The #6 screw diameter measures exactly 0.138 inches or 3.505 millimeters, according to ANSI standards. You can see how this size fits between #4, #8, and #10 screws in the table below.

| Screw Number | Diameter (inches) | Diameter (mm) |

|---|---|---|

| #4 | 0.112 | 2.845 |

| #6 | 0.138 | 3.505 |

| #8 | 0.164 | 4.166 |

| #10 | 0.190 | 4.826 |

If you know the exact screw diameter, you can pick the right fastener for strength, fit, and safety. You avoid problems like stripping threads or leaks by matching the screw to your project needs.

Key Takeaways

- The #6 screw diameter is 0.138 inches (3.5 mm). It is bigger than #4 screws but smaller than #8 and #10 screws. This size is good for light and medium jobs.

- Picking the right screw size and type stops problems. It helps avoid stripped threads, weak joints, or splitting wood. This makes your project strong and safe.

- #6 screws are great for woodwork, cabinets, and light builds. #4 screws are best for delicate work. #8 and #10 screws are used for medium or heavy jobs.

- Drilling pilot holes that match the screw diameter helps a lot. It stops wood from splitting and makes screwing easier. This is very helpful in hard woods.

- Use corrosion-resistant screws like stainless steel or galvanized ones. These are needed for outdoor or wet jobs to stop rust and damage.

#6 Screw Diameter

Measurement in Inches and Millimeters

You might wonder how big a #6 screw really is. The #6 screw diameter measures 0.138 inches. If you prefer metric, that equals about 3.505 millimeters. This size comes from the standards set by fastener manufacturers in the United States. You can see the main measurements for a #6 screw in the table below:

| Measurement Type | Value (inches) |

|---|---|

| Body Diameter | 0.138 |

| Minimum Thread Length | 11/16 |

| Hex Key Size | 7/64 |

| Head Diameter | 0.226 |

| Head Height | 0.138 |

| Maximum Thread Length | 1 1/8 |

Tip: Manufacturers usually list #6 screw diameter in inches, not millimeters, because these screws follow US standards.

When you choose a screw, knowing the #6 screw diameter helps you match it to the right hole size and material. This prevents problems like loose fits or stripped threads. You will also notice that #6 screws are a bit thicker than #4 screws but thinner than #8 or #10 screws. This makes them a popular choice for light to medium-duty projects.

Thread Count and Gauge Explanation

You may have seen numbers like “6-32” or “6-20” on screw packages. The first number tells you the gauge, which is the size. The second number shows the thread count, or how many threads fit in one inch. For a #6 screw, the gauge number 6 means the screw has a body diameter of 0.138 inches. You get this number by multiplying the gauge (6) by 0.013 and then adding 0.060.

The Unified Thread Standard (UTS) sets two main thread counts for each screw size. For #6 screws, you will find both coarse and fine threads. Coarse threads are easier to drive into wood or soft materials. Fine threads work better in metal or hard plastics. The gauge number always matches the screw’s diameter and helps you pick the right screw for your project.

When you use #6 screws, you might notice some common issues. Here are a few things users often report:

- #6 screws can snap or break more easily than #8 screws, especially if you use longer screws.

- You will find #6 screws work best for short, light jobs like attaching drawer slides or hinges.

- #8 screws give you more strength for furniture or structural work.

- Stainless steel #6 screws are harder to find, so they are not the best for outdoor or heavy-duty use.

- Many people use #6 screws with glue for extra hold, but they avoid them for long or high-stress jobs.

- #4 screws are for delicate tasks, while #10 screws handle heavy-duty needs.

Knowing the #6 screw diameter, thread count, and gauge helps you avoid these problems and pick the right screw every time.

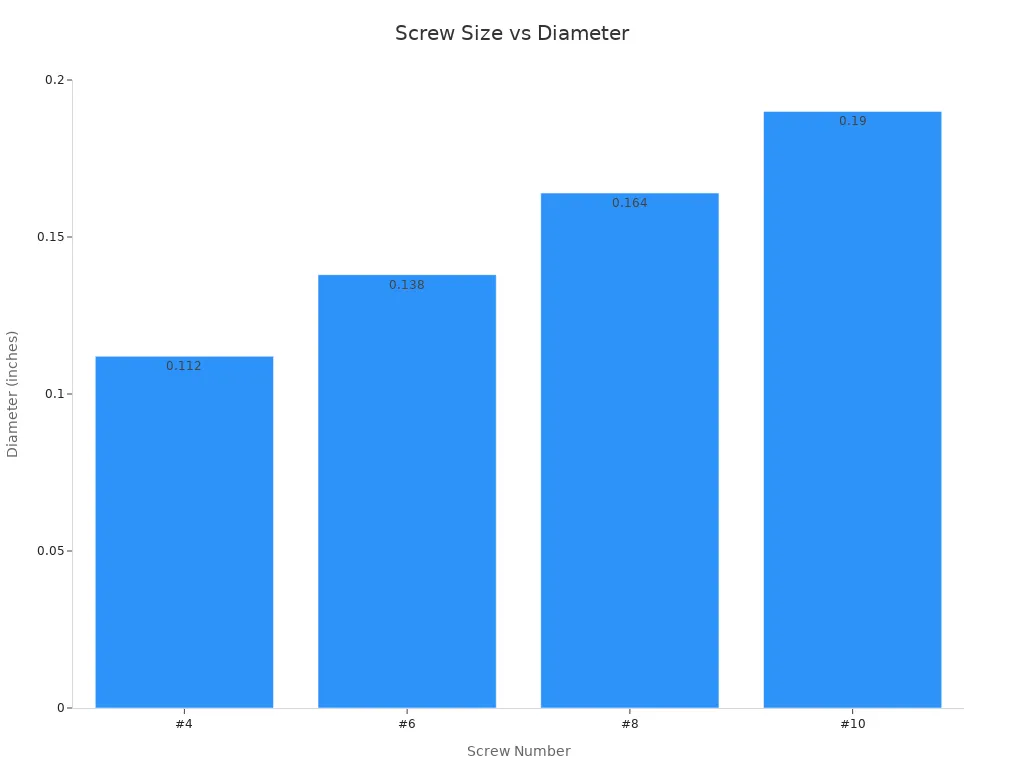

Screw Diameters

#4, #8, and #10 Screw Sizes

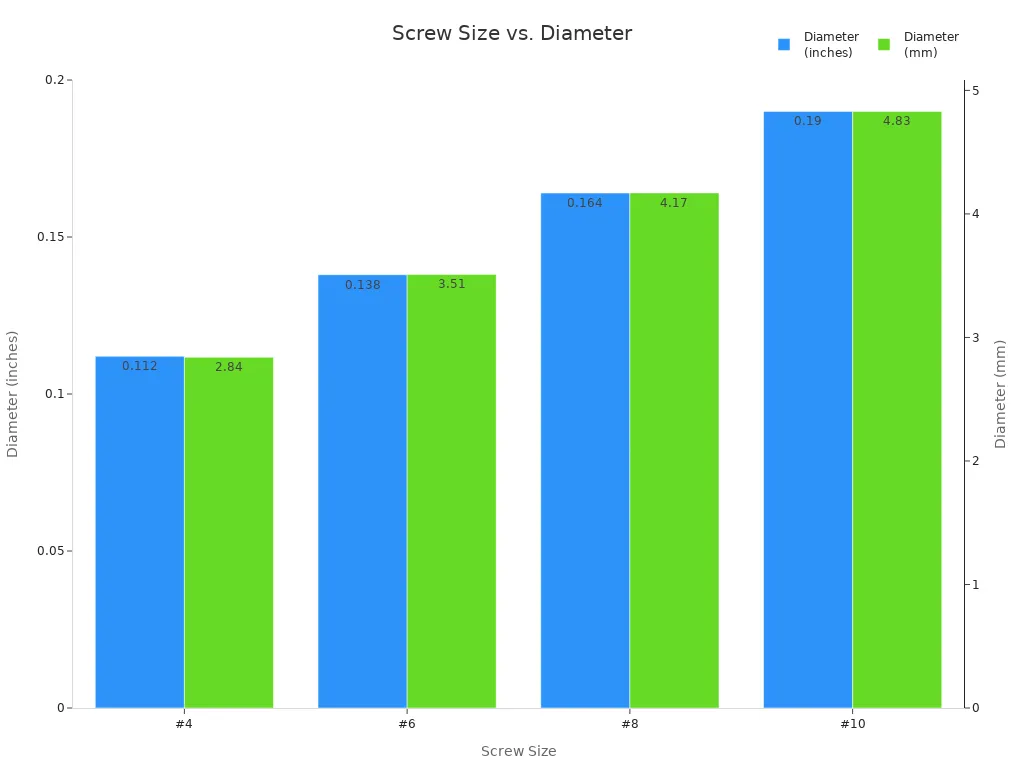

When you look at screws, you will notice that each size has a specific diameter. The screw size number tells you how thick the screw is. For example, a #4 screw has a diameter of 0.112 inches, which is about 2.84 millimeters. A #8 screw measures 0.164 inches, or about 4.17 millimeters. The #10 screw is even thicker, with a diameter of 0.190 inches, or 4.83 millimeters. These measurements come from standard fastener charts that many builders and DIYers use.

Here is a quick table to help you see the differences:

| Screw Size | Diameter (inches) | Diameter (millimeters) |

|---|---|---|

| #4 | 0.112 | ~2.84 |

| #6 | 0.138 | ~3.50 |

| #8 | 0.164 | ~4.17 |

| #10 | 0.190 | 4.83 |

You can use this table to compare the #6 screw diameter with other common sizes. The #6 screw sits right between the smaller #4 and the larger #8 and #10 screws.

Size Comparison Overview

Screw gauge numbers help you pick the right screw for your project. The gauge number is not a direct measurement, but it does show you the relative thickness of the screw. As the gauge number goes up, the screw gets thicker. For example, a #8 screw is thicker than a #6 screw, but the increase is not double. The relationship between gauge and diameter is not perfectly even. You will see that a #8 screw is less than twice as thick as a #4 screw.

Note: The gauge system works with other measurements like threads per inch and screw length. You need all these details to choose the best screw for your job.

Here is another table that shows how the diameter increases with the gauge number:

| Gauge | Diameter (inches) | Diameter (mm) |

|---|---|---|

| #4 | 0.112 | 2.85 |

| #6 | 0.138 | 3.5 |

| #8 | 0.164 | 4.17 |

| #10 | 0.190 | 4.83 |

You can see that the #6 screw diameter is a good middle ground for many tasks. It is thicker than a #4 screw, so it gives you more strength. It is not as thick as a #10 screw, so it works well for lighter jobs where you do not want to split the material.

If you want a visual comparison, check out this chart:

You will notice that the diameter increases as the gauge number goes up. This pattern helps you choose the right screw for the strength and fit you need.

Many fastener guides and charts, like those from Albany County Fasteners and The Ultimate Screw Size Guide, use these numbers to help you convert between US and metric sizes. These resources also explain that higher gauge numbers mean thicker screws. For example, a #6 screw is 0.138 inches wide, while a #10 screw is 0.190 inches wide.

When you pick a screw, always check the diameter and gauge. This helps you avoid problems like loose fits or stripped threads. You will also make sure your project is strong and safe.

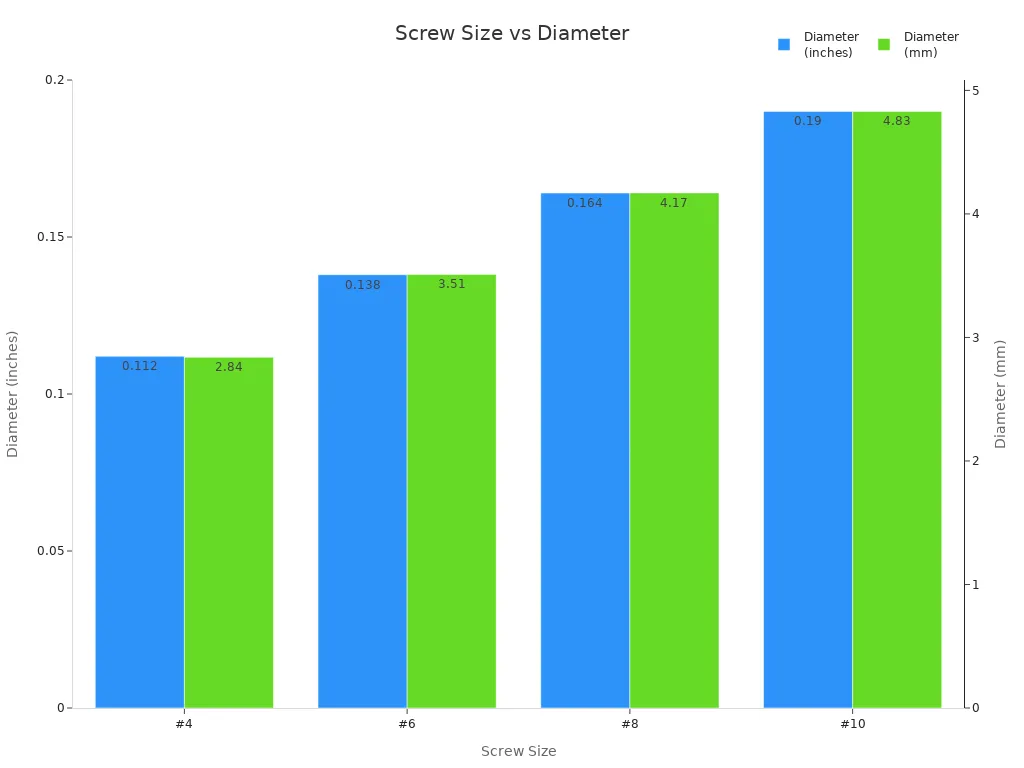

Comparison Table

Quick Reference Chart

A quick reference chart helps you pick the right screw fast. You can quickly see the differences between #4, #6, #8, and #10 screws. Charts like the one from DK Hardware show screw sizes by gauge number, decimal inch diameter, metric size, and closest fractional inch. This makes it easy to compare screw sizes and find what you need.

| Screw Size | Diameter (inches) | Diameter (mm) | Fractional Inch Equivalent |

|---|---|---|---|

| #4 | 0.112 | 2.84 | 7/64″ |

| #6 | 0.138 | 3.51 | 9/64″ |

| #8 | 0.164 | 4.17 | 5/32″ |

| #10 | 0.190 | 4.83 | 3/16″ |

Tip: The fractional inch column helps you match screws with drill bits or pilot holes. This keeps your project safe and helps you avoid mistakes.

When the screw number goes up, the diameter gets bigger too. This pattern makes it simple to choose the right screw for strength and fit. The chart above gives you all the main measurements in one spot, so you do not have to look everywhere for answers.

Quick reference charts are helpful for both pros and people who do projects at home:

- You can find the right screw thread and size for your job.

- You make sure the screw is strong enough for your project.

- You avoid getting confused by all the different screw types and sizes.

- You make picking screws faster and easier.

A chart like this helps you pick screws that fit well and hold tight. You save time and avoid mistakes, whether you are fixing furniture or building something new. With this info, you can feel sure every time you pick a screw.

Choosing Screw Size

Factors to Consider

When you choose a screw size, you need to think about more than just the number on the box. Picking the right screw helps your project stay strong and last longer. Here are the main things you should check:

- Material Compatibility: Make sure the screw matches the material. For example, use corrosion-resistant screws for outdoor projects.

- Screw Length: The screw should go at least halfway into the material you are fastening. Too short, and it will not hold. Too long, and it might poke through or split the material.

- Screw Gauge (Diameter): Match the diameter to the strength you need. Thicker screws hold more weight but can split thin materials.

- Thread Type: Coarse threads work best in softwoods and drywall. Fine threads are better for hardwoods and metals.

- Strength Needs: Think about the load. Heavy items need thicker, stronger screws.

- Corrosion Resistance: Use stainless steel or galvanized screws for wet or outdoor areas.

- Head Style and Tool Fit: Pick a head style that fits your tool and sits well in your material.

- Point Type: Sharp points drive into wood easily. Blunt points may need a pilot hole.

- Building Codes: Some jobs require screws that meet certain standards.

- Quality: Choose screws from trusted brands to avoid breakage or rust.

Tip: Always match the screw to your material and project needs. This prevents weak joints, splitting, or rust.

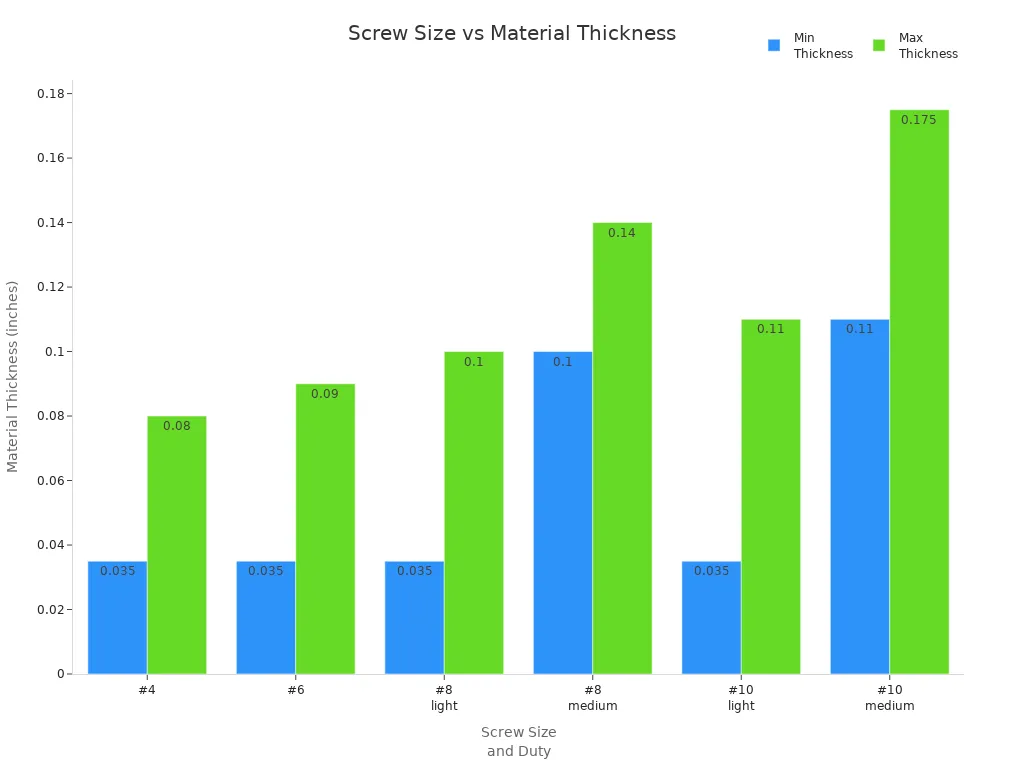

Light, Medium, and Heavy Duty Uses

You can match screw size to the job by thinking about how much weight or stress the joint will handle. Here is a quick guide:

| Screw Size | Duty Level | Material Thickness (inches) | Typical Uses |

|---|---|---|---|

| #4 | Light Duty | 0.035–0.080 | Thin metals, small hardware, crafts |

| #6 | Light/General | 0.035–0.090 | Drywall, light wood, attaching hardware |

| #8 | Medium Duty | 0.035–0.140 | Framing, decking, furniture, medium gauge metals |

| #10 | Medium/Heavy Duty | 0.035–0.175 | Plywood, heavy wood, structural, machinery |

- #4 screws work best for light jobs like crafts or thin metal.

- #6 screws fit general tasks, such as drywall or light wood.

- #8 screws handle medium jobs like furniture or decking.

- #10 screws support heavy-duty needs, including structural work and machinery.

Using the right screw size keeps your project safe and strong. Always check the material thickness and load before you choose.

Common Uses

#4 Screw Applications

People use #4 screws for small, careful jobs. These screws are good for crafts and electronics. They also work for small hardware projects. You can use them to hold thin metal sheets together. They are great for light brackets too. Many people pick #4 screws for jewelry boxes and picture frames. They are also used in model building. The small size helps stop soft materials from splitting. If you work with thin plastic, #4 screws hold things tight. They do not damage your project when you mount small hinges.

#6 Screw Applications

#6 screws are common in woodworking and cabinets. Cabinet makers use them to join wood frames. They also hang cabinet boxes with these screws. You can pick different head styles for kitchen or bathroom cabinets. These screws can replace nails or glue in subfloors. This helps stop squeaks in floors. If you build furniture, #6 screws work for drawer guides and hinges. They also help mount hardware. Bugle head screws sink in neatly and hold strong. Pocket hole screws make clean joints in cabinets. Some #6 screws have coatings for dry or outdoor use. You can use them outside if needed. Carbon steel is cheap for indoor jobs. Stainless steel is better if you want to stop rust. The #6 screw diameter fits most wood-to-wood jobs. This makes them a good all-around screw.

Tip: Use round washer head screws for putting furniture together. Pan head screws are good for attaching metal or plastic parts to wood.

| Material | Key Properties | Typical Use Case |

|---|---|---|

| Stainless Steel | Does not rust easily | Outdoor cabinets, bathroom projects |

| Brass | Looks nice, resists rust | Indoor cabinets, furniture |

| Hardened Steel | Very strong and tough | Heavy wood connections |

| Galvanized Steel | Stops rust and corrosion | Subfloors, outside trim |

| Carbon Steel | Cheap, but rusts more | Indoor woodworking |

#8 Screw Applications

#8 screws are used for medium-strength jobs. They hold wood together in furniture and cabinets. You can join thin metal sheets like aluminum or steel. You do not need to drill first. At home, #8 screws help put up light fixtures and siding. They also fix cabinets. You can hang pictures or fix fences with them. Many people use #8 screws for plastic toys and cases. They hold tight without breaking the plastic.

- Hold wood in furniture and cabinets

- Join thin metal sheets in making things

- Attach panels and trim inside cars

- Put up light fixtures and siding

- Hang pictures and fix fences

- Build plastic toys and cases

#10 Screw Applications

You use #10 screws when you need strong, tough fasteners. These screws are best for big and outdoor jobs. You can build docks and jetties with them. They connect beams in timber frame houses. They make pergolas and gazebos stable. #10 screws hold decking and boardwalks together. They fasten fencing and walls outside. Outdoor furniture and playgrounds need #10 screws for safety. You can get stainless, galvanized, or coated screws for tough weather. Pick the finish that fits your budget and the weather.

- Build docks and jetties

- Connect beams in timber houses

- Make pergolas and gazebos stable

- Hold decking and boardwalks together

- Fasten fencing and walls outside

- Build outdoor furniture and playgrounds

Tips for Screws

Pilot Holes

Drilling a pilot hole before driving a screw can make your project stronger and easier to finish. You create a small guide hole that helps the screw go in straight and reduces the risk of splitting the wood. This step is especially important when you use #4, #6, #8, or #10 screws in hardwoods or near the edge of a board.

Tip: Always match the pilot hole size to the screw diameter. For example, use a smaller drill bit for #4 screws and a slightly larger one for #10 screws.

You should also think about the type of wood. Hardwoods like oak or maple need pilot holes more than softwoods like pine. If you skip this step, you might split the wood or strip the screw head. When you work with soft or thin wood, consider using threaded inserts for a stronger hold.

Here are some quick tips for pilot holes:

- Use a drill bit that matches the screw’s core diameter.

- Drill deep enough for the full length of the screw.

- For hardwoods, always pre-drill to avoid splitting.

- In softwoods, a pilot hole is helpful but not always required.

Preventing Stripping and Splitting

You can avoid common problems like stripping screw heads or splitting wood by following a few simple steps. First, choose the right screw size and type for your material. Coarse-thread screws work best in wood and help prevent stripping. Always measure screw length based on the head type to ensure a proper fit.

- Avoid overtightening screws, as this can strip the threads or damage the wood.

- Use longer screws for hardwoods and load-bearing jobs, but do not go so long that you split the wood or poke through.

- Repair stripped holes by gluing in a wooden pin or plug, letting it dry, and then redrilling a pilot hole.

- Do not rely on fillers like plastic wood alone, as they may not hold screws well.

- When upsizing screws, allow for wood movement by reaming the hole slightly.

Note: Matching screw material to the environment, such as using stainless steel in wet areas, helps prevent rust and keeps your project strong.

By following these tips, you make your projects safer and more durable. You also reduce waste and avoid costly mistakes. 🛠️

You can easily spot the size and use differences for #4, #6, #8, and #10 screws. The table below shows that the #6 screw diameter is between the smaller and bigger sizes:

| Screw Size | Nominal Thread Diameter (inches) | Nominal Thread Diameter (mm) | Typical Usage Context |

|---|---|---|---|

| #4 | 0.112 | 2.84 | Small fastening, electronics |

| #6 | 0.138 | 3.51 | General woodworking, light assembly |

| #8 | 0.164 | 4.17 | Medium-duty fastening |

| #10 | 0.190 | 4.83 | Heavy-duty, machinery |

Picking the right screw size helps your project stay safe and strong. Quick charts make it easy to match screws to your material and stop mistakes. Always use these guides and tips to get the best results on every project.

FAQ

What does the screw gauge number mean?

The screw gauge number shows the thickness of the screw. A higher number means a thicker screw. For example, a #10 screw is thicker than a #6 screw. You can use the gauge to pick the right screw for your project.

How do you choose the right screw length?

You should pick a screw that goes at least halfway into the material you want to join. If the screw is too short, it will not hold. If it is too long, it might poke through or split the material.

Can you use #6 screws for outdoor projects?

You can use #6 screws outdoors if you choose stainless steel or galvanized types. These resist rust and last longer in wet weather. Always check the packaging for outdoor use.

Why do pilot holes matter when using screws?

Drilling a pilot hole helps the screw go in straight. It also stops the wood from splitting. You get a stronger and cleaner result, especially with hardwoods or near the edge of boards.

What happens if you use the wrong screw size?

- The joint may become weak.

- The screw could strip or break.

- The material might split or crack.

- The project may not stay together.

Choosing the right size keeps your work safe and strong.