Welcome to قفل الأمير السحابة! We’re here to help you navigate the world of fasteners with clarity and expertise. Let’s dive into the M10 screw, a cornerstone in many of your projects.

If you’re in the manufacturing, construction, or any industry that relies on fasteners, you know how crucial it is to get the details right. Today, we’re diving deep into the world of “10 screw diameter” to give you a comprehensive understanding of M10 screws and their applications.

From our years of experience in the fastener industry, we’ve seen countless projects hinge on the right choice of screws. For instance, in a recent project involving the assembly of heavy machinery, we recommended M10 × 1.5 screws due to their robustness and quick assembly capabilities. These screws not only saved time but also ensured the structural integrity of the machinery, highlighting the importance of choosing the correct screw diameter and pitch.

We understand that selecting the right fastener can be daunting, especially with the variety of options available. That’s why we’re here to provide you with detailed insights, real-world examples, and practical advice to help you make informed decisions. Whether you’re dealing with high-vibration environments, precision machinery, or everyday construction tasks, this blog will equip you with the knowledge you need to choose the perfect M10 screw for your project.

Understanding the 10 Screw Diameter

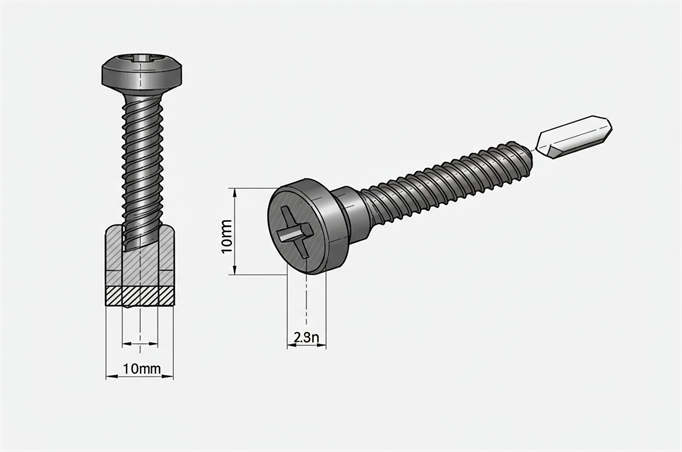

When we refer to a “10 screw,” we generally mean an برغي M10, which has a nominal diameter of 10 millimeters. Here’s what that means for you:

- Thread Outer Diameter (Major Diameter): This is a standard 10 mm.

- Actual Measurement Range: You’ll typically find this between 9.77 mm and 9.97 mm, depending on the precision grade and manufacturing tolerances.

- Pitch (Standard Coarse Thread): For an M10 screw, the common standard coarse pitch is 1.5 mm (M10x1.5).

Important Notes:

- Fine-Pitch Screws: If you’re working with a fine-pitch M10 screw (like M10x1.25 or M10x1), the pitch will be smaller, but the outer diameter remains 10 mm.

- US or Imperial Threads: If you encounter an inch-based “#10 screw,” you’ll need to convert. For example, a #10 UNC/UNF (American Standard) has an outer diameter of approximately 4.83 mm (this refers to #10-24 or #10-32).

M10 Screw Pitch Options

| نوع الخيط | Pitch (mm) | Marking Example | الملاحظات |

| Coarse | 1.5 | M10 | We don’t typically mark the pitch for coarse threads as it’s the default. |

| Fine | 1.25 | M10×1.25 | We often use these for precision or thin-walled parts. |

| Fine | 1.0 | M10×1.0 | These are for higher-precision applications. |

| Fine | 0.75 | M10×0.75 | We use these very rarely, only for special requirements. |

At قفل الأمير السحابة, we recognize that different applications demand different specifications. M10 screws come with several standard pitch options, categorized by coarse and fine threads:

M10 screws are available in four common pitch options. The 1.5 mm pitch is the default coarse thread, while you’ll need to specify the others as fine-pitch options.

What are the Uses for an M10 Screw with a 1.5mm Pitch?

The M10x1.5 screw (M10 coarse thread, 1.5 mm pitch) is one of the most common standard fasteners in the industrial sector. At قفل الأمير السحابة, we see its typical uses falling into these categories:

- General Mechanical Assembly

- We use it to connect medium to large transmission components, such as gears, bearing housings, couplings, and reducers. Its larger pitch and deeper thread profile provide excellent damage resistance, allowing for quick assembly and disassembly.

- You’ll find it used as a fastening bolt for bases, motors, or gearboxes in machinery, as well as in pumps and compressors, where it can withstand significant tensile and impact loads.

- Steel Structure and Construction Installation

- We extensively use M10x1.5 bolts in steel structure beam-column joints, purlin connections, pipe supports, and curtain wall keels. They work perfectly with standard or high-strength nuts to meet code requirements.

- This specification is also common for concrete embedded parts, bridge guardrails, and tower crane standard section connections, offering high construction efficiency and excellent interchangeability during on-site work.

- Automotive and Rail Transit

- You’ll see M10x1.5 bolts used for removable connections in engine blocks, transmission housings, chassis suspensions, and car body frames, which simplifies maintenance and repair.

- Because coarse threads are highly resistant to fouling and less likely to seize in harsh outdoor environments, we also recommend them for rail fasteners and external vehicle supports.

- Home Appliances and Electronic Heat Dissipation Structures

- For high-power power supplies, inverters, and industrial control cabinets, we often use stainless steel M10x1.5 combination screws to fix heat sinks, housing grounds, or internal structural components, ensuring both conductivity and strength.

- Jigs, Molds, and Fixtures

- We use these as locating screws or clamping bolts in tooling fixtures. When paired with T-slot nuts, they enable quick clamping. The 1.5 mm coarse thread also offers better wear resistance during frequent assembly and disassembly.

The M10x1.5 screw is renowned for its high strength, excellent versatility, and efficient assembly. If your application doesn’t have extreme self-locking requirements but demands reliable fastening and frequent disassembly, this is often your top choice. For environments with severe vibration, add a spring washer or a self-locking nut to compensate for the reduced self-locking ability of the coarse thread.

What are the Advantages of M10 Screws in Steel Structure Installation?

At قفل الأمير السحابة, we recognize the M10 screw (especially the M10x1.5 coarse thread) as an ideal choice for steel structure installation due to its moderate size and strong versatility. Here are its significant advantages:

✅ 1. High Installation Efficiency and Convenient Construction * High Standardization: M10 is one of the most commonly used bolt specifications in steel structures. Widely available tools (like 15 Nm torque wrenches) mean you can quickly install it on-site without special equipment. * Strong Adaptability: We can flexibly use it for various nodes, including steel beam connections, column base anchoring, and secondary structure fixing. هذا reduces the variety of spare parts you need and lowers inventory pressure.

✅ 2. Load-Bearing Capacity Matches Light Steel Structures * Single Bolt Load Capacity: For example, a 4.6-grade M10 screw achieves a preload of 5.0 kN and an approximate tensile design value of 2.1 kN. هذا makes it suitable for small to medium-load scenarios, such as purlins, wall beams, and support systems. * Compatibility with Channel Steel Systems: For instance, with Halfen HM series channel steel, you can directly use M10 screws with locking plates. They accommodate a maximum flange thickness of 25 mm, meeting the clamping needs of light steel beams.

✅ 3. Good Seismic and Durability Performance * Coarse Thread Advantage: The deeper 1.5 mm pitch thread is more resistant to damage under vibration or wind loads. When combined with a spring washer, it prevents loosening, making it suitable for dynamic environments like rooftop photovoltaic brackets and equipment platforms. * Flexible Anti-Corrosion Treatment: You can choose electro-galvanized, hot-dip galvanized, or stainless steel materials, which adapt to C3-C4 corrosive environments (like coastal factories) and extend maintenance cycles.

✅ 4. Outstanding Economy * Lower Cost Than High-Strength Bolts: Compared to 10.9-grade M12 and larger high-strength bolts, the unit price of M10 ordinary bolts is 30%-50% lower. هذا makes them incredibly cost-effective in non-load-bearing main nodes (such as enclosure systems and pipe supports). An M10 ordinary bolt, which costs around $0.30 to $0.50 (depending on grade and finish), offers significant savings compared to a high-strength alternative that might cost $0.45 to $1.00 or more.

✅ 5. Preferred Choice for Prefabricated Buildings * Precast Component Connection: In prefabricated steel structure residential buildings, we use M10 screws for limit connections between ALC floor slabs and steel beams. You only need to arrange them at 600 mm intervals to ensure the floor slab’s seismic and anti-detachment properties.

📌 Typical Cases We’ve Handled

- Curtain Wall Keel Fixing: M10 screws, combined with T-slot bolts, allow for quick adjustment of installation positions. A single point can support 100 kg (like the RS PRO Beam Clamp system).

- Equipment Bracket Installation: In industrial plants, we utilize M10 expansion bolts or chemical anchors to secure pipes and cable trays to steel beams or concrete foundations, thereby reducing installation time by 40%.

⚠️ Important Considerations

- Avoid Main Beam Splicing: For large-span or heavy-load nodes, you should upgrade to M16 or larger high-strength bolts.

- مقاومة التآكل: If the environmental corrosion level is ≥C5, we recommend using stainless steel M10 (A2-70) or increasing the coating thickness.

At قفل الأمير السحابة, we affirm that the M10 screw, with its core advantages of efficiency, Economy, and versatility, is an ideal choice for balancing cost and performance in light steel structures, enclosure systems, and equipment installation.

Which Mechanical Parts are Suitable for M10x1.25 Pitch Screws?

The M10x1.25 screw (1.25 mm pitch) is a fine-pitch thread. At قفل الأمير السحابة, we recognize that compared to the standard M10x1.5 coarse thread, its smaller pitch and denser thread profile make it suitable for mechanical designs that demand higher self-locking, sealing, and anti-loosening properties. Specifically, it applies to these mechanical parts:

✅ 1. Key Components in Automobiles and Motorcycles: * Engine cylinder head bolts, camshaft fixing bolts, flywheel bolts. * Fine threads offer good vibration resistance, preventing loosening in high-temperature and high-vibration environments. * Wheel hub bolts/rim bolts. * For example, we widely use M10x1.25 flange bolts for aluminum alloy wheels to prevent loosening during driving.

✅ 2. Hydraulic and Pneumatic Systems * Hydraulic cylinder end caps, valve body connecting bolts. * Fine threads better prevent oil leakage, enhancing sealing performance. * Compressor, pump body fasteners. * Under high pressure or pulsating loads, fine threads offer superior anti-loosening capabilities.

✅ 3. Precision Machinery and Instruments: Optical equipment, measuring instrument housings, fasteners. * Fine threads offer high adjustment precision, suitable for fine-tuning applications. * Precision mold frames, jig locating screws. * Their denser thread profile provides more precise clamping force control.

✅ 4. Fasteners in Vibrating Environments: Power tools, generators, and air compressor housings. * Fine threads are less likely to unwind under continuous vibration, reducing maintenance frequency.

✅ 5. Space-Constrained Thin-Walled Structures * Electronic device heat sinks, thin metal plate structures. * The shallower thread profile of fine threads suits short engagement lengths or thin-walled parts, reducing the risk of cracking.

⚠️ Important Considerations

- Not Suitable for High-Load Connections: Because of its shallower thread profile, the M10x1.25’s tensile strength is slightly lower than that of coarse threads. We do not recommend it for main load-bearing structures.

- Requires Special Nuts/Taps: Mixing it with M10x1.5 nuts/taps will damage the threads.

The M10x1.25 fine-pitch thread from قفل الأمير السحابة is ideal for mechanical scenarios that involve high vibration, high sealing requirements, short engagement lengths, or precise adjustments, such as in automotive wheels, hydraulic systems, and precision instruments.

What are the Special Uses for M10 Screw Pitch Specifications?

At قفل الأمير السحابة, we understand that while the four common M10 screw pitches (1.5, 1.25, 1.0, 0.75 mm) differ by only a few tenths of a millimeter, each has a very specific “special purpose” in “extreme conditions” or “function-oriented” designs.

- M10x1.5 (Coarse Thread) – “General Purpose + Speed”

- On-site Steel Structure Installation: For high-altitude work, an operator only needs to turn a wrench a dozen times to tighten it, offering the highest assembly and disassembly efficiency.

- Large-Volume Fixtures: Machine jigs and welding fixtures require frequent replacement of locating blocks. Coarse threads are resistant to fouling and less prone to cross-threading.

- M10x1.25 (First-Generation Fine Thread) – “Anti-Loosening + Medium Load”

- Automotive Wheel Bolts: Significant driving vibration means fine threads, with their smaller helix angle, offer better self-locking. They also maintain sufficient strength to withstand wheel-bending moments.

- Motorcycle Engine Cylinder Heads: Under high-temperature cyclic loads, fine threads reduce the likelihood of loosening while balancing ease of maintenance.

- M10x1.0 (Second-Generation Fine Thread) – “Precision + Thin Wall”

- Hydraulic Valve Bodies/High-Pressure Pump Heads: A smaller pitch results in a larger thread root area, leading to tighter sealing surface contact and reduced high-pressure leakage.

- Aluminum Alloy Thin Plate Structures: When the wall thickness is less than 3 mm, a 1.0 mm pitch can still ensure at least four threads of engagement, preventing stripping.

- M10x0.75 (Extra Fine Thread) – “Fine Adjustment + Short Engagement”

- Optical Instrument Focusing Mounts: A 0.75 mm lead means that one rotation advances the component by only 0.75 mm, allowing for micrometer-level focal length adjustment.

- Precision Mold Limit Screws: Within a short engagement length (≤6 mm), they still maintain≥6 effective threads, providing high positioning repeatability.

At قفل الأمير السحابة, we see coarse threads as “efficiency-first,” while fine threads are “function-first.” Each decrease in pitch maximizes one of these “trump cards”: anti-loosening, sealing, fine-tuning, or thin-wall suitability.

What’s the Difference Between Metric M10 and Imperial #10 Threads?

At قفل الأمير السحابة, we often explain the key differences between Metric M10 and Imperial #10 threads, as they’re not interchangeable.

1. Size and Units

- Metric M10 Thread:

- Nominal Diameter: 10 mm.

- Pitch: Common pitches include 1.5 mm (coarse thread) and 1.25 mm (fine thread).

- Unit: Millimeters (mm).

- Imperial #10 Thread:

- Nominal Diameter: A #10 thread’s diameter is approximately 4.826 mm.

- Pitch: We usually express this in threads per inch (TPI); a #10 thread typically has 32 TPI.

- Unit: Inches.

2. Thread Angle

- Metric M10 Thread: We use a 60° thread angle.

- Imperial #10 Thread: We use a 55° thread angle.

3. Application Scenarios

- Metric M10 Thread:

- We widely apply it across mechanical engineering, automotive, and construction industries, fitting most modern equipment.

- It suits high-load, general connection scenarios.

- Imperial #10 Thread:

- You’ll often find it in older equipment, as well as in the aerospace and military sectors.

- It remains widely used in specific North American equipment.

4. Interchangeability

- Metric and Imperial threads, due to differences in units, pitch, and thread angle, cannot be directly interchanged.

- If you need to connect between metric and imperial systems, you typically require an adapter or conversion fitting.

5. Designation Method

- Metric M10 Thread: We designate it as “M10x1.5” (indicating a 10 mm diameter and 1.5 mm pitch).

- Imperial #10 Thread: We designate it as “#10-32” (indicating a #10 diameter and 32 threads per inch).

At قفل الأمير السحابة, we emphasize that Metric M10 and Imperial #10 threads have significant differences in size, unit, thread angle, and application scenarios. Metric threads are better suited for modern general-purpose equipment, while Imperial threads retain unique uses in specific North American and older equipment.

How Do Metric and Imperial Threaded Fasteners Differ?

At قفل الأمير السحابة, we know that metric and imperial threaded fasteners show significant differences in design, specifications, and application scenarios. Here are their main distinctions:

1. Size and Units

- Metric Threads:

- Unit: Millimeters (mm).

- Diameter: We express diameter in millimeters, such as M10, M12.

- Pitch: We express pitch in millimeters, such as M10x1.5 (1.5 mm pitch).

- Pitch Designation: We typically state the pitch directly, such as M10 x 1.5.

- Imperial Threads:

- Unit: Inches.

- Diameter: We express diameter in inches, such as #10, 1/4-20.

- Pitch: We express pitch as threads per inch (TPI), such as #10-32 (32 threads per inch).

- Pitch Designation: We designate it as “diameter-TPI,” such as 1/4-20, meaning a 1/4-inch diameter and 20 threads per inch.

2. Thread Angle

- Metric Threads:

- Thread Angle: 60°.

- Design Characteristics: They feature deeper threads, offering high strength and suitability for high-load and general connections.

- Imperial Threads:

- Thread Angle: 55° (for common Imperial threads like UNC/UNF) or 60° (for Unified threads like UNJ).

- Design Characteristics: They have shallower threads but offer good sealing, making them suitable for pipe connections (such as NPT threads) and certain specialized purposes.

3. Application Scenarios

- Metric Threads:

- تعدد الاستخدامات: We widely use them in machinery, automotive, construction, and electronics industries.

- Advantages: They have a larger pitch and high strength, suitable for high-load and frequently assembled/disassembled scenarios.

- Typical Uses:

- Mechanical assembly, such as engine blocks and transmission housing connections.

- Steel structures, such as steel beams and column base anchoring.

- Home appliances and electronic equipment, such as heat sinks and housing fixtures.

- Imperial Threads:

- تعدد الاستخدامات: We widely use them in North America and some older equipment.

- Advantages: They have a smaller thread angle and good sealing properties, making them suitable for pipe connections and precision instruments.

- Typical Uses:

- Pipe connections, such as NPT threads for water and gas pipes.

- Aerospace: such as UNJ threads for high-strength connections.

- Older equipment, such as some early machinery and tools.

4. Interchangeability

- Metric and Imperial Threads:

- Not Directly Interchangeable: Due to differences in units, pitch, and thread angle, metric and imperial threads cannot be directly interchanged.

- Solutions: You need to use adapters or conversion fittings to achieve connections.

5. Designation Method

- Metric Threads:

- Designation: For example, M10x1.5 indicates a 10 mm diameter and 1.5 mm pitch.

- Coarse and Fine Threads: We don’t specify the pitch for coarse threads, e.g., M10; we must specify the pitch for fine threads, e.g., M10x1.25.

- Imperial Threads:

- Designation: For example, #10-32 indicates a #10 diameter and 32 threads per inch.

- Coarse and Fine Threads: You must explicitly specify coarse threads (UNC) and fine threads (UNF), e.g., 1/4-20 UNC.

6. Materials and Strength

- Metric Threads:

- المواد: We commonly use carbon steel, stainless steel, and alloy steel, among others.

- درجات القوة: Such as 4.6 grade, 8.8 grade, 10.9 grade.

- Imperial Threads:

- المواد: Common materials include carbon steel, stainless steel, brass, etc.

- درجات القوة: Such as SAE Grade 2, SAE Grade 5, SAE Grade 8.

At قفل الأمير السحابة, we recognize that metric and imperial threads differ significantly in terms of size, units, thread angle, and application scenarios. Metric threads are suited for modern general-purpose equipment, emphasizing strength and versatility. Imperial threads, on the other hand, offer unique advantages in North America and specific fields (like aerospace and pipe connections). In practical applications, you must choose the appropriate thread type based on your particular needs and standards.

Thank you for joining us on this detailed exploration of the “10 screw diameter.” At Prince Fastener, we’re committed to providing you with the highest quality fasteners and the knowledge to use them effectively. We hope this blog has given you a clearer understanding of the various M10 screw options and their applications.

Remember, the right fastener can make all the difference in the success of your project. If you have any questions or need further assistance, our team of experts is always here to help. Feel free to reach out to us for personalized advice or solutions to any fastener-related challenges you may face.

Stay tuned for more informative content from Prince Fastener, where we continue to bring you the best in fastening solutions and industry insights. Until next time, keep building with confidence!

FAQ for M10 Screws

1. What are the common pitches for M10 screws, and how do I choose the right one for my project?

M10 screws are available in several standard pitches, including 1.5 mm (coarse thread), 1.25 mm, 1.0 mm, and 0.75 mm (fine thread). The choice of pitch depends on the application:

– **1.5 mm (coarse thread)**: Suitable for general-purpose applications where quick assembly and disassembly are required. It is commonly used in construction, the automotive industry, and mechanical assemblies.

– **1.25 mm (fine thread)**: Provides better vibration resistance and is often used in automotive engines, hydraulic systems, and other applications requiring higher precision.

– **1.0 mm and 0.75 mm (extra-fine threads)**: These are used in precision instruments, thin-walled structures, and applications where fine adjustments are necessary, such as optical devices and high-pressure systems.

2. What are the advantages of using M10×1.5 screws in construction projects?

M10 × 1.5 screws are widely used in construction due to their robustness and ease of installation. They offer high tensile strength and can withstand significant loads, making them ideal for steel structures, concrete anchors, and other heavy-duty applications. Their coarse thread design allows for quick assembly and disassembly, which is crucial in time-sensitive construction projects.

3. Can I use M10 screws in high-vibration environments?

Yes, M10 screws, especially those with finer pitches like 1.25 mm or 1.0 mm, are well-suited for high-vibration environments. Fine threads provide better resistance to loosening under vibration compared to coarse threads. Additionally, using lock washers or thread-locking compounds can further enhance their vibration resistance.

4. What are the differences between M10 metric screws and #10 imperial screws?

M10 metric screws have a nominal diameter of 10 mm and are available in various pitches (1.5 mm, 1.25 mm, etc.). In comparison, #10 imperial screws have a diameter of approximately 4.83 mm and are typically specified by threads per inch (TPI). Metric screws use a 60° thread angle, whereas imperial screws often use a 55° angle. Metric screws are more common in modern applications, while #10 imperial screws are still used in some older or specialized equipment.

5. How do I determine the correct tap drill size for an M10 thread?

The tap drill size for an M10 thread depends on the pitch of the thread. For a coarse thread (1.5 mm pitch), the tap drill size is typically 8.5 mm. For finer pitches, the tap drill size will be slightly larger. It’s essential to refer to a reliable thread chart or consult with a fastener expert to ensure the correct tap drill size is used, thereby avoiding thread damage.

6. What are some common issues to watch out for when using M10 screws, and how can I avoid them?

Common issues include thread stripping, cross-threading, and corrosion. To avoid these problems:

– Ensure the correct pitch and thread type are used for the application.

– Use appropriate tools and techniques during installation to prevent cross-threading.

– Apply anti-seize compounds or corrosion-resistant coatings to prevent rust and thread seizing, especially in harsh environments.