At Prince Fastener, we live and breathe hardware nuts and bolts. Every day, our engineers, metallurgists و logistics teams move more than 5 million pieces through our ISO 9001-certified plants in Nantong—yet we still remember the first lesson our founder taught us: a single misplaced thread can stop an entire production line. That obsession with precision is why we decided to create this definitive guide to hardware nuts and bolts.

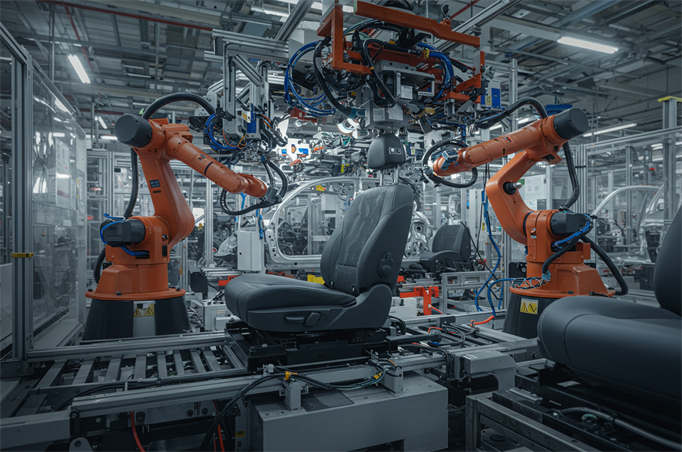

Whether you are a procurement veteran looking to consolidate suppliers, a design engineer hunting for the perfect anti-vibration lock-nut for a wind-turbine nacelle, or an overseas buyer trying to decode the maze between SAE Grade 8 and 10.9 metric bolts, this article is your one-stop knowledge base. We will walk you through our proprietary “Purpose-Structure-Thread-Material-Performance” tree, share 30-second field tips that save hours on the shop floor, and reveal how we at Prince Fastener use robotic optical sorting and salt-spray chambers to guarantee 1,000-hour corrosion resistance on every stainless-steel bolt that leaves our dock.

Along the way you will see real inspection photos from our lab, downloadable CAD files for M3–M48 standard parts, and checklists you can paste straight into your next RFQ. Our goal is simple: when you type “hardware nuts and bolts” into any search engine, we want the first result to be a resource that actually helps you build safer, faster, and more cost-effective products. So bookmark this page, grab your torque wrench, and let’s dive into the fascinating micro-world of threads, tensile zones و surface coatings—where millimeters matter and Prince Fastener has been setting the global benchmark for 30+ years.

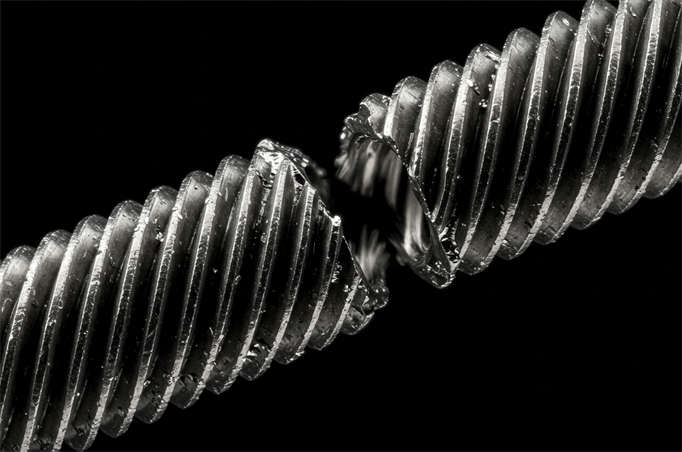

At Prince Fastener, we understand that hardware nuts and bolts are the most common fastener combinations in mechanical structures. They typically work together to secure or connect components.

1. براغي

Structural Features:

- Head: We commonly see hex heads (for easy wrench operation), round heads, and countersunk heads.

- Threads: Bolts feature external threads, available as fully threaded or partially threaded.

- Material: We manufacture bolts from carbon steel (e.g., Grade 8.8), stainless steel (e.g., 304/316), alloy steel, and brass.

Examples of Bolt Types:

- Hex Bolts: Highly versatile, we use them for heavy-duty connections.

- مسامير النقل: Their square neck prevents rotation, making them suitable for wood or metal channels.

- مسامير التمدد: We use these to secure objects to concrete foundations.

2. Nuts

Structural Features:

- Internal Threads: Nuts feature internal threads that match bolt threads. We commonly find them in metric (M5-M24) or imperial (UNC/UNF) sizes.

- Shape: Hex nuts are the most common, while flange nuts offer anti-loosening properties, and wing nuts allow for hand-tightening.

Anti-Loosening Designs:

- Nylon Lock Nuts (e.g., Nylon Insert Nuts): We use a nylon ring to provide friction and prevent loosening.

- All-Metal Lock Nuts: These feature thread deformation or crimping designs.

3. Key Matching Parameters

- Thread Standard: We ensure consistency (e.g., an M10x1.5 bolt pairs with an M10x1.5 nut).

- Strength Grade:

- A bolt designation like “8.8” indicates a tensile strength of 800MPa and a yield strength of 640MPa.

- The nut grade must match (e.g., an 8-grade nut for an 8.8-grade bolt).

- المعالجة السطحية: We offer various treatments like galvanizing (for rust prevention), blackening (for industrial use), and Dacromet (for high مقاومة التآكل).

4. Application Scene Differences

- Dynamic Loads (e.g., Vibrating Equipment): We require anti-loosening nuts plus spring washers.

- High-Temperature Environments: We select stainless steel or brass nuts to prevent galling.

- Insulation Requirements: We utilize nylon or plastic nuts.

5. Common Issues

- Galling: Stainless steel threads easily seize due to friction welding; we recommend lubrication or anti-galling coatings.

- Loosening Causes: Insufficient pre-tightening force, vibration, or thermal expansion/contraction. We recommend regular torque re-checks.

6. Selection Recommendations

- General Machinery: Hex bolts + hex nuts (8.8 grade carbon steel, galvanized).

- Outdoor Rust Prevention: A2-70 stainless steel bolts + nylon lock nuts.

- Precision Instruments: Fine-pitch threads (e.g., M6x0.75) + flange nuts to prevent eccentric pressure.

How to Classify Hardware Nuts and Bolts

To systematically classify hardware nuts and bolts, we use a “tree-like” structure across five dimensions: “application, structure, thread, material, and performance.” This approach ensures we don’t miss anything and helps us quickly locate the required components.

I. By Application (First Determine the Scenario)

- Structural Connections: General machinery, building steel structures, bridges.

- Vibration Prevention: Car chassis, compressors, rail transit.

- Pipes/Profiles: U-bolt clamps, T-slots, curtain walls.

- Decorative Exposed Parts: Furniture, appliance casings, display racks.

- Lifting/Towing: Eye bolts, rigging accessories.

II. By Thread System (Determine Compatibility)

- Metric Threads:

- Coarse pitch (M6, M8…)

- Fine pitch (M8x1, M10x1.25…)

- Imperial Threads:

- UNC (Unified National Coarse)

- UNF (Unified National Fine)

- BSW (British Standard Whitworth)

- Special Threads:

- Pipe threads (G, R)

- Trapezoidal threads (for transmission)

What’s the Difference Between SAE and Metric Hardware Nuts and Bolts?

The core differences between SAE (American) and Metric (ISO) hardware nuts and bolts lie in four aspects: measurement units, thread parameters, strength grade systems, and marking methods.

Quick Conversion Examples

- Diameter: 3/8 inch ≈ 9.5 mm

- Strength: SAE Grade 5 ≈ Metric 8.8 grade; SAE Grade 8 ≈ Metric 10.9 grade

Selection Tips

- If equipment drawings specify “M12x1.75,” you must use metric. If they specify “3/8-16 UNC,” you must use SAE.

- You cannot mix the two: While both have a 60° thread angle, the pitch or threads per inch (TPI) differ. Forcing them together will cause galling or loosening.

How to Distinguish Between SAE and Metric Hardware Nuts and Bolt Threads?

To quickly distinguish between SAE (American) and Metric (ISO) threads on physical hardware nuts and bolts, simply follow our “three-step method”: first, look at the unit; second, count the threads; third, measure the pitch. With simple tools, you can achieve 100% confirmation.

- If you see “M” or “x” followed by millimeters → Metric

- If you see a fraction/decimal or “-” followed by a number (e.g., 20, 28) → SAE

✅ On-Site 30-Second Rhyme

“If you see an M, it’s metric, fractions and inches are American; Metric threads measure pitch in millimeters, American threads count 20, 28 per inch; Head markings like 8.8 are metric, radial lines are Grade 8.”

Using these methods, you can quickly and accurately distinguish between the two thread systems on physical hardware nuts and bolts.

What’s the Difference Between Metric and SAE Hardware Nuts and Bolts Threads?

Metric and SAE hardware nuts and bolts threads share the same thread angle but differ in measurement systems and pitch/TPI rules, making them non-interchangeable. Here are the specific differences:

Measurement System

- Metric: We use millimeters (mm) for both diameter and pitch.

- SAE: We use inches (inch) for diameter and threads per inch (TPI) for pitch.

Pitch vs. Threads Per Inch (TPI)

- Metric: We directly provide the pitch P (e.g., M10x1.5 ⇒ adjacent thread peaks are 1.5 mm apart).

- SAE: We provide the TPI (e.g., 1/4-20 ⇒ 20 threads per inch, converting to a pitch of 25.4/20 = 1.27 mm).

Result: For the same diameter, metric pitches have fixed millimeter values, while SAE pitches are decimal values (25.4 divided by TPI). The two almost never overlap.

Thread Angle

Both have a 60° thread angle, but the pitch difference leads to mismatched crest-to-root engagement. Forcing them together will cause galling or loosening.

Metric and SAE hardware nuts and bolts threads are “same angle, different pitch.” You can distinguish them immediately by measuring the pitch once or using a thread gauge, and you must never mix them.

How to Quickly Identify Metric and SAE Hardware Nuts and Bolts?

We use a “three-piece set” identification method that takes just 10 seconds on-site (all you need is your naked eye + a metal ruler):

1. Check Head Markings

- If you see “M” (e.g., M8, M10) → Metric

- If you see a fraction or decimal (e.g., 1/4, 3/8) or “#” (e.g., #10) → SAE

2. Look at Strength Markings

- Numbers 4.8, 8.8, 10.9 → Metric strength grades

- Radial dashes (3 or 6 dashes) + “Grade 5/8” → SAE strength grades

3. Measure the Pitch (Ruler Quick Measure)

- Place the bolt’s tip at the 0 mark on a ruler and count 10 threads:

- If the total length of 10 threads is a whole number of millimeters (e.g., 15 mm) → Metric (pitch 1.5 mm)

- If the total length of 10 threads is an inch fraction (e.g., 5/8″ ≈ 15.9 mm) → SAE (20 TPI)

Rhyme:

“M marks metric, fractions are SAE; Measure 10 threads’ length, millimeters are metric, inches are SAE.”

Hardware Nuts and Bolts Manufacturers

Here’s a quick reference list of “China’s Mainstream Hardware Nuts and Bolts Manufacturers and Their Advantages,” organized by Brand/Manufacturer, Core Products, Application Areas, and Region. You can directly use this for supply chain or brand selection.

Manufacturer & Advantage Spotlight:

- JinYi : High-strength fasteners, especially for high-speed rail, wind power, and heavy-duty steel structures.

- Haili : Specializes in high-strength bolts and nuts for critical applications.

- TBF: Known for large-diameter, high-strength fasteners for infrastructure projects.

- Dongming TONG : A leading manufacturer of stainless steel fasteners, ideal for corrosion-resistant applications and curtain wall projects.

- Fule : Focuses on high-quality مثبتات الفولاذ المقاوم للصدأ for various industries.

- Pengchi Hardware: Produces high-strength fasteners for automotive and mold industries.

- Jianbo : Offers a wide range of high-strength fasteners for automotive and general industrial use.

- Gaoyi Precision : Specializes in precision high-strength fasteners.

- BOSSARD: A global leader offering a comprehensive range of fasteners and logistics solutions, excellent for international trade and diverse standard requirements.

- Ningbo Yongliante: Known for its extensive coverage of American, German, and Japanese standards, suitable for export and multi-standard demands.

Usage Recommendations:

- High-Speed Rail, Wind Power, Heavy-Duty Steel Structures: Prioritize JinYi, Haili, TBF.

- Stainless Steel or Curtain Wall Projects: Choose Dongming TONG, Fule.

- Automotive/Mold High Strength: Consider Pengchi Hardware, Jianbo, Gaoyi Precision.

- Foreign Trade/Multi-Standard Needs: BOSSARD, Ningbo Yongliante (they cover American/German/Japanese standards comprehensively).

How to Communicate with Hardware Nuts and Bolts Manufacturers

Efficient communication with hardware nuts and bolts manufacturers means “translating your needs into industrial language.” Follow this 6-step template to get accurate quotes, shorten lead times, and reduce rework in one go.

✅ 1. Opening Statement (3 Sentences): Help the Factory Decide “Whether to Take the Order” in 30 Seconds

- Quantity Range: “Annual usage 500,000 sets / first batch trial production 5,000 sets, with subsequent rolling orders.”

- Standard or Drawing: “Executing GB/T 5783 M10x1.5×50 Grade 8.8, attached PDF drawing version 3.” (If no standard, state directly: “Non-standard part, attached STEP 3D drawing + 2D dimension table.”)

- Delivery & Location: “First batch 30 days to Shenzhen Yantian warehouse, FOB terms.”

✅ 2. Provide Key Specifications (The “What” and “How”)

- Product Type: “Hex bolt with hex nut.”

- Material: “Carbon steel (8.8 grade).”

- Dimensions: “M10 x 1.5 x 50mm (thread length 30mm).”

- المعالجة السطحية: “Hot-dip galvanized, thickness ≥ 60 microns.”

- Quantity: “50,000 sets (or as specified above).”

✅ 3. Package and Send Files (Email Subject: Inquiry + Company Name + Date)

- Attachment 1: PDF/STEP drawing (Name: PartNo_Rev3)

- Attachment 2: Excel requirement table (Quantity, Delivery, Packaging Method)

- Attachment 3: Reference photos (e.g., anti-loosening washer and bolt assembly schematic)

✅ 4. Factory’s Top 5 Questions (Prepare Your Answers in Advance)

- Do you require a salt spray test report? → Reply: Yes, ≥ 96 hours.

- Do you allow combined processing (cold heading + machining)? → Reply: Yes, but concentricity must be ≤ 0.05.

- What are your packaging requirements? → Reply: Small bags, 50 sets/pack → inner box → outer carton, palletized.

- Do you accept partial shipments? → Reply: First batch 5,000 sets, then 10,000 sets monthly.

- Do you require third-party inspection (SGS/BV)? → Reply: First batch requires SGS report, then once a year.

✅ 5. Price and Delivery Negotiation (3 Bottom Lines)

- MOQ (Minimum Order Quantity): First ask the factory for their “economic order quantity,” then discuss if 5,000 sets are feasible.

- Tiered Pricing: Provide 3 quantity tiers (5k / 20k / 100k) for the factory to quote all at once.

- Mold Fee: For non-standard parts, you can request the one-time mold fee to be “returned after the first batch” or “amortized over 100,000 sets.”

If the Factory Asks if I Need a Salt Spray Test Report, How Should I Respond?

When the factory asks about salt spray test requirements, your answer should be a concise statement providing the “test standard + duration + acceptance criteria.” هذا prevents further questions from the factory.

You can directly copy and paste this template:

English: “Salt spray test is required: Standard: ASTM B117 (or GB/T 10125 equivalent) Duration: ≥ 240 hours per our drawing. Acceptance: No red rust, no white corrosion, rating ≥ 9 per ISO 10289. Please enclose a third-party test report with the shipment.”

Selection Advice:

- Indoor Dry Environment: 96 hours is sufficient.

- Outdoor or Coastal: Start with 240 hours.

- Automotive Chassis: Over 480 hours, consider adding UV cycling.

By explicitly stating the duration and standard, you avoid repeated confirmations from the factory.

What if the Factory Says They Don’t Have This Test?

First, determine if “they don’t have it” means a lack of laboratory equipment or an unwillingness to perform the test. Then, provide three actionable solutions that both protect your interests and prevent losing the order. You can directly copy and paste these to the factory, prioritized as follows:

✅ Path A: Ask the Factory to Outsource the Test (Fastest, Lowest Cost)

Reply Template: “If your company lacks salt spray equipment, you can commission a nearby third-party laboratory (SGS, ITS, BV, CTI, Huace, or local quality inspection institutes) to perform the test on your behalf. We will bear/share the testing fee. Please provide the quote and lead time within 4 hours.”

✅ Path B: Switch to a Qualified Sister Factory or Request a Joint Quote

Reply Template: “Please transfer this to your affiliated factory with salt spray qualifications, or recommend a supply chain partner who can complete both production and testing. We accept joint quotes.”

✅ Path C: Accept a Compromise, But Add Warranty Clauses

If neither of the above options is feasible, then consider this fallback:

“If you genuinely cannot provide a report, please provide a written commitment:

- Plating process adheres to GB/T 9799, thickness ≥ 8 μm.

- If rust appears within 30 days of arrival, your company is responsible for free replacement and return shipping costs.

- For each batch, we will randomly select 5 pieces for third-party re-inspection at our expense, with the cost borne by your company.

Please stamp and return the above terms.”

If the Factory Proposes Adding Warranty Clauses, What Should We Pay Attention to?

When a factory proposes “adding warranty clauses,” you must explicitly define rust liability, inspection rights, compensation procedures, and failure determination. Otherwise, the “warranty” is just verbal reassurance. Here are 7 key points to directly include in a supplementary agreement:

1. Warranty Period

“Valid for 24 months from the date of goods arrival at the buyer’s warehouse (or 12 months for agreed outdoor environments).”

2. Failure Determination Standard

“Visible red rust covering > 5% of the surface area or an ISO 10289 rating < 7 is considered a failure.” (This prevents the factory from dismissing minor discoloration.)

3. Inspection Rights & Re-inspection Costs

“The buyer reserves the right to take samples within 10 days of arrival for salt spray verification by a third-party laboratory (SGS/BV/CTI, etc.). If found unqualified, the testing costs shall be borne by the seller.”

4. Scope of Compensation

“The seller is responsible for:

- Free replacement of the same quantity of qualified goods.

- Bearing round-trip shipping costs.

- If it causes downtime for the buyer, compensation will be calculated as (downtime hours × direct labor hourly rate), with a maximum limit of 30% of the batch’s total value.”

5. Notification Period

“The buyer shall notify the seller in writing within 7 working days of discovering rust; the seller shall provide a solution within 3 working days of receiving the notification.”

6. Force Majeure Exemption

Exemption only applies to acts of God, chemical corrosion, or improper storage by the buyer; requires on-site photos and third-party reports for proof.

7. Dispute Resolution

“If both parties dispute the inspection results, the re-inspection results from the provincial quality inspection institute at the buyer’s location shall prevail; if still unresolved, submit the dispute to the China International Economic and Trade Arbitration Commission.”

Usage:

Create a one-page “Supplementary Quality Warranty Agreement” incorporating these 7 clauses. Have both parties stamp and return it. هذا clearly defines boundaries for the factory and provides evidence for your rights.

How Exactly Do We Calculate the Warranty Period?

You can establish the start and end points of the warranty period with one clear statement, leaving no room for dispute with the factory:

“The warranty period begins on the day following the buyer’s warehouse sign-off date, calculated continuously for X months (or X years), and automatically terminates at 24:00 on the expiration date.”

Practical Template (Can Be Directly Written into a Contract):

Start Date:

“We designate the date of the buyer’s warehouse manager/system sign-off as Day-0; the warranty period begins on the following day as Day-1.” (If receiving partial shipments, we calculate each batch separately.)

Duration:

- Indoor Dry Environment: 24 months

- Outdoor or Highly Corrosive Environment: 12 months

- Automotive Chassis, Coastal Projects: 18 months (or as otherwise agreed)

End Date:

“The warranty automatically ends at 24:00 on the expiration date; if that day is a non-working day, it extends to 24:00 on the next working day.”

Suspension/Interruption Clause:

“If, due to buyer reasons, the goods are suspended or put into storage for more than 90 days, upon written confirmation by both parties, the calculation of the warranty period may be suspended and will resume when the goods are put back into use.”

Clearly stating the “sign-off date,” specifying the duration, and setting the termination time at 24:00 will prevent any disputes about “when the warranty expires.”

Do you have any specific scenarios in mind for your hardware nuts and bolts needs? We’re here to help you get it right.

Thank you for investing your valuable time in this deep-dive on hardware nuts and bolts. If you have followed us from the opening paragraphs to this final line, you now possess the same decision-making framework that Prince Fastener uses to supply Boeing, CRRC و Tesla: start with the application, lock down the standard, match the strength grade, and always—always—secure an enforceable quality clause.

The next step is simple: put the theory into practice. Download our complimentary “Prince Fastener RFQ Template” (link below) and send it to princefastener@gmail.com; within 24 hours a bilingual project engineer will return a detailed quotation that covers everything from raw-material mill certificates to salt-spray test reports in SGS format.

Prefer to test before you trust? Ask for our free “Sample-10” program: we will ship ten pieces of any standard or custom hardware nuts and bolts to your facility by DHL Express at no charge. For readers managing large-scale infrastructure projects, ask about our VMI (Vendor-Managed Inventory) hubs in Houston, Dubai و Rotterdam—strategically placed stock points that can cut lead times from weeks to days.

And because sustainability is no longer optional, every Prince Fastener warehouse is ISO 14001 compliant, powered by rooftop solar, and certified to recycle 100 % of our scrap steel and brass. Finally, keep this conversation going.

Follow قفل الأمير السحابة on LinkedIn for weekly QA tips, subscribe to our YouTube channel for slow-motion torque-test videos, and use the hashtag #PrinceFastener on Twitter when you need real-time answers from our global community of 30,000+ engineers. When the world searches for “hardware nuts and bolts,” we want them to find not just a catalog, but a partner who stands behind every thread, every shipment, every promise. That partner is Prince Fastener—tightening the future, one bolt at a time.