End-to-end joints

- Baluster attachment

- Furniture making

- Mining machinery

- Boiler steel structures

- Crane towers

Moreover, some factor to consider during the installation of dowel screws should be the material of the surface you are working on. It is important to choose the right drill or driver bit when installing double-ended screws as it can into proper insertion or failure. Lastly, the inner diameter of the pilot hole should match the diameter of the screw, while materials like hardwood may need larger pilot holes than softwood.

Example pilot hole sizes for double-ended screws

Double-ended Screw Sizes | Pilot Hole Size (inches) | |

Soft Wood | Hard Wood | |

⅛ #6 | 7/64 | 7/64 |

5/32 #8 | 9/64 | 9/64 |

3/16 #10 | 5/32 | 11/64 |

Surface treatment for double-ended screws

- Electroplating

- Blackening

- Oxidation

- Phosphating

- Non-electrolytic

- Zinc flake coating

Purchase High-quality Double-ended Screws from a Leading Manufacturer and Supplier

Prince Fastener is a renowned manufacturer and supplier of double-ended screws, dowel screws, wood screws, machine screws, custom fasteners, bolts, nuts, drywall screws, masonry screws, step screws, and other high-quality fasteners for any industry. We offer different capabilities for innovating solutions in fastening according to customer requirements, specifications, designs, or drawings. We support OEM, ODM, private-label, custom fasteners, wholesale fasteners, bulk fasteners, and any type of business around the globe. All manufactured products by the company comply with the standards of ISO, DIN, JIS, ASTM, ANSI, and others.

Please feel free to contact us anytime for fastening essentials and any related industrial components. We can give you a free quotation for products within 24 hours of inquiry.