In engineering and woodworking fields, selecting appropriate fasteners is crucial to ensuring the stability and safety of structures. Among these, wing screws have become a preferred choice for many professionals due to their unique design and excellent performance. Prince Fastener will provide a detailed analysis of dovetail screw characteristics and advantages and how they deliver exceptional fixing effects across various materials.

Whether you are an engineer or a DIY enthusiast interested in home renovation, understanding dovetail screws will bring significant convenience to your projects. The adaptability of wing screws to various materials will give you the confidence to tackle any project. Let’s explore the world of these versatile fasteners and see how they have established themselves in contemporary construction and woodworking.

Wing Screws

Wing screws are a special category of dovetail screws with a design that enhances wing flaps, beneficial for expanding holes when drilling into thin or heavier materials (such as metal), providing a more straightforward method for coils and other screws. These screws are particularly suitable for materials like calcium silicate boards, offering more substantial fixing power and better hole-opening effects. They can also be used in wood, plastic, and other materials commonly found in construction and woodworking.

Countersunk Wing Screws

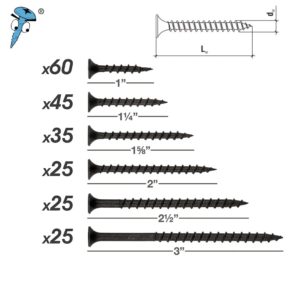

Countersunk Wing Screws are a type of winged dovetail screw. They have multiple subtypes, including different sizes, and can be considered with or without wing flaps to meet various project requirements. The use of wing screws is relatively simple, often used with electric drills to confirm the precise placement of screws on materials before drilling them in.

Various brands and models of winged dovetail screws are available in the market. For example, the countersunk dovetail screws from the brand “Master” have diameters of M3.5 and M4.2, with product specifications of 3.525 and 3.535, packed 12,000 and 9,000 per box, with oxide and black surface treatments, made of metal. These screws are widely used in construction and industry, favoured for their unique design.

What Differentiates wing screws from Regular Dovetail Screws?

The main differences between wing screw and regular dovetail screws lie in their design and purpose:

Design Differences:

- Wing Screws: Some types feature wing flaps designed to help drill into thin or heavier materials (like metal). Additionally, the wings help expand holes and provide a more straightforward method for coils and other screws.

- Regular Dovetail Screws: Typically made of stainless steel, characterized by a drill head shape that allows screws to be inserted into materials without pre-drilling, completing a more efficient tightening process.

Usage Differences:

- Wing Screw: Suitable for fixing interfaces, which refers to the points where two materials meet in thicker or heavier materials, such as steel structure colour steel plate fixation, ideal for thin plate fixing in simple constructions.Regular Dovetail Screws: Suitable for soft materials like wood and plastic, requiring no additional processing, capable of drilling holes, threading, and tightening on materials.

Characteristic Differences:

- Wing Screws: When fixing wooden plates over 0.5 inches thick to metal, winged self-tapping screws are needed. Wings will drill holes, preventing screws from entering too early. When wings contact metal, they break, allowing the screw to enter.

- Regular Dovetail Screws: Generally lack hole-drilling and wing-breaking capabilities and thus may be less effective when fixing thick materials and different material types.

Generally, dovetail screws’ external design enhances wing flaps, making them more suitable for fixing thick materials and different compositions, while regular dovetail screws are typically used for soft material fixation.

Practical Differences Between Dovetail Screws and Wing Screws

In actual use, the main differences between countersunk dovetail screws and wing screws include:

Head Design:

- Countersunk Dovetail Screws: Head is approximately a 90-degree cone. This design ensures the head aligns with the surface of the tightened object, which is commonly used in areas requiring a smooth or aesthetically pleasing surface.

- Wing Screws: The design includes enhanced wing flaps beneficial for expanding holes when drilling into thin or heavier materials.

Primary Uses:

- Countersunk Dovetail Screws: Suitable for areas where installed parts should not protrude, such as thin plate fixation, often used for tightening and connecting external workpiece surfaces to maintain a smooth finish.

- Wing Dovetail Screws: Suitable for fixing wooden plates over 0.5 inches thick to metal, with wings drilling holes and preventing premature screw insertion.

Fixing Effects:

- Countersunk Dovetail Screws: Generally used for fixing thinner materials or in areas where screw heads must align with the surface.

- Wing Screws: More efficient in fixing thick materials and different materials due to wing flaps, especially in wood and metal fixation.

Installation Process:

- Countersunk Dovetail Screws: During installation, screw heads align with the tightened material surface, suitable for high surface flatness requirements.

- Winged Dovetail Screws: Wings help drill holes during installation, then break, allowing screw threads to tighten metal, suitable for scenarios requiring thick material fixation.

Countersunk dovetail screws and winge screws differ in planning, primary uses, fixing performance, and installation processes. Choose the appropriate dovetail screw based on actual usage requirements and material characteristics.

Advantages of Wing Screw in Solid Wood Processing

The advantages of winged dovetail screws in solid wood processing are primarily reflected in the following aspects:

- Reducing Crack Risk: The tip design of wing screws is similar to a drill bit. During the screw insertion process, it can pre-drill a small circular hole before inserting the screw. This design reduces the risk of wood cracking.

- Enhanced Fixing Strength: wing screws provide strong fixation in wood. Because the dovetail portion creates the initial hole, screws can be more firmly placed in the wood, providing a firmer grip.

- Simplified Construction Procedures: Using dovetail screws saves the pre-drilling process, directly drilling and threading in wood, significantly reducing project duration.

- Improved Construction Efficiency: wing screw can complete hole-drilling and threading in one step, making them convenient and improving construction efficiency.

- High Adaptability: wing screws are primarily suitable for solid wood processing scenarios, including shed and auxiliary building construction, maintenance, and repairs.

- Durability and Reliability: wing screws feature a unique design, maintaining their composition over extended periods and being highly trustworthy.

The primary characteristics of wing screw in solid wood processing include reducing crack risk, enhancing fixing strength, simplifying construction procedures, improving construction efficiency, high adaptability, and durability and reliability. These characteristics make winged dovetail screws extremely useful in the woodworking industry.

How to Correctly Install Wing Screw?

Steps for correctly installing wing screws include:

- Prepare Tools: First, ensure you have a suitable electric drill and adapter. The adapter type depends on the screw head model.

- Assemble Screw: Securely install the winged dovetail screw on the electric drill adapter.

- Mark Position: Mark the exact location where the screw will be placed on the material.

- Drill Material: Use the electric drill to pass the winged dovetail screw through the target material, maintaining a stable grip while drilling the screw into position.

- Long-term Maintenance: During drilling, ensure the drill’s stability to prevent the screw from tilting.

- Rotate Until Passed: Allow the dovetail screw to rotate until it completely passes through the material.

- Avoid over-tightening: Be careful not to over-tighten the screw, as this could damage the material or cause screw fracture.

- Check Fixation: After installation, verify that the winged dovetail screw is firmly fixed and does not come loose.

These steps provide essential guidance, but actual operation may require adjustments based on specific material and project requirements. Correct installation of wing screw ensures their fixing performance and durability in solid wood processing.

Advantages of wing screw

Due to their unique design and advantages, wing screw demonstrate the following benefits in various application scenarios:

- Self-Drilling and Self-Tapping: wing screw can immediately drill into materials like a drill bit without pre-drilling, significantly simplifying the installation process.

- Increased Efficiency: Eliminating the need for pre-drilling and threading can significantly improve construction efficiency, saving time, effort, and labor.

- Enhanced Fixing Strength: The dovetail design helps expand holes during drilling, allowing screws to be more firmly placed in materials, increasing fixing strength.

- Reduced Material Damage: The self-drilling effect of wing screws reduces material damage caused by improper pre-drilling.

- High Adaptability: Primarily suitable for wood, metal, and plastic, especially in fixing timber and metal components.

- Prevention of Loosening: Due to the dovetail section’s tightening effect, these screws provide better-tightening characteristics, reducing loosening caused by vibration or the passage of time.

- Improved Construction Safety: Reduces potential accidents during drilling and threading, such as drill bit breakage or tool displacement.

- Durability: wing screw are typically made of high-strength materials, capable of withstanding significant loads with strong durability.

- Aesthetics: Without the need for pre-drilling, the final assembly appears neater, especially in applications where screw heads must be concealed.

- Cost Efficiency: Reducing pre-drilling and threading processes can lower overall project costs.

- Ease of Operation: Even non-professionals can more conveniently use wing screws for fixing operations.

- Reusability: In some cases, wing screws can be removed and reapplied without compromising their function.

These advantages promote the widespread use of dovetail screws in construction, woodworking, and precision processing industries.

Applications for wing screw Beyond Wood

Beyond wood, wing screws can be used in the following materials:

- Metal: It is typically used to fix metal to wood or connect metal to metal. It is particularly suitable for steel structure colour steel plate fixation and thin plate fixing in simple constructions.

- Calcium Silicate Boards: Specialized self-tapping screws for calcium silicate boards, commonly used in the construction sector.

- Cement Boards: wing screws are also suitable for cement boards, indicating broader applications in the construction decoration industry.

- Plastic: Self-tapping screws are suitable for non-metallic or soft metal materials and can be directly screwed into soft materials like plastic without pre-drilling.

- Steel Structures: Used for fixing steel structures, especially when metal needs to be fixed.

- Concrete: In the construction industry, self-tapping screws are used to connect steel structures and concrete, enhancing overall building stability and earthquake resistance.

Wing screws can be widely applied to various materials, including metal, calcium silicate boards, cement boards, plastic, and concrete, proving highly practical in engineering, decoration, and industrial manufacturing sectors.

Due to their self-drilling and self-tapping characteristics, versatility, and broad applicability, wing screw demonstrate significant advantages in projects, woodworking, and precision processing. They improve construction efficiency, reduce material damage, and enhance structural stability and safety. With continuous technological advancement and innovation, the usage of wing screws continues to expand, providing more solutions for various engineering projects.

Whether you need to fix wood, metal, calcium silicate boards, or concrete, dovetail screws offer reliable, efficient, and economical options. In the future, it’s easy to imagine that dovetail screws will continue to shine as a star in the standard parts market with their exceptional performance. If you’re seeking a fastener that can improve efficiency, save costs, and ensure project quality, wing screws are your ideal choice.