We’re diving deep into the world of fender washers—a crucial yet often overlooked component in various industries. Whether you’re a mechanic, a DIY enthusiast, or an engineer, understanding the ins and outs of fender washers can make a significant difference in your projects. From automotive applications to industrial machinery, these washers play a vital role in ensuring stability, preventing damage, and enhancing the overall performance of your equipment.

Over the years, we at Prince Fastener have encountered numerous scenarios where the right choice of fender washer has not only improved functionality but also saved time and resources. For instance, in the automotive sector, using a stainless steel fender washer can prevent corrosion and ensure that critical components like mudguards and luggage racks remain securely fastened.

In industrial settings, these washers help distribute the load over a larger area, preventing damage to delicate components. But choosing the right fender washer isn’t always straightforward. It involves understanding the material properties, dimensions, and specific requirements of your application. That’s why we’re here—to provide you with the knowledge and tools to make informed decisions.

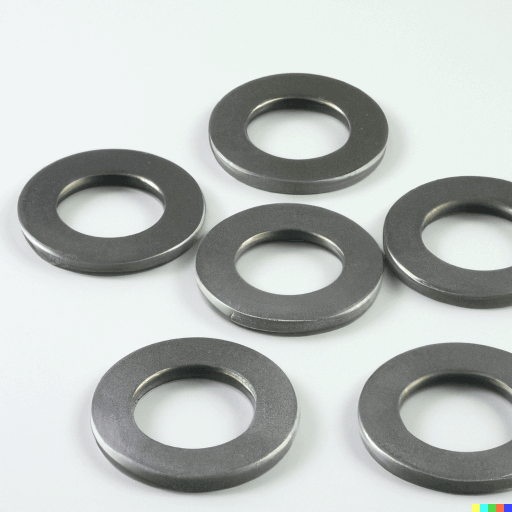

A fender washer is a specialized type of washer with a large outer diameter and a small center hole. We primarily use it to distribute pressure during tightening, preventing bolts or nuts from damaging the fastened material. Here’s what you need to know about fender washers:

Structure and Features

- Large Outer Diameter: Compared to standard flat washers, fender washers have a larger outer diameter. هذا provides a wider support surface, which helps distribute the tightening force more effectively.

- Small Inner Hole: The small center hole is suitable for bolts or screws with smaller diameters.

المواد

- Metal Materials: We commonly use stainless Steel (like A2/304 and A4/316 stainless steel) for fender washers. These materials offer strong corrosion resistance, making them suitable for outdoor or humid environments.

- Other Materials: Some fender washers also utilize materials like aluminum or plastic. We generally use these for special modifications or decorative purposes.

Main Applications

- Cars and Motorcycles: You’ll often find fender washers securing mudguards, luggage racks, and other components, preventing fasteners from damaging the vehicle body or mudguards.

- Bicycles: We use them to secure mudguards, water bottle cages, and other parts, preventing bolts from damaging plastic or aluminum components.

Key Selection Points

- Size Matching: We select the appropriate inner diameter based on the bolt or screw diameter, and the proper outer diameter based on the installation process and requirements.

- Material Suitability: We choose the right material based on the application scenario. For example, stainless Steel is ideal for outdoor use, while aluminum or plastic washers are better for decorative or lightweight applications.

What are Fender Washers Used For?

A fender washer is a highly useful mechanical component that plays a vital role in various applications. Here are the primary uses of fender washers:

1. Pressure Distribution

- Protection of Fastened Components: One of the main functions of a fender washer is to distribute the tightening force. When you tighten a bolt or nut, the washer evenly transfers the pressure to the fastened component, preventing excessive localized force that could damage the part.

- Preventing Deformation: For thinner or softer materials (like plastic or aluminum components), a fender washer prevents deformation or damage caused by bolt tightening.

2. Preventing Bolt Loosening

- Increasing Friction: The surface of a washer usually has a certain roughness, which increases friction between the bolt and the fastened component. هذا prevents the bolt from loosening due to vibration or impact.

- Locking Effect: Some fender washer designs incorporate a locking function (such as spring washers or toothed washers), which further prevents bolt loosening.

3. Sealing and Waterproofing

- Sealing Function: In some applications, fender washers can provide a sealing function, preventing liquid or gas leakage. For instance, when using fender washers on cars or motorcycles, they can avoid rainwater or dust from entering the vehicle body.

- Waterproof Protection: In humid environments, washers prevent moisture penetration, protecting fasteners and tightened components from corrosion.

4. Decoration and Aesthetics

- Appearance Improvement: Fender washers can improve the appearance of fasteners, making them look neater and more aesthetically pleasing. Especially in custom or modified applications, you can match the washer’s color and material with the overall design.

- Hiding Bolt Heads: In some cases, washers can partially or completely cover bolt heads, making them less conspicuous and enhancing the overall visual effect.

5. Providing Additional Support

- Enhanced Stability: When using heavy components, fender washers provide additional support, ensuring a more stable assembly.

- Adjusting Gaps: In certain situations, we use washers to adjust the gap between components, ensuring assembly precision.

6. Preventing Scratches

- Surface Protection: During installation, washers prevent the sharp edges of bolts or nuts from scratching the surface of the fastened component, especially for parts with high surface finish requirements (like painted or plated surfaces).

7. Integrating Different Materials

- Compatibility: We select fender washers of appropriate materials for different application scenarios. For example, stainless steel washers are suitable for humid or corrosive environments, while plastic washers are more suitable for lightweight or decorative purposes.

What is the Difference Between a Fender Washer and a Standard Washer?

The main differences between a fender washer و standard washer (usually referring to a flat washer) lie in their structure, Function, and applications. Here’s a detailed comparison:

| ميزة | غسالة الحاجز | Standard Flat Washer |

| Structure | Large outer diameter, small center hole, typically flat and wide, offering a large support area. | Smaller outer diameter-to-inner diameter ratio, moderate thickness, basic structure. |

| Function/Purpose | Primarily disperses tightening force over a large area, preventing localized damage to soft or thin materials. Suitable for accommodating large or irregular holes. | Primarily distributes fastener load evenly, preventing damage to the tightening surface during fastening. |

| Main Applications | Widely used in vehicle and motorcycle fender installation. Also used in pipelines, electrical installations, drywall installations, and other areas requiring load distribution over a large area. | Widely used in construction, vehicles, electronics, furniture manufacturing, and other general fastening applications. |

| Material Choices | Typically made of metal materials (like stainless steel, carbon steel), with some plastic materials for special modifications or decoration. | Diverse materials, including steel, stainless steel, copper, brass, etc. |

| Size Standards | Generally, a flat washer with an outer diameter more than three times its inner diameter is considered a fender washer. | Size standards are more basic, with various options like DIN and ANSI standards. |

What Materials are Fender Washers Made From?

Fender washers come in various materials, with the following being common:

- الفولاذ المقاوم للصدأ

- الخصائص: Excellent corrosion resistance, high toughness, good durability, suitable for humid or outdoor environments.

- التطبيقات: Widely used in cars, motorcycles, and bicycles for fender installation, and areas requiring waterproofing and rust prevention.

- الفولاذ الكربوني

- الخصائص: Low cost, strong load-bearing capacity, but poor corrosion resistance, often requiring surface treatment like galvanizing.

- التطبيقات: Suitable for mechanical and construction projects in non-corrosive environments.

- Plastic

- الخصائص: Lightweight, easy to install and form, good aging resistance, and corrosion resistance.

- التطبيقات: Commonly used for lightweight component assembly in cars, motorcycles (fenders), and water bottle holders.

- Rubber

- الخصائص: Good toughness, anti-aging, corrosion-resistant.

- التطبيقات: Suitable for car fenders and other components requiring cushioning and sealing.

- Copper

- الخصائص: Good electrical conductivity, good corrosion resistance.

- التطبيقات: Rarely used for fender washers, but can be used in some special occasions (like marine or electronic equipment).

- نايلون

- الخصائص: Lightweight, wear-resistant, corrosion-resistant, and has some self-lubricating properties.

- التطبيقات: Suitable for areas requiring lightness and corrosion resistance.

- Thermoplastic Elastomer (TPE)

- الخصائص: Good aging resistance, weather resistance, and corrosion resistance, and can be customized in color and surface finish.

- التطبيقات: Suitable for car fenders and other exterior components.

- Polyurethane

- الخصائص: High corrosion resistance, good stability.

- التطبيقات: Suitable for car fenders, gaskets, and other locations.

- الألومنيوم

- الخصائص: Lightweight, rust-proof, good corrosion resistance, good recyclability.

- التطبيقات: Suitable for aerospace components or where lightweight materials are required.

Different fender washer materials have their advantages and disadvantages. We should choose them based on specific application scenarios and requirements.

What Thickness Do Fender Washers Require?

The thickness of fender washers varies depending on the actual size and application. Here are some general specifications and thickness information:

| Inner Diameter (ID) | Outer Diameter (OD) | Thickness (T) | General Applications |

| 3 mm | 9 mm | 0.8 mm – 1.0 mm | Light-duty applications, electronics, small fixtures |

| 4 mm | 12 mm | 1.0 mm – 1.2 mm | General purpose, bicycle accessories |

| 5 mm | 15 mm | 1.2 mm – 1.5 mm | Automotive interior, medium-duty fasteners |

| 6 mm | 18 mm | 1.5 mm – 2.0 mm | Automotive fenders, general machinery |

| 8 mm | 24 mm | 1.5 mm – 2.0 mm | Heavy-duty automotive, construction |

| 10 mm | 30 mm | 2.0 mm – 2.5 mm | Industrial machinery, structural fastening |

Please note that fender washer thickness is not fixed; different manufacturers and standards may vary. For example, the DIN 125 standard includes various specifications for flat washers, and their thickness changes with different inner and outer diameters. Additionally, some specially customized fender washers can be adjusted according to actual needs.

What Thickness Can You Request for Custom Fender Washers?

You can choose the thickness of custom fender washers based on your actual needs. Here’s some relevant information:

Thickness Range

- Thin Washers: Thickness can be as low as 0.05 mm.

- Common Thicknesses: 1.5 mm, 2 mm.

- Thick Washers: Thickness can reach 3 mm to 5 mm.

- Special Thick Washers: Thickness can even reach 6 mm.

Customization Requirements

- Material and Thickness: Washers made of different materials can offer different thickness options. For example, we can customize stainless steel washers to a thickness of 1.5 mm, and plastic fender washers can reach a thickness of 3-5 mm.

- Special Applications: For some special applications, such as heavy truck fenders, the thickness may need to be greater (e.g., 3 mm to 5 mm) to provide better protection.

Customization Advice

- Choose Based on Application: If you are using fender washers for lightweight materials or areas that require fine adjustment, you can choose thinner washers (e.g., 0.05 mm to 1.5 mm). For areas that need to withstand greater pressure or outdoor environments, you can choose thicker washers (e.g., 2 mm to 6 mm).

- Communicate with Suppliers: When customizing, you should inform your supplier about the required thickness, material, size, and other relevant requirements to ensure the product meets your usage needs.

You can select the thickness of customized fender washers based on actual needs, allowing for various specifications from thin to thick. We recommend determining the appropriate thickness based on the actual application and material properties.

What Specifications Do You Need for Custom Fender Washers?

When customizing fender washers, you must provide the following key dimension information:

- Inner Diameter (ID)

- Definition: The diameter of the washer’s center hole, used to match the size of the bolt or screw.

- Examples: Common inner diameter specifications include M3, M4, M5, M6, M8, etc.

- Outer Diameter (OD)

- Definition: The outer diameter of the washer, which determines the washer’s support area.

- Examples: We typically choose the outer diameter based on the inner diameter and application. For example, an M3 washer’s outer diameter might be 9 mm, and an M6 washer’s outer diameter might be 18 mm.

- Thickness (T)

- Definition: The thickness of the washer, which affects its load-bearing capacity and tightening effect.

- Examples: Thickness can vary from 0.05 mm (thin) to 6 mm (thick). Common thicknesses include 1.5 mm, 2 mm, 3 mm, etc.

- Tolerance

- Definition: The allowable error range for dimensions, ensuring the washer fits the fastener.

- مثال: Outer diameter tolerance might be ±0.018 inches.

- Other Customization Requirements

- Material: We select the appropriate material (such as stainless Steel, aluminum, plastic) based on the application scenario.

- المعالجة السطحية: Such as galvanizing, black oxide, polishing, etc., to meet corrosion resistance or aesthetic requirements.

- Special Appearance: If you require a non-standard appearance, you can submit detailed drawings or descriptions.

A fender washer, seemingly insignificant, plays a crucial role in the world of fasteners. It’s not just a simple spacer; it’s a critical link in connection and protection. As an expert in the fastener industry at قفل الأمير السحابة, I will guide you through every aspect of fender washers, sharing our industry experience, real-world case studies, and practical advice to ensure you make the most informed decisions when selecting and using them.

Structure and Features of Fender Washers

A fender washer, as its name suggests, is designed to have a support surface that is much larger than that of a traditional flat washer. Its key characteristics include:

- Large Outer Diameter: Compared to standard flat washers, fender washers have a significantly larger outer diameter. هذا allows them to disperse tightening pressure more effectively, preventing localized stress concentrations on the fastened material. This design is particularly crucial when dealing with thin sheets, soft materials (such as plastic and rubber), or fragile surfaces.

- Small Inner Diameter: The center hole diameter usually closely matches the bolt or screw diameter, ensuring the fastener passes through securely while maximizing the contact area between the washer and the fastened component.

Prince Fastener’s Experience Sharing: In our collaborations with automotive manufacturing clients, they previously encountered issues when using standard flat washers to secure car mudguards. Because the car body’s steel plates were thin, tightening the bolts often led to localized indentations or even deformation. By introducing custom large-outer-diameter fender washers, we successfully helped the client resolve this pain point. This washer’s diameter increased by 30% compared to traditional washers, evenly distributing the tightening pressure and eliminating indentations, while also enhancing the mudguard’s installation firmness.

Material Selection for Fender Washers

The choice of material for a fender washer directly impacts its performance and suitability for various environments.

- Metal Materials:

- Stainless Steel (e.g., A2/304 and A4/316 stainless steel): This is the most common choice, highly popular due to its excellent مقاومة التآكل. A2/304 stainless steel is suitable for general outdoor and humid environments. In contrast, A4/316 stainless Steel contains higher nickel and molybdenum content, offering stronger resistance to salt spray and acid-base corrosion, making it an ideal choice for marine environments or chemical applications.

- Prince Fastener Case Study: We once supplied A4/316 stainless steel fender washers to a marine accessories manufacturer located in a coastal area, for securing protective panels on ship hulls. After three years of actual use, the client reported that these washers maintained excellent appearance and performance in extreme marine climates, showing no signs of rust, far exceeding the lifespan of their previously used galvanized carbon steel washers.

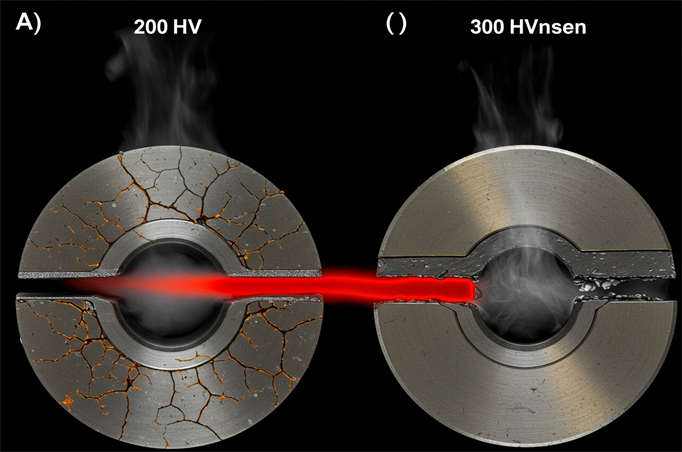

- Carbon Steel: Lower cost and strong load-bearing capacity, but poor corrosion resistance. It typically requires surface treatments like galvanizing, nickel plating, or hot-dip galvanizing to improve its anti-corrosion properties.

- Prince Fastener’s Observation: Although carbon steel washers are inexpensive, they still have a market in certain indoor applications where corrosion requirements are not high. However, we found that improperly surface-treated carbon steel washers can show significant rust in less than six months in humid environments, which directly affects the fastener’s lifespan and appearance.

- Stainless Steel (e.g., A2/304 and A4/316 stainless steel): This is the most common choice, highly popular due to its excellent مقاومة التآكل. A2/304 stainless steel is suitable for general outdoor and humid environments. In contrast, A4/316 stainless Steel contains higher nickel and molybdenum content, offering stronger resistance to salt spray and acid-base corrosion, making it an ideal choice for marine environments or chemical applications.

- Other Materials:

- Aluminum: Lightweight, rust-proof, good corrosion resistance, often used in aerospace components or where lightweighting is required.

- Plastic (e.g., Nylon, Polypropylene, TPE, Polyurethane): Offers good insulation, chemical resistance, and a soft texture that provides some cushioning and sealing. Commonly used in decorative applications, electronic products, or where insulation is required.

- Prince Fastener Case Study: A well-known electric vehicle brand found that metal washers easily scratched or wore down the surface of their plastic body components during installation. We customized high-strength nylon fender washers for them, which not only perfectly solved the surface damage issue but also, due to nylon’s self-lubricating properties, made the installation process smoother, reducing the labor intensity on the assembly line.

Main Uses of Fender Washers: Value Beyond Expectation

The value of a fender washer extends far beyond mere “pressure distribution”; it plays multiple roles in practical applications:

1. Pressure Distribution and Material Protection

This is the core function of a fender washer. By increasing the contact area with the fastened component, it effectively distributes the localized pressure from bolts or nuts, effectively preventing:

- Material Deformation and Damage: For softer or thinner materials like plastic, aluminum sheets, or fiberglass, direct fastening with bolts or nuts can easily lead to deformation, cracking, or even perforation. Fender washers effectively avoid these issues.

- Surface Scratches: On components requiring high surface finishes (such as painted, electroplated, or polished surfaces), the washer prevents the sharp edges of bolts or nuts from directly contacting and scratching the surface.

- Prince Fastener’s Experience: We assisted a high-end furniture manufacturer in resolving the issue of bolt cap edges scratching wooden veneer surfaces during assembly. By using custom stainless steel fender washers with chamfered edges, we not only protected the furniture surface but also enhanced its overall aesthetic appeal.

2. Preventing Bolt Loosening

Although a fender washer itself does not have an anti-loosening function (like spring washers or toothed washers), it indirectly enhances the fastener’s stability in the following ways:

- Increased Friction: The increased friction between the washer’s surface and the fastened component’s surface helps resist loosening caused by vibration and impact.

- Improved Stress Distribution: Even pressure distribution reduces localized stress concentrations, thereby lowering the risk of fasteners loosening due to uneven forces.

3. Sealing and Waterproofing

In certain specific applications, fender washers can provide additional sealing and waterproofing functions.

- Prince Fastener’s Practical Experience: When supplying a client, an outdoor lighting equipment manufacturer, they encountered water ingress into their light fixtures, leading to circuit shorts. We advised them to use fender washers with EPDM rubber sealing layers at the fastening points on the light fixture casing. This composite washer, while providing pressure distribution, effectively isolates moisture and dust ingress, significantly improving the product’s waterproofing performance and lifespan.

4. Decoration and Aesthetics

- Improved Appearance: Fender washers can make the installation of fasteners look neater and more professional.

- Hiding Bolt Heads: In some custom or decorative applications, the washer can partially or completely cover the bolt head, making it less conspicuous and enhancing the overall visual effect.

- Prince Fastener’s Observation: Many custom car enthusiasts, when choosing fender washers, not only focus on their functionality but also on how their color and material match the vehicle’s overall style. For example, anodized aluminum fender washers in various colors are very popular in the custom car market.

5. Providing Additional Support and Adjusting Gaps

- Enhanced Stability: When securing heavier or highly loaded components, a fender washer can provide a broader support surface, strengthening the component’s stability.

- Gap Adjustment: In precision assembly, we can use washers as shims to precisely adjust the gap between components, ensuring assembly accuracy.

What’s the Difference Between a Fender Washer and a Standard Washer? A Clear Overview

Understanding the difference between a fender washer و standard flat washer (such as those adhering to DIN 125 standards) is key to selecting the correct fastener.

| ميزة | غسالة الحاجز | Standard Flat Washer |

| الخصائص الهيكلية | Outer diameter significantly larger than inner diameter (typically more than 3 times the inner diameter), relatively thin. | Smaller outer diameter-to-inner diameter ratio, moderate thickness. |

| Primary Function | Distributes pressure over a large area, protects soft, thin, or fragile materials, accommodates large or irregular holes. | Evenly distributes fastener load, prevents bolt or nut from damaging the fastening surface. |

| Typical Applications | Car/motorcycle mudguards, bicycle components, thin plate structures, pipe installations, drywall installations, etc. | Widely used in metal structures, machinery, furniture, electronic products, and general fastening applications. |

| Material Choices | Commonly stainless steel, carbon steel (requiring plating), aluminum, nylon, TPE, polyurethane, etc. | Diverse materials, such as steel (common, stainless steel), copper, brass, aluminum, etc. |

| Size Characteristics | Primarily characterized by its large outer diameter, usually without strict standardized dimensions (though common sizes exist). | Has strict international and national standards (e.g., DIN 125, ANSI B18.21.1), with standardized dimensions. |

Prince Fastener’s Sales Experience: Many clients often misunderstand the difference between these two types of washers, leading to incorrect selections. For example, one company used standard flat washers to secure thin aluminum plates, which resulted in deformation of the aluminum plates. When we suggested they switch to fender washers, the problem immediately resolved. Properly identifying and selecting the correct washer not only avoids production issues but also effectively reduces rework rates and material waste. In the long run, this is true cost savings.

Material Composition of Fender Washers: Performance and Potential Issues

The material options for fender washers are diverse, and each material has its unique advantages and disadvantages:

- الفولاذ المقاوم للصدأ

- الإيجابيات: Excellent corrosion resistance (especially A4/316), high strength, good durability, aesthetic appeal.

- السلبيات: Relatively higher cost, non-conductive (compared to copper), still susceptible to corrosion in extremely high chloride environments.

- Prince Fastener’s Addition: Some unscrupulous vendors in the market may pass off inferior stainless Steel as 316 stainless steel, or the stainless steel material content may not meet standards, leading to rust spots appearing on the product after a period of use. We advise clients purchasing stainless steel washers to always request a Material Test Certificate (MTC) from the supplier to ensure the product complies with international standards.

- الفولاذ الكربوني

- الإيجابيات: Low cost, strong load-bearing capacity, easy to process.

- السلبيات: Poor corrosion resistance, must undergo surface treatment (e.g., galvanizing, blackening) for outdoor or humid environments. Once the coating is damaged, it rusts easily.

- Prince Fastener’s Addition: We’ve encountered clients complaining that galvanized carbon steel washers showed rust within a few months due to coating damage from wrench friction during installation. For such issues, we typically advise clients to consider more wear-resistant coatings, like hot-dip galvanizing, or to upgrade directly to stainless Steel.

- Plastic (Nylon, Polypropylene, etc.)

- الإيجابيات: Lightweight, insulating, corrosion-resistant, offers some elastic cushioning, non-conductive, easy to color, and low cost.

- السلبيات: Relatively lower strength, not suitable for high-stress or high-temperature environments, can become brittle after long-term UV exposure.

- Prince Fastener’s Addition: Plastic washers can become more brittle in low temperatures and may soften and deform in high temperatures. When selecting, you need to evaluate them based on the specific operating temperature range.

- Rubber/Thermoplastic Elastomer (TPE)

- الإيجابيات: Excellent sealing, cushioning, and shock absorption properties, good weather resistance and aging resistance, pleasant tactile feel.

- السلبيات: Lower strength, not suitable for heavy-load applications, relatively higher cost.

- Prince Fastener’s Addition: While rubber washers offer excellent sealing, their oil or solvent resistance varies depending on the specific type of rubber; you need to pay attention to this when selecting.

- الألومنيوم

- الإيجابيات: Lightweight, rust-proof, good electrical and thermal conductivity, aesthetic appeal (after anodizing).

- السلبيات: Lower strength than Steel, susceptible to galvanic corrosion in certain environments, higher cost.

- Prince Fastener’s Addition: Aluminum washers, when in direct contact with certain metals (like copper or some steels) in humid environments, may experience galvanic corrosion. هذا is a potential drawback we must consider when selecting materials.

Prince Fastener’s Advice: Understanding the pros and cons of each material is crucial. For example, if you need fasteners for outdoor billboards and have a limited budget, galvanized carbon steel might be an initial choice, but you must be aware of the rust risk if the coating is damaged and inform your client that regular maintenance or replacement might be necessary. If you want a long-term solution, investing in stainless steel washers will be a wiser choice.

Fender Washer Thickness: Details Determine Success

The thickness of a fender washer is not fixed; we customize and select it based on specific application requirements.

- Thin Washers (0.05 mm – 1.5 mm):

- Suitable for lightweight materials, precision assembly, or applications requiring fine gap adjustment.

- Prince Fastener Case Study: In the installation of precision electronic devices, we customized stainless steel fender washers with a thickness of only 0.2 mm for a client to secure circuit boards. This thin washer not only ensured the fasteners’ security but also avoided any additional stress on the fragile circuit boards while saving valuable internal space.

- Common Thicknesses (1.5 mm – 3 mm):

- هذا is the most common thickness range in the market, suitable for most general mechanical and automotive applications.

- Thick Washers (3 mm – 6 mm or thicker):

- Suitable for applications requiring greater pressure, vibration, or higher structural stability, and for example, securing heavy machinery or high-strength building structures.

- Prince Fastener Case Study: We once supplied a mining equipment manufacturer with custom five mm-thick carbon steel fender washers to secure the tracks of their mining equipment. In an environment of extreme vibration and impact, these thickened washers demonstrated exceptional resistance to deformation, significantly extending the lifespan of the tracks and reducing maintenance frequency by 20%.

Prince Fastener’s Customization Advice:

- Application Scenario Assessment: First, clearly define the load the washer will bear, environmental conditions (temperature, humidity, corrosiveness), and the hardness of the fastened material.

- Structural Space Constraints: Consider whether the installation space allows for the use of thicker washers.

- Communicate with Suppliers: When customizing, clearly state your requirements, including inner diameter, outer diameter, thickness, material, and tolerance requirements. Providing detailed drawings or descriptions of the use case will help us offer the most precise solution.

After-Sales Issues and Solutions:

Even seemingly simple fender washers can encounter various issues during use. As experts at قفل الأمير السحابة, we’ve summarized some common after-sales problems and their solutions, hoping to provide you with practical assistance:

- Problem: The washer quickly rusts after use.

- Cause Analysis:

- Improper material selection: Using materials with insufficient corrosion resistance (like ungalvanized carbon steel) in humid or corrosive environments.

- Coating damage: The carbon steel washer’s coating gets damaged during installation or use, exposing the base material to rust.

- Substandard material: The actual material does not match the stated specifications.

- Solution:

- Prevention: Before purchasing, clearly inform your supplier about the operating environment and request recommendations for appropriate materials. For stainless steel washers, always ask for material certificates. For carbon steel washers, choose a thicker coating or a more wear-resistant galvanizing process.

- Remedy: For rusted washers, if the rust is not severe, you can remove it and reapply a rust-proof coating. If the rust is severe or affects structural integrity, you should immediately replace it with a washer of suitable material.

- Cause Analysis:

- Problem: The washer deforms or cracks during tightening.

- Cause Analysis:

- Insufficient washer thickness, unable to withstand the tightening force.

- Insufficient material strength (e.g., using plastic washers where high strength is required).

- Excessive tightening force, exceeding the washer’s load limit.

- Solution:

- Prevention: Based on the load requirements and the characteristics of the fastened component, select a washer material with sufficient thickness and strength. For example, when securing heavy components, you should choose thicker metal washers.

- Remedy: Replace with a thicker, stronger washer. Also, check if the tightening torque complies with standards to avoid overtightening.

- Cause Analysis:

- Problem: The washer and bolt or fastened component are not size-matched.

- Cause Analysis:

- Inner diameter doesn’t match the bolt diameter: Too large leads to looseness, too small prevents installation.

- Outer diameter conflicts with installation space: The outer diameter is too large to prevent installation.

- Poor tolerance control.

- Solution:

- Prevention: Before placing an order, be sure to provide accurate bolt diameters, installation hole diameters, and acceptable maximum outer and minimum inner diameter dimensions. Confirm the supplier’s production tolerance range.

- Remedy: You can only replace it with a size-matched product. Before replacement, we recommend precisely measuring the existing fastener dimensions to avoid recurring size issues.

- Cause Analysis:

- Problem: Scratches or wear appear on the washer’s surface after installation.

- Cause Analysis:

- Insufficient surface hardness of the washer, easily damaged by tools or fastener friction.

- Improper installation tools or procedures.

- Solution:

- Prevention: If you have high requirements for the washer’s surface appearance, you can choose washers with polished, passivated surfaces or those with protective films. For easily scratched components, consider using plastic or rubber washers.

- Remedy: For scratched washers, if it’s just an aesthetic issue and doesn’t affect functionality, you can accept it. Otherwise, you need to replace it.

- Cause Analysis:

What are the different sizes of fender washers?

Fender washers come in a wide range of sizes. Common specifications include the following:

Inner Diameter (ID)

- M3: Approximately 3.2 mm inner diameter.

- M4: Approximately 4.3 mm inner diameter.

- M5: Approximately 5.3 mm inner diameter.

- M6: Approximately 6.4 mm inner diameter.

- M8: Approximately 8.4 mm inner diameter.

- M10: Approximately 10.5 mm inner diameter.

- M12: Approximately 13.0 mm inner diameter.

- M14: Approximately 15.0 mm inner diameter.

- M16: Approximately 17.0 mm inner diameter.

Outer Diameter (OD)

- M3: Approximately 9.0 mm outer diameter.

- M4: Approximately 12.0 mm outer diameter.

- M5: Approximately 15.0 mm outer diameter.

- M6: Approximately 18.0 mm outer diameter.

- M8: Approximately 24.0 mm outer diameter.

- M10: Approximately 30.0 mm outer diameter.

- M12: Approximately 37.0 mm outer diameter.

- M14: Approximately 44.0 mm outer diameter.

- M16: Approximately 50.0 mm outer diameter.

Thickness (T)

- 0.8 mm: Suitable for M3 size.

- 1.0 mm: Suitable for M4 size.

- 1.2 mm: Suitable for M5 size.

- 1.6 mm: Suitable for M6 size.

- 2.0 mm: Suitable for M8 size.

- 2.5 mm: Suitable for M10 size.

- 3.0 mm: Suitable for M12, M14, M16 sizes.

Additionally, there are some special sizes of fender washers, such as:

- M5 Wide Flat Fender Washer: 5.0 mm inner diameter, 25.0 mm outer diameter.

- 1/4-inch Size: 0.285 inches inner diameter, 1 inch outer diameter, 0.047 inches thickness.

Different manufacturers may offer fender washers in varying sizes. It is recommended to choose the appropriate specifications based on your specific needs.

Custom Fender Washers: Provide Your Core Specifications

Customizing fender washers can perfectly match your unique needs. Please be sure to provide the following key dimension information:

- Inner Diameter (ID): The diameter of the washer’s center hole, which determines which diameter bolt or screw it can fit. For example, a washer for an M6 bolt usually has an inner diameter of 6.4 mm or 6.5 mm.

- Outer Diameter (OD): The outer diameter of the washer directly affects the size of the support area. For example, an M6 bolt’s corresponding fender washer might have an outer diameter of 18 mm or even 25 mm.

- Thickness (T): The thickness of the washer, which affects its load-bearing capacity and compression performance. It can range from 0.05 mm (ultra-thin) to 6 mm or even thicker for heavy-duty applications.

- Tolerance: The allowable range of dimensional error. For example, the inner diameter tolerance might be ±0.1 mm, and the outer diameter tolerance might be ±0.2 mm. Strict tolerance control is crucial for precision assembly.

- Other Customization Requirements:

- Material: Stainless Steel (specific grade), carbon steel (and surface treatment requirements), aluminum, plastic (specific type), rubber, etc.

- المعالجة السطحية: Such as galvanizing (blue-white zinc, color zinc, hot-dip galvanizing), blackening, polishing, passivation, etc.

- Special Shape: If you need non-circular or other irregularly shaped washers, please provide detailed drawings.

- Packaging Requirements: Specific quantities, anti-rust packaging, etc.

Prince Fastener’s Advice: When providing customization information, it’s best to include pictures or simple diagrams of your application scenario. This will help us understand your needs more intuitively, allowing us to provide more precise and cost-effective customized solutions.

A fender washer, though small, plays an irreplaceable role in ensuring the stability of fastener systems, protecting fastened materials, and enhancing the overall performance of products. Selecting the correct fender washer is a crucial step for every engineer and procurement specialist. As experts at قفل الأمير السحابة, we are committed to providing you with high-quality products and professional solutions, ensuring every one of your fastenings is strong and reliable.

As we wrap up our exploration of fender washers, it’s clear that these small but mighty components are indispensable in a wide range of applications. At Prince Fastener, we pride ourselves on offering a diverse range of fender washers, each tailored to meet specific needs. Whether you require stainless steel washers for their corrosion resistance or plastic ones for lightweight applications, we’ve got you covered.

We also understand that challenges can arise. For example, one common issue is the potential for washers to corrode over time, especially in harsh environments. To combat this, we recommend using materials like stainless Steel or coated metals, which offer superior durability. Another concern is the risk of washers not fitting properly, leading to instability or damage. To avoid this, always ensure that the dimensions of the washer match the specifications of your fasteners and the components being secured.

Our commitment to customer satisfaction means we’re always here to assist with any questions or issues you may encounter. Whether you need advice on selecting the right material or guidance on customizing washers to fit unique requirements, our team is ready to help. By providing the right tools and support, we can empower you to tackle any project with confidence and precision. So, gear up with Prince Fastener’s fender washers and let’s fasten the world together—one washer at a time.

الأسئلة الشائعة

1. What are the primary functions of fender washers?

Fender washers are designed to distribute the load of a fastener over a larger surface area, preventing damage to the material being secured. They are particularly useful for soft or thin materials like plastic, aluminum, or sheet metal. Additionally, they can prevent corrosion, reduce abrasion and noise, and provide electrical insulation.

2. What materials are commonly used for fender washers?

Fender washers are available in various materials, each suited to different applications:

- الفولاذ المقاوم للصدأ: Corrosion-resistant and ideal for outdoor use.

- الفولاذ الكربوني: Strong and cost-effective, though less corrosion-resistant.

- Plastic/Nylon: Lightweight and non-conductive, suitable for electrical insulation.

- الألومنيوم: Lightweight and corrosion-resistant.

- النحاس: Offers good مقاومة التآكل and aesthetic appeal.

3. How do I choose the right fender washer for my project?

When selecting a fender washer, consider the following factors:

- توافق المواد: Choose a material that matches the environmental conditions and the material being fastened.

- توزيع الحمل: Ensure the washer’s large diameter can distribute the load effectively.

- Corrosion Resistance: For outdoor or wet environments, opt for stainless Steel or other corrosion-resistant materials.

- Size and Thickness: Select the appropriate inner and outer diameters and thickness to match your fasteners and application requirements.

4. What are some common applications of fender washers?

Fender washers are widely used in:

- Automotive and Motorcycle: Securing fenders, mudguards, and other thin metal parts.

- البناء: Fastening sheet metal, roofing materials, and drywall.

- السباكة: Sealing and securing pipes and fittings.

- DIY and Home Repair: Furniture assembly, securing decorative elements, and other household projects.

5. Can fender washers prevent fasteners from loosening?

While fender washers primarily distribute load and protect surfaces, they can also help prevent fasteners from loosening. Their larger surface area helps absorb vibrations, reducing the risk of nuts or bolts coming loose. For more secure applications, consider using lock washers in conjunction with fender washers.

6. What are some tips for using fender washers effectively?

- الحجم المناسب: Ensure the inner diameter matches the fastener size, and the outer diameter provides sufficient load distribution.

- Surface Preparation: Clean and prepare the surface to ensure the washer sits flat and distributes the load evenly.

- Combining with Other Washers: Use in combination with lock washers for added security or with spring washers for vibration resistance.

- Material Matching: Choose a washer material that complements the fastener and the material being secured to avoid galvanic corrosion