You need strong fasteners for your project. Stainless steel bolts and nuts are special because they do not rust. They can hold heavy things and look nice anywhere. You can use them inside or outside. They work well in bad weather or places with chemicals. Many experts pick stainless steel because it lasts a long time. It is also easy to take care of. Picking the right grade, like 304 or 316, helps you choose the best fasteners for your project.

النقاط الرئيسية

- Stainless steel bolts and nuts do not rust easily. They do not get damaged by water or salt. This makes them great for inside or outside jobs. They work well in wet or salty places.

- Pick the right grade for your job. Use 304 for most uses. Use 316 for tough, salty, or chemical spots. This helps your fasteners last longer. It also helps them work better.

- Stainless steel fasteners are strong and last a long time. They bend before they break. This keeps your projects safe when under pressure.

- These bolts and nuts do not need much care. You save time and money. You do not have to replace them often. You do not have to fix rust often.

- Stainless steel fasteners come in many sizes and looks. You can find the right one for your project. There are many kits to choose from.

مقاومة التآكل

Stainless steel bolts and nuts stand out because they resist rust and corrosion much better than regular steel fasteners. You can trust them to last longer, even in tough environments. The secret lies in their special mix of metals. Both 304 and 316 grades contain chromium and nickel, which help form a thin, invisible layer on the surface. This layer protects the metal underneath from moisture and air, stopping rust before it starts.

الوقاية من الصدأ

You want your fasteners to stay strong and safe. Stainless steel bolts and nuts do just that. Scientific tests show that these bolts can handle harsh conditions. For example:

- Salt fog tests show that stainless steel bolts do not rust, even when exposed to salty air. Other bolts, like carbon steel or galvanized steel, show heavy rust and become hard to remove.

- In marine environments, 304 stainless steel bolts show only small spots of corrosion, while regular steel bolts rust all over.

- The special passive film on stainless steel, made from chromium and nickel, keeps the bolts working well for many years.

نصيحة: If you need bolts for a project near the ocean or in a place with lots of salt, choose 316 فولاذ مقاوم للصدأ. This grade has extra molybdenum, which gives it even better protection against salt and chemicals.

Here is a quick comparison of how different bolts perform in tough environments:

| المواد | Rust Resistance | أفضل حالات الاستخدام |

|---|---|---|

| الفولاذ الكربوني | Poor | Dry, indoor areas |

| Galvanized Steel | Fair | Short-term outdoor use |

| فولاذ مقاوم للصدأ 304 | جيد | Most indoor and outdoor projects |

| 316 فولاذ مقاوم للصدأ | ممتاز | Marine, chemical, salty areas |

Indoor & Outdoor Use

You can use stainless steel bolts and nuts both inside and outside. They work well in places with high humidity, rain, or even snow. The chromium in stainless steel forms a shield that keeps out water and air. This means your bolts will not rust, even if you use them in your garden, on a boat, or in a factory.

- Outdoor areas with lots of moisture or salt can quickly damage regular bolts. Stainless steel bolts and nuts keep their strength and shape, even after years of use.

- Indoors, these bolts stay clean and shiny. You do not need to worry about rust stains or weak spots.

- Choosing the right grade matters. Use 304 stainless steel for most jobs. Pick 316 stainless steel for the best protection in salty or chemical-heavy places.

Stainless steel bolts and nuts help you save money over time. You will not need to replace them as often, and they keep your projects safe and strong.

Strength & Durability

Mechanical Properties

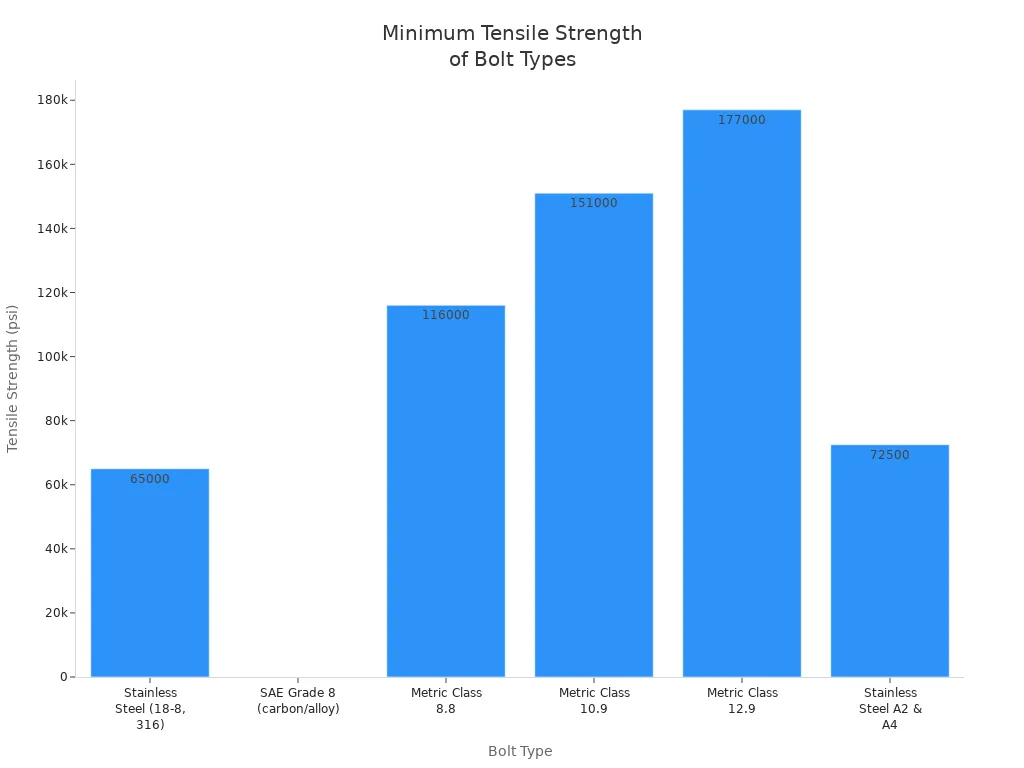

When you choose stainless bolts for your project, you get reliable strength. Stainless steel bolts and nuts offer good mechanical properties, but they do not match the strength of hardened steel bolts like SAE Grade 8. You can see the difference in the table below:

| نوع البرغي | Minimum Yield Strength (psi) | Typical Yield Strength (psi) | Minimum Tensile Strength (psi) | Typical Tensile Strength (psi) |

|---|---|---|---|---|

| Stainless Steel (18-8, 316) | 20,000 | 65,000 | 65,000 | 100,000 – 150,000 |

| SAE Grade 8 (carbon/alloy) | 120,000 | 120,000 | غير متوفر | Up to 150,000 |

| Metric Class 8.8 | غير متوفر | غير متوفر | 116,000 (800 MPa) | غير متوفر |

| Metric Class 10.9 | غير متوفر | غير متوفر | 151,000 (1040 MPa) | غير متوفر |

| Metric Class 12.9 | غير متوفر | غير متوفر | 177,000 (1220 MPa) | غير متوفر |

| Stainless Steel A2 & A4 | 30,000 (210 MPa) | 65,000 (450 MPa) | 72,500 (500 MPa) | 101,500 (700 MPa) |

You will notice that stainless steel bolts have lower tensile strength than SAE Grade 8 bolts. SAE Grade 8 bolts are used in heavy machinery and automotive applications because they can handle high torque and stress. Stainless steel bolts, such as A2-70 and A4, reach strengths close to SAE Grade 5, making them suitable for most construction and DIY projects. Specialty stainless alloys can match or exceed Grade 8, but these are less common.

Stainless steel bolts gain strength through cold working. You cannot heat treat 300 series stainless steel bolts, but 400 series bolts can be heat treated for higher hardness. If you need extra strength, ask stainless steel bolts and nuts suppliers about specialty grades.

Longevity

You want your fasteners to last. Stainless steel nuts bolts and washers offer excellent durability. They resist corrosion, which means they keep their strength over time. Stainless steel bolts show high ductility, so they bend and stretch before breaking. This property helps them absorb energy and resist cracking under impact.

Studies show that austenitic stainless steel bolts, like A2-70 and A4-80, perform better than carbon steel bolts in fire and high-stress situations. Stainless bolts maintain their shape and resist fracture, even when exposed to heat or heavy loads. You will find that stainless steel bolts fail by ductile fracture, which means they stretch and neck before breaking. Carbon steel bolts often fail suddenly and can strip threads.

نصيحة: For projects that need extra toughness, such as marine or outdoor builds, consider using 3 8 stainless steel bolts and nuts. These fasteners handle vibration and movement well, making them ideal for semi-rigid connections.

Stainless steel bolts and nuts suppliers offer a wide range of sizes and grades. You can find stainless steel nuts bolts and washers for almost any application. When you choose stainless bolts, you invest in long-term reliability and safety for your project.

Stainless Steel Grades

304 vs. 316

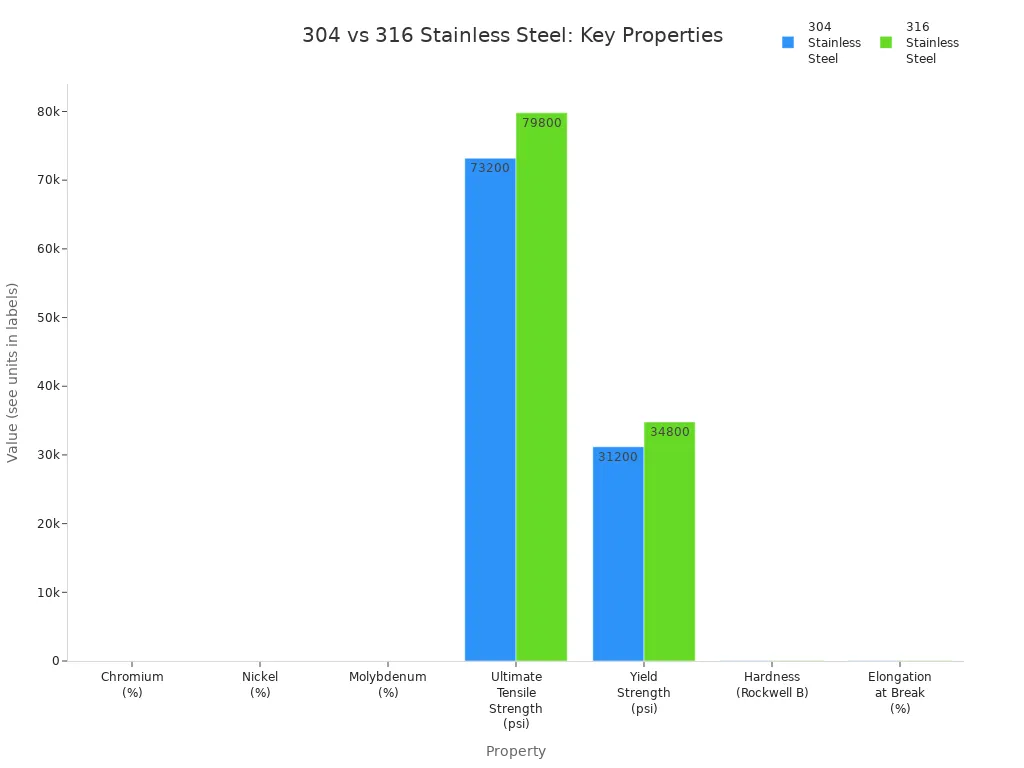

You often see two main grades when you shop for stainless bolts: 304 and 316. These grades look similar, but they have important differences. You need to know these differences to pick the right fastener for your project.

304 stainless steel is the most common type. It works well for most indoor and outdoor jobs. You get good corrosion resistance, strong mechanical properties, and easy welding. 316 stainless steel has a special ingredient called molybdenum. This element makes 316 better at fighting corrosion, especially in salty or chemical-heavy places.

إليك table that shows how 304 and 316 compare:

| Property / Element | فولاذ مقاوم للصدأ 304 | 316 فولاذ مقاوم للصدأ |

|---|---|---|

| Chromium (%) | Approximately 18 | 16.5 – 18.5 |

| Nickel (%) | 8 – 10.5 | 10 – 13 |

| Molybdenum (%) | None | 2 – 2.5 |

| Ultimate Tensile Strength | ~73,200 psi | ~79,800 psi |

| Yield Strength | ~31,200 psi | ~34,800 psi |

| Hardness (Rockwell B) | 70 | 80 |

| Elongation at Break (%) | 70 | 60 |

| مقاومة التآكل | ممتاز | Superior (especially vs chlorides, acids, saltwater) |

| Weldability | عالية | جيد |

| Formability | جيد جداً | جيد |

| مغناطيسي | غير مغناطيسية | غير مغناطيسية |

You notice that 316 stainless steel has more nickel and adds molybdenum. This change gives it higher strength and better corrosion resistance. You find 316 stainless bolts in places like boats, chemical plants, and food factories. 304 stainless steel bolts and nuts suppliers recommend 304 for general use, but they suggest 316 for tough environments.

ملاحظة: If you work near the ocean or with chemicals, 316 stainless steel nuts bolts and washers last longer and need less maintenance.

Choosing the Right Grade

You want your project to last. You need to pick the right grade of stainless steel bolts and nuts. Here are some tips to help you choose:

- Check the environment. If you see moisture, saltwater, or chemicals, pick 316 stainless steel. For dry or mild conditions, 304 works well.

- Look at the load. If your project needs high strength, compare the tensile and yield strengths in the table above.

- Match the size and thread. Make sure your bolts and nuts fit together. This keeps your connection strong.

- Follow industry standards. ASTM and SAE rules help you get safe and reliable fasteners.

- Think about installation. Clean the surfaces and tighten bolts by hand first. This prevents cross-threading.

- Plan for maintenance. Inspect your bolts and nuts regularly. This helps you catch problems early.

You find 3 8 stainless steel bolts and nuts in many kits for marine, construction, and DIY jobs. Stainless steel bolts and nuts suppliers offer both 304 and 316 grades in many sizes. You can ask for advice if you are not sure which grade fits your needs.

نصيحة: For harsh environments, always choose 316 stainless steel nuts bolts and washers. You save money and time because you replace them less often.

You make your project safer and stronger when you choose the right grade. Stainless steel gives you options for every job, from simple repairs to big builds.

Maintenance & Look

Low Upkeep

You want fasteners that are easy to care for. Stainless bolts make this simple. When you use stainless steel nuts bolts and washers, you do not need to check them often. These fasteners do not rust or stain easily. You will not have to clean or change them much. You can put them in your garden, kitchen, or on a boat. They will still look nice for a long time.

Many stainless steel bolts and nuts suppliers say these fasteners are great for outside jobs. You do not have to paint or cover them to keep them safe. Rain, snow, and sun do not hurt them like regular steel bolts. You will not need to scrape off rust or deal with stuck bolts. This helps you save time and money as your project lasts.

نصيحة: If you want even less work, try 3 8 stainless steel bolts and nuts. These are common sizes that fit many kits and need almost no care.

Finishes & Colors

Stainless steel bolts come in many finishes and colors. You can pick the one that matches your project’s style. Some finishes help stop rust, while others just look cool.

Here is a table that shows some finishes, what they look like, and how well they stop rust:

| نوع التشطيب | المظهر | مقاومة التآكل | الملاحظات |

|---|---|---|---|

| Hard Chrome | Shiny, easy to clean | عالية | Makes bolts harder; costs more |

| طلاء النيكل | Bright, decorative | جيد | Helps bolts last longer |

| Zinc Plating | Silver or yellow | معتدل | Cheap; rusts if scratched |

| Hot Dip Galvanizing | Thick, matte coating | متفوقة | Best for outside; may change bolt size |

| أكسيد أسود | Smooth black finish | منخفضة | Looks nice; does not stop rust |

| Black Zinc | Black finish | معتدل | Stops some rust; may change bolt size |

| Black Xylan® | Black, non-stick coating | ممتاز | Has PTFE; lasts a long time |

| Ruspert® | Black, multi-layer | استثنائي | Many layers for best strength |

| Stainless Steel (304, 316) | Natural metallic finish | Inherent (especially 316) | 316 is best for boats and tough places |

You can choose a finish that works for you. If you want shiny and strong bolts, pick hard chrome or nickel plating. If you want a black look, black oxide or black Xylan® is a good choice. Stainless steel’s natural color looks clean and nice, especially in kitchens or on boats.

Stainless steel bolts and nuts suppliers have many finishes and sizes. You can find stainless steel nuts bolts and washers for almost any job or style. This makes stainless bolts a smart choice for both looks and use.

Material Comparison

When you pick fasteners, you should know how each material works. Every type has good and bad points. Let’s see how zinc, galvanized, and carbon steel bolts compare to stainless steel.

Zinc & Galvanized

Zinc and galvanized bolts have a coating that helps stop rust. Galvanized bolts use a thick zinc layer to protect the steel. This layer works well outside in mild weather. You often find galvanized bolts in fences and decks. Zinc-plated bolts have a thin layer, so they fit indoor jobs or places with little moisture.

- Galvanized bolts cost less than stainless steel bolts and nuts. You save money at first.

- The zinc layer can wear away after some time. You need to check and sometimes recoat these bolts, especially outside.

- Galvanized bolts are strong because they use carbon steel inside.

- يجب عليك use galvanized nuts with galvanized bolts. This helps stop rust and makes sure they fit.

Galvanized bolts are good for cheap outdoor projects, but you need to check them every few years. Stainless steel nuts bolts and washers last longer and need less work.

Here is a table to help you compare:

| Aspect | Galvanized Bolts and Nuts | Stainless Steel Bolts and Nuts |

|---|---|---|

| مقاومة التآكل | Good in mild/moderate environments, zinc wears off | Superior, self-repairing layer, best for harsh conditions |

| العمر الافتراضي | Moderate, depends on coating durability | Long, needs little maintenance |

| Maintenance | Regular inspection and recoating needed | Occasional cleaning only |

| التكلفة | Budget-friendly | Higher initial cost |

الفولاذ الكربوني

براغي من الفولاذ الكربوني are very strong. Builders use them for big machines and heavy jobs. These bolts cost the least, but they rust fast if you do not protect them. You need to paint or coat carbon steel bolts for use outside.

- Carbon steel bolts work best inside or in dry places.

- They are stronger than stainless steel bolts, but rust makes them weak.

- You need to plan for extra care if you use carbon steel outside.

Stainless steel bolts are special because they do not rust and last longer. You pay more at first, but you save money later because you do not need many repairs. Stainless steel bolts and nuts suppliers say stainless bolts are best for places with water, chemicals, or salt.

If you want strong bolts for dry indoor jobs, carbon steel is a good choice. For outdoor or marine projects, pick stainless steel nuts bolts and washers or 3 8 stainless steel bolts and nuts for better safety.

التطبيقات

Stainless steel bolts and nuts are used in many projects. You see them in boats, buildings, and home repairs. These fasteners are strong and do not rust. This means you can use them in tough places and trust them to last.

| Sector | Common Applications of Stainless Steel Bolts and Nuts |

|---|---|

| بحري | – Shipbuilding: putting together hulls and decks with bolts that do not rust. – Offshore platforms: holding up structures and equipment in the ocean. – Marine engines and equipment: using bolts for winches and cranes that need to be strong and resist rust. |

| البناء | – Steel framework: joining beams and columns in buildings and bridges. – Concrete anchoring: using anchor bolts in concrete for safety. |

| DIY | – Furniture assembly: putting together beds, tables, and chairs with strong bolts. – Home repairs: fixing cabinets and shelves at home. – Various custom projects: building furniture or outdoor things with different bolt sizes. |

Marine Use

You need bolts that last in salty water and bad weather. Stainless steel bolts and nuts are the best for boats and docks. Here is why they work so well:

- Chromium in stainless steel makes a shield that stops rust.

- These bolts stay strong, even when waves and wind are rough.

- You can clean them easily because they are smooth.

- There are many finishes and sizes for different boat parts.

- You do not need extra coatings like with carbon steel. Stainless bolts last longer and keep your boat safe.

- 316 stainless steel bolts have molybdenum, which helps fight salt and chemicals.

- These bolts do not rust, even after many years in the sun and sea.

- You can use them for over 20 years without changing them.

- They stay shiny, so your boat or dock looks nice.

- You spend less time fixing things because they need little care.

- Many sizes and finishes work for all kinds of boat jobs.

Tip: Ask your supplier for 316 grade if you work near the ocean. This gives your project the best protection.

Kits & Sizes

You can get stainless steel nuts bolts and washers in many sizes and kits. This makes it easy to finish any job, big or small. Here is what you can find:

| السمة | Details/Range |

|---|---|

| نطاق القطر | M2 to M100 (metric), 1/2″-13 (imperial) |

| Length Range | 6 mm to 500 mm (metric), 1″ to 24″ (imperial) |

| Head Types | Square, Hex, Hex flange, Round, T-head, Flat, Triangular |

| Drive Types | Slotted, Phillips, Torx, Hex socket, Square slot |

| Thread Types | UNC (Coarse), others per standards |

| Material Grades | 304, 316, and more |

You can buy kits with 3 8 stainless steel bolts and nuts. These kits often have washers and locking nuts. Some kits come with anti-seize on the bolts, so you save time. Suppliers offer small boxes or big pallets. You can always find the right size and type for your job.

Note: Stainless bolts come in many shapes and sizes. You can use them for furniture, decks, or big machines. Always check the size and grade before you buy.

You get strong, reliable fasteners when you choose stainless bolts for your project. Stainless steel bolts and nuts suppliers offer products that last longer and need less maintenance than other materials. You save money over time because stainless steel nuts bolts and washers resist rust and stay tight. You can pick the right grade for your needs, like 3 8 stainless steel bolts and nuts for tough jobs. Stainless steel fasteners are recyclable and safe for many industries. Make your next project stronger and safer with stainless steel.

الأسئلة الشائعة

What makes stainless bolts better than regular steel bolts?

You get better rust protection with stainless bolts. These bolts last longer outside and in wet places. Stainless steel nuts bolts and washers do not need much care. You save time and money because you do not have to replace them often.

Can I use stainless steel bolts and nuts for marine projects?

Yes, you can use stainless steel bolts and nuts for boats and docks. Choose 316 grade for the best results. Stainless steel bolts and nuts suppliers recommend 3 8 stainless steel bolts and nuts for strong, rust-free connections in salty water.

How do I choose the right size and grade for my project?

Check your project’s needs first. Use 304 grade for most jobs. Pick 316 grade for harsh or salty places. Stainless steel bolts and nuts suppliers offer many sizes, including kits with 3 8 stainless steel bolts and nuts for easy matching.

Do stainless steel nuts bolts and washers come in different finishes?

Yes, you can find many finishes. Some look shiny, others look black or matte. Stainless steel nuts bolts and washers keep their color and resist rust, so you can pick what fits your style and needs.

Where can I buy quality stainless bolts and kits?

You can buy from local hardware stores or online. Many stainless steel bolts and nuts suppliers offer kits with different sizes. Look for trusted brands to get strong, long-lasting stainless bolts for your project.