When you look at 18-8, 304, and 316 stainless steel bolts, you notice they are different. They have different materials, how well they fight rust, price, and where they work best. The table below shows that 18-8 and 304 stainless steel (also called a2) are good for most jobs. 316 stainless steel (a4 or marine grade) is better when you need strong bolts that do not rust, like near the ocean or in tough places.

| Stainless Steel Type | Corrosion Resistance | Best Use Scenarios | Approximate Surcharge (per pound) |

|---|---|---|---|

| 18-8 | Good, but can rust from salt | Not good for use near the ocean | – |

| 304 | Good, but can rust from salt | Good for most jobs, not for the ocean | $0.92–$0.95 |

| 316 | Great, works well near the ocean | Good for boats and hospitals | $1.39 |

You must pick the right stainless steel bolts for where you use them. This helps them last a long time. Prince Fastener can help you choose the best bolts for your job.

النقاط الرئيسية

- اختر 18-8 or 304 stainless steel bolts for most indoor jobs. These bolts also work well for light outdoor use. They do not cost a lot and resist rust well.

- Use 316 stainless steel bolts in places with lots of water or chemicals. These bolts have molybdenum, which helps stop rust better. This makes them great for hard or wet places.

- Know how each bolt fights rust. 18-8 bolts work in mild places. 316 bolts are best for salty or rough areas.

- Think about how long your bolts will last. 316 bolts cost more at first. But they save money later because you do not need to replace them often.

- دائماً اختر المسمار المناسب for your job. If you are not sure, ask experts like Prince Fastener for help.

Stainless Steel Bolts Overview

Key Differences at a Glance

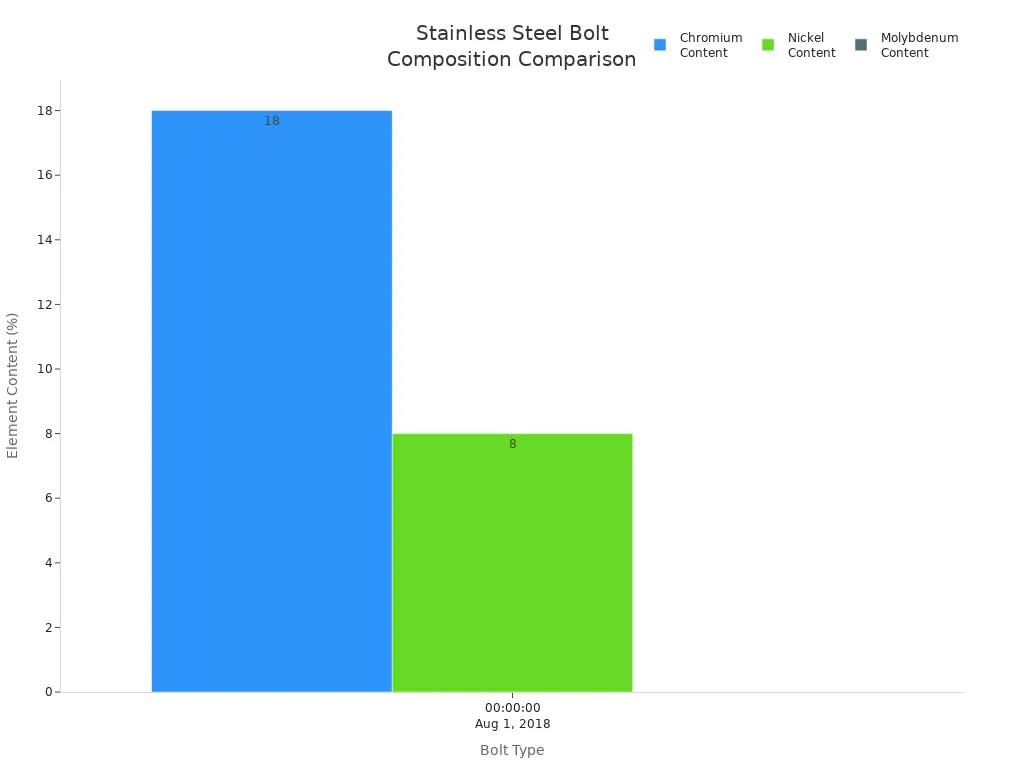

There are clear differences between 18-8, 304, and 316 stainless steel bolts. These differences come from what they are made of and their features. The table below shows the main parts in each type and what makes them special:

| Type | Chromium Content | Nickel Content | Molybdenum Content | Key Characteristics |

|---|---|---|---|---|

| 18-8 | 18% | 8% | غير متوفر | General designation for 300 series stainless steel. |

| 304 | 18% | 8% | غير متوفر | Most popular 300 series stainless steel. |

| 316 | 16% | 10% | 2% | Higher resistance to chlorides, suitable for marine use. |

316 stainless steel has molybdenum. This helps it fight rust better, especially in salty or tough places.

Why Material Choice Matters

Picking the right bolt material is important. It helps your project last longer and work better. If you work with cars, you need bolts that can handle shaking and bumps. In building things, you want bolts that are strong and steady. For boats or docks, you need bolts that do not rust in saltwater. Food factories need bolts that stay clean and safe.

Stainless steel bolts do not rust easily. They are strong and can handle heat. These things make them better than carbon steel or aluminum for many jobs. When you pick the right type, you save money and stop problems before they start.

Prince Fastener can help you find the right bolts for your job. You get the best results when you use bolts that match your needs and where you use them.

18-8 and 304 Stainless Steel (A2)

Composition and Properties

People in the fastener business call 18-8 and 304 stainless steel a2. Many use these names for the same thing. Both types have about 18% chromium and 8% nickel. That is why they are called 18-8. Sometimes, 304 stainless steel has extra stuff like manganese, silicon, molybdenum, and iron. These extras help the bolts work better in some places.

| Type | Chromium Content | Nickel Content | Additional Elements |

|---|---|---|---|

| 18-8 | ~18% | ~8% | Varies, general category |

| 304 | ~18% | ~8% | May include manganese, silicon, molybdenum, iron |

Both 18-8 and 304 stainless steel are strong. They bend without breaking. You can use a2 bolts for most jobs. The table below shows how strong they are:

| Property | 18-8 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Tensile Strength (MPa) | 500-750 | 540-750 |

| Yield Strength (MPa) | 215 | 215 |

| Ductility | عالية | Excellent |

| Corrosion Resistance | Good | Better in high-moisture environments |

Strengths and Limitations

18-8 stainless steel bolts are tough and dependable. They do not bend easily and work well under pressure. 304 stainless steel, or a2, bends more and fights rust better. This is helpful in wet places. Grade 304 stainless steel makes a shield on its surface. This shield helps it last longer in rough spots. 18-8 stainless steel does not have this shield. It may not work as well near saltwater.

نصيحة: 18-8 stainless steel costs less than 304 stainless steel. If you want to save money, pick 18-8 bolts for most jobs.

Best Uses for 304 Stainless Steel Bolts

Pick 304 stainless steel bolts, or a2, when you need strong bolts that do not rust. These bolts are used in many places:

| Industry/Application | Reason for Use |

|---|---|

| Food Mixing | High corrosion resistance |

| Dairy | Strength and durability in harsh conditions |

| Pharmaceutical | Essential for hygiene and safety |

| Cryogenic | Performance in extreme temperatures |

| التعدين | Resistance to harsh environmental conditions |

304 stainless steel bolts are used in food, dairy, and medicine factories. These bolts stay strong and clean in hard places. You can use a2 bolts in mining and cold places too. If you need help picking bolts, Prince Fastener can help you choose the right ones.

316 Stainless Steel (A4)

Unique Composition and Molybdenum Advantage

A4 bolts are the best for tough places. 316 stainless steel has special ingredients. It has chromium, nickel, and molybdenum. Molybdenum makes a4 bolts stronger. It helps stop pitting and crevice corrosion from chloride. This means a4 bolts last longer, even in salty water.

- Chromium helps stop rust.

- Nickel makes bolts tough and keeps them steady.

- Molybdenum makes bolts last longer and fight rust, especially in marine and chemical jobs.

Corrosion Resistance and Durability

A4 bolts are great at fighting rust. You can trust 316 stainless steel for boats, chemical plants, and places with lots of chloride. Molybdenum stops pitting and crevice corrosion. These bolts last a long time, even in saltwater. Marine grade bolts do not rust as fast as 304 or 18-8. You do not need to replace them often.

- 316 stainless steel is called marine grade because it fights salt water.

- A4 bolts work well for boats and chemical plants.

- 304 stainless steel does not last as long as a4 in tough places.

Best Uses for 316 Stainless Steel Bolts

A4 bolts are picked for hard jobs. 316 stainless steel is used in many areas:

- Marine parts: boat pieces, dock parts, propeller shafts

- Medical tools: surgery tools, bone implants

- Chemical plant gear: tanks, valves, pipes

- Medicine and food factories: clean rooms, safe pipes

- Outdoor things: bolts outside, statues, covers near the ocean or factories

A4 bolts cost more money. You pay 30% to 50% more than for 304 or 18-8 bolts.

| Bolt Type | Cost Difference |

|---|---|

| 304/18-8 bolts | Baseline |

| 316 stainless steel | 30% to 50% more expensive |

You pay more for a4 bolts because they last longer and fight rust better. You save money over time. Prince Fastener says a4 bolts are best for marine and chemical jobs. You get bolts that are safe, strong, and last a long time.

18-8, 304, and 316 Stainless Steel Bolts Compared

Corrosion Resistance in Real-World Environments

You need to know how a2 and a4 stainless steel bolts perform in different places. Corrosion resistance changes based on where you use the bolts. The table below shows how each type stands up to tough environments:

| Stainless Steel Grade | Corrosion Resistance in Marine Environments | Corrosion Resistance in Industrial Environments | Corrosion Resistance in Outdoor Settings |

|---|---|---|---|

| 18-8 | معتدل | Good | Good |

| 304 | Better than 18-8 | Good | Better than 18-8 |

| 316 | Best | Best | Best |

If you work near the ocean or with chemicals, you should pick a4 bolts. 316 stainless steel bolts last the longest in salty air and harsh chemicals. For most outdoor or indoor jobs, a2 bolts made from 304 stainless steel work well. 18-8 bolts do not resist corrosion as well as a4, but they still perform better than regular steel.

نصيحة: High humidity, salt, and chemicals can make bolts rust faster. Always match the bolt to the environment.

Mechanical Strength and Wear

You want bolts that stay strong under pressure. Both a2 and a4 stainless steel bolts have good strength, but some differences matter for your project. The tables below show how each type compares:

| Attribute | 18-8 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Tensile Strength (MPa) | 500-750 | 540-750 |

| Yield Strength (MPa) | 215 | 215 |

| Attribute | 18-8 / 304 Stainless Steel | 316 فولاذ مقاوم للصدأ |

|---|---|---|

| Mechanical Ranges (Tensile/Yield, min) | 515/205 MPa | 515/205 MPa |

| Stainless Steel Type | القوة | Corrosion Resistance | Stress Corrosion Cracking | Suitability for High-Stress Applications |

|---|---|---|---|---|

| 18-8 | Lower | معتدل | Susceptible | Not ideal |

| 304 | عالية | Good | Possible | Suitable for many applications |

| 316 | عالية | Exceptional | Less likely | Ideal for harsh environments |

You can use a2 bolts for most jobs that need strength and some corrosion resistance. If you need bolts for high-stress or harsh places, a4 bolts made from 316 stainless steel are the best choice. They resist cracking and last longer when things get tough.

Cost and Value

You want to get the best value for your money. The price of a2 and a4 stainless steel bolts changes based on what you need. 316 stainless steel bolts cost more at first, but they save you money over time in tough environments.

- 316 stainless steel bolts offer the best corrosion resistance. You pay more at first, but you spend less on repairs and replacements.

- If you use 304 stainless steel or 18-8 bolts in harsh places, you may need to replace them sooner. This can cost more in the long run.

- In mild or indoor settings, a2 bolts give you good value and performance.

ملاحظة: Prince Fastener helps you choose the right bolts for your budget and job. You can trust their advice for both cost and quality.

When to Choose A2 or A4

You need to match the bolt to your job. The table below helps you pick between a2 and a4 stainless steel bolts:

| Stainless Steel Type | Recommended Scenarios |

|---|---|

| A2 (304) | Indoor or non-chloride outdoor uses |

| A4 (316) | Coastal & marine environments, exposure to chlorides/chemicals, crevice/standing water, and higher budget for corrosion resistance |

- Use a2 bolts made from 304 stainless steel for indoor jobs, dry outdoor areas, and places without harsh chemicals.

- Pick a4 bolts made from 316 stainless steel for boats, docks, pools, chemical plants, and anywhere with salt or strong cleaners.

- If you work in a place with lots of humidity or changing temperatures, a4 bolts give you extra safety.

🌊 Pro Tip: Always check the environment before you choose. If you are not sure, ask Prince Fastener for help. They know which stainless steel bolts work best for your needs.

Misconceptions About Stainless Steel Grades

18-8 vs 304: Are They the Same?

You may see 18-8 and 304 stainless steel bolts and think they are identical. Many people use these names for the same type of bolt. In most cases, a2 bolts cover both 18-8 and 304 grades. However, you should know that small differences exist. 304 stainless steel sometimes contains extra elements like manganese or silicon. These extras can improve performance in certain jobs. You should not assume that 316 bolts work the same as 18-8 or a2. The molybdenum in 316, or a4, makes a big difference in places with lots of chloride, such as near the ocean. Prince Fastener recommends checking the grade before you choose bolts for your project.

- The main difference between 316 and 304 is corrosion resistance, not strength.

- يجب عليك not use a nut one grade lower than the bolt, especially in critical jobs.

- Mixing nuts and bolts of different standards can cause problems, even if they look similar.

Myths About Corrosion Resistance

You might believe that all stainless steel bolts resist rust the same way. This is not true. While a2 bolts made from 304 stainless steel work well indoors and in mild outdoor settings, they do not last in seawater or chemical-rich places. Only a4 bolts, made from 316 stainless steel, can handle these tough environments. Some people think stainless steel is always non-magnetic. In reality, a2 and a4 bolts can show slight magnetism, especially after hardening. Prince Fastener suggests you match the bolt grade to the environment for best results.

- 18-8 and a2 bolts may fail in continuous seawater.

- a4 bolts resist pitting and crevice corrosion better than a2.

- Stainless steel can be slightly magnetic.

⚠️ Always check the job site before picking a2 or a4 bolts.

Understanding Markings: A2 and A4

You will see markings like a2 and a4 on stainless steel bolts. These markings help you know what you are buying. A2 means the bolt is made from 304 stainless steel, also called 18-8 in the U.S. A4 means the bolt is made from 316 stainless steel, often called marine grade. The key difference is that a4 bolts contain molybdenum. This helps them resist pitting and crevice corrosion in places with chloride. You should use a2 bolts for most indoor or non-chloride outdoor jobs. Choose a4 bolts for marine, chemical, or high-humidity environments. Prince Fastener can help you select the right bolts for your needs.

- a2 bolts work well for most jobs.

- a4 bolts cost more but last longer in tough places.

- a4 bolts save money over time because you replace them less often.

You should pick A2 bolts for most indoor jobs. They also work well for food factories and light outdoor use. If you need bolts for salty or tough places, choose A4 bolts. A4 bolts are best for pools and near the ocean. They fight rust better and last longer.

| Type | Corrosion Resistance | Typical Applications |

|---|---|---|

| 304/A2 | معتدل | Indoor, food-grade, light outdoor |

| 316/A4 | عالية | Marine, poolside, coastal |

Think about where you will use the bolts. Check the size and what they are made of. Make sure they are strong enough. Look at the price too. Prince Fastener can help you find bolts that work for your job and budget.

الأسئلة الشائعة

What is the main difference between 304 and 316 stainless steel bolts?

304 bolts work well for most jobs. 316 bolts have molybdenum, which gives them better corrosion resistance. You should use 316 bolts in marine or chemical environments. Prince Fastener recommends 316 for harsh conditions.

Can I use 18-8 bolts outdoors?

You can use 18-8 bolts outdoors in mild environments. They resist rust better than regular steel. In salty or wet areas, you should choose 304 or 316 bolts for longer life.

How do I know if I need A2 or A4 bolts?

Check your environment. Use A2 (304) bolts for indoor or dry outdoor jobs. Pick A4 (316) bolts for marine, poolside, or chemical areas. Prince Fastener can help you select the right grade.

Are stainless steel bolts magnetic?

Most stainless steel bolts show little or no magnetism. After cold working, some may become slightly magnetic. This does not affect their corrosion resistance or strength.

Why do 316 bolts cost more?

316 bolts contain molybdenum, which increases their corrosion resistance and cost. You pay more upfront, but you save money over time because you replace them less often. Prince Fastener offers both grades for your needs.