You face many choices when selecting flat fasteners for your project. The right option helps you build strong, safe, and lasting assemblies. If you pick the wrong fastener, you risk weak joints or damage. Many types exist, and this can make you feel uncertain. You want clear facts to guide your decision. Prince Fastener understands your need for reliable solutions.

النقاط الرئيسية

- Learn about different flat fasteners like bolts, screws, nuts, washers, and rivets. This helps you pick the best one for your project.

- دائماً choose a fastener that fits your project’s needs. This makes your project strong, safe, and last longer.

- Think about what the fastener is made of. Stainless steel works well in wet places. Aluminum is light and easy to use.

- Washers help protect surfaces and spread out the load. They stop damage and help your project last longer.

- Do not make mistakes like using the wrong fastener or tool. This can make joints weak and repairs expensive.

Types of Flat Fasteners

Overview of Flat Fasteners

Flat fasteners help you join materials together with a flush or low-profile finish. You use them when you want surfaces to stay smooth and free from bumps. These fasteners work well in woodworking, metalworking, furniture assembly, and many other projects. You often see them in places where safety and appearance matter.

You find several main categories of flat fasteners. Each type serves a different purpose. The most common groups include:

- براغي

- مسامير

- المكسرات

- غسالات

- برشام

نصيحة: Always match the fastener type to your project’s needs. The right choice gives you a strong, safe, and long-lasting result.

Common Types and Their Uses

You need to know the main types of fasteners before you start your project. Each one has a special job. Here is a quick guide to help you:

| Fastener Type | الوصف | الاستخدامات الشائعة |

|---|---|---|

| براغي | Cylindrical rods with threads and a head. You use them with nuts. | Machinery, construction, automotive |

| مسامير | Threaded fasteners that cut their own path. Some have flat heads for a flush finish. | Woodworking, cabinetry, electronics |

| المكسرات | Hexagonal or square pieces that pair with bolts. They hold parts together. | Furniture, equipment, vehicles |

| غسالات | Thin, flat discs. They spread load and protect surfaces. | Preventing damage, spacing, sealing |

| برشام | Permanent fasteners. You deform them to hold materials together. | Aircraft, metalwork, heavy-duty repairs |

You should always think about the job before picking a fastener. For example, if you need to take things apart later, bolts and nuts work best. If you want a smooth surface, flat head screws or washers help you get that look. Rivets give you a permanent hold when you do not plan to remove the parts.

Prince Fastener offers a wide range of flat fasteners for every application. You can find the right solution for your project by understanding the types of fasteners and their uses. This knowledge helps you avoid weak joints and keeps your work safe.

ملاحظة: Choosing the wrong fastener can lead to damage or failure. Take time to match the fastener to your project’s needs.

Comparing Types of Fasteners

Bolts and Their Applications

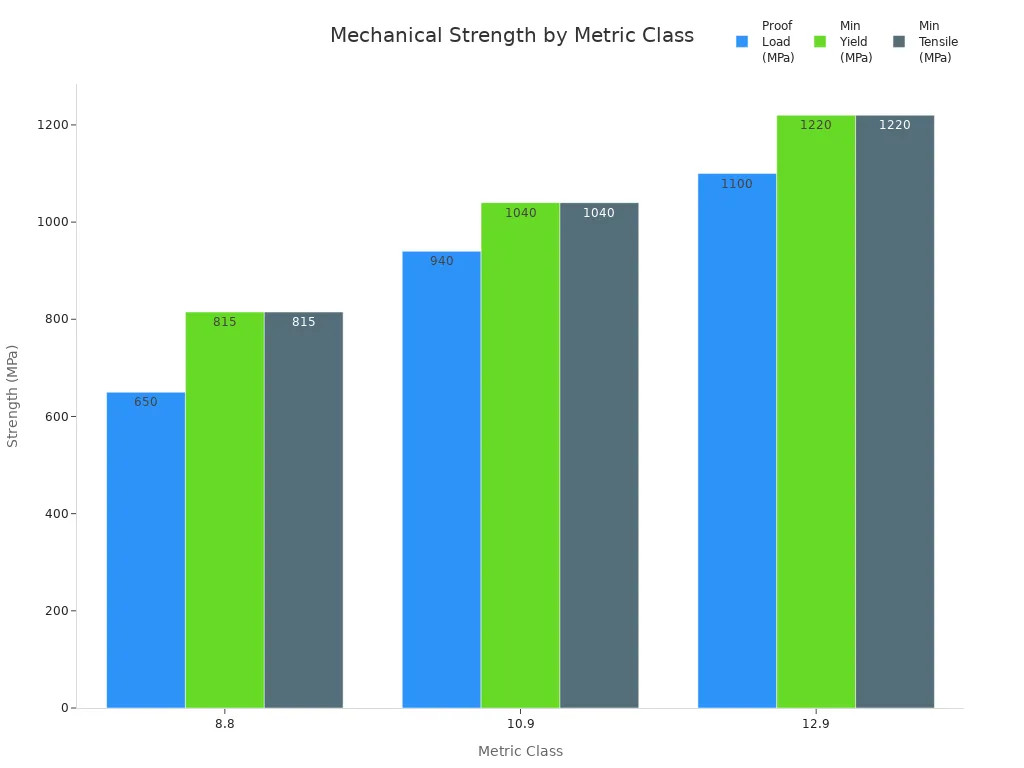

You use bolts when you need strong and secure connections. Bolts work best in heavy-duty projects like building construction, bridges, and machinery. You pair bolts with nuts to hold parts together tightly. Bolts have high mechanical strength and can handle large loads. You see bolts in steel-framed buildings, towers, and transportation infrastructure. Bolts also help protect structures during earthquakes because they absorb energy.

Here is a table that shows how bolts compare in strength:

| Metric Class | Proof Load (MPa) | Min Yield (MPa) | Min Tensile (MPa) |

|---|---|---|---|

| 12.9 | 1,100 | 1,220 | 1,220 |

| 10.9 | 940 | 1,040 | 1,040 |

| 8.8 | 640–660 | 800–830 | 800–830 |

You choose bolts for projects that need high strength and flexibility. For example, you use bolts in bridges to handle dynamic loads. You use galvanized bolts for outdoor projects because they resist corrosion. Prince Fastener offers bolts made from alloy steel, stainless steel, and titanium. Each material gives you different levels of strength and resistance.

Screws and Flat Head Screws

You use screws when you want to join materials without nuts. Screws cut their own path into wood, metal, or plastic. Flat head screws let you create a smooth surface because the head sits flush with the material. You see flat head screws in furniture, cabinetry, and electronics. You choose screws for projects that need easy assembly and disassembly.

Screws come in many shapes and sizes. Flat head screws have different angles, such as 82°, 90°, or 100°. You pick the angle based on the material and the look you want. Screws do not match bolts in strength, but they work well for lighter loads and precise work.

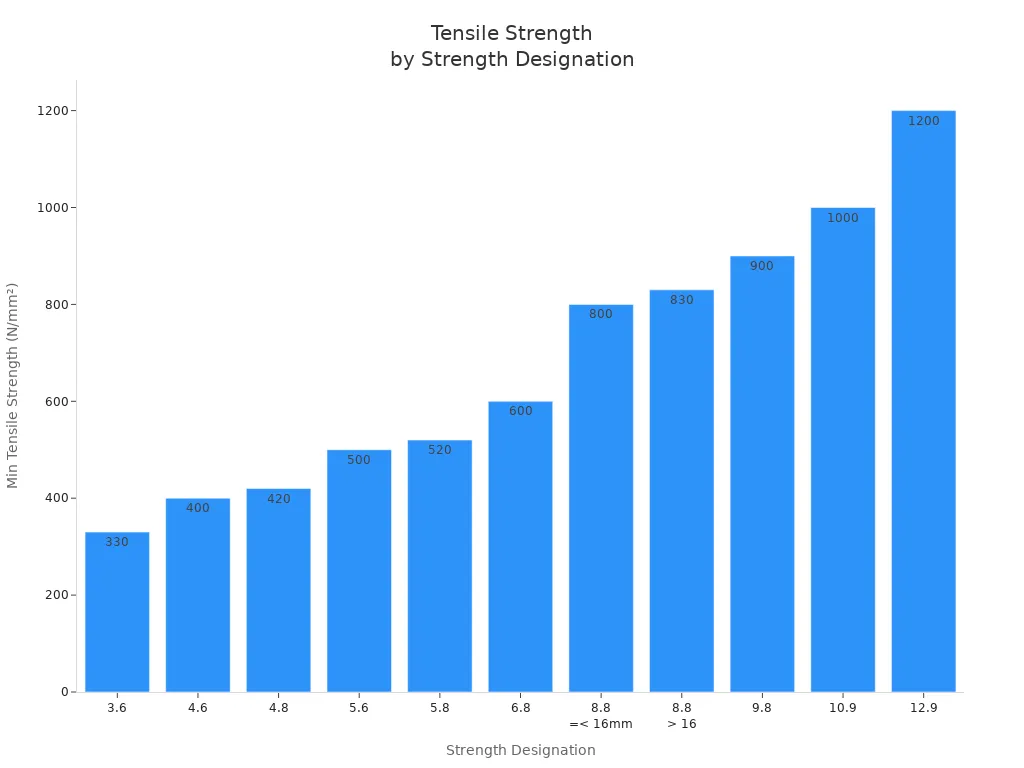

Here is a table that shows the tensile strength of different screw grades:

| Strength Designation | Min Tensile Strength (N/mm²) |

|---|---|

| 3.6 | 330 |

| 4.6 | 400 |

| 4.8 | 420 |

| 5.6 | 500 |

| 5.8 | 520 |

| 6.8 | 600 |

| 8.8 =< 16mm | 800 |

| 8.8 > 16 | 830 |

| 9.8 | 900 |

| 10.9 | 1000 |

| 12.9 | 1200 |

You use screws for woodworking, light metalwork, and repairs. Flat head screws help you get a neat finish. Prince Fastener supplies screws in many styles and materials, so you can find the right one for your project.

Nuts and Pairing Functions

You use nuts to secure bolts and sometimes screws. Nuts come in shapes like hexagonal or coupling. You tighten nuts to hold parts together. You see nuts in furniture, engines, and electronic devices. Nuts let you take things apart when needed.

Here is a table that shows common nut types and their uses:

| Type of Fastener | الخصائص | التطبيقات |

|---|---|---|

| صواميل التوصيل | Strong, hexagonal shape for easy tightening | Used in demanding assemblies like airframe structures, structural applications |

| صواميل سداسية الشكل | Commonly used, available in various sizes | Joining steel beams, securing engine components, fastening electronic elements, assembling furniture |

You pick the nut based on the material, load, and environment. For high-vibration areas, you use lock nuts or thread-locking adhesives. Nylon insert lock nuts stay tight because the nylon creates friction. All-metal lock nuts work in extreme temperatures. You use nuts when you need to disassemble or adjust parts.

Tip: Always match the nut to the bolt or screw for the best fit and strength. Prince Fastener helps you choose the right nut for your assembly.

You see that flat fasteners like bolts, screws, and nuts each have special strengths. You use bolts for heavy loads, screws for easy assembly, and nuts for secure connections. By understanding the types of fasteners, you make your projects safer and stronger.

Washers and Specialty Flat Fasteners

Flat Washers and Repair Washers

Washers help protect surfaces when you tighten bolts or screws. Flat washers go between the fastener and the material. They stop damage, especially with soft materials. Repair washers are bigger and give more support. You use them to cover a larger area.

Here is a table that shows how flat washers and flat round washers spread force:

| Washer Type | Load Distribution Properties |

|---|---|

| غسالات مسطحة | Spread force evenly, protect soft materials, lower stress, and help assemblies last longer. |

| Flat Round Washers | Give even force, stop bending when tightening, and work best for careful jobs. |

SAE and USS washers are common. SAE washers fit tighter and are thinner. USS washers are thicker and have a bigger outer edge. You pick the type based on size and strength needed.

| Washer Type | Outer Diameter | Thickness | Inside Diameter |

|---|---|---|---|

| USS | 1.38 inches | 0.109 inches | Larger, close fit |

| SAE | 1.06 inches | 0.093 inches | Tight fit |

Prince Fastener sells both SAE and USS washers. You can choose the right washer for your project to make it last longer.

Tip: Flat washers help stop stress and keep your project safe.

Rivets, Clips, and Retainers

Specialty flat fasteners are used in electronics and machines. These fasteners help you make strong connections. Rivets are for joints you do not want to take apart. Clips and retainers hold things together without tools.

Here are some specialty flat fasteners and what they do:

- Heat resistant snap rivets handle high heat and are easy to install.

- Cap nuts cover bolts or screws to keep them safe.

- Flat washers keep out water and electricity, fight rust, and cushion surfaces.

- Barbed rivets let you put things together fast and fit many holes.

- Machine screws with cheese heads hide the head for a smooth look.

- Captive fasteners hold parts together for good and protect from force.

You pick the specialty fastener that fits your project. Prince Fastener has many flat fasteners for electronics, furniture, and machines. You get better results when you use the right fastener for the job.

Materials and Finishes

Material Options for Flat Fasteners

You must pick the best material for your flat fasteners. The material changes how strong and tough the fastener is. It also affects how well it fights rust. Some jobs need fasteners that work in rough places. You might use stainless steel, brass, or aluminum. Each one has special good points.

| المواد | Tensile Strength (PSI) |

|---|---|

| الفولاذ المقاوم للصدأ | 80,000 – 250,000 |

| النحاس | 55,000 – 65,000 |

| الألومنيوم | 37,000 – 75,000 |

Stainless steel is very strong and does not rust easily. Brass is strong and looks shiny. Aluminum is light and simple to use. If you need fasteners for tough or rusty places, try special alloys. Monel®, Hastelloy®, and titanium are very tough and last long.

| المواد | Composition | Key Properties |

|---|---|---|

| Monel® | Copper and Nickel | Harder than most steels, very tough, great at fighting rust. |

| Hastelloy® | Nickel, Molybdenum, Chromium | Fights rust very well, strong, good for hard jobs. |

| التيتانيوم | Titanium Alloys | Very strong for its weight, does not rust, lasts a long time. |

Prince Fastener has flat fasteners made from all these materials. You can pick the one that fits your job best. Choose what you need, like strength, light weight, or rust protection.

الطلاءات ومقاومة التآكل

You want your fasteners to last a long time. Coatings help keep them safe from rust and damage. Zinc plating gives simple protection and works inside buildings. Galvanized coatings are thicker and protect fasteners outside. Zinc flake coatings give even better protection and stop hydrogen embrittlement.

| نوع الطلاء | Characteristics and Benefits |

|---|---|

| Zinc Plating | Fights rust well, costs less, can be put on in different ways. |

| Hot Dipped Galvanized (HDG) | Covers steel, fights rust very well, helps fasteners last longer. |

| Zinc Flake Coating | Best at stopping rust, protects from hydrogen embrittlement, works in many ways. |

| الفولاذ المقاوم للصدأ | Fights rust, stains, and oxidation, easy to care for, good for tough places, costs more. |

- Zinc-plated fasteners have a thin layer (5-25 μm). They are best for indoor use.

- Galvanized fasteners have a thick layer (43-86 μm). They last longer outside and do not rust easily.

- The thick layer on galvanized fasteners helps them stay strong in hard places.

Tip: Pick the right coating for where you use your fastener. Prince Fastener has many finishes to help your project last a long time.

Head and Drive Styles

Flat Head, Pan Head, and Other Profiles

There are many head styles for flat fasteners. Each style changes how the fastener looks and fits. Flat head screws sit even with the surface. This makes the surface smooth with no bumps. You use flat heads in furniture and electronics when looks matter. Pan head screws have a rounded top. They stick out above the surface and give more grip. Use pan heads when you want a strong hold but do not need a flat finish. Other styles are oval, truss, and cheese heads. Oval heads look nice and add decoration. Truss heads spread force over a bigger area. Cheese heads have straight sides and a flat top. They work well in machines.

نصيحة: Choose the head style that fits your project. Prince Fastener has many profiles for the look and strength you need.

Drive Types (Slotted, Phillips, Torx)

Drive type tells you how to put in or take out fasteners. Slotted drives use flat-head screwdrivers. They are simple and easy to find. Phillips drives have a cross shape. They work well with power tools and help stop slipping. Torx drives have a star shape. They give better grip and higher turning force.

Here is a table that compares the main drive types:

| نوع محرك الأقراص | Strengths & Benefits | Negatives | الاستخدامات الشائعة |

|---|---|---|---|

| مشقوق | Simple design; easy to find; cheap to make | Slips easily; can scratch surfaces | Light woodworking, furniture, electrical |

| فيليبس | Less slipping; good with power tools | Can slip if turned too hard | Construction, woodworking, automotive |

| توركس | Great grip; lasts longer | Needs special Torx bits; costs more | Automotive, aerospace, electronics |

You want to stop cam-out, which is when the tool slips out. Torx screws have six points for better grip and less slipping. Phillips screws help stop over-tightening but can still slip if you use too much force. Slotted screws slip the most, especially with high force.

- Torx and Robertson drives grip better and slip less.

- Star drives almost never slip, so they are good for hard jobs.

- Slotted drives slip more, so use them for easy jobs.

Prince Fastener has all these drive types. You can pick the best one for your project and avoid problems when installing.

Choosing the Right Flat Fastener

Assessing Project Requirements

Look at your project before picking a flat fastener. Every project needs something different. Think about the materials, how much weight it will hold, and where it will be used. For DIY jobs, use screws or bolts that do not cost much. Construction jobs need bolts, lag screws, or strong fasteners for heavy work. Cars need stainless steel or strong alloy fasteners. These last longer and handle shaking. Sheet metal jobs use self-tapping or self-drilling screws. These are easy to put in. Rivets make strong, permanent joints. Woodworking needs wood screws with big threads for a tight hold. Boats and docks need bronze fasteners that do not rust. Outdoor projects need stainless steel or galvanized lag bolts. These stand up to rain and sun. Fasteners for hot places must stay strong when it gets hot. Heavy jobs need rivets or bolts for strong holds.

Tip: Always pick a fastener that fits your project and where you use it. Prince Fastener can help you choose the best fastener for every job.

Matching Fastener to Application

Match the fastener to the job you are doing. Think about where you will use it. Fasteners for outside must be tough. Saltwater jobs need fasteners that do not rust. Water, heat, and chemicals can make fasteners wear out faster. Wet places need stainless steel or coated fasteners. Hot places need fasteners that stay strong when hot. For outside jobs, use stainless steel or galvanized fasteners. For hot jobs, use fasteners that do not get weak in heat. If you use the wrong fastener for heavy loads, the joint can break or fail. This can cost a lot to fix or replace.

Note: Prince Fastener has many flat fasteners for every job, so you can always find the right one.

Common Selection Mistakes

You can stop problems by picking the right fastener for your job. A big mistake is using fasteners that do not fit together. Fasteners should screw in by hand. If they do not, you might have the wrong match and this can cause trouble.

Here is a table of common mistakes and what happens:

| Mistake Type | الوصف |

|---|---|

| Wrong fastener type | Fastener does not work well and can break. |

| Improper tools | Fasteners get damaged or the job is not finished. |

| Over-tightening or under-tightening | Joints get weak or fasteners break, which can make things fail. |

| Ignoring environmental factors | Fasteners wear out too soon in tough places. |

| Mixing different fastener types | Fasteners do not sit right and the job has problems. |

Do not forget about water, heat, or chemicals. These can make fasteners break early. Tightening too much or too little makes joints weak. Using the wrong tools can break fasteners and leave the job unfinished.

Callout: For every job, trust Prince Fastener for good flat fasteners and smart advice.

Bolts are best for strong, heavy jobs. Screws are good for lighter work. Nuts go with bolts to hold things tight. Washers keep surfaces safe from damage. Specialty fasteners help with special problems. Use this checklist to pick a flat fastener:

- Make sure the materials work well together

- Think about how strong the fastener needs to be

- Look at where you will use it and if it might rust

| السحابة | Best Use | Needs Nut? |

|---|---|---|

| بولت | Heavy-duty | نعم |

| برغي | Light-duty | Sometimes |

| Washer | Load spread | لا يوجد |

Prince Fastener says to follow rules for your job. Ask experts for help on important safety projects.

الأسئلة الشائعة

What is the main difference between a bolt and a screw?

A bolt needs a nut to hold things together. A screw can hold materials by itself. You use bolts for heavy jobs and screws for lighter work.

When should I use a flat washer?

Use a flat washer when you want to protect surfaces or spread the load from a bolt or screw. Flat washers help prevent damage and make your project last longer.

How do I choose the right material for my fastener?

| المواد | الأفضل لـ |

|---|---|

| الفولاذ المقاوم للصدأ | Wet or outdoor places |

| النحاس | Looks and light jobs |

| الألومنيوم | Light weight projects |

Pick the material that matches your job and environment.

Can I mix different types of fasteners in one project?

You should not mix fastener types. Mixing can cause weak joints or damage. Always use fasteners that fit together for the best results.

Where can I find help choosing the right fastener?

You can contact Prince Fastener for expert advice. Their team helps you pick the best flat fastener for any project.