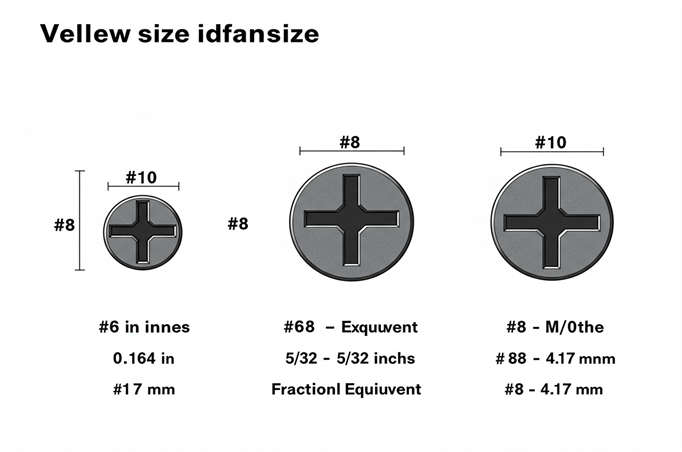

You might see #8 screws in lots of projects. The exact size is very important. The #8 screw diameter is 0.1640 inches in decimal. It is 5/32 inches in fractional. It is 4.17 millimeters in metric.

| Measurement Type | Value |

|---|---|

| Decimal | 0.1640 in |

| Fractional | 5/32 in |

| Metric | 4.17 mm |

Knowing the right diameter helps you choose the best screw. هذا helps stop cracks in plastic. It also makes things stronger. Your projects will be safer and last longer.

النقاط الرئيسية

- The #8 screw diameter is about 0.164 inches. هذا is also 5/32 inches or 4.17 mm. It is a common mid-size screw for many jobs.

- Always check both decimal and fractional sizes. هذا helps you pick the correct screw. It also enables you to avoid mistakes in your work.

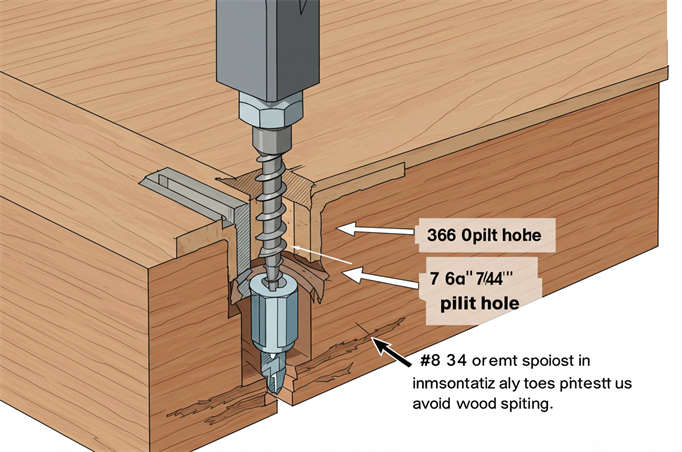

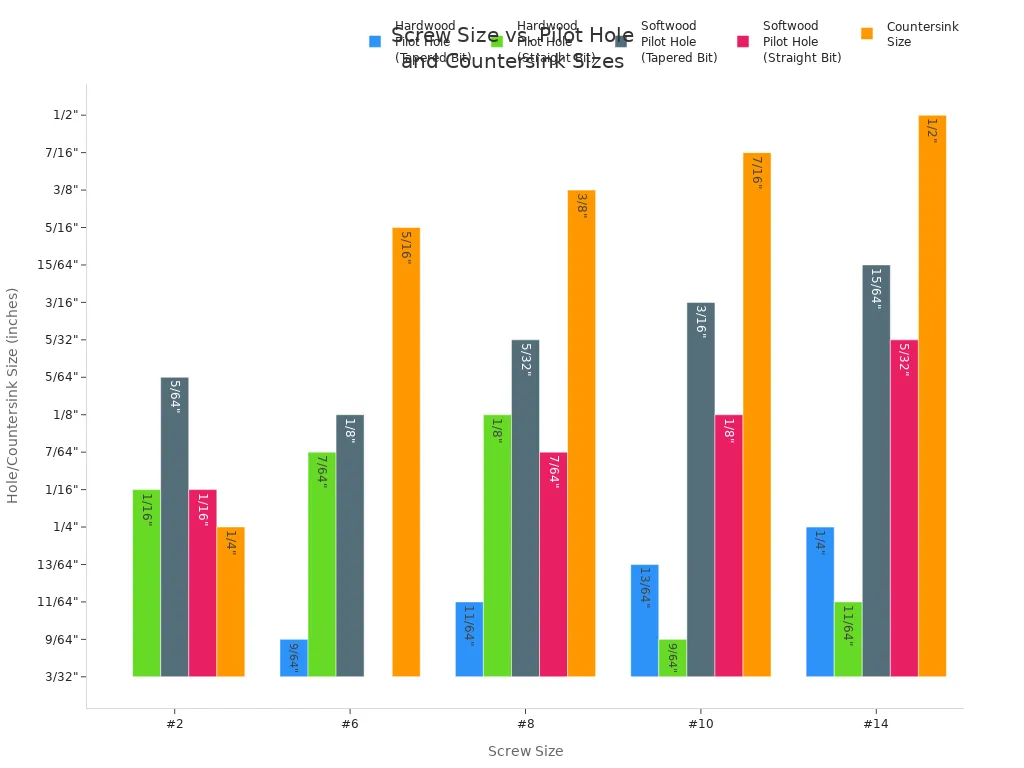

- Use the correct pilot hole size for your project. Use 7/64 inch for hardwood. Use 3/32 inch for softwood. هذا stops wood from splitting. It also makes the screw hold better.

- #8 screws are suitable for furniture and cabinets. They are also used in light construction. You can also use them in electronics and cars. They are strong and valuable for many things.

- Select the appropriate screw material and length for your project. Use stainless steel for outdoor projects. هذا keeps your work safe and secure, ensuring its long-lasting durability.

#8 Screw Diameter

Decimal and Fractional Sizes

When you look at screws in North America, you often see numbers like #6, #8, or #10. These numbers tell you the size of the screw. The #8 screw diameter is a common choice for many projects. You measure this diameter across the outside of the threads. In decimal form, the #8 screw diameter is 0.1640 inches. This measurement is based on the Unified Thread Standard, which establishes the guidelines for screw sizes in the United States.

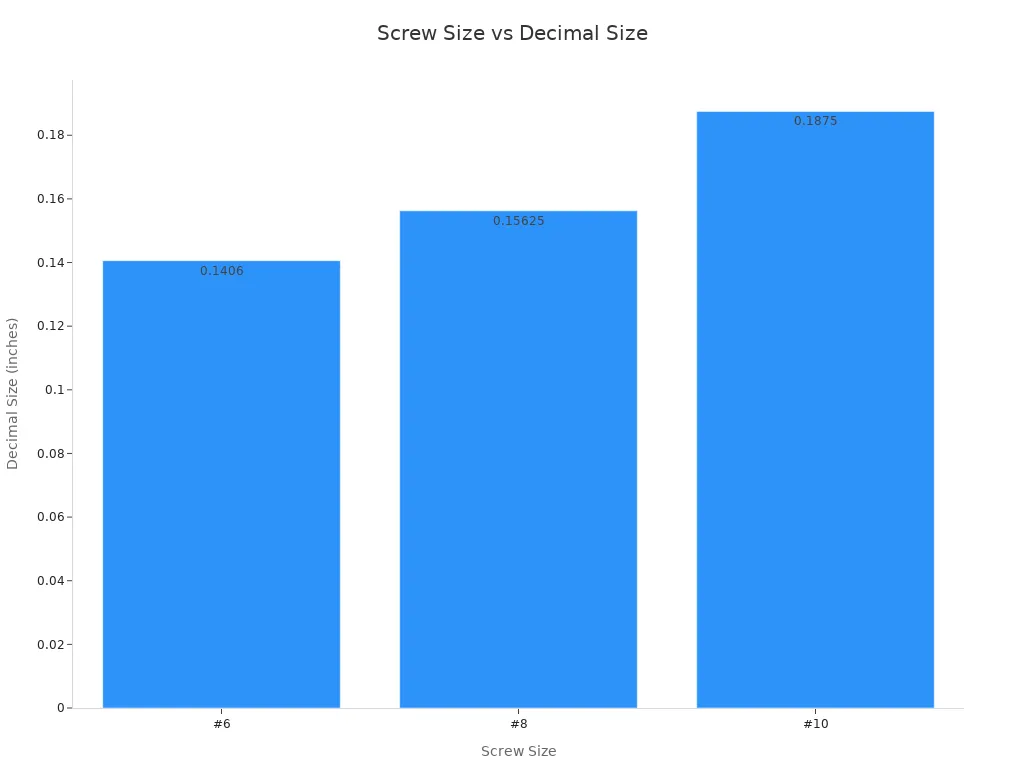

You might also see fractional sizes used in woodworking or construction. For a #8 screw, the closest fractional size is 5/32 inches. هذا is not an exact match, but it helps you compare the #8 screw to other sizes. Here is a table that shows how the #8 screw diameter compares to other popular screw sizes:

| حجم المسمار | Fractional Size | Decimal Size (inches) |

|---|---|---|

| #6 | 9/64 | 0.1406 |

| #8 | 5/32 | 0.15625 |

| #10 | 3/16 | 0.1875 |

You can see that the #8 screw sits right between the #6 and #10 screws. هذا makes it a great mid-range option for many tasks. Most builders and DIYers use #6, #8, and #10 screws the most. The #8 screw diameter strikes a balance between strength and size.

نصيحة: When you pick a screw, always check both the decimal and fractional sizes. هذا helps you avoid mistakes and choose the right fit for your project.

Metric Conversion

Sometimes, you need to use metric measurements, primarily when working with international parts or tools. The #8 screw diameter in metric units is about 4.17 millimeters. You get this number by multiplying the decimal inch size (0.164 inches) by 25.4, which is the number of millimeters in an inch.

| حجم المسمار | Decimal Inch | Metric Equivalent (mm) |

|---|---|---|

| #8 | 0.164 | 4.17 |

You should know that there is no exact metric screw that matches the #8 screw diameter. Metric screws use direct millimeter measurements, while the #8 screw uses the Imperial gauge system. For example, a metric M4.2 screw is similar in size, but the threads and shape differ. You cannot swap them without checking the fit.

ملاحظة: Metric and Imperial screws are not interchangeable. Always match the screw type to the hole and material you use.

The #8 screw diameter gives you flexibility. You can use it in both Imperial and metric projects if you know the right conversions. هذا makes it a popular choice for builders, woodworkers, and anyone who needs a reliable fastener.

Screw Sizing Explained

What “#8” Means

When you see a screw labeled as “#8,” you are looking at a code that indicates its thickness. The number “8” stands for the screw’s diameter, not its length or thread type. According to industry standards, a #8 screw has a diameter of about 0.164 inches, which is close to 5/32 inches. This size works well for many jobs, especially in furniture and cabinet making. You will often find #8 screws in kits for shelves, drawers, and light construction.

The “#8” label helps you pick the right screw for your project. It gives you a quick way to match the screw to the hole size and the material you are using.

You should also know that the #8 screw diameter comes with a standard thread count. Most #8 screws have 32 threads per inch (TPI). This thread count makes the screw strong and easy to drive into wood or plastic.

| حجم المسمار | القطر (بوصة) | Threads Per Inch (TPI) |

|---|---|---|

| #8 | 0.164 | 32 |

Thread Pitch and Head Diameter

Thread pitch indicates the number of threads that run along one inch of the screw. For an #8 screw, the standard coarse thread pitch is 15 threads per inch. This design helps the screw grip tightly and hold materials together. You can use this screw in wood, plastic, or thin metal.

The head diameter is another essential part of screw sizing. The head is the top part of the screw that sits above the surface. For a #8 screw, the head diameter changes based on the type of head:

- Flat and oval heads: about 0.312 inches (5/16 inch)

- Round heads: about 0.298 inches (19/64 inch)

| نوع الرأس | Head Diameter (inches) |

|---|---|

| Flat/Oval | 0.312 |

| Round | 0.298 |

Knowing the thread pitch and head diameter helps you choose the right driver bit, ensuring the screw fits your project. Always verify these numbers before beginning your work.

Measuring Screw Diameter

Tools for Measurement

You need the right tools to measure screw diameter. A ruler can help, but it is not very exact. Calipers provide a more accurate measurement of the threads. A screw gauge has holes for different sizes. You slide the screw into each hole to find the right one.

For critical projects, always check the screw size first. Follow industry standards to ensure you have the correct size. Here are some steps you can use:

- Verify the screw size and shape using industry standards, such as ASME B1.3.

- Use a GO gage at Maximum Material Condition to see if the screw fits.

- Try GO/NO GO gages for a fast check.

- Use indicating gauges if you need a more exact measurement.

- Utilize advanced tools, such as optical comparators or coordinate measuring machines, for a comprehensive check.

- The screw and hole must fit well and stay tight for best results.

Tip: Always check your screw size before you start. هذا helps you avoid mistakes and keeps your project firm.

Pilot Hole Sizes

Drilling the right pilot hole is essential for a firm hold. It also stops the material from splitting. The pilot hole guides the screw, making it easier to drive in. For an #8 screw, the pilot hole size depends on the material being used.

| المواد | Recommended Pilot Hole Size for #8 Screws |

|---|---|

| خشب صلب | 7/64 inches |

| Softwood | 3/32 inches |

| معدن | N/A (not specified in manufacturer guidelines) |

| Plastic | N/A (not specified in manufacturer guidelines) |

If you use hardwood, pick a 7/64-inch drill bit. For softwood, use a 3/32-inch drill bit. These sizes help the screw hold tight and stop cracks. For metal and plastic, check the manufacturer’s guide. The correct pilot hole size varies depending on the type and thickness of the material.

ملاحظة: Using the correct pilot hole size for the #8 screw diameter ensures your project’s safety and helps the screw last longer.

Common Applications

You can use #8 screws in a variety of projects. They work well in lots of situations. These screws are called all-purpose fasteners. Many people use them for home or workshop jobs. Here are some common ways to use them:

- Furniture assembly

- Cabinet installation

- Light construction projects

- Electronics mounting

- Automotive repairs

Furniture and Cabinets

#8 screws are commonly used in furniture and cabinets. They hold wood pieces together in hardwood and softwood. Their size provides a firm grip without splitting wood. Many #8 screws are self-tapping. You do not need to drill a hole first. هذا saves time and effort.

When selecting screws for furniture, consider the material of the furniture. Stainless steel screws do not rust. Brass screws look nice when visible. Coarse threads are best for softwood. Fine threads are better for hardwood. Select the right length so that the screw does not protrude beyond the surface. These things make #8 screws a good choice for strong furniture and cabinets.

Tip: Use the correct screw length and material for optimal performance. هذا helps your furniture stay strong and look good.

Light Construction

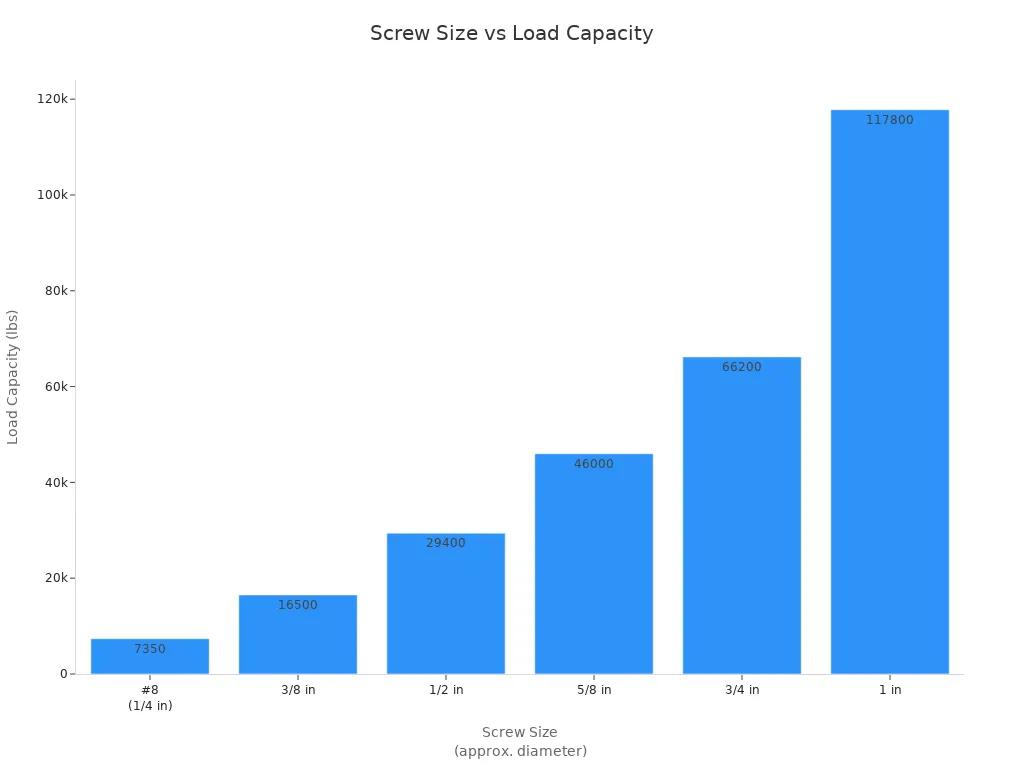

#8 screws are great for light construction jobs. You can use them to build shelves or attach trim. They also work on putting up wall panels. These screws are strong and hold things tightly. In tests, an #8 screw can hold about 7,350 pounds. That is as heavy as a large SUV! هذا makes them suitable for jobs that require strength and ease of use.

Always match the screw size to your job. For most home projects, #8 screws are a strong and easy-to-use option.

Electronics and Automotive

#8 screws are essential in electronics and cars. You use them to mount circuit boards and attach panels. They also hold small parts in place. These screws come in many types. Some have Torx, Philips, or hex drives. Some have special coatings or glue to stop them from coming loose.

| Aspect | التفاصيل |

|---|---|

| النوع اللولبي | Machine screws, including 8-32 Torx machine screws |

| Drive Types | Torx, Philips, Hex Socket, Posidriv, Slotted, Square Robertson |

| Head Types | Binding, Fillister, Flat, Hexagon, Oval, Pan, Round, Socket Head Cap, Square, Truss |

| التطبيقات | Electronics (e.g., board mounting, slim-line PC screw terminals), Automotive (tiered sectors) |

| Special Features | Pre-applied adhesive fasteners (Dri-Loc®) converting screws into self-locking fasteners |

| Industry Standards | ASME/ANSI, DIN, ISO, SAE |

| Material Examples | Stainless steel, titanium socket head cap screws |

| Length Range | 2.5 to 6 inches (varies by product) |

Always check the industry standards for electronics or car work. هذا ensures safety and ensures that parts fit correctly.

Note: #8 screws are popular because they are versatile and work in many applications. You can use them in wood, metal, plastic, and more. هذا makes them a top pick for pros and hobbyists.

Size Comparison Table

#8 vs Other Screw Sizes

When selecting screws for your project, it’s essential to understand how different sizes compare. هذا helps you choose the right one for your strength and fitness needs. The #8 screw diameter sits between the smaller #6 and the larger #10. You can see the differences in the table below. The table displays the screw size, diameter in inches, and its metric equivalent in millimeters.

| حجم المسمار | القطر (بوصة) | Diameter (mm) |

|---|---|---|

| #6 | 0.138 | 3.51 |

| #8 | 0.164 | 4.17 |

| #10 | 0.190 | 4.83 |

| #12 | 0.216 | 5.49 |

You can use this table as a quick reference when shopping for screws or planning your next project.

If you examine the numbers, you will see that the #8 screw diameter strikes a balance between strength and size. You might use #6 screws for lighter jobs, like hanging small pictures. You might pick #10 or #12 screws for heavy-duty tasks, such as mounting shelves or building frames.

- #6 screws work well for thin materials and light loads.

- #8 screws are suitable for most home and workshop projects.

- #10 screws give extra holding power for thicker or heavier materials.

You should always match the screw size to your material and the job you want to do. هذا helps you avoid problems like stripped holes or weak joints. If you use the right size, your project will last longer and stay safe.

You have learned that choosing the correct screw size keeps your projects safe and strong. The table below highlights essential facts about #8 screws:

| Aspect | التفاصيل |

|---|---|

| Diameter | 0.164 inches |

| Threads per Inch | 32 (standard), 36 (some standards) |

| Length Range | 1″ to 3″ |

| Head Styles | Hex washer, truss, pan, flat undercut |

| المواد | Stainless steel, zinc-plated steel |

| Typical Uses | Metal-to-metal, wood-to-metal, roofing, custom jobs |

Always match screw size, length, and material to your project. Drill pilot holes that fit the screw and prevent splitting.

Follow these tips:

- Pick screw length to reach at least halfway into the material.

- Use stainless steel for outdoor projects.

- Avoid over-tightening to prevent damage.

- Inspect screws before use.

FAQ about #8 screw diameter

What does the “#8” mean on a screw?

You see “#8” on a screw. This number indicates the diameter of the screw. A #8 screw measures approximately 0.164 inches in diameter. It does not tell you the length or thread type.

Can you use #8 screws for outdoor projects?

Yes, you can use #8 screws outside. Pick stainless steel or coated screws. These resist rust and weather. Always check the material before you start your project.

What drill bit size should you use for an #8 screw?

For hardwood, use a 7/64-inch drill bit. For softwood, using a 3/32-inch bit. هذا helps the screw grip well and prevents splitting.

Are #8 screws suitable for metal?

You can use #8 screws for thin metal. Choose self-tapping or machine screws. Always check the manufacturer’s guide for the best fit.

How do you measure an #8 screw?

Use a caliper or screw gauge. Measure across the threads, not the head. هذا gives you the correct diameter for matching holes and tools.