When you buy machine screw nut products in bulk, you must focus on the right size and type for your project. Choosing a trusted supplier like Prince Fastener helps avoid delays and quality issues. You may face challenges such as cost control and ensuring reliable supply. The global bolt and nut market is growing fast:

- The market will reach USD 78.2 billion by 2032.

- It grows at a rate of 5.1% each year.

You can learn simple steps to make bulk buying easier and smarter.

النقاط الرئيسية

- اختر correct type and size of machine screw nuts for your project so the connections stay strong.

- Choose a reliable supplier like Prince Fastener to stop delays and make sure you get good quality when you buy a lot.

- Always look at the material and grade of the nuts to see if they fit your project and where you will use them.

- Check prices from different suppliers to find the best deals and save money when you buy in bulk.

- Use good inventory management to keep the right amount in stock and stop your project from being late.

Machine Screw Nut Basics

Types and Sizes

You should learn about the main types and sizes before buying any machine screw nut. Each type has its own shape and job. Some common types are hex nuts, jam nuts, cap nuts, and flange nuts. The table below shows what they do and where you use them:

| Type of Nut | الوصف | Common Applications |

|---|---|---|

| صواميل سداسية الشكل | These are regular nuts with six sides. | You use them to join steel beams, hold engine parts, fasten electronics, and build furniture. |

| مكسرات المربى | These are thin nuts that lock another nut in place. | They help keep bolts tight in machines, pipes, and cars. |

| Cap Nuts | These nuts have a rounded top to cover threads. | You see them in furniture, lights, and outdoor things like handrails. |

| صواميل الفلنجة | These nuts have a wide bottom for spreading pressure. | People use them in cars, machines, planes, and furniture. |

Machine screw nut sizes are measured by diameter and thread pitch. Some sizes are small like #2-56, and some are bigger like 1/2-13. You should look at the size chart from your supplier, such as Prince Fastener, to make sure you pick the right one.

نصيحة: Always check the thread size and type before you order a lot. This step helps you stop mistakes and waiting.

Common Uses

People use machine screw nut products in many jobs. These nuts hold things together in machines, cars, and furniture. You also find them in electronics, building work, and fixing things at home. When you need to connect two pieces of metal or attach something to a surface, you often use a machine screw nut.

These nuts give strong and safe connections. They work with bolts and machine screws. You can find them in toolboxes, workshops, and factories. If you want to buy a lot, you need to know which type and size are best for your work. This helps you save time and money.

Key Factors for Bulk Buying

When you want to buy a lot of machine screw nuts, you should think about some important things. These things are material and grade, size and fit, and industry rules. If you pay attention to these, you will not make mistakes. Your project will go well.

Material and Grade

You need to check the material and grade before buying many nuts. The material tells you how well the nut fights rust and damage. For example, 316 stainless steel does not rust as fast as 18-8 (304) stainless steel. This is why people use it near the ocean or with chemicals. The grade shows how strong the nut is. Higher grades are stronger and good for tough jobs.

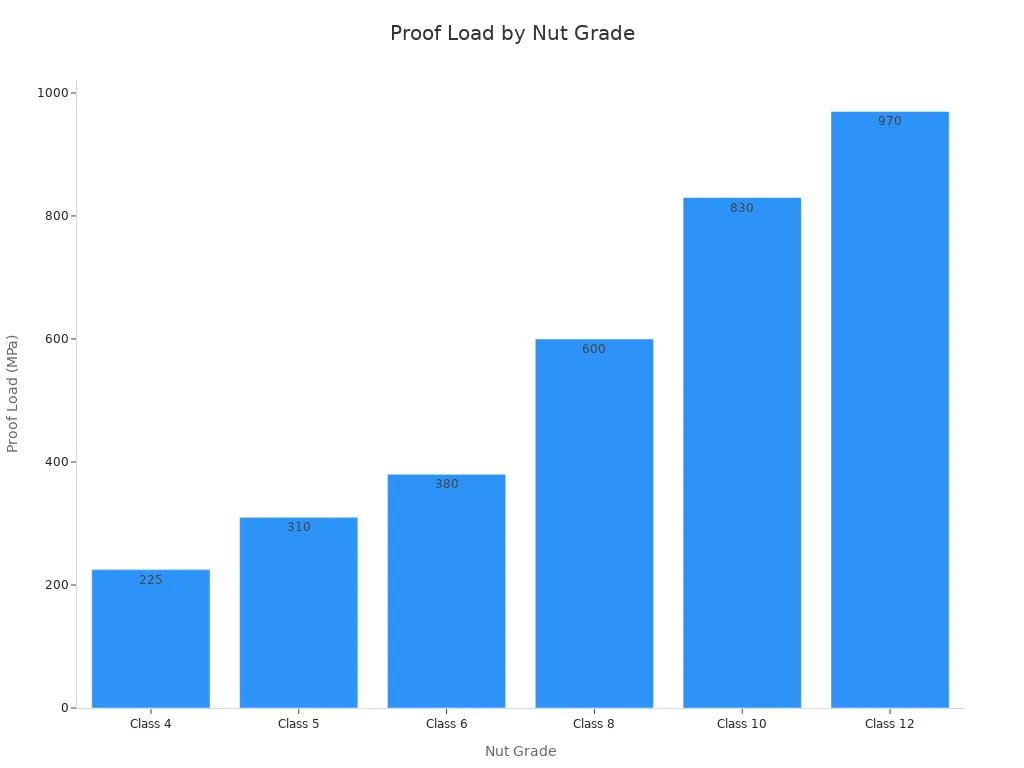

Here is a table that lists common nut grades and what they are used for:

| Nut Grade | Typical Use | Proof Load (MPa) | Matches Bolt Grades |

|---|---|---|---|

| Class 4 | Light-duty, low stress | ~225 MPa | 4.6 bolts |

| Class 5 | Medium-duty | ~310 MPa | 5.8 bolts |

| Class 6 | General construction | ~380 MPa | 6.8 bolts |

| Class 8 | Machinery, automotive | ~600 MPa | 8.8 bolts |

| Class 10 | Heavy machinery | ~830 MPa | 10.9 bolts |

| Class 12 | High-stress applications | ~970 MPa | 12.9 bolts |

نصيحة: Pick the right material and grade for your job. If you work in a tough place, choose nuts that do not rust easily. For big machines, use higher grades to stay safe.

Using the right grade and material helps you stop problems. Prince Fastener has many grades and materials, so you can find what you need.

Sizing and Compatibility

Getting the right size is very important when you buy a lot. If you pick the wrong size, things can break or fall apart. For example, if you use a weak nut where you need a strong one, the joint can come loose or break. This can cause things to fall or get damaged.

You should always match the nut size to the bolt and the job. Check the diameter and thread pitch. Some nuts have UNC or UNF threads, so make sure they fit your machine screws. Prince Fastener gives you size charts to help you choose.

- Measure the bolt’s diameter and thread pitch.

- Match the nut to the bolt’s grade.

- Check that everything fits before you order a lot.

ملاحظة: Do not use a weak nut for a strong job. This keeps your project safe and stops accidents.

Industry Standards

Industry rules help you pick safe and good nuts. Rules like ISO and DIN tell you how nuts should look and work. If you follow these rules, your nuts will do their job right.

Here is a table of common rules for machine screw nuts:

| Standard Type | الوصف |

|---|---|

| ISO 4032 | Hex nut |

| DIN 934 | Hex nut |

| DIN 1587 | Domed hex cap nut |

| DIN 6923 | Hex flange nut |

| DIN 6926 | Nylon insert hex flange nut |

| DIN 6927 | Top lock flange nut |

Following these rules is important in many jobs. The table below shows why these rules matter:

| مجال التطبيق | Importance of Compliance with Standards |

|---|---|

| البناء | Makes sure things are strong and safe. |

| Automotive | Stops parts from shaking loose while driving. |

| الفضاء الجوي | Keeps planes safe and parts working right. |

| Energy Sector | Helps nuts last in hard places like pipelines and rigs. |

Callout: دائماً ask your supplier, like Prince Fastener, for nuts that follow ISO or DIN rules. This helps you avoid mistakes and keeps your project safe.

If you follow these tips, your nuts will fit, be safe, and last longer. Planning ahead saves you time and money. You will get the best results when you buy in bulk.

Supplier Selection for Bulk Orders

Picking the right supplier for your machine screw nuts is important. It can make your project go smoother and help you finish on time. You should look at prices and see if the supplier is trusted. You also need to choose between a local store or an online shop. Each choice helps you avoid problems and get the most for your money.

Comparing Prices and Deals

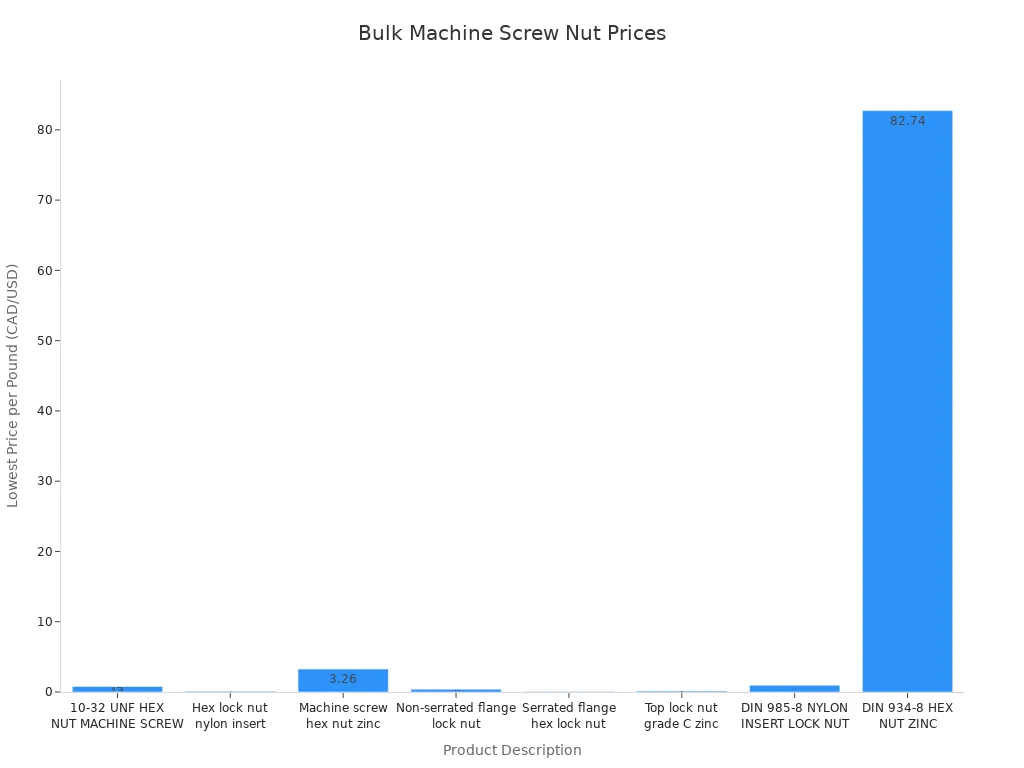

You should always check prices before buying a lot. The price for machine screw nuts can be very different. Some suppliers give better deals if you buy more. Others might have extra fees or high shipping costs. Look at the price for each pound to see who has the best deal.

Here is a table that shows how prices can change:

| المورد | Product Description | نطاق السعر (per pound) |

|---|---|---|

| Tools Fasteners | 10-32 UNF HEX NUT MACHINE SCREW ZINC | CAD$0.78 for 100, CAD$100.84 for 15000 |

| Boltcraft MFG | Hex lock nut nylon insert zinc | From: $0.09 |

| Boltcraft MFG | Machine screw hex nut zinc | From: $3.26 |

| Boltcraft MFG | Non-serrated flange lock nut grade G black phosphate | From: $0.40 |

| Boltcraft MFG | Serrated flange hex lock nut zinc | From: $0.08 |

| Boltcraft MFG | Top lock nut grade C zinc | From: $0.13 |

| Tools Fasteners | DIN 985-8 NYLON INSERT LOCK NUT ZINC | CAD$0.96 – CAD$14.75 |

| Tools Fasteners | DIN 934-8 HEX NUT ZINC | CAD$82.74 – CAD$117.67 |

You can also see the price changes in this chart:

نصيحة: Always get quotes from more than one supplier. This helps you find the best price and not pay too much.

Supplier Reputation

A good supplier gives you strong products and good service. You should check if the supplier is trusted before you buy. Look for these things:

| المعايير | الوصف |

|---|---|

| Product Quality | Makes sure you get strong and long-lasting nuts. |

| الشهادات | Shows the nuts meet industry rules and safety standards. |

| Customer Reputation | Tells you if other buyers trust the supplier. |

| Global Reach | Means the supplier can ship to many places. |

| Innovation | Shows the supplier works to improve and create new products. |

You can use these steps to check if a supplier is good:

- Ask for a video tour of the factory to see how they make the nuts.

- Request lab tests from another company to check the nuts’ strength.

- Order a sample first to see if the nuts are right for you.

ملاحظة: Good suppliers like Prince Fastener give certifications and samples. This helps you feel sure about your order.

Local vs. Online Options

You can buy machine screw nuts from a local store or online. Each way has good and bad points. You need to think about what is best for your project.

| Advantages of Local Suppliers | Disadvantages of Local Suppliers |

|---|---|

| Faster delivery and reduced lead times | مجموعة منتجات محدودة |

| Lower costs due to reduced shipping fees | Higher prices for small orders |

| Personalized service and expertise | Minimum order quantities |

| Bulk discounts available | May need to visit more than one store |

| Advantages of Online Suppliers | Disadvantages of Online Suppliers |

|---|---|

| Wide selection, including rare items | Shipping can take longer |

| Easy to compare prices | Harder to fix order problems |

| Better stock availability | Cannot check quality before shipping |

| 24/7 ordering convenience | Returns or exchanges take more time |

If you need your order fast and want help, pick a local store. If you want more choices and easy price checks, try an online shop. Always read reviews and ask questions before you buy.

When you pick a supplier for your big order, you stop delays and extra costs. You also make sure you get safe and strong machine screw nuts every time.

Benefits of Bulk Machine Screw Nut Purchases

Cost Savings

When you buy nuts in bulk, you lower your overall cost. You do not just save on the cost per item. You also cut down on hidden costs that come with small orders. These hidden costs include time spent on sourcing, ordering, delivery, and handling. The table below shows how these costs add up and how you can save:

| Cost Component | الوصف |

|---|---|

| Indirect Costs | Typically make up 80% of the total cost of C-parts, including sourcing, ordering, delivery, handling, and inventory. |

| Cost Reduction Potential | Indirect costs are easier to reduce than direct costs, leading to significant savings when buying in bulk. |

| Supplier Negotiation | Larger orders may allow for better negotiation with suppliers for price reductions. |

You can often get better prices when you place a large purchase. Prince Fastener helps you find ways to save money and get the most value for your project.

نصيحة: Always ask for better prices when you order a large amount. This can help you stretch your budget further.

Quality Consistency

You want every nut to work the same way. Buying in bulk from one supplier means all your nuts come from the same batch. This gives you steady quality and fewer problems. Here are some reasons why quality stays high:

- All fasteners meet the same high standards.

- You avoid mixing nuts from different vendors.

- Wholesale nuts are made for big jobs and do not lose quality.

You can trust Prince Fastener to deliver nuts that match your needs every time. This keeps your work safe and reliable.

Fast Project Turnaround

You finish projects faster when you have all the nuts you need on hand. You do not waste time waiting for new shipments or searching for missing pieces. Fastener kits and bulk orders help you stay organized and ready. You can start work right away and keep your team moving.

Having a steady supply means you do not stop work. You meet deadlines and keep your customers happy.

Screw and Fastener Assortments

Variety for Different Projects

When you work on projects, you need different things. Screw and fastener assortments give you many sizes and types in one box. For example, the 1500 Piece Machine Screw Small Drawer Assortment has many machine screw sizes, nuts, and Phillips bits. You get all these parts in a steel case. This makes it easy to find what you need fast. Having many choices helps you fix, build, or take care of things without looking for missing parts.

You can use these assortments for jobs that need strong and rust-proof fasteners. They have different sizes and thread types. This means you can match them to many machine screws. Your work becomes stronger and does not rust as easily. Prince Fastener sells assortments that help you get ready for any job. You can use them in a shop or outside.

Here is a table that shows how having many machine screw nuts in bulk helps your projects:

| الفائدة | الوصف |

|---|---|

| Cost Savings | Lower unit price when purchasing larger quantities. |

| Consistent Supply | Ensure you have ample stock for large projects without delays. |

| Efficiency | Streamline your procurement process by reducing the frequency of orders. |

- Make your work stronger and stop rust.

- Good for jobs that need strong, rust-proof fasteners.

- You get many sizes and threads to fit different machine screws.

Cost-Effectiveness

You want to save money and not waste parts. Buying assortments is easy, but sometimes you pay more for sizes you do not use. One person said buying single sizes can cost less. Another person spent $53 on a 170-piece set and had extra fasteners left over. But a field worker said assortments save time and money. You do not need to go back to the store for more parts.

Tip: Pick assortments that fit what you use most. You will not pay for parts you do not need. You also keep your space neat.

Prince Fastener helps you pick the right assortment for your job. You get the good parts of buying in bulk and keep your costs low.

Storage and Organization

Bolt Bins and Storage Solutions

You need a good way to keep your machine screw nuts safe. This helps you find them fast and not lose any. If you use the right storage, you will not waste time looking for parts. Many shops use bolt bins, bins on the wall, or cabinets with many drawers. Each one has its own good and bad points.

| Storage Solution | Pros | Cons | الأفضل لـ |

|---|---|---|---|

| Portable Parts Organizers | Easy to carry, cheap, stackable, clear lids help you see inside | Can get heavy, hard to find the right case sometimes | Beginners and workers who need hardware at different places |

| Wall-Mounted Bins | Easy to see, you can change them, saves floor space | Gets dusty, needs wall space, can cost more | Shops with big walls and people who need to grab things often |

| Multi-Drawer Cabinets | Saves space, keeps dust out, easy to label | You cannot see inside without opening, takes time to label | Big collections, small wall space, people who want things very neat |

| Jars, Cans, Recycled Containers | Almost free, good for odd shapes | Wastes space, hard to find what you need | Hobbyists, small amounts, people who like a simple look |

You can also use soft things like nylon or lead shot between bolt tips and nut threads. This stops damage. Jam nuts with clamping screws keep the main nut tight. A special box-wrench can hold nuts still so they do not spin when you do not want them to.

Tip: Always put labels on every bin or drawer. This helps you grab the right size quickly and keeps your work area clean.

Inventory Management

If you manage your inventory well, your projects will not stop. You do not want to run out of nuts or have too many taking up space. Here are some ways to keep your supply just right and avoid problems:

- Set the lowest and highest number of nuts you want to keep. This tells you when to buy more or stop buying.

- Try vendor managed inventory (VMI) systems. Your supplier, like Prince Fastener, can help you keep enough in stock.

- Use just-in-time (JIT) inventory. You get nuts only when you need them, so you save space and money.

- Use automatic supply tools. These track what you use and help you order the right amount.

Automatic inventory systems give you many good things:

| الفائدة | الشرح |

|---|---|

| Better cash management | You do not spend money on extra nuts. |

| Lower storage costs | You pay less for keeping nuts in storage. |

| Less work managing inventory | Your supplier does more of the work for you. |

| More correct orders | You get the right nuts every time. |

| Faster order processing | You spend less time filling out forms. |

| Better workspace layout | Your work area stays neat and works well. |

Callout: Good inventory management means you always have the right machine screw nuts for your big jobs. You save time, money, and do not get stressed.

When you want to buy a lot of machine screw nuts, you should follow some easy steps to do well. First, think about what you need and pick the right type. Next, look up suppliers like Prince Fastener and see who has the best price and rules. Make sure the nuts are good quality by checking for certifications and looking at samples. Set up your storage so you can find nuts fast and keep things neat.

| Key Component | الأهمية |

|---|---|

| Solid Business Plan | Helps you save money and buy nuts you can trust. |

| Learning from Peers | Lets you learn from others and not make mistakes. |

Use these tips to get good prices and strong nuts for your next job.

الأسئلة الشائعة

What should you check before buying fasteners in bulk?

You should check the size, type, and material of each fastener. Look at the quality and make sure the fasteners match your project. Prince Fastener gives you charts and guides to help you pick the right screw and nut.

How do you compare prices for machine screw fasteners?

You can compare prices by looking at the cost per pound or per piece. Ask for quotes from different suppliers. Prince Fastener often gives you better prices for large orders. Always check if the prices include shipping and handling.

Why does fastener quality matter for your project?

Quality keeps your project safe and strong. Low-quality fasteners can break or rust. You should always ask for quality certificates. Prince Fastener tests all fasteners for strength and rust resistance. This helps you trust the fastener you use.

How do you store fasteners to keep quality high?

You should use bins, cabinets, or boxes to keep fasteners dry and clean. Label each bin with the size and type of fastener. Good storage keeps the quality of each screw and nut. Prince Fastener can suggest storage ideas for your shop.

Can you save money by buying screw fasteners in assortments?

Yes, you can save money with assortments. You get many sizes of screw fasteners for one price. This helps you finish jobs faster. Prince Fastener sells assortments at good prices. You do not waste money on sizes you do not need.