A hex bolt has a head with six sides. It has machine threads. You can use it with a nut. You can also use it in a tapped hole. This helps join materials together. The hexagonal head is easy to grip. You can tighten it with regular tools. These bolts are strong and last a long time. They are simple to put in or take out. Many people pick hex bolts for many jobs. They work well in building things, machines, and furniture.

- Easy to use with wrenches

- Strong and reliable for heavy-duty jobs

- Available in different sizes and materials

النقاط الرئيسية

- Hex bolts have heads with six sides. This shape makes them easy to hold and turn with tools. – Pick the right type, الحجم, and material of hex bolt. This helps your project stay strong and last longer. – Use nuts and washers that fit the hex bolt. This keeps the connection safe and secure for a long time. – Get ready by measuring and drilling pilot holes. Put oil on the threads before you put in the hex bolts. – Do not make mistakes like tightening too much or using the wrong tools. Do not use parts that do not match. This keeps your project safe and strong.

Hex Bolt Basics

What Is a Hex Bolt

A hex bolt has a head with six sides. You can hold the head with a wrench or socket. The shaft has machine threads that fit nuts or tapped holes. This makes strong and safe connections. Hex bolts come in many sizes and materials like steel, stainless steel, and carbon steel. You can find them in metric or inch sizes. The wide head gives more space for tightening. This helps stop slipping.

نصيحة: Use the right size wrench so you do not damage the bolt head.

Hex Bolt Types

There are different kinds of مسامير سداسية. Each type has its own features. Here is a table to show the most common types:

| Hex Bolt Type | الميزات | الاستخدامات النموذجية |

|---|---|---|

| Standard Hex Bolts | Partly threaded, flat six-sided head | Building, machines |

| مسامير سداسية ثقيلة | Bigger, thicker head for more turning power | Steel frames, heavy machines |

| Flange Hex Bolts | Flange built-in to spread force | Cars, machines with shaking |

| Hex Tap Bolts | Shaft is fully threaded | Factory machines, building |

| Stainless Steel Hex Bolts | Does not rust, good for tough places | Boats, outside, food factories |

Some مسامير سداسية have serrated flanges for better grip. Some are called hex lag bolts and are used for wood. Each kind works best for certain jobs. Pick the one that fits your project.

الاستخدامات الشائعة

You can use a hex bolt for many things. Builders use them to join steel, wood, and concrete. Mechanics use them to put together engines and fix cars. Farmers use them for tractors and water systems. If you like DIY, you can use مسامير سداسية for furniture, decks, and fixing things at home.

- Construction: Joining steel, wood, and concrete

- Machinery: Putting together machines and lines

- Automotive: Holding engine parts and car frames

- DIY: Making furniture, decks, and repairs

Hex bolts give strong and safe fastening almost anywhere.

Choosing Hex Bolts

Materials and Grades

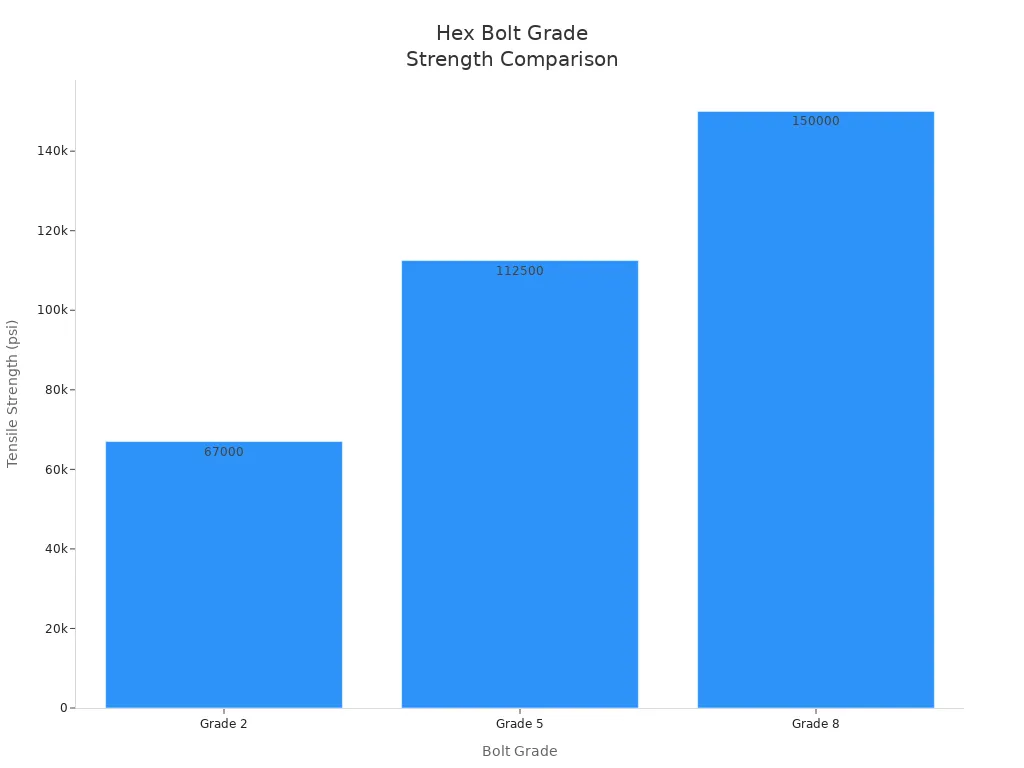

When you pick a hex bolt, you need to think about the material and grade. Most hex bolts use carbon steel, stainless steel, or alloy steel. Carbon steel bolts cost less and work well for indoor jobs. Alloy steel bolts give you extra strength for heavy-duty tasks. Stainless steel bolts resist rust, so you can use them outside or near water. Some bolts use brass or other alloys for special needs. You may also see zinc-plated or hot-dip galvanized bolts. These coatings help stop rust and wear.

Grades show how strong a bolt is. You will find Grade 2, Grade 5, and Grade 8 bolts in stores. Grade 2 bolts work for light jobs. Grade 5 bolts fit medium-strength needs, like car repairs. Grade 8 bolts handle tough jobs, such as heavy machinery. Higher grades cost more but last longer. Look at this chart to compare the strength of each grade:

ملاحظة: For outdoor projects, choose stainless steel or galvanized bolts. These last longer in wet or salty places.

Sizes and Threads

You need the right size and thread for your project. Hex bolts come in metric sizes (M3 to M60) and imperial sizes (1/4 inch to 2 inches). Threads can be coarse or fine. Coarse threads work for most jobs and are easier to start. Fine threads hold better in thin materials. Use this table to see common sizes and thread types:

| Size Type | Range | نوع الخيط | المعايير |

|---|---|---|---|

| متري | M3 – M60 | Coarse, Fine | DIN 931, DIN 933 |

| Imperial | 1/4″ – 2″ | BSW, BSF | ISO 4014, ISO 4018 |

نصيحة: Always check the bolt length and thread pitch before you buy.

Nuts and Washers

You need nuts and washers that match your bolt. Pick nuts with the same size and thread as your hex bolt. Flange nuts spread force and help keep things tight. Lock nuts stop bolts from coming loose. Washers protect surfaces and spread the load. Flat washers work for most jobs. Lock washers help in places with lots of shaking. Choose nuts and washers made from the same material as your bolt for best results.

- Match nut size and thread to your bolt

- Use flat washers for load distribution

- Use lock washers or lock nuts for vibration

Safety: Always use the right nut and washer to keep your project safe and secure.

Using Hex Bolts

Tools Needed

You need the right tools to install مسامير سداسية safely and securely. Choose tools that match the size and type of bolt you plan to use. Here are the most common tools for the job:

- Wrenches (open-end, box-end, or adjustable)

- Socket drivers and ratchets

- Power drills for making pilot holes

- Impact drivers for tough materials

- Hammers for tapping bolts into place

- Safety gear like gloves and goggles

Use a wrench or socket that fits the bolt head snugly. This helps you avoid slipping and damaging the bolt. Always wear protective equipment when working with power tools. Washers help spread the load and protect surfaces.

نصيحة: Select the correct tool for each step. This prevents over-tightening and keeps your project safe.

Preparation Steps

Good preparation makes your installation easier and safer. Follow these steps before you start:

- Measure the length, diameter, and head size of your hex bolt.

- Check the material type and thickness. Pick bolts that match your project.

- Mark the drilling points with a ruler or measuring tape.

- Secure your workpiece so it does not move.

- Choose a drill bit that matches the bolt diameter.

- Drill pilot holes with steady, light pressure.

- Clean the surfaces and remove any debris.

- Lubricate the bolt threads and contact surfaces. This helps you reach the right bolt load and reduces stress.

- Gather all tools and washers before you begin.

Hand-tighten bolts first to check alignment. Wear gloves and ear protection if you use power tools. Inspect your setup before moving to the next step.

ملاحظة: Lubrication helps you achieve consistent torque and prevents bolt failure.

Installation Guide

You can install hex bolts in wood, metal, or other materials. Follow these steps for a secure fit:

- Measure and mark the spot for the pilot hole.

- Drill the hole to the correct size. Keep the hole clean.

- Insert the bolt through the material with the head accessible.

- Place a washer under the bolt head if needed.

- Hand-tighten the nut onto the bolt until snug.

- Use a wrench or socket to tighten the bolt further.

- If you use a nut, make sure it matches the bolt size and thread.

- Check the stability of the connection. Make adjustments if needed.

For wood, you may need to use a lag bolt and drive it in with a wrench. For metal, ensure the threads match and the bolt seats firmly.

Safety: Always check your work for stability before finishing.

Tightening Tips

Proper tightening keeps your project safe and strong. Use the right torque for your bolt size and grade. Over-tightening can damage threads or break the bolt. Under-tightening can cause parts to loosen.

Here is a table with recommended torque values for common hex bolts:

| Bolt Size | Grade 5 Torque (ft-lbs) | Grade 8 Torque (ft-lbs) | Stainless Steel Torque (ft-lbs) |

|---|---|---|---|

| 1/4″-20 | 6.3 | 9 | 6 |

| 1/2″-13 | 57 | 80 | 55 |

| 1″-8 | 400 | 682 | 380 |

Lubricated bolts need less torque than dry bolts. Dry bolts may require up to 30% more torque. Always follow the manufacturer’s specifications for your project.

نصيحة: Tighten bolts in stages. Start by hand, then use a wrench. Check the torque with a gauge if possible.

Mistakes to Avoid

Mistakes can happen when you use hex bolts, but you can prevent most of them with a little know-how. Here is a quick overview of common mistakes, their causes, and how you can avoid them:

| Common Mistake | الشرح | How to Avoid | Consequences |

|---|---|---|---|

| Stripped Threads | Threads get damaged from too much force or poor tools | Use correct tools, avoid excess force, maintain bolts | Loose joints, hard removal |

| Over-Tightening | Too much torque damages threads or breaks bolts | Use torque wrenches, follow specs | Broken bolts, damaged materials |

| Mismatched Parts | Wrong size, thread, or coating causes poor fit | Match size, thread, and coating | Loose, weak, or corroded assemblies |

Stripped Threads

Stripped threads happen when you use too much force or the wrong tool. You might also see this problem if you use bolts made from soft materials or if rust builds up on the threads. When threads strip, bolts cannot hold tight, and you may struggle to remove them.

To prevent stripped threads:

- Pick high-quality bolts and tools.

- Make sure your wrench or socket fits the bolt head exactly.

- Avoid using too much force when tightening.

- Clean bolts and nuts before use. Apply anti-rust oil if needed.

- Use anti-seize compound on bolts you remove often.

نصيحة: If you notice resistance while tightening, stop and check for dirt or rust. Clean the threads before you continue.

الإفراط في التشديد

الإفراط في التشديد is a common mistake. You might think tighter is better, but too much torque can damage threads, snap bolt heads, or even harm the material you are joining. Sometimes, over-tightened bolts become impossible to remove without special tools.

You can avoid over-tightening by:

- Using a torque wrench to control the force you apply.

- Following the manufacturer’s torque specifications.

- Tightening bolts in stages, not all at once.

- Using your fingers to start bolts, then finishing with a wrench.

ملاحظة: Over-tightening does not make a joint stronger. It can actually weaken the connection and cause failure over time.

Mismatched Parts

Mismatched parts cause many problems in hex bolt assemblies. If you use a nut or washer with the wrong size, thread, or coating, the connection may not hold. Mixing metric and imperial sizes or different coatings (like zinc-plated with galvanized) can lead to poor fit, stripped threads, or even rust.

To avoid mismatched parts:

- Always check that your bolt, nut, and washer match in size, thread type, and material.

- Use the same coating for all parts in one assembly.

- Double-check thread pitch and bolt grade before you start.

Safety: Matching all parts ensures your project stays strong and safe. If you mix parts, you risk loose joints, corrosion, or even total failure.

Quick Tips

Time Savers

You can finish your hex bolt projects faster with some easy tricks. Try these ideas to save time and work less:

- Get all your tools and parts ready before you begin.

- Use a socket wrench or power driver to tighten bolts quickly.

- Sort bolts, nuts, and washers by size so you do not waste time looking for them.

- Mark where to drill with a pencil or marker to be more exact.

- Put oil on the threads before you start to make turning easier.

نصيحة: Keep a small tray or container close for bolts and nuts. This helps you keep track of small parts while you work.

السلامة

You should always think about safety when using مسامير سداسية. Follow these steps to keep yourself and your project safe:

- Wear safety glasses, gloves, and strong clothes to protect from sharp edges and flying bits.

- Pick the right tool for the job and make sure it works well.

- Turn bolts slowly and gently so you do not strip the head or break things nearby.

- Be careful with impact wrenches and follow the maker’s rules.

- Look around your work area for dangers like loose stuff or wires before you start.

Staying safe lets you finish your project without getting hurt or breaking things.

Maintenance

Taking care of your مسامير سداسية keeps them strong, especially outside or in rough places. Use these tips to help them last longer:

| ممارسة الصيانة | Description and Benefit |

|---|---|

| اختيار المواد | Pick stainless steel or weathering steel to stop rust. |

| Protective Coatings | Use hot-dip galvanizing or special paint to protect bolts for a long time. |

| Regular Inspections | Check bolts often to find rust or damage early. |

| Proper Installation | Use the right torque, washers, and oil for a tight fit. |

| Environment-Specific Care | Follow rules for care in places near the ocean or where it is very wet. |

- Check bridges or big machines every 6 months.

- Look at bolts in offices or stores at least once a year.

- For homes or safe places, check bolts every 2 years.

- Clean bolts once a year and put on new coatings every 2 or 3 years.

- Tighten bolts and check if they are straight each time you inspect or after big storms.

Checking and caring for bolts often helps you find problems early and keeps your projects safe for a long time.

You now know why a hex bolt stands out for easy projects. Its six-sided head lets you grip from many angles و apply strong torque. You can use it with wood, steel, or concrete. Hex bolts help keep your work safe and secure by spreading loads evenly. With the right tools and a little practice, you can handle any project confidently. Try these tips and see how simple building with hex bolts can be!

الأسئلة الشائعة

What size wrench should you use for hex bolts?

You should match the wrench size to the bolt head. Check the bolt packaging or measure the head with a ruler. Use a snug-fitting wrench to prevent slipping or damage.

Can you reuse hex bolts?

You can reuse hex bolts if they show no rust, wear, or stripped threads. Always inspect bolts before using them again. Replace any damaged bolts to keep your project safe.

How do you prevent hex bolts from loosening?

You can use lock washers, lock nuts, or thread-locking fluid. Tighten bolts to the recommended torque. Check bolts regularly, especially in places with vibration.

نصيحة: Use a torque wrench for best results.

Are stainless steel hex bolts better for outdoor projects?

Stainless steel hex bolts resist rust and corrosion. You should use them for outdoor projects or places with moisture. They last longer than regular steel bolts in wet conditions.