As Furniture manufacturers, have you ever faced the challenge of unstable furniture construction or intricate connections during your production processes? Or are you struggling to strike a balance between beauty and functionality? In the intricate world of furniture manufacturing, every detail matters, especially those seemingly insignificant connection screws.

They are not just bridges connecting various components but also crucial factors in ensuring furniture stability and durability. In this blog, Prince Fastener will delve into the world of furniture screw types, model selection, and quality assurance, providing you with professional guidance and recommendations. This article will serve as a valuable resource, whether you’re looking to enhance efficiency or achieve the highest product quality. Let’s explore how these seemingly small screws can significantly enhance your furniture’s overall performance and market competitiveness.

Here is some basic information about furniture screws:

What types of screws are used in furniture?

Self-tapping screws:

Screws with sharp and wide threads that can be directly tightened into metal or plastic materials without pre-drilling. Suitable for connecting hard materials like steel-wood cabinets and iron bed frames.

Equipment screws: Screws with flat or countersunk heads and fine threads requiring pre-drilled holes or nuts. Suitable for connecting different materials like wood or metal furniture, such as wooden tables and chairs.

Wood screws:

Screws with flat or countersunk heads and coarse threads that can be directly tightened into wood without pre-drilling. Suitable for connecting wood or engineered board furniture, such as wooden wardrobes and engineered board bookshelves.

Four-claw nails:

Screws with four sharp claws and a garden plate head that can be inserted into wood or engineered board without rotation. Suitable for connecting wood or engineered board furniture partitions or shelves.

Furniture Screws Specifications:

Screw Diameter:

Represents the primary diameter of the screw, typically indicated with “M” followed by a number, such as M4, indicating approximately 4mm diameter.

Screw Length:

Indicates the total length from head to tail, usually represented by “L” followed by a number, such as L20, which means 20mm long.

Head shape of screws:

Generally includes flat head, countersunk head, round head, semi-countersunk, etc.

Slot type of screw:

Typically includes single-slot, cross-slot, internal hexagon slot, etc.

Furniture Screw Selection Guidelines:

Material of screws:

Choose appropriate screw types based on furniture board materials, such as wood screws, metal self-tapping screws, or mechanical screws.

Construction:

Select suitable screw specifications based on furniture construction, such as connection part thickness, total width, position, etc., to create the appropriate diameter and length.

Function:

Choose appropriate head styles based on furniture functionality, such as whether disassembly, adjustment, or concealment is required, selecting flat or countersunk heads, single or cross slots, etc.

Aesthetics:

Consider the visual appeal of your furniture when selecting screw colours and surface treatments. Match the screw colours with your furniture tone, choose surface treatments that prevent rust and provide anti-slip properties. Whether it’s a sleek black finish or a shiny chrome-plated look, the right screws can add a touch of elegance to your furniture.

How to Choose Furniture Screw Diameter and Length?

When selecting furniture screw diameter and length, pay attention to the following factors:

Material:

Choose appropriate screw types based on furniture materials. For example, wood screws are suitable for wood or engineered boards, while metal self-tapping screws are suitable for metal materials.

Construction:

Determine appropriate diameter and length based on furniture construction details, such as wood thickness and space constraints. Larger diameters provide stronger connections but require larger holes or more space. Longer lengths offer greater penetration but may cause over-penetration or protrusion.

Function:

Choose appropriate head shapes and slot types based on furniture usage requirements, such as disassembly or adjustment. For example, flat and countersunk heads can create smoother surfaces, while round and semi-countersunk heads can highlight surface details.

Aesthetics:

Consider overall furniture aesthetics, selecting appropriate screw colours and surface treatments, such as matching furniture tone, rust prevention, and anti-slip properties.

Guidelines for selecting diameter and length:

Diameter: Generally indicated with “M” followed by a number, such as M4 indicating approximately 4mm. Common diameter specifications include M3 screws, M4 screws, M5 screws , M6 screws, M8 screws tc.

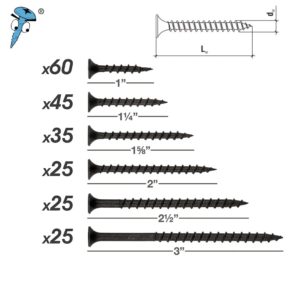

Length:

Length is typically expressed in mm, such as 20mm, 30mm, 40mm, etc. The screw length must exceed wood thickness and have sufficient volume to ensure a solid connection.

For example, when installing a wooden wardrobe, you might choose a screw with approximately M4 diameter, L20 length, countersunk head, and cross-slot, ensuring a secure and aesthetically pleasing connection. Similarly, for connecting wooden boards with metal threaded rods, you might choose a mechanical screw with approximately M6 diameter, L30 length, round head, and internal hexagon slot.

For connecting wooden boards with metal threaded rods, you might choose a mechanical screw with approximately M6 diameter, L30 length, round head, and internal hexagon slot.

When selecting furniture screw diameter and length, it’s crucial to comprehensively consider furniture materials, construction, functional requirements, and aesthetic factors. By doing so, you can choose the most suitable screw for your specific application, ensuring furniture solidness and service life.

How Much Do Screw Diameter and Length Affect Furniture Stability?

Screw diameter and length have a significant impact on furniture stability, detailed as follows:

Diameter Impact:

The screw diameter is its primary specification, generally represented by M followed by a number, such as M4 representing approximately 4mm. The larger the diameter, the more muscular the screw connection strength due to more contact surface and better gripping power. However, a larger diameter also requires a larger hole or more space for installation, which may limit its application in tight spaces.

Length Impact:

Screw length refers to the total length from head to tail, generally represented by L followed by a number. For example, L20 indicates a length of 20mm. The screw length must be sufficiently long to extend beyond the connection and have additional capacity to ensure connection solidness. If the screw is too short, the connection will certainly not be solid; if the screw is too long, it will affect the connection’s appearance or characteristics and may even cause connection damage.

Comprehensive Impact:

The diameter and length of a screw together determine its penetration and connection strength. By choosing the right diameter and length screws, you can ensure the stability and durability of your furniture. For wooden furniture, opt for corrosion-resistant screws with low hardness to avoid damaging the wood. For metal furniture, choose high-toughness carbon steel screws that can bear more load. These comprehensive considerations will give you the confidence that your furniture is built to last.

External Factors:

Besides diameter and length, screw material, screw type (such as coarse and fine threads), and head shape will affect its connection solidness with furniture. For instance, stainless steel bolts have good corrosion resistance, suitable for humid environments; zinc-plated screws have very high rust-prevention performance. The type of screw, whether it’s self-tapping, equipment, wood, or four-claw nails, also plays a significant role in the stability of the furniture. The head shape, whether it’s flat, countersunk, round, or semi-countersunk, can affect the appearance and functionality of the furniture connection.

Screw diameter and length are essential factors in measuring furniture solidness and choosing appropriate screw specifications is crucial to ensuring furniture stability and durability.

How to Choose Furniture Screw Manufacturers?

When choosing furniture screw manufacturers, consider the following standards:

Product Quality of screws:

Choose furniture screw manufacturers that can provide high-quality products. High-quality screws can ensure furniture stability and durability.

Product Variety of screws:

Choose furniture fastener manufacturers with comprehensive product ranges that can provide different types of furniture screws, such as self-tapping screws, machine screws, wood screws, etc.

Material Types of screws:

Choose appropriate screw types based on furniture boards, such as wood screws for wood, metal self-tapping screws for metal, etc.

Specification Matching of screws:

Choose appropriate screw specifications based on furniture construction, including diameter and length, to ensure connection solidness.

Function of screws:

Choose appropriate screw head styles and slots based on furniture functional requirements, such as whether disassembly or adjustment is needed.

Aesthetics of screws:

Consider whether the screw colour and surface treatment meet furniture style, such as rust prevention, anti-slip properties, etc.

Price and Service :

Compare prices and services from different furniture screw manufacturers, choosing economical and well-serviced furniture screw manufacturers.

Supply Capacity:

Consider the furniture fastener manufacturer’s supply capacity and timeliness to meet production requirements.

Reputation and Evaluation:

Check the furniture screw manufacturer’s market reputation and customer feedback, choosing furniture screw manufacturers with good reputations and strong evaluations.

Collaboration Cases:

Grasp the manufacturer’s collaboration cases, especially their experience cooperating with the furniture industry, which can be an essential basis for choosing a manufacturer.

How to Ensure Screw Quality?

To ensure screw quality, adopt the following strategies:

Thread Processing Quality: Thread precision and surface quality significantly impact connection tightening force and stability. Appropriate production processes must be used to avoid thread processing defects.

Tightening Force Control:

Screw connection tightening force is closely related to connection stability. This requires adjusting torque spacing, angle, or stretching force to ensure appropriate screw connection tightening, avoiding over-tightening or looseness.

Appearance and Inspection:

Checking the appearance of screw connections helps detect surface defects, rust, and other issues and immediately handle and replace them. Additionally, ultrasonic testing and magnetic particle testing can be used to further ensure connection quality. Ultrasonic testing can detect internal defects like cracks and air holes; magnetic particle testing is suitable for checking surface cracks and fatigue damage.

Material Type and Quality Control:

Choose appropriate bolt and nut materials to ensure specific strength and corrosion resistance. Simultaneously, establish quality records, including material certificates, dimensional measurement results, processing records, torque control information, etc., for future reference.

Setting Quality Standards:

Develop screw connection quality standards based on equipment regulations and technical standards. This includes conducting strict quality control at each stage, from raw material entry to finished product exit under the quality system.

Visual Detection: Use the naked eye or magnifying glass to observe thread appearance, dimensions, and surface quality. This method is suitable for basic inspection and simple thread defect identification.

Measurement Inspection:

Use callipers, thread gauges, thread ring gauges, and other facilities to measure thread dimensions and appearance and ensure thread specifications meet design requirements.

Instrument Detection: To conduct precise three-dimensional thread measurements, use three-coordinate measuring machines, thread comprehensive inspection instruments, and other high-precision instruments.

Non-Destructive Testing: Use ultrasonic testing, magnetic particle testing, and other non-destructive testing methods to check internal thread defects, such as cracks and air holes.

Screw Function Checking:

Including thread tightening torque, tensile strength and other system tests, evaluating screw tightening characteristics and load-bearing capacity.

Through these strategies, you can ensure screws have good durability and safety during furniture installation, improve overall furniture quality and service life, and enhance consumer brand recognition and satisfaction.

What Specifications Do Furniture Connection Bolts Need?

Furniture connection bolt specifications require consideration of multiple factors, including diameter, length, screw type, head shape, and slot type. Here are some standard specifications:

Diameter Specifications:

Furniture screw hole diameter specifications are generally based on mm, with standard sizes including M3 screw, M4 screw, M5 screw, M6 screw, M8 screw etc. Different diameter screws are used for other connections and fixings.

Length Specifications:

Screw length specifications are determined based on furniture structure and design points. For example, when fixing a board, the screw length must exceed the board’s thickness and have a specific capacity to ensure a solid connection.

Screw Types:

Furniture screw thread types also affect their specifications. Common thread types include coarse thread and fine thread. Coarse threads have larger tooth spacing and are suitable for general connections; fine threads have smaller tooth spacing with stronger connection tightening strength.

Head Shapes:

Furniture screw head shapes include flat head, countersunk head, round head, semi-countersunk, etc., affecting installation aesthetics and tool usage convenience.

Slot Types:

Furniture screw slot types include single-slot, cross-slot, internal hexagon slot, etc., affecting installation tool selection and ease of use.

Material and Surface Treatment: Furniture screw materials and surface treatment also impact their specifications. For instance, stainless steel bolts have good corrosion resistance and strength, suitable for humid environments; zinc-plated screws have better rust prevention performance.

In some practical cases, here are some reference standards:

For wooden wardrobes, wood screws connecting wooden boards can be approximately M4 in diameter, L20 in length, with a countersunk head and cross-slot.

Machine screws connecting wooden boards to metal hanging rods can be approximately M6 in diameter, L30 in length, with a round head and internal hexagon slot.

For metal bookshelves, self-tapping screws connecting metal pipes can be approximately M5 in diameter, L15 in length, with a semi-countersunk head and cross-slot.

Self-tapping screws connecting metal pipes and wooden boards can be approximately M4 in diameter and L10 in length, with a flat head and single slot.

Choosing appropriate screw specifications is an essential stage in furniture production and assembly and should be customized according to specific usage scenarios and requirements.

What Are the Head Shapes of Furniture Screws?

Furniture screw head shapes vary, with each head shape having its unique purpose and installation advantages. Here are some common furniture screw head shapes:

Flat Head:

Flat surface with rounded edges

Suitable for surfaces requiring smoothness or high aesthetic requirements

Countersunk Head:

Conical head

It needs to be flush with or slightly below the surface

Commonly used in wooden furniture

Round Head:

Smooth head with rounded edges

Suitable for surfaces requiring smoothness or high aesthetic requirements

Raised Countersunk Head:

Shape between flat and countersunk heads

Slightly below the surface

Suitable for partial head concealment during assembly

Pan Head:

Circular raised head with rounded edges

Suitable for large contact surface assembly

Hex Head:

Hexagonal head

Suitable for areas requiring wrench or hexagonal socket tool tightening

Hex Socket Head:

Hexagonal head with a central recess

Suitable for tightening with a hex wrench

Triangular Head:

Triangular head

Suitable for areas requiring notable tool tightening

Cross Recessed Head:

Circular head with cross slot

Suitable for tightening with a Phillips screwdriver

Slotted Head:

Circular head with single slot

Suitable for tightening with a flathead screwdriver

Star Head:

Five-pointed star shape

Suitable for tightening with specific star-head screwdriver

Knurled Head:

Circular head with rolled surface

Suitable for manual tightening and increased friction

The selection of these head shapes depends on furniture design requirements, installation procedures, and aesthetic regulations. Different head shapes can provide varying tightening performance and aesthetics.

As a furniture supplier, you understand that product quality is closely related to brand reputation and market position. Based on today’s sharing, we hope you can more deeply understand the importance of furniture screws and how to select appropriate screw types and specifications for different furniture boards, structures, and functions. We’ve also discussed the necessity of quality management, as only high-quality screws can ensure furniture’s continued stability and safety.

In a competitive market, details often determine success. Therefore, we encourage you to continuously pursue excellence in your production process, starting from each screw, to provide your customers with beautiful and durable furniture products. Please remember that high-quality screws are not just connectors but also embody your brand’s promise and professional spirit.

We look forward to seeing you apply these contents in practice, creating furniture writings that satisfy customers. Thank you for your reading, and we hope this article can become a powerful tool for improving product quality and innovative capabilities.