Image Source: pexels

Here are the 10 main ways solid rivets are used in 2025: aerospace, automotive, electronics, construction, appliance assembly, heavy machinery, shipbuilding, railcar manufacturing, bridge construction, and aviation maintenance.

The world market for solid rivets is growing quickly. The aerospace field uses almost 28% of all rivets in 2024.

You can find solid rivets almost everywhere. They make joints that are strong, last a long time, and work in many places. Look at the table below to see how different jobs use them:

الصناعة | وصف التطبيق |

|---|---|

Automotive | Used in body panels, chassis, and exhaust systems for strong and lasting connections. |

البناء | Used in frames, roofs, and sides for great strength and weather protection. |

Aerospace and Defense | Needed for building aircraft parts and satellites because they are strong but light. |

إلكترونيات | Makes safe links between circuit boards and parts, helping electricity flow. |

Appliance Assembly | Used in fridges and washing machines for tough connections in doors and hinges. |

Heavy Machinery | Holds big parts like engines and transmissions, handling heavy loads and shaking. |

Shipbuilding | Used for tight connections in hulls and decks, important for building ships. |

Railcar Manufacturing | Needed for holding railcar parts, giving good strength and lasting power. |

Bridge Construction | Helps bridges and other structures stay safe and last long with strong connections. |

Aviation Maintenance | Used to fix aircraft parts, making sure repairs are safe and strong. |

النقاط الرئيسية

Solid rivets are very important in many industries. They are used in aerospace, automotive, and construction. Solid rivets make strong and lasting connections.

In aerospace, solid rivets help keep things safe. They make permanent bonds that can handle heavy loads. These bonds also stand up to tough conditions.

Car makers use solid rivets for durability. Rivets help cars deal with stress and shaking over time.

Electronics use solid rivets to hold parts tightly. This helps devices work well even with daily use.

Solid rivets do not cost much and are fast to put in. This makes them a good choice for many uses, like home appliances and big machines.

Aerospace Applications

Industry Overview

The aerospace industry is changing quickly in 2025. Planes, rockets, and satellites need parts that stay together. These parts face a lot of stress and move very fast. Strong connections are needed to keep everyone safe in the air. Right now, the aerospace rivets market is worth almost $294 million. By 2030, it could be worth over $529 million. That is a big increase. The market grows about 10% every year. This shows that solid rivets are more important than ever.

The aerospace industry uses solid rivets for strong, permanent bonds.

Rivets help planes handle heavy loads and tough weather.

Solid rivets are used in almost every big aerospace project.

Solid Rivets in Aircraft

If you look at an airplane, you will see many solid rivets. These small fasteners hold wings, bodies, and tails together. They are made from aluminum, titanium, or stainless steel. Each metal is good for a different job. Countersunk rivets make surfaces smooth. Round head rivets give extra strength. Solid rivets help planes stay strong and safe in the air. You find them in both passenger and military planes. Their simple shape means fewer weak spots and better safety.

Solid rivets connect important parts and make planes stronger.

Different head shapes fit different jobs and help with airflow.

The aerospace industry trusts solid rivets for safe planes.

Benefits for Safety

Safety is the most important thing in aerospace. Every flight needs to be safe. Solid rivets make a bond that cannot be easily changed. They hold heavy loads and keep parts from moving during flight. Studies show that riveted joints can get tired over time, so checks are needed. The 1988 Aloha Airlines accident showed why good design and checks are important. The aerospace industry uses solid rivets to help stop accidents and keep people safe.

Solid rivets give long-lasting strength and safety.

The industry checks design and rivets to stop damage from happening.

Solid rivets help protect people and equipment.

Automotive Manufacturing

Industry Overview

Cars are everywhere. Have you thought about how they stay together? The automotive industry needs strong connections. Solid rivets help keep vehicles safe and working well. You find these fasteners in cars, trucks, and buses. They help vehicles last for many years. New designs and materials are used more now. Car makers want parts that can handle bumps and heat. They also want parts that can handle shaking. Solid rivets make this possible.

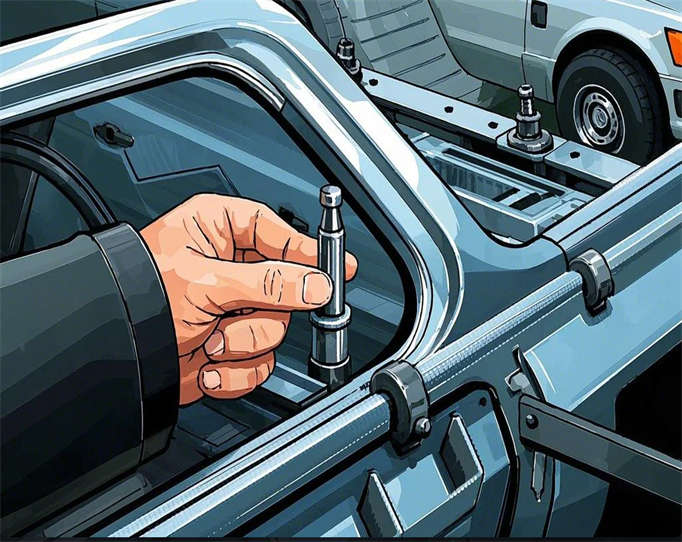

Rivets in Vehicle Assembly

A car looks smooth and shiny on the outside. Underneath, solid rivets hold the parts together. You find them in body panels and frames. They are also in exhaust systems. Rivets join metal sheets and other materials. This keeps parts from coming loose. Rivets make strong, permanent bonds. Screws can shake loose, but rivets do not. Welds can crack, but rivets stay strong. Robots use rivets on assembly lines. This helps car makers build cars fast and safely.

Tip: If you visit a car factory, watch the robots. They install solid rivets quickly and carefully. This helps cars stay strong for a long time.

Durability and Performance

You want your car to last many years. Solid rivets help make cars strong. Studies show riveted joints handle stress and shaking. They also handle changes in temperature. Look at this table to see what researchers found:

Study Description | Key Findings |

|---|---|

Service behavior of rivets in high-speed trains | Stress and the environment affect how long riveted joints last. |

Mechanical behavior of riveted joints under loading | Rivets can come loose from heat, shaking, and wetness. |

Numerical analysis of interference fit rivets | Interference fit makes rivets stronger under tough conditions. |

Modeling of thermally driven riveted joints | More rivet preload makes joints stronger and changes how they react. |

Solid rivets make vehicles safer and stronger. Automotive makers use these fasteners to keep cars working well. Rivets help cars stay together on rough roads. They also help in bad weather. You get better performance and longer life from your car.

Electronics Manufacturing

Industry Overview

You use electronics all the time. Phones and laptops are everywhere. Smart home devices are common too. These gadgets keep getting smaller and smarter. Inside, there are many tiny parts. These parts must stay connected. Sometimes you drop your phone or move your laptop. The parts still need to hold together. Electronics makers want fasteners that are small and strong. They do not want fasteners that are heavy or big. Solid rivets help with this problem. They keep parts together without adding much weight.

Solid Rivets for Circuit Boards

Solid rivets are important in electronics today. They join circuit boards to heat sinks. This helps the boards stay cool and work well. If you open a computer or game console, you may see these metal fasteners. They keep the boards in place. Even if the device shakes or gets hot, the boards stay put. Solid rivets also connect screens and battery holders. These fasteners are strong and easy to use. That is why they work in many devices.

Tip: If you open an old radio or a tablet, look for tiny metal dots on the green boards. Those are usually solid rivets!

Secure Connections

You want your electronics to last a long time. Solid rivets help keep the inside connections tight. Screws can get loose, but rivets do not. This means your phone or tablet keeps working for years. Solid rivets also help make devices smaller. Engineers can fit more parts in less space. Look at this table to see why solid rivets are important in electronics:

ميزة | What It Means for Electronics |

|---|---|

Reliability | Devices work longer without breaking |

Miniaturization | Smaller, lighter gadgets for you to carry |

المتانة | Parts stay together, even with daily bumps |

Solid rivets give strong, lasting connections. That is why electronics companies use them in your favorite devices.

Bridge Construction

Industry Overview

Bridges are everywhere. They cross rivers, highways, and railroads. Bridges carry heavy things every day. They face wind, rain, and earthquakes. Builders use strong materials and smart plans. People want bridges to last a long time. Safety is very important. Engineers use solid rivets in many bridge projects. These fasteners make joints that do not break easily. When you cross a bridge, solid rivets help hold it together.

Applications of Solid Rivets

Solid rivets are important in building bridges. You see them in many parts of a bridge. Here are some ways they are used:

They connect steel beams and girders for the main frame.

They hold plates and trusses for more support.

They join expansion joints so the bridge can move safely.

They fasten railings and walkways to keep people safe.

You need to reach both sides to put in these rivets. This makes the connection even stronger. Solid rivets are best for big, heavy jobs. That is why they are good for bridges and large buildings.

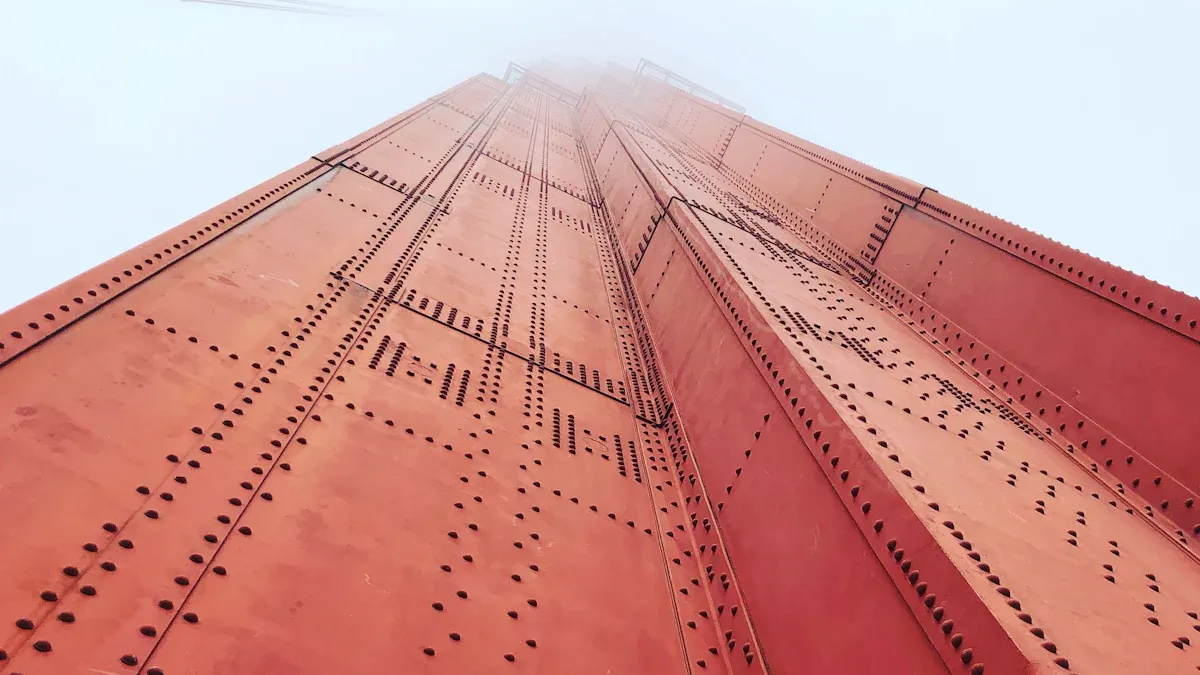

Note: Famous bridges like the Golden Gate Bridge use many solid rivets. These rivets help the bridge stay strong for many years.

السلامة الهيكلية

Bridges need to last a long time. Solid rivets help make this happen. They hold steel parts together tightly. This lets bridges handle lots of cars and bad weather. Look at this table to see how rivets help different structures:

مجال التطبيق | الوصف |

|---|---|

Bridges | Used to connect steel beams and girders. This makes strong joints. |

Buildings | Needed for parts that hold weight. This helps keep buildings stable. |

Railway | Used in railway bridges. This makes them strong for heavy loads. |

Riveted joints get a lot of stress from cars and trains. Heavy traffic or mistakes during building can cause problems. Truss bridges need solid rivets because they have less backup if something fails. That is why checks and good work are important. Using solid rivets helps bridges stay safe and last longer.

Shipbuilding

Industry Overview

Ships have used solid rivets for a very long time. Riveting started in the Bronze Age. Iron ships in the 1800s used rivets to join metal plates. From 1830 to 1940, more ships sailed across oceans. Strong connections became more important. Welding got popular, but shipyards still used rivets. Rivets worked well and saved money. Today, shipbuilders use riveting because it is quick and cheap. Riveting works with many kinds of materials.

Shipbuilders have used riveting for many years.

Liberty ships used rivets and were very strong.

Rivets in Marine Structures

Ships are big and must survive rough seas. Solid rivets help hold ships together. You find them in hulls, decks, and frames. Aluminum rivets join hull panels and decks. They keep ships strong during storms. These connections are not just for looks. They help keep ships safe and reliable. Shipbuilders use rivets where safety matters most. Rivets hold the main frame together.

Did you know? Rivets help ships last longer. They keep parts tight even after many years.

Corrosion Resistance

Saltwater can hurt metal fasteners. Solid rivets do not get damaged easily. They resist corrosion, which is important for ships at sea. Aluminum rivets do not rust much. This means hulls and decks stay strong. You do not need to worry about weak spots. Solid rivets help ships stay safe trip after trip.

ميزة | Benefit for Ships |

|---|---|

Corrosion resistance | Hulls last longer |

Strong connections | Marine structures are safer |

Fast installation | Building costs are lower |

Heavy Machinery

Industry Overview

You see heavy machinery everywhere—on farms, in factories, and at construction sites. These machines lift, dig, crush, and move huge loads every day. You need them to work safely and last for years. That’s why builders use the strongest fasteners they can find. Solid rivets play a big role in these machines. They help hold together the frames, arms, and buckets that face tough jobs and heavy stress.

Solid Rivets in Equipment

When you look at a bulldozer or a crane, you might not notice the small metal pins holding it together. These are rivets, and they do a lot of hard work. Here’s how they get used in heavy equipment:

Impact or press clinching expands the rivet shank to fill the hole, making a super strong joint.

Spun, orbital, or radial clinching uses less force and keeps the rivet from swelling too much.

Most machines need pre-punched or drilled holes before you add the rivets.

Automated rivet machines can put in a rivet in just 0.3 seconds, so assembly goes fast.

Once you set a solid rivet, it stays put. You can’t remove it without breaking one end.

You get the highest shear strength from these fasteners. The way the metal flows and swells inside the hole makes the joint even stronger than most bolts or screws.

Load-Bearing Strength

Heavy machinery needs to handle huge forces. Solid rivets give you the load-bearing power you need. They keep parts from slipping or breaking, even when the machine lifts or pushes tons of weight. Take a look at this table to see what makes these rivets so strong:

Aspect | التفاصيل |

|---|---|

Rivet Materials | Usually made from ductile steel or wrought iron, but sometimes copper or aluminum |

Design Stresses | Tensile (40% yield), shear (36.6% yield), bearing (80% yield) for hand-driven rivets |

Load-Bearing Capacity | Known for outstanding strength, which keeps your machines safe and reliable |

You might wonder what can go wrong. Here are some ways riveted joints can fail:

Shearing through one or two sections of the rivet

Compressive bearing failure of the rivet

Shearing or tearing of the plates being joined

But with the right design, these problems rarely happen. That’s why you see solid rivets in so many heavy machinery applications—they keep your equipment working hard, day after day.

Railway Industry

Industry Overview

You see trains moving people and goods every day. The railway industry depends on strong connections to keep everything running safely. Tracks, bridges, and railcars all face heavy loads and constant vibration. When you ride a train, you trust that every part will hold together, even after years of use. That’s why the industry looks for fasteners that can handle tough jobs and last a long time.

Rivets in Railcars and Tracks

You might not notice them, but rivets play a big role in railways. They help put together railcars and keep tracks in place. Here’s how they get used:

Rivets and other fasteners hold railcar frames and panels together, making sure nothing comes loose during travel.

You find them in the assembly and maintenance of railway tracks, where vibration resistance is key.

These fasteners must handle intense pressure and heavy loads every day.

Heavy-duty types, like HuckBolts, add extra clamp force and fight off rust, which helps trains stay safe and last longer.

Tip: Next time you see a train up close, look for the small metal heads along the car’s seams. Those are rivets doing their job!

Reliability

You want trains to be safe and reliable. Solid rivets are the most common type because they are simple and dependable. They work well in places where safety matters most, like the main parts of railcars and tracks. Many old steel bridges and rail structures still use these connections. Even today, workers use solid rivets to repair damaged joints in older railway constructions.

Some studies show that riveted joints can be the weakest spots in old structures, especially as materials age. Still, many of these structures keep working after decades of service. That shows how much trust the industry puts in these fasteners. When you see a train rolling by, you can thank solid rivets for helping keep it all together.

Towers and Steel Structures

Industry Overview

You see towers and steel structures almost everywhere. Think about radio towers, skyscrapers, and even big stadiums. These structures reach high into the sky and face strong winds, heavy rain, and sometimes even earthquakes. Engineers want these buildings to stay safe and last for many years. They choose strong materials and smart designs. You need fasteners that can handle big loads and never come loose. That’s where solid rivets come in.

Applications of Rivets

You might wonder how builders put together such huge steel frameworks. They use rivets for many important jobs. Here’s how the process usually works:

They push the hot rivet through holes that line up in the steel sheets.

One end of the rivet already has a dome shape. Workers hammer the other end until it looks like a mushroom.

As the rivet cools, it shrinks and pulls the steel sheets together. This makes a tight, strong joint.

You find these connections in radio towers, bridges, and tall buildings. Solid rivets help keep these structures standing tall, even in tough weather.

Permanent Fastening

You want towers and steel structures to stay safe for a long time. Solid rivets create a permanent bond that does not loosen over time. When you use this method, you get a joint that resists shaking, pulling, and bending. That’s why so many famous towers and bridges still use riveted connections today. You can trust these fasteners to hold up heavy loads and keep people safe. If you ever visit a tall steel tower, remember that solid rivets are working hard behind the scenes.

Tip: Next time you see a steel bridge or tower, look for the round heads along the beams. Those are rivets doing their job!

Home Appliances

Industry Overview

You use home appliances every day. Think about your fridge or microwave. These machines help you do chores faster. They make life easier for everyone. Companies want these products to last a long time. They look for ways to build strong appliances that do not cost too much. Solid rivets are important in making these machines. You find them inside doors, hinges, and handles. Rivets help keep everything together. They work even when you open and close things many times.

Solid Rivets in Consumer Goods

You might not see the small metal fasteners inside your appliances. But they do a lot of work. Solid rivets hold moving parts like doors and lids. They also join panels and frames. Rivets make a strong connection that does not get loose. They work well for joints that do not carry heavy loads. That is why you see them in many places. The way they are put in is safe and does not use high heat. This keeps the materials strong. You can trust your appliances to work well because of these fasteners.

Tip: Next time you open your fridge or washing machine, look for small round metal heads near the hinges. Those are rivets keeping things safe!

Cost-Effectiveness

Companies want to save money and make good products. Solid rivets help them do both things. Rivets are quick to install, so factories build more appliances faster. Small rivets can cost as little as $0.002 each. This helps companies save money on every appliance. Rivets are strong and resist rust and water. You do not have to worry about leaks or rust. The process does not use heat, so parts stay in good shape.

Here’s a quick look at the benefits:

الفائدة | What It Means for You |

|---|---|

Low cost | Cheaper appliances |

Quick installation | Faster production |

High durability | Products last longer |

Corrosion resistance | No rust or damage |

Safe process | Strong parts, no heat damage |

You get good appliances for a fair price because of solid rivets.

Versatile Material Joining

Industry Overview

Every year, more products use different materials together. Car makers mix metal, plastic, and composites in one car. Electronics can have wood, metal, and polymers in one device. This trend is growing in 2025. You need fasteners that work with all these materials. Solid rivets are good for joining many types. They help connect metal to plastic, wood to metal, or composites to steel. This makes them popular in many industries.

Note: Factories want products that are lighter and stronger. They need ways to join all kinds of materials.

Rivets for Mixed Materials

You might ask how rivets hold different materials together. Researchers tested many combinations. Look at this table to see what they learned:

Study | Materials Joined | Findings |

|---|---|---|

Ma et al. | Aluminum alloy and mild steel | Rivet and die design affect joint quality |

Abe et al. | Aluminum alloy and mild steel | Panel setup changes joint strength |

Wang et al. | Carbon-reinforced plastic and aluminum alloy | Post-curing methods improve joint quality |

Wood et al. | Aluminum sheets | Interlock failure affects shear performance |

Han et al. | Multi-layered aluminum and steel alloy | Panel order changes joint characteristics |

Huang et al. | Various materials | Shot peening increases joint strength |

You can use friction rivet joining for wood-metal mixes. This method makes strong mechanical and chemical bonds. Polymer rivets are good for joining wood, metal, and plastic. These joints have high pull-out and shear strength. Your products stay together even when stressed.

القدرة على التكيف

Versatility is very important in manufacturing today. Mixing materials brings new challenges. Here’s why adaptable joining methods like solid rivets matter:

Multi-material designs can cause compatibility problems.

Mechanical joining gives you choices and strong joints.

Old tools do not work well with new materials.

You want your products to last and work well. Solid rivets give you the flexibility you need for modern jobs. They help you build safer and better products, no matter what materials you use.

You can find solid rivets in many places, like cars and bridges. They help make things strong and keep parts together for a long time. Solid rivets work for lots of different jobs. Industries are always changing and trying new ideas. Companies want to use lighter materials that are better for the planet. Machines now put in rivets faster and more easily. Solid rivets still work well with these new changes. You can count on them to be useful in the future.

الأسئلة الشائعة

What makes solid rivets different from other fasteners?

Solid rivets create a permanent bond. You can’t remove them without breaking the joint. They work best when you need strength and reliability in your project.

Can you install solid rivets at home?

You can install small solid rivets with a hammer and anvil. For bigger jobs, you need special tools. Always wear safety glasses when you work with rivets.

Which materials can you join with solid rivets?

You can use solid rivets to join metal, wood, plastic, and composites. This makes them perfect for mixed-material projects in many industries.

Are solid rivets safe for high-stress applications?

Yes! Solid rivets handle heavy loads and vibration. You see them in airplanes, bridges, and trains because they keep parts secure under stress.

How much do solid rivets cost?

Solid rivets are budget-friendly. Small rivets can cost less than a penny each. You save money on big projects and still get strong, lasting connections.