Image Source: pexels

Imagine a technician picking an elevator bolt at a busy work site. Grade 2, Grade 5, and Grade 8 have different strengths. Picking the right grade and material keeps machines safe. It also makes them work well. The best choice makes bolts last longer. It helps stop rust and saves money. Every part is important for strong, long-lasting connections.

النقاط الرئيسية

There are three main grades of elevator bolts. Grade 2 is for light jobs. Grade 5 works for medium loads. Grade 8 is for heavy stress. Picking the right grade keeps things safe and working well.

Bolt grades show how strong and good bolts are. Higher grades, like Grade 8, can take more force before breaking. These are best for tough jobs.

The material of the bolt is important. Carbon steel costs less but can rust. Zinc-plated steel helps stop rust a little. Stainless steel is best for wet or rough places.

Always pick the right grade and material for the job. This stops problems and saves money over time.

Do not make mistakes when picking bolts. Do not forget about the environment. Always check what the bolt can do. Picking and putting in bolts the right way keeps machines safe.

Elevator Bolt Grades

What Are Bolt Grades

Bolt grades show the strength and quality of a bolt. Each grade follows strict standards set by groups like ASTM and ISO. These standards help workers pick the right bolt for each job. The grade tells how much force a bolt can handle before it breaks. Different types of bolts have different grades. For elevator bolts, the most common grades are Grade 2, Grade 5, and Grade 8.

ملاحظة: The grade of a bolt depends on several factors:

The materials used in the construction of the bolt

The material properties of the bolt

The maximum amount of stress that the bolt can handle

The tools suitable for tightening the bolts

The method used for tightening the bolt

Here is a table showing some official standards for bolt grades:

قياسي | Grade/Type |

|---|---|

ASME B18.2.1 | 3/8 inch to 3 inch |

BS 1769 | ½ inch to 2 inch |

ASME B18.2.3.6M | M12 to M36 |

ASTM A193 | Grade B5, B6, B7, B7M, B16, B8, B8 class 1, B8 class 2, B8 class 2B, B8A, B8C, … |

ASTM A307 | Grade A, Grade B |

ASTM A325 | Type 1, Type 2, Type 3 |

ASTM F1554 | Grade 36, Grade 55, Grade 105 |

ISO 7412 | M12 to M36 |

DIN 6914 | M12 to M36 |

Why Grades Matter

Choosing the right grade keeps machines safe and working well. Higher grades mean stronger bolts. For example, Grade 8 bolts have more tensile strength than Grade 2 or Grade 5. This means they can handle more force before breaking. The table below shows the difference in strength:

Grade | Tensile Strength (psi) |

|---|---|

Grade 2 | 60,000 – 74,000 |

Grade 5 | 105,000 – 120,000 |

Grade 8 | 150,000 |

Many types of bolts are used in machines. Each type has a job. Some hold light loads. Others must handle heavy stress. Bolt grades help workers match the right bolt to the right job. In industrial machinery, bolts must not bend or break under load. Fatigue strength is also important. It shows how well a bolt can handle repeated stress over time. Grade 8 bolts work best for heavy loads and high stress. They keep connections strong and safe.

Elevator Bolt Materials

Plain Carbon Steel

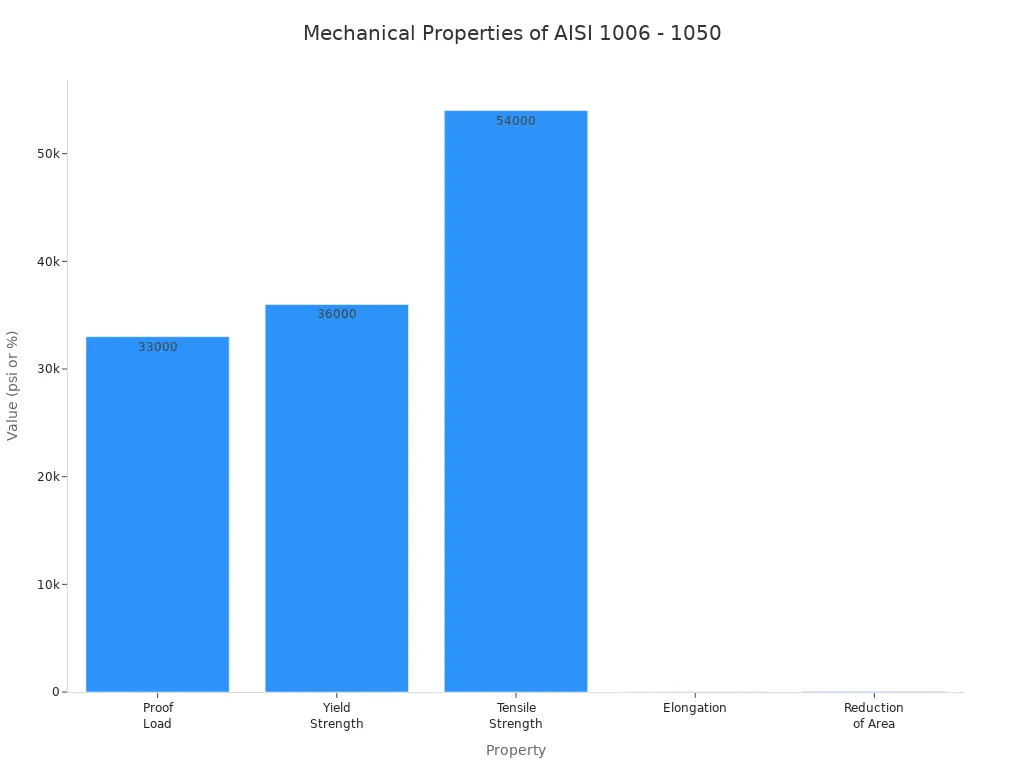

Plain carbon steel elevator bolts use a mix of iron and carbon. This material gives strong bolts at a low cost. Many builders choose carbon steel for general structures because it holds up well under stress. The table below shows some key properties:

Property | Value |

|---|---|

Rockwell B70-B100 | |

Proof Load | |

Yield Strength | 36,000 psi min |

Tensile Strength | 54,000 psi min |

Elongation | 18% min |

Reduction of Area | 35% |

نصيحة: Carbon steel bolts need a protective coating for outdoor or wet areas. Without it, they can rust quickly.

Plain carbon steel costs less than stainless steel. However, it does not resist corrosion well. Builders should avoid using plain carbon steel in marine or chemical settings unless they add extra protection.

Zinc Plated Steel

Zinc plated steel bolts start with plain carbon steel. A thin layer of zinc covers the surface. This zinc layer helps protect the bolt from rust. Zinc plated bolts work well in dry or indoor places. They cost less than stainless steel but offer only limited corrosion resistance.

Zinc plating slows down rust but does not stop it in harsh or wet environments.

These bolts suit light-duty jobs where moisture is not a big problem.

الفولاذ المقاوم للصدأ

Stainless steel elevator bolts stand out for their high corrosion resistance. Most use 18-8 stainless steel, which contains chromium and nickel. This mix keeps bolts strong and shiny, even in wet or chemical-heavy areas.

Material Type | Corrosion Resistance | Suitability for Harsh Environments |

|---|---|---|

Superior | Highly suitable | |

Black Steel | معتدل | Less suitable |

Zinc-Plated Options | Limited | Not suitable |

304 stainless steel bolts fit most general uses. For marine or chemical plants, 316 stainless steel works best because it resists corrosion even more. Stainless steel bolts cost more, but they last longer in tough environments.

ملاحظة: Choosing the right material depends on the job site. Moisture, chemicals, and cost all play a role in making the best choice.

Grade Comparison

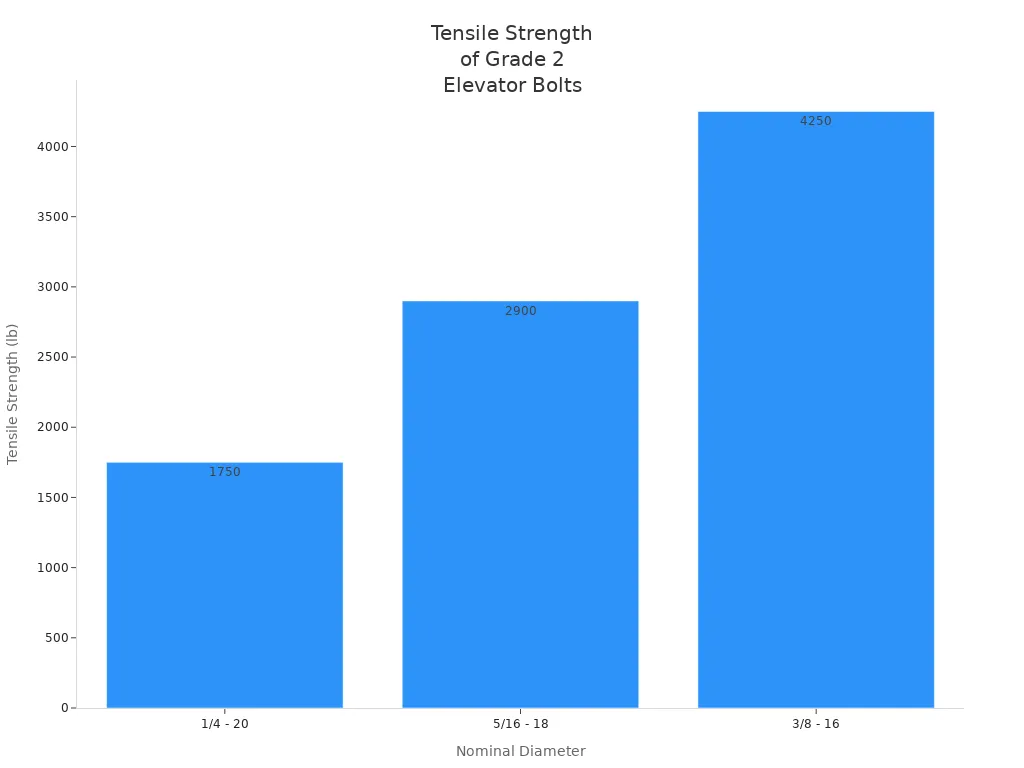

Grade 2

Grade 2 elevator bolts are the most basic kind. People use them for light jobs. These bolts are made from low carbon steel. They do not get extra heat treatment. Grade 2 bolts are not as strong as other grades.

Nominal Diameter | |

|---|---|

1/4 – 20 | 1750 |

5/16 – 18 | 2900 |

3/8 – 16 | 4250 |

Grade 2 elevator bolts work well when loads are light. They are used in conveyor systems and farm machines. Workers use them to attach buckets to conveyor belts. These bolts are also used in belting systems. Their shape stops them from turning in soft materials.

الإيجابيات:

Low price

Simple to put in

Good for soft things

السلبيات:

Not very strong

Wears out fast

Not good for heavy loads

The material you pick matters for Grade 2 bolts. Plain carbon steel is best for dry, indoor spots. Zinc plating gives some rust protection. Stainless steel keeps bolts from rusting but costs more.

Grade 5

Grade 5 elevator bolts are stronger than Grade 2. They are made from medium carbon steel and get heat treated. These bolts can handle more weight than Grade 2. Grade 5 bolts are used in many machines and vehicles.

People pick Grade 5 bolts when they need more strength but not the most. These bolts are found in farm tools, light machines, and car parts. Their strength makes them good for medium stress.

الإيجابيات:

Stronger than Grade 2

Good mix of price and strength

Works for many uses

السلبيات:

Not as strong as Grade 8

Might need coatings to stop rust

Not great for very heavy loads

You can get Grade 5 bolts in zinc-plated steel for inside use. Stainless steel is better for wet or rusty places. Grade 5 bolts work better than basic bolts but are not as strong as Grade 8.

Grade 8

Grade 8 elevator bolts are the strongest of these grades. They are made from alloy steel and get special heat treatment. These bolts are very strong and last a long time.

Specification | Definition | Amount |

|---|---|---|

Tensile strength | The maximum amount of force a fastener can withstand before fracturing | |

Proof load | The minimum amount of force that a fastener must withstand without deforming | ≥ 120,000 PSI |

Yield strength | The load carried at the point where a fastener permanently deforms | ≥ 130,000 PSI |

Grade 8 elevator bolts can hold very heavy loads. Their strength depends on their size:

1/4″ diameter: about 7,365 lbs

3/8″ diameter: about 16,500 lbs

1/2″ diameter: about 29,400 lbs

5/8″ diameter: about 46,000 lbs

3/4″ diameter: about 66,200 lbs

1″ diameter: about 117,800 lbs

Grade 8 bolts are used in elevators and conveyor systems. Their flat head and square neck fit tight spaces. These bolts can take a lot of stress and keep parts safe. They also hold soft materials in factories.

الإيجابيات:

Strongest of the common bolts

Very tough

Good for important jobs

السلبيات:

Costs more

May need special tools to put in

Too much for light jobs

The material you choose changes how the bolt works. Alloy steel gives the most strength. Zinc plating is good for dry places. Stainless steel stops rust in tough spots but costs more.

Tip: Always pick the right bolt grade and material for your job. Grade 8 elevator bolts are best for heavy work. Grade 2 and Grade 5 are better for lighter jobs.

Elevator Bolt Selection

Application Needs

Every industrial job has unique needs. Workers must look at the load, the environment, and the cost before choosing a bolt. Heavy machines need bolts that can handle high force. Wet or chemical-filled areas need bolts that resist rust. Some projects have tight budgets, so cost matters too.

The table below shows important criteria for picking the right bolt:

المعايير | الوصف |

|---|---|

Shows the maximum force a bolt can handle before breaking. This is key for heavy-duty jobs. | |

Bolt Grade Standards | Each grade follows standards that tell if a bolt fits a certain job. |

Material Composition | Strong bolts use special steel and treatments to last longer in tough tasks. |

A worker should always check these points before making a choice. Picking the wrong bolt can cause machines to fail or break.

Matching Grade and Material

Choosing the right grade and material keeps machines safe and working. Grade 2 bolts fit light jobs. Grade 5 bolts work for medium loads. Grade 8 bolts hold up under heavy stress. The material also matters. Carbon steel works for dry, indoor places. Zinc-plated bolts add some rust protection. Stainless steel bolts last longest in wet or harsh areas.

A good match between grade and material means:

The bolt will not break under load.

The bolt will not rust too soon.

The cost stays within budget.

Workers should always match the bolt’s strength to the job’s needs. They should also think about where the bolt will be used. For example, a stainless steel Grade 8 bolt costs more but lasts longer in a wet factory.

نصيحة: Always check the machine’s manual or ask an expert if unsure about which bolt to use.

Common Mistakes

Many people make mistakes when picking bolts. These errors can lead to machine failure or extra costs. Some of the most common mistakes include:

اختيار wrong grade for the job, which can cause bolts to fail early.

Ignoring the bolt’s mechanical properties, like tensile and shear strength.

Forgetting to check how the material reacts to the environment, especially in places with lots of moisture or chemicals.

Not using the right coatings for bolts in wet or harsh areas, which can lead to rust.

Overlooking the importance of alloy composition and heat treatment for bolt performance.

Failing to match the bolt’s property class to the machine’s needs.

Not tightening bolts to the correct torque, which can cause them to loosen or break.

ملاحظة: Careful selection and proper installation help prevent these problems. Workers should always follow best practices and double-check their choices.

جدول المقارنة

Key Factors

Picking the right elevator bolt means thinking about a few things. You need to look at strength, how long it lasts, if it can fight rust, the price, and what jobs it fits best. The table below shows how Grade 2, Grade 5, and Grade 8 bolts are different when made from different materials.

Grade | المواد | القوة | المتانة | Corrosion Resistance | التكلفة | Best Use |

|---|---|---|---|---|---|---|

Grade 2 | Plain Carbon | Low | Low | Poor | Lowest | Light loads, dry areas |

Grade 2 | Zinc-Plated | Low | Low | Fair | Low | Indoor, basic jobs |

Grade 2 | الفولاذ المقاوم للصدأ | Low | متوسط | Excellent | عالية | Light, wet areas |

Grade 5 | Plain Carbon | متوسط | متوسط | Poor | معتدل | Medium loads, dry areas |

Grade 5 | Zinc-Plated | متوسط | متوسط | Fair | معتدل | Indoor, moderate jobs |

Grade 5 | الفولاذ المقاوم للصدأ | متوسط | عالية | Excellent | Highest | Medium, wet areas |

Grade 8 | سبائك الصلب | عالية | عالية | Poor | عالية | Heavy loads, dry areas |

Grade 8 | Zinc-Plated | عالية | عالية | Fair | عالية | Heavy, indoor jobs |

Grade 8 | الفولاذ المقاوم للصدأ | عالية | Highest | Excellent | Highest | Heavy, wet areas |

نصيحة: Stainless steel bolts are best for stopping rust outside. They work great near the ocean or where it is very damp. Zinc-plated bolts are good for dry or inside places.

The price of elevator bolts changes with grade and material. Grade 5 bolts cost more than Grade 2 because they are stronger. Stainless steel bolts cost the most, but they last longer in tough places. Zinc-plated steel gives a good mix of price and rust protection for most inside jobs.

Grade 2 bolts are good for light jobs and save money.

Grade 5 bolts are better for medium jobs and give more strength for the price.

Grade 8 bolts are best for heavy jobs and work the hardest, but they cost the most.

When workers pick bolts, they should match the grade and material to the job. Stainless steel bolts are best near the sea because they do not rust from salt or water. Zinc-plated bolts look nice and last well inside. Hot-dip galvanized coatings help in country or dry places.

Workers should always think about where and how the bolt will be used before picking one. The right bolt keeps machines safe and saves money in the long run.

Picking the right elevator bolt means thinking about grade, material, and what the job needs. Grade 2 bolts are good for light work. Grade 8 bolts are strong and can handle heavy jobs. Stainless steel does not rust easily, but it costs more money. Workers should choose bolts that fit the place and the weight they must hold. Charts و guides help people see how strong bolts are and what jobs they fit. Checking bolts often, tightening them, and keeping them clean helps them last longer. If the job is hard, asking an expert is a smart idea.

Trusted sources show charts with grade marks, types of material, and how strong bolts are.

Guides tell about strength, how well bolts fight rust, and head shapes for different jobs.

Taking care of bolts means checking them, tightening them again after putting them in, and cleaning them so they do not rust.

الأسئلة الشائعة

What is the main difference between Grade 2, Grade 5, and Grade 8 elevator bolts?

Grade 2 bolts have low strength. Grade 5 bolts offer medium strength. Grade 8 bolts provide the highest strength. Each grade fits different load needs in machines and structures.

Can stainless steel elevator bolts rust?

Stainless steel bolts resist rust much better than carbon steel. In most wet or chemical areas, they stay strong and shiny. However, extreme conditions may still cause some corrosion over time.

How do workers know which elevator bolt grade to choose?

Workers check the load, environment, and cost. They use charts or guides to match the bolt grade and material to the job. Heavy loads need higher grades. Wet areas need rust-resistant materials.

Are zinc-plated bolts good for outdoor use?

Zinc-plated bolts slow down rust but do not stop it in harsh weather. They work best indoors or in dry places. For outdoor jobs, stainless steel or hot-dip galvanized bolts last longer.