Custom Washers

The best custom manufacturer of different fastening needs

Prince fastener specializes in fabricating thousands of standard and non-standard fasteners including custom washers. We provide professional service in meeting specific requirements of industries and projects with the aim of a better and safer world of fastening. Why source custom washers and fasteners with us?

- Over 30 years of industrial manufacturing

- We are equipped with a complete and advanced production line or facility to meet your requirements

- We stand by our principle to provide customer satisfaction to the best we can

- Wide range of manufacturing capabilities under international standards and quality

What Are Washers For?

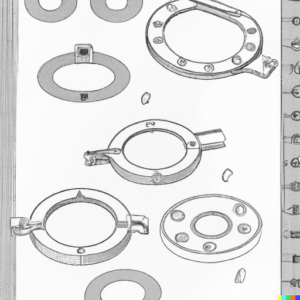

Washers are known for their major visual difference from other types of fasteners. They come in variations of types that propose a reliable purpose in assembly once installed. Generally, washers appear flat disc-shaped with a hole in the middle. Their purpose is to help in distributing the load received by threaded fasteners to prevent failure and damage in the application. Washers are applied between screws or bolts and nuts. They act as the bearing surface of load and force to prevent the loosening of nuts, therefore, enhancing the lifespan of the threaded fastener’s application.

Different Types of Custom Washers

1. Plain Washers

This type of washer is commonly used as a spacer, though plain washers distribute the load and reduce the friction during the tightening of installation. The different types of plain washers include;

Flat washers – Also known as flat nut washers, flat washers provide insulation and spacing. They are commonly used in manufacturing and maintenance or repair.

Finishing washers – are also called flush countersunk washers. Finishing washers are used for their reliability to provide a boring surface usually in woodworking pieces like cabinet and furniture making.

Shoulder washers – usually used in areas of electrical equipment as a bushing to insulate shafts of fasteners. Therefore shoulder washers are made out of non-conductive material such as plastic or nylon.

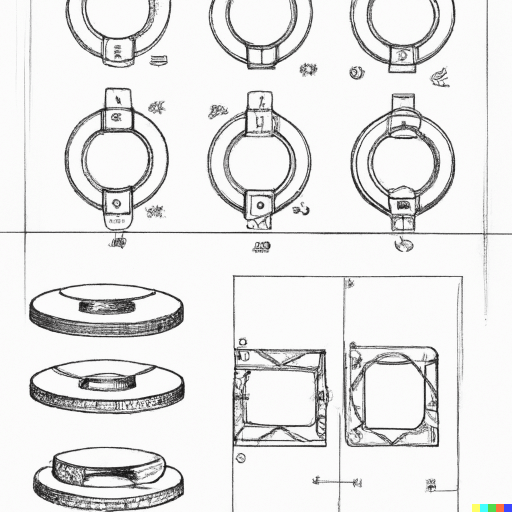

2. Lock Washers

From the name itself, lock washers prevent threaded fasteners to loosen or rotate from vibrations and torque. They are commonly used along with bolts and nuts in the transportation, automotive, and aerospace industries. The common types of lock washers are the following;

Tooth lock washers – have tooth-like appearance or serrations in the external or internal body. These features allow them to prevent the loosening of threaded fasteners in the application due to friction.

Retaining washers – have features of internal teeth grip in its hole. Retaining washers are used in electrical applications.

Sealing washers – also called tap washers, are commonly used in applications that maintain an ingress-protection like plumbing. Sealing washers provide a closed and tight seal between the screw head and the surface of the material.

3. Spring Washers

The main purpose of spring washers is to provide axial load (a force in the same direction as the axis) to fasteners. This limits the unnecessary movement of the components during vibration or thermal expansion. Spring washers are used in applications that require flexibility like actuators on airplanes, flight controls, and landing gear.

Spring washers – absorb the shock within their application to prevent the bolt or nut from coming loose in the assembly.

Cup washers – are used for their insulating purpose. They protect the head of screws from contacting electricity in an application. Cup washers also provide a decorative or aesthetic look and anti-tampering measure for assemblies.

Other types of washers

- Beveled Washers

- Flange Washers

- Plastic Washers

- Wave Washers

- Special Washers

- Hardened Washers

Custom Washers and Standard Fastener Manufacturer and Supplier

Prince Fastener is a renowned manufacturer and supplier of thousands of fastening components in standard or non-standard elements. We guarantee high-quality custom washers and standard fasteners for different applications. The company is certified by ISO, DIN, JIS, GB, and more.

Prince fastener has served thousands of customers and clients worldwide for over 30 years. We specialize in helping many industries with their crucial requirements in fasteners and its application. We offer services in custom manufacturing, OEM, ODM, and private-label of many varieties of screws, bolts, nuts, washers, etc.