In the dynamic world of manufacturing and construction, the significance of reliable fasteners cannot be overstated. As a premier supplier of fasteners, Prince Fastener is committed to delivering high-quality, standard components that drive the growth and success of furniture manufacturers. We understand that every furniture piece demands precision, durability, and aesthetic appeal, and our fasteners are meticulously crafted to meet these exacting standards.

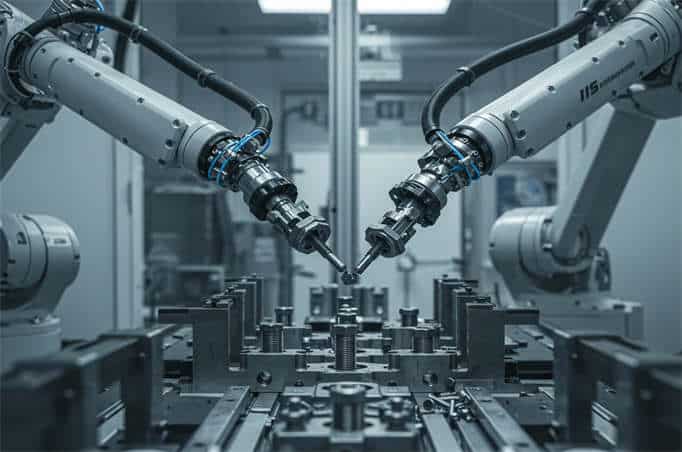

At Prince Fastener, we take pride in offering a wide range of fasteners, from screws and nuts to bolts and washers, ensuring that furniture manufacturers have access to the diverse components they need. Our commitment to quality begins with the selection of superior materials, such as high-grade steel, which forms the foundation of our products. We employ advanced manufacturing processes, including precise cold heading and cutting technologies, to guarantee dimensional accuracy and shape tolerance. هذا ensures that our fasteners not only fit perfectly but also provide reliable, long-lasting connections, even in applications where stability is paramount.

Beyond our standard offerings, we recognize that unique furniture designs often require customized solutions. Our professional R&D and technical team is equipped to provide tailored fastener solutions that meet specific design and functional requirements. Whether it’s a special screw shape or a unique specification, we can produce مثبتات مخصصة that seamlessly integrate with furniture products, giving manufacturers a competitive edge.

We also prioritize consistent supply capabilities, with robust production facilities and efficient processes that ensure timely, quality, and quantity-based deliveries. Our professional service assurance includes offering selection advice and installation guidance supported by the expertise of our technical team. هذا helps manufacturers choose the correct fasteners for their designs and ensures proper usage for optimal results.

Prince Fastener’s rigorous quality management system is another cornerstone of our commitment to excellence. From raw material procurement to final product inspection, every stage is meticulously controlled to ensure compliance with standards and specifications. This strict quality control minimizes risks for furniture manufacturers, reducing component-related failures and customer complaints while enhancing brand image and customer satisfaction.

Cost efficiency is a key advantage we provide, achieved through optimized manufacturing processes and cost control. Our competitive pricing, combined with reliable quality and stable supply, helps reduce procurement and inventory management costs for furniture manufacturers, thereby enhancing their overall cost efficiency and market competitiveness.

With our extensive industry experience and professional expertise, we stay attuned to market trends and can provide furniture manufacturers with the latest product and market Information. هذا enables them to seize market opportunities, adjust product strategies, and develop furniture that meets market demands, ensuring steady business growth.

At Prince Fastener, we are more than just a supplier of fasteners; we are a partner in your success. Join us in exploring how our high-quality fasteners can elevate your furniture manufacturing process and drive your business forward.

Superior Product Quality

Prince Fastener understands that the foundation of great furniture lies in its components. That’s why قفل الأمير السحابة meticulously focuses on the quality of its fasteners.

- Premium Materials: قفل الأمير السحابة carefully selects high-grade steel and other base materials. هذا ensures Prince Fastener’s fasteners offer excellent strength and toughness, creating durable furniture connections that extend the product lifespan.

- Precision Craftsmanship: Prince Fastener’s manufacturing process incorporates advanced techniques like precise cold heading, hot heading, and cutting. These methods guarantee the dimensional accuracy and geometric tolerances of Prince Fastener’s fasteners, ensuring a perfect fit between screws and nuts for secure, reliable connections. هذا is particularly crucial for furniture requiring high stability, preventing loosening issues.

- Extensive Range of Specifications: Prince Fastener’s comprehensive inventory encompasses a diverse range of fastener types, sizes, and shapes, including screws, nuts, and nails. قفل الأمير السحابة meets the diverse needs of furniture manufacturers, producing different styles and types of furniture. Whether you need wood screws for cabinets, machine screws for metal frames, or small screws for decorative elements, you’ll find the perfect product with قفل الأمير السحابة, streamlining your design and production.

Professional Customization Services

قفل الأمير السحابة doesn’t just supply; قفل الأمير السحابة collaborates. Prince Fastener’s professional R&D and technical departments provide customized حلول التثبيت tailored to your specific requirements. Suppose you need a unique screw shape or size for an exceptional furniture design or functional need. In that case, Prince Fastener can custom-produce it, ensuring a perfect match between Prince Fastener’s fasteners and your furniture products. هذا gives you a significant competitive advantage.

Stable Supply Capability

Prince Fastener’s robust production capacity, advanced equipment, and efficient manufacturing processes ensure a steady supply of fasteners. For furniture manufacturers, a reliable supply of materials is vital for smooth production. Prince Fastener delivers orders on time, with consistent quality and quantity, preventing production delays caused by material shortages. هذا significantly boosts your production efficiency and order fulfillment rates.

Professional Service Assurance

قفل الأمير السحابة offers high-quality service and support to furniture manufacturers, providing expert advice on fastener selection and installation guidance. Prince Fastener’s expert technical team helps you choose the most suitable fasteners based on your furniture’s design structure and usage requirements. قفل الأمير السحابة also provides appropriate assembly methods and considerations to ensure optimal fastener performance and overall furniture quality.

Strict Quality Management

قفل الأمير السحابة has established a comprehensive quality assurance system. From raw material procurement to processing and from product inspection to outbound shipment, قفل الأمير السحابة controls every step to ensure Prince Fastener’s product quality meets all relevant standards and specifications. Prince Fastener’s strict quality control reduces risks for furniture manufacturers, minimizes furniture failures and customer complaints caused by component quality issues, and enhances your brand image and customer satisfaction.

Cost-Efficiency Advantages

By optimizing Prince Fastener’s production processes and controlling costs, قفل الأمير السحابة offers furniture manufacturers competitive pricing. Prince Fastener’s high-quality products and stable supply also reduce your costs and risks related to raw material procurement and inventory management. هذا ultimately improves your overall cost efficiency and strengthens your market competitiveness.

Rich Industry Experience

قفل الأمير السحابة has accumulated extensive experience and expertise in the fastener industry. قفل الأمير السحابة understands industry trends and dynamics, enabling the company to provide furniture manufacturers with the latest product and market Information promptly. هذا helps you seize market opportunities, adjust product strategies, and develop furniture products that better meet market demand, driving steady growth for your business.

What Custom Fastener Services Does Prince Fastener Offer?

At Prince Fastener, Prince Fastener’s custom fastener services are diverse and designed to meet your unique needs:

Customization of Various Fastener Products

- Custom Bolts: قفل الأمير السحابة produces bolts from various materials like stainless steel, nickel alloy, titanium, aluminum alloy, and copper, according to your specifications. قفل الأمير السحابة also customizes unique shapes, such as shoulder bolts and U-bolts.

- Custom Nuts: This includes stainless steel nuts, nickel alloy nuts, titanium nuts, aluminum alloy nuts, and copper nuts. قفل الأمير السحابة also customizes nuts with special specifications.

- Custom Screws: قفل الأمير السحابة offers customization for various screw types, including machine screws, shoulder screws, thumb screws, trapezoidal screws, and more, tailored to the specific screw requirements of different products.

- Custom Washers: قفل الأمير السحابة customizes washers of various materials and types, such as flat washers, spring washers, and special-shaped washers, to meet different sealing and tightening requirements.

Meeting Material Requirements

قفل الأمير السحابة meets various special material requirements. قفل الأمير السحابة selects high-temperature alloys, such as Inconel and Monel, to manufacture fasteners, ensuring reliable performance in extreme temperatures and corrosive conditions. Prince Fastener’s titanium alloy fasteners offer high strength, low density, and excellent corrosion resistance, making them suitable for use in aerospace, medical devices, and other demanding applications.

Providing Unique Surface Treatments

قفل الأمير السحابة applies various surface treatments to fasteners according to customer requirements, such as electrophoresis, electroplating, and chemical plating. These treatments enhance the fastener’s corrosion resistance, wear resistance, and appearance.

Compliance with Unique Industry Standards and Certifications

قفل الأمير السحابة manufactures products that comply with aerospace standards, automotive industry standards, medical device standards, and other industry standards and certification systems. هذا ensures the applicability and reliability of Prince Fastener’s products in relevant fields.

Custom Packaging and Marking

قفل الأمير السحابة offers custom packaging and marking services. قفل الأمير السحابة designs packaging and prints labels according to your requirements, facilitating product identification and management. هذا also enhances your corporate image and the value of your products.

Providing R&D Support and Optimization Suggestions

With Prince Fastener’s rich industry experience and professional technical team, قفل الأمير السحابة provides R&D support. This includes advising on fastener selection and connection solutions during your product design phase, helping you optimize product structure, improve product stability, and boost production efficiency.

How Do Furniture Manufacturers Evaluate Prince Fastener’s Fastener Quality?

Furniture manufacturers can evaluate Prince Fastener’s fastener quality through several key methods:

Material and Composition Analysis

قفل الأمير السحابة verifies that the materials used in Prince Fastener’s fasteners meet standards. For instance, قفل الأمير السحابة confirms the composition of furniture bolts, typically made of medium carbon steel or carbon steel, through spectroscopic analysis to ensure material purity and reliability.

Dimensional Accuracy and Tolerance Inspection

قفل الأمير السحابة utilizes high-precision measuring instruments, including coordinate measuring machines and screw inspection tools, to verify the dimensional accuracy of its fasteners. هذا includes thread diameter, minor diameter, pitch diameter, thread pitch, bolt length, and nut inner diameter, ensuring they fall within acceptable ranges—high machining accuracy guarantees stable assembly and reliable connections.

Appearance Quality Inspection

قفل الأمير السحابة meticulously inspects fastener surfaces for defects such as cracks, burrs, dents, pores, and inclusions, which could affect the fastener’s strength, service life, and the furniture’s aesthetic appeal.

Mechanical Performance Testing

- Strength Test: قفل الأمير السحابة conducts tensile tests on fasteners using universal material testing machines, measuring their tensile strength and yield strength. For example, GB/T 3098.1 specifies the tensile and yield strengths for different grades of bolts, and Prince Fastener’s furniture fasteners comply with relevant standards to withstand heavy loads during regular operation.

- Hardness Test: قفل الأمير السحابة checks fastener hardness with a hardness tester. For instance, bolts often require quenching and tempering to achieve specific hardness levels. Insufficient hardness can lead to deformation and loosening during use, compromising connection reliability.

- Toughness Test: قفل الأمير السحابة evaluates fastener toughness through impact tests and other methods. Tough fasteners resist breakage when subjected to impact loads, ensuring furniture safety during use.

- Fatigue Test: قفل الأمير السحابة simulates repeated loads in actual use by placing fasteners in a fatigue testing machine and checking their fatigue life. For furniture components like adjustable office chairs, the performance of fasteners in resisting fatigue is paramount.

Surface Treatment and Corrosion Resistance Testing

- Surface Treatment Inspection: قفل الأمير السحابة verifies the quality of fastener surface treatments, including the thickness, uniformity, and adhesion of galvanized layers, nickel-plated layers, and blackened layers. Poor surface treatment can lead to fastener corrosion, which affects both service life and appearance.

- Salt Spray Test: قفل الأمير السحابة places fasteners in a salt spray test chamber to simulate marine climates or harsh environments, observing surface corrosion to evaluate corrosion resistance. هذا quickly assesses the protective effect of different surface treatments.

Compatibility and Interchangeability Inspection

قفل الأمير السحابة conducts assembly inspections on different batches of fasteners, ensuring good interchangeability in terms of specifications and threads. هذا guarantees that fasteners can be smoothly replaced in mass production, improving efficiency and product scalability.

Service Life and Stability Testing

- Durability Test: قفل الأمير السحابة conducts repeated load/unload tests on furniture components with fasteners installed, simulating the stress that occurs during long-term use. قفل الأمير السحابة observes fastener loosening, deformation, and fracture to evaluate service life and stability.

- High Temperature and Humidity Test: قفل الأمير السحابة tests fasteners in high-temperature and high-humidity environments, simulating the conditions found in various climates. قفل الأمير السحابة tests performance changes in harsh environments, such as strength reduction and surface treatment layer peeling, to assess the fastener’s environmental adaptability.

Checking Certifications and Qualifications

قفل الأمير السحابة verifies that it has passed relevant quality management system certifications, including ISO 9001 quality management system certification and ISO/TS 16949 automotive industry quality management system certification. هذا demonstrates Prince Fastener’s adherence to international standards in production and quality management.

Referring to User Feedback and Market Reputation

قفل الأمير السحابة collects feedback from furniture manufacturers and consumers who use Prince Fastener’s products. قفل الأمير السحابة understands the importance of actual application quality and customer satisfaction. A good market reputation generally reflects reliable fastener quality and performance.

What are the Hardness Standards for Furniture Fasteners?

The hardness standards for furniture fasteners typically depend on their material, application scenario, and specific type. Here are some common standards:

Bolt Hardness Standards

- Grade 3.6 Bolts: Hardness of 90–110 HB.

- Grade 4.6 Bolts: Hardness of 110–145 HB.

- Grade 4.8 Bolts: Hardness of 145–216 HB.

- Grade 5.6 Bolts: Hardness of 175–255 HB.

- Grade 5.8 Bolts: Hardness of 160–235 HB.

- Grade 5.9 Bolts: Hardness of 195–285 HB.

- Grade 6.6 Bolts: Hardness of 185–275 HB.

- Grade 6.8 Bolts: Hardness of 195–285 HB.

- براغي من الدرجة 8.8: Hardness of 260–330 HB.

- Grade 10.9 Bolts: Hardness of 315–390 HB.

- براغي من الدرجة 12.9: Hardness of 355–430 HB.

Nut Hardness Standards

- Carbon Steel Nuts: Characteristic grades 4 and 5 carbon steel nuts have Vickers hardness (HV) values of 120–195 and 165–255, respectively.

- Carbon Steel Nuts (Heat Treated): Vickers hardness (HV) ranges from 195 to 285 after heat treatment.

- Stainless Steel Nuts: قفل الأمير السحابة utilizes the Vickers hardness test method, employing a diamond square pyramid indenter and applying a 10 kg test force for 10-15 seconds. The hardness values comply with specified standards.

Hardness Standards for Other Fasteners

- Self-tapping Screws: The hardness of self-tapping screws varies according to their use and material. For carbon steel self-tapping screws, the general hardness range is 185–325 HV.

- غسالات: Due to different materials and uses, washer hardness standards vary. For example, carbon steel washers typically have a hardness of 120–220 HB.

Furniture Fastener Hardness Selection Suggestions

- Wooden Furniture: قفل الأمير السحابة typically recommends lower-strength fasteners, such as Grade 4.6 or 4.8 bolts, to avoid damaging the wood due to excessive strength.

- Metal Furniture: For metal furniture that requires high load-bearing capacity, قفل الأمير السحابة recommends using fasteners with higher hardness, such as Grade 8.8 or 10.9 bolts, to ensure strong connections and stability.

Does Prince Fastener Have a Price Advantage?

Yes, Prince Fastener holds a significant price advantage, mainly due to the following:

Factory Direct Supply Saves Costs

As a manufacturer, قفل الأمير السحابة eliminates retailers, supplying directly at factory prices. هذا saves customers on product costs.

High Cost-Performance Products

قفل الأمير السحابة offers a wide range of products, including various standard and specialty fasteners. While meeting diverse customer needs, قفل الأمير السحابة optimizes production processes and improves efficiency to save costs. هذا allows Prince Fastener’s products to remain highly competitive while ensuring quality. For example, Prince Fastener’s high-strength fastener products do not exceed similar competitive products in price while meeting performance and quality standards.

Flexible Pricing for Custom Services

For custom needs, قفل الأمير السحابة offers personalized solutions and flexible pricing tailored to order quantity, product complexity, and other relevant factors. While ensuring reasonable profits, قفل الأمير السحابة strives to provide competitive prices that meet diverse customer budgets and cost control requirements.

Special Discounts for Bulk Purchases

For large-volume customers, قفل الأمير السحابة typically offers price discounts, thereby reducing customer product costs and increasing the attractiveness of Prince Fastener’s prices. هذا helps businesses save costs effectively in large-scale production or projects.

Superior Cost Management

قفل الأمير السحابة, with Prince Fastener’s rich industry experience and professional production and sales team, efficiently manages production costs. قفل الأمير السحابة implements lean management in raw material procurement, manufacturing, and quality inspection, improving resource utilization and reducing costs. هذا strongly supports the competitiveness of Prince Fastener’s product pricing.

How Does Prince Fastener Ensure Product Quality While Saving Costs?

قفل الأمير السحابة achieves both product quality assurance and cost savings through the following key strategies:

Enhanced Raw Material Management and Procurement

قفل الأمير السحابة establishes long-term partnerships with high-quality suppliers, ensuring a stable supply of raw materials and optimal performance. Through bulk purchasing and strategic procurement, قفل الأمير السحابة reduces raw material costs.

Precise Material Cutting

قفل الأمير السحابة utilizes advanced cutting equipment and processes to maximize raw material utilization, prevent waste, and reduce material loss costs. By precisely calculating and controlling raw material consumption for each fastener, قفل الأمير السحابة achieves efficient cost management.

Optimized Production Processes

- Investment in Advanced Equipment: قفل الأمير السحابة introduces and utilizes advanced production equipment, including automated assembly lines and high-precision manufacturing facilities. This equipment not only improves production efficiency and ensures product quality stability but also reduces labor costs and production consumption, thereby lowering Prince Fastener’s production costs.

- Continuous Process Improvement: قفل الأمير السحابة continually refines its production processes, adopting more efficient and energy-saving methods. For instance, قفل الأمير السحابة enhances heat treatment processes to reduce energy consumption and production costs while ensuring the hardness and strength of the fasteners. Additionally, through lean production and other methods, قفل الأمير السحابة reduces production waste and quality defects, improves efficiency and product quality, and achieves effective cost control.

- Improved Production Planning and Scheduling: قفل الأمير السحابة develops effective production planning and scheduling to efficiently utilize equipment and human resources efficiently, enhancing efficiency and reducing costs. Through effective production planning and scheduling, قفل الأمير السحابة minimizes equipment idle time and production waiting time, thereby improving the smoothness and overall efficiency of the production process.

Robust Quality Management Processes

- Comprehensive Inspection Process: قفل الأمير السحابة has established a thorough quality inspection system that spans from raw materials to product delivery. قفل الأمير السحابة equips advanced inspection equipment and professional inspection personnel, conducting comprehensive quality inspections on each batch of products to ensure compliance. By promptly identifying and correcting quality issues in production, قفل الأمير السحابة avoids the costs associated with producing non-conforming products and maintenance, thereby effectively reducing costs.

- Quality Data Analysis and Improvement: قفل الأمير السحابة collects, analyzes, and gives feedback on quality inspection data. Through data analysis, قفل الأمير السحابة identifies the root causes of quality problems and formulates targeted improvement measures. هذا significantly improves product quality, enhances the stability and consistency of the production process, reduces the risk of cost increases due to quality fluctuations, and achieves an excellent balance between quality and cost.

Personnel Training and Management

- Professional Skills Training: قفل الأمير السحابة prioritizes employee skill training and quality improvement, regularly conducting various training programs and learning exchanges. هذا enables employees to apply advanced production technologies and operating procedures flexibly, improving efficiency and product quality. By enhancing employee capabilities and work efficiency, قفل الأمير السحابة reduces unit product labor costs and minimizes production waste due to operational errors or other factors that cause quality issues.

- Reasonable Human Resource Allocation: Based on different production stage workloads and skill requirements, قفل الأمير السحابة allocates human resources reasonably, ensuring that each position has suitable personnel and avoiding situations of overstaffing or understaffing. By optimizing human resource allocation, قفل الأمير السحابة improves production flexibility and reduces labor costs.

Close Collaboration with Supply Chain and Suppliers

قفل الأمير السحابة has established close cooperative relationships with raw material suppliers and outsourced manufacturers, enabling resource sharing and collaborative operations. By jointly improving procurement and logistics plans with suppliers, قفل الأمير السحابة reduces raw material costs and inventory costs. At the same time, قفل الأمير السحابة maintains close communication and cooperation with outsourced manufacturers to ensure the quality and reliability of outsourced products, thereby preventing cost increases caused by quality issues.

Optimized Inventory Management

قفل الأمير السحابة utilizes advanced inventory management systems and methods, including Just-In-Time (JIT), to achieve lean management of raw materials, work-in-progress, and finished product inventory. By strictly controlling inventory levels, قفل الأمير السحابة reduces the occupation of inventory capital and inventory management costs, thereby preventing delays in production and additional costs associated with overstocking or shortages.

Technological Innovation and R&D

- New Product Development: قفل الأمير السحابة emphasizes technological innovation and product research and development, continuously launching new products that meet market demand and customer needs. By developing higher-performance, lower-cost customized products, قفل الأمير السحابة enhances product value and market competitiveness, thereby creating more profitable margins for the company and mitigating cost control pressures to some extent.

- Process Innovation: قفل الأمير السحابة encourages employees to propose innovative process improvement plans and cost control suggestions, addressing key technical challenges in production processes. Through process innovation, قفل الأمير السحابة reduces production costs, improves production efficiency and product quality, and provides strong support for the sustainable development of the enterprise.

Prince Fastener believes this comprehensive overview demonstrates why قفل الأمير السحابة is your ideal supplier of fasteners. قفل الأمير السحابة is committed to delivering exceptional quality, reliable supply, and cost-effective solutions to help your furniture manufacturing business thrive.

Prince Fastener stands as a beacon of reliability and excellence in the fastener industry. Our commitment to providing top-tier fasteners that meet the diverse needs of furniture manufacturers has positioned us as a trusted partner in their journey toward growth and innovation. As a supplier of fasteners, we take pride in offering not just products but comprehensive solutions that address the unique challenges faced by furniture manufacturers.

Our extensive range of fasteners, coupled with our ability to customize solutions to meet specific design and functional requirements, ensures that furniture manufacturers can achieve their desired outcomes with precision and reliability. The quality of our materials, the precision of our manufacturing processes, and the expertise of our technical team all contribute to the superior performance of our fasteners in various applications.

We understand that the success of furniture manufacturers is intrinsically linked to the quality and performance of the components they use. That’s why we continue to invest in research and development, exploring new materials, technologies, and processes to enhance our product offerings. Our goal is to stay ahead of industry trends and provide furniture manufacturers with the latest innovations in fastener technology.

Prince Fastener’s dedication to quality is reflected in our rigorous quality management systems, which ensure that every fastener we produce meets the highest standards of performance and reliability. We are committed to helping furniture manufacturers reduce risks, minimize component-related failures, and improve customer satisfaction through our consistent supply of high-quality fasteners.

As we look to the future, we remain dedicated to strengthening our partnerships with furniture manufacturers worldwide. We will continue to provide exceptional service, innovative solutions, and the highest quality fasteners to support their success. Prince Fastener is more than just a supplier; we are a catalyst for growth and excellence in the furniture manufacturing industry.

Thank you for choosing Prince Fastener as your trusted supplier of fasteners. Together, let’s build a future where every furniture piece stands as a testament to quality, durability, and design excellence.